BET Method for Surface Area Analysis: A Complete Guide for Pharmaceutical Researchers

This comprehensive article explores the Brunauer-Emmett-Teller (BET) method for measuring the specific surface area of porous materials, with a focus on applications in pharmaceutical research and drug development.

BET Method for Surface Area Analysis: A Complete Guide for Pharmaceutical Researchers

Abstract

This comprehensive article explores the Brunauer-Emmett-Teller (BET) method for measuring the specific surface area of porous materials, with a focus on applications in pharmaceutical research and drug development. It covers the foundational principles of gas adsorption theory, detailed methodological protocols for accurate measurement, practical troubleshooting and optimization strategies for real-world samples, and a comparative analysis with complementary techniques. The content is tailored to help researchers, scientists, and development professionals select, execute, and validate BET surface area data to enhance drug formulation, catalyst design, and material characterization.

Understanding BET Theory: The Science Behind Surface Area Measurement

Surface area, specifically the specific surface area (SSA) of solid drug substances and excipients, is a pivotal physicochemical parameter that dictates critical quality attributes throughout the drug development lifecycle. Within the broader thesis of BET (Brunauer-Emmett-Teller) theory application for nanomaterial characterization in pharmaceutics, this article delineates its non-negotiable role. The BET method provides the definitive quantitative framework for measuring SSA, which directly influences dissolution kinetics, bioavailability, stability, and manufacturability of solid dosage forms. Mastery of SSA measurement and control is therefore fundamental to transitioning from candidate selection to a robust, efficacious commercial product.

Application Notes: The Impact of Surface Area on Key Pharmaceutical Properties

Table 1: Correlation Between Specific Surface Area and Drug Performance Metrics

| Drug Property / Process | Low SSA Impact | High SSA Impact | Typical SSA Range for Actives | Key Measurement Method |

|---|---|---|---|---|

| Dissolution Rate | Slower, potential for incomplete release. | Faster, enhanced initial release. | 1 - 100 m²/g (micronized/nano) | BET Gas Adsorption (N₂) |

| Oral Bioavailability | Reduced absorption, especially for BCS Class II/IV drugs. | Potentially increased Cₘₐₓ and AUC. | > 5 m²/g often targeted for poor solubility. | Derived from dissolution & BET data. |

| Chemical Stability | Lower reactivity, potentially more stable. | Higher susceptibility to degradation (hydrolysis, oxidation). | Critical for biologics & peptides. | BET + Accelerated Stability Studies |

| Flowability & Blend Uniformity | Generally better flow (coarse powders). | Poor flow, cohesion, potential for segregation. | Excipients: 0.5 - 3 m²/g; Actives: variable. | BET complemented by bulk/tap density. |

| Tablet Compaction | May require higher compression force. | Can enhance bonding but may cause capping. | Optimized via granulation to modify SSA. | BET on pre- & post-granulation material. |

Protocol: BET Surface Area Analysis for API Lot Release

1.0 Objective: To determine the specific surface area of an Active Pharmaceutical Ingredient (API) batch using multi-point BET analysis via nitrogen adsorption at 77 K.

2.0 Materials & Equipment (The Scientist's Toolkit)

Table 2: Essential Research Reagent Solutions & Materials

| Item | Function / Explanation |

|---|---|

| High-Purity Nitrogen (N₂) Gas | Adsorptive gas; its cross-sectional area (0.162 nm²) is the standard for BET calculations. |

| High-Purity Helium (He) Gas | Used for dead volume calibration and sample purging. |

| Ultra-High Vacuum Grease | Ensures a leak-free seal on the sample tube. |

| Liquid Nitrogen Dewar | Maintains a constant 77 K bath temperature for adsorption. |

| Certified Reference Material (e.g., alumina) | Validates instrument performance and methodology. |

| Sample Tubes with Stem | Hold the API sample during analysis; must be scrupulously clean. |

| Micromeritics 3Flex or Equivalent | Automated surface area and porosity analyzer. |

| Ultra-Micro Balance (≤ 0.001 mg accuracy) | For precise sample mass measurement. |

| Vacuum Degassing Station | Prepares the API surface by removing adsorbed contaminants. |

3.0 Experimental Methodology

3.1 Sample Preparation:

- Accurately weigh (to 0.01 mg) an appropriate mass of API (targeting a total surface area of 40-120 m² for the sample) into a clean, tared analysis tube.

- Attach the tube to the degassing station. Seal and apply a vacuum (≤ 10 µmHg) while heating to a predetermined, non-degrading temperature (e.g., 40°C) for a minimum of 12 hours.

- Back-fill the tube with inert gas, seal, and re-weigh to obtain the degassed sample mass.

3.2 Analysis Setup:

- Mount the degassed sample tube onto the analysis port.

- Immerse the sample tube in a liquid nitrogen bath (77 K) to establish the analysis temperature.

- Initiate the automated analysis sequence via the instrument software.

3.3 Data Acquisition (BET Multipoint Method):

- The instrument admits successive doses of N₂ gas onto the sample at 77 K.

- After each dose, the system reaches equilibrium pressure (P), and the quantity adsorbed (V) is measured.

- Data is collected across a relative pressure (P/P₀) range typically between 0.05 and 0.30.

3.4 Data Analysis & Reporting:

- Apply the BET equation to the adsorption data in the linear relative pressure region:

[P/(V(P₀-P))] = (1/(VₘC)) + ((C-1)/(VₘC))*(P/P₀)where V is volume adsorbed, Vₘ is monolayer volume, and C is the BET constant. - Plot

[P/(V(P₀-P))]vs.(P/P₀)and perform linear regression. - Calculate Vₘ from the slope and intercept.

- Calculate the specific surface area (SSA):

SSA = (Vₘ * N * A_cs) / (M * V_s), where N is Avogadro's number, Acs is the cross-sectional area of N₂ (0.162 nm²), M is the molar volume of gas, and Vs is the sample volume. - Report the SSA in m²/g with ± confidence interval, the correlation coefficient (R²) of the BET plot, and the C constant.

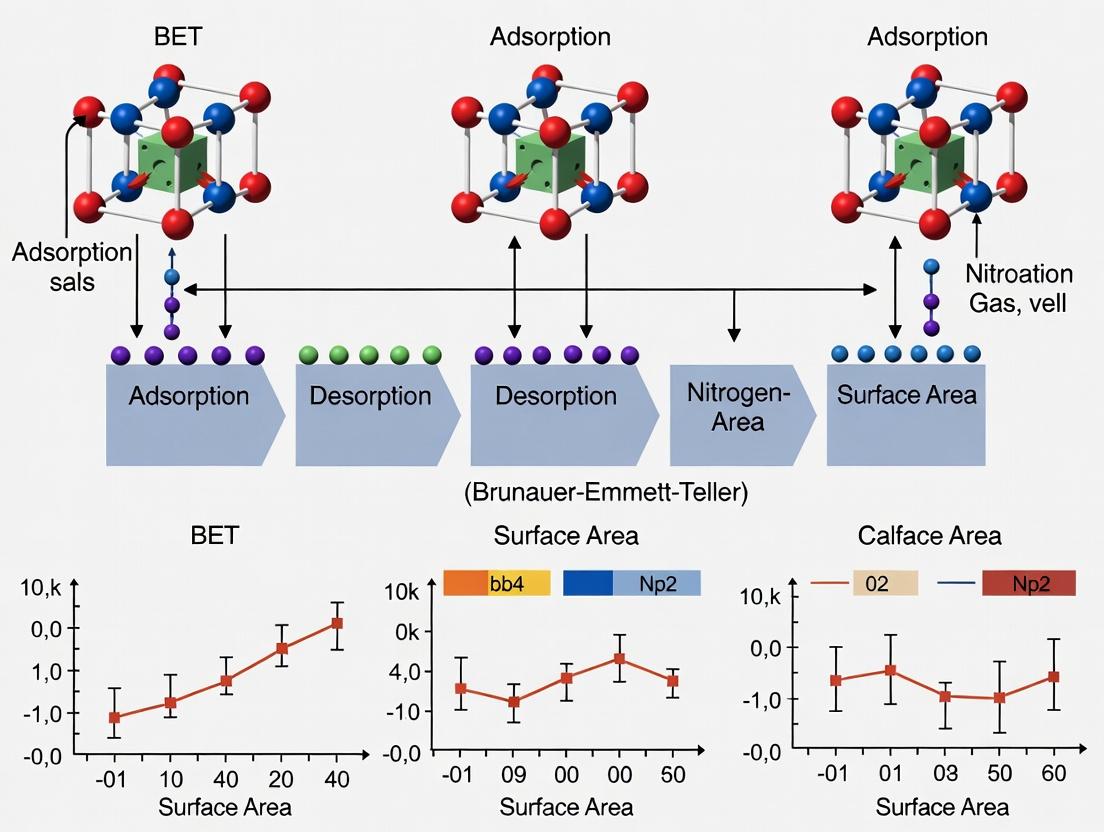

Visualizations

BET Surface Area Analysis Workflow

SSA Impact on Drug Product Attributes

The quantification of solid surface area is a cornerstone in materials science, catalysis, and pharmaceutical development. The Brunauer-Emmett-Teller (BET) theory, introduced in 1938, remains the standard method. Its development is rooted in earlier work by Irving Langmuir, establishing a direct historical and theoretical lineage from gas adsorption monolayer concepts to multilayer theory.

Table 1: Key Milestones in Gas Adsorption Theory Development

| Year | Scientist(s) | Contribution | Key Limitation Overcome |

|---|---|---|---|

| 1915-1918 | Irving Langmuir | Langmuir Isotherm: Monolayer adsorption theory for non-porous, uniform surfaces. | Described chemisorption/strong physisorption only. |

| 1938 | Stephen Brunauer, Paul Hugh Emmett, Edward Teller | BET Theory: Extended model to multilayer physical adsorption on non-porous solids. | Enabled surface area calculation from multilayer physisorption isotherms. |

| 1940s-1950s | Various | Standardization of BET method using N₂ at 77 K. | Established reproducible experimental protocol. |

| 1985 | IUPAC | Classification of six adsorption isotherm types. | Provided framework for pore structure analysis. |

| 2000s-Present | - | Development of DFT/NLDFT methods for pore size analysis; High-throughput analyzers; Standards for microporous materials. | Addresses limitations of classic BET for microporous and heterogeneous surfaces. |

Core Theoretical Principles & Data Interpretation

The BET equation is derived from kinetic principles of gas molecule adsorption and desorption on a free surface and atop already-adsorbed layers.

Equation: ( \frac{P}{Va(P0 - P)} = \frac{1}{Vm C} + \frac{C - 1}{Vm C} \cdot \frac{P}{P0} ) Where ( P ) = equilibrium pressure, ( P0 ) = saturation pressure, ( Va ) = adsorbed gas volume, ( Vm ) = monolayer capacity, ( C ) = BET constant related to adsorption heat.

Table 2: Standard BET Analysis Parameters for Common Probe Gases

| Probe Gas | Analysis Temperature (K) | Cross-sectional Area (Ų/molecule) | Typical Application | Recommended P/P₀ Range (BET linearity) |

|---|---|---|---|---|

| Nitrogen (N₂) | 77 (liquid N₂ bath) | 16.2 | General purpose, mesoporous materials | 0.05 - 0.30 |

| Krypton (Kr) | 77 (liquid N₂ bath) | 20.2 (common) / 21.0 (recent) | Very low surface area solids (< 1 m²/g) | 0.05 - 0.30 |

| Argon (Ar) | 87 (liquid Ar bath) or 77 | 14.2 (on carbon) / 16.2 (on oxide) | Microporous materials, alternative to N₂ | 0.05 - 0.30 |

| Carbon Dioxide (CO₂) | 273 (ice bath) | 17.0 (at 273K) | Ultramicroporous characterization (0.3-0.8 nm) | 0.001 - 0.03 |

Detailed Experimental Protocols

Protocol 3.1: Sample Preparation for BET Surface Area Analysis

Objective: To prepare a solid sample (e.g., active pharmaceutical ingredient - API) for accurate surface area measurement by removing adsorbed contaminants. Materials: BET analyzer, sample tube, degassing station, furnace, high-purity N₂ gas, vacuum pump, micrometrics sample tube, analytical balance. Procedure:

- Weighing: Accurately weigh an empty, clean sample tube. Add sufficient sample to achieve a total surface area between 5-200 m². Weigh again to determine exact sample mass.

- Degassing: Attach tube to degassing station. Heat sample to appropriate temperature (typically 100-300°C for APIs; below decomposition T) under vacuum or flowing inert gas for a minimum of 6 hours, or until outgassing rate is negligible.

- Cooling & Transfer: Isolate tube under vacuum. Cool to room temperature. Transfer to analysis port of BET instrument without exposure to atmosphere.

- Validation: Post-analysis, check the isotherm for hysteresis closure and low pressure uptake to confirm adequate degassing.

Protocol 3.2: Static Volumetric N₂ Adsorption Measurement at 77 K

Objective: To collect a high-resolution N₂ adsorption-desorption isotherm for surface area and pore size distribution calculation. Materials: Prepared sample tube, BET analyzer (e.g., Micromeritics 3Flex, Quantachrome Autosorb), liquid N₂ Dewar, high-purity (99.999%) N₂ and He gases, pressure transducers. Procedure:

- Dead Volume Calibration: With sample tube installed, immerse Dewar of liquid N₂. Perform a free space measurement using He gas.

- Dosing & Equilibration: Set instrument to collect 50-100 data points across P/P₀ range 10⁻⁵ to 0.995. The system doses precise volumes of N₂ and measures equilibrium pressure at each point.

- Adsorption Branch: Measure up to saturation pressure (P/P₀ ~0.995). Record equilibrium adsorbed quantity at each point.

- Desorption Branch: Gradually reduce pressure by evacuating the system, measuring desorbed quantity at each step.

- Data Output: Instrument software records P/P₀ vs. V_ads (cm³/g STP).

Data Analysis & Reporting Protocol

Protocol 4.1: BET Surface Area Calculation from N₂ Isotherm

Objective: To calculate the specific surface area from the adsorption isotherm data. Procedure:

- Select Linear Region: Identify the linear range in the BET transform plot (typically 0.05-0.30 P/P₀ for most non-porous/mesoporous materials).

- Perform Linear Regression: On the plot of ( \frac{P/P0}{Va(1-P/P0)} ) vs. ( P/P0 ). Slope = ( \frac{C-1}{Vm C} ), Intercept = ( \frac{1}{Vm C} ).

- Calculate Vm and C: ( Vm = \frac{1}{\text{slope} + \text{intercept}} ) ( C = \frac{\text{slope}}{\text{intercept}} + 1 )

- Calculate Surface Area: ( S{BET} = \frac{Vm \cdot NA \cdot \sigma}{V0 \cdot m} ) Where ( NA ) = Avogadro's number, ( \sigma ) = cross-sectional area of N₂ (16.2 x 10⁻²⁰ m²), ( V0 ) = molar volume at STP (22414 cm³/mol), ( m ) = sample mass (g).

Table 3: Critical Quality Checks for Valid BET Analysis

| Check | Criteria | Rationale |

|---|---|---|

| C-Value | Positive and typically between 50-200 for N₂. | Indicates adequate adsorbate-adsorbent interaction. |

| Linearity (R²) | R² > 0.9995 for BET transform in selected range. | Ensures theory applicability. |

| Pressure Range | 0.05 ≤ P/P₀ ≤ 0.30 (IUPAC recommendation). | Avoids capillary condensation and weak adsorption regions. |

| Monolayer Uptake | V_m should lie within the chosen P/P₀ range. | Confirms correct linear region selection. |

Visualizations

Title: Evolution of Surface Area Analysis Theory

Title: BET Surface Area Measurement Protocol

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for BET Surface Area Analysis

| Item | Function | Specification/Notes |

|---|---|---|

| High-Purity Nitrogen (N₂) | Primary adsorbate gas for analysis. | 99.999% minimum purity, dry, to prevent contamination. |

| High-Purity Helium (He) | Used for dead volume (free space) calibration. | 99.999% purity, inert, non-adsorbing at 77K. |

| Liquid Nitrogen (LN₂) | Cryogen to maintain analysis temperature at 77 K. | Standard laboratory grade, ensure steady level during run. |

| BET Reference Material | Validation of instrument performance and method. | NIST-certified or similar (e.g., alumina, silica, carbon black). |

| Sample Tubes (with filler rods) | Hold sample during degassing and analysis. | Glass or metal, accurately calibrated for volume. |

| Degas Station | Removes adsorbed contaminants from sample surface. | Must provide controlled heat (ambient to 450°C) under vacuum/inert flow. |

| Microbalance | Accurately measure sample mass. | Capacity 0.1 mg sensitivity, critical for low-surface-area samples. |

The Brunauer-Emmett-Teller (BET) theory stands as a cornerstone in the characterization of porous and finely divided materials. Within the broader thesis on BET method validation and application, this article unpacks the core equation and its foundational assumptions. The method is indispensable for quantifying the specific surface area (SSA) of catalysts, adsorbents, pharmaceutical powders, and nanomaterials, directly influencing research in drug formulation, bioavailability, and quality control.

Deconstructing the BET Equation

The BET equation models multilayer physical adsorption of gas molecules (typically N₂ at 77 K) on a solid surface. Its linearized form is:

[ \frac{P/P0}{n(1 - P/P0)} = \frac{1}{nm C} + \frac{C - 1}{nm C} (P/P_0) ]

Where:

- (P): Equilibrium adsorption pressure

- (P_0): Saturation pressure of the adsorbate at analysis temperature

- (n): Quantity of gas adsorbed at relative pressure (P/P_0)

- (n_m): Monolayer capacity (amount of gas required to form a single molecular layer)

- (C): BET constant related to the adsorption energy of the first layer

From (nm), the specific surface area (S) is calculated: [ S = \frac{nm NA \sigma}{m} ] Where (NA) is Avogadro's number, (\sigma) is the cross-sectional area of one adsorbate molecule (0.162 nm² for N₂ at 77 K), and (m) is the sample mass.

Table 1: Key Variables in the BET Equation

| Variable | Symbol | Typical Units | Physical Meaning |

|---|---|---|---|

| Relative Pressure | (P/P_0) | Dimensionless | Driving force for adsorption. |

| Amount Adsorbed | (n) | cm³/g STP, mol/g | Total gas uptake at a given P/P₀. |

| Monolayer Capacity | (n_m) | cm³/g STP, mol/g | Core result; gas needed for monolayer coverage. |

| BET Constant | (C) | Dimensionless | Indicates adsorbent-adsorbate interaction strength. |

| Cross-sectional Area | (\sigma) | m², nm² | Area occupied by a single adsorbed molecule. |

| Specific Surface Area | (S) | m²/g | Final reported metric. |

Foundational Assumptions and Their Implications

The derivation of the BET equation relies on several physical assumptions, which also define its limits of validity.

Table 2: Core BET Assumptions and Practical Implications

| Assumption | Implication for Measurement | Common Violation & Effect |

|---|---|---|

| 1. Adsorption occurs on open, flat, homogeneous surfaces. | Simplifies energy distribution. | Real materials have roughness, pores, and chemical heterogeneity. This affects C value and linearity. |

| 2. No lateral interactions between adsorbed molecules. | Enables simple statistical derivation. | High C values (>300) may indicate significant interactions, questioning model fitness. |

| 3. The heat of adsorption for the first layer is constant and unique; for subsequent layers, it equals the heat of liquefaction. | Enables the multilayer model. | Microporous materials (pores < 2 nm) have enhanced adsorption energy in confined spaces, invalidating this. |

| 4. Adsorption/desorption is infinite at (P/P_0 = 1). | Mathematical boundary condition. | All real systems have a limit. Mesopores (2-50 nm) fill via capillary condensation, causing isotherm hysteresis. |

Diagram Title: BET Model Assumptions and Their Violations

The Scientist's Toolkit: Key Reagents & Materials

Table 3: Essential Research Reagent Solutions for BET Analysis

| Item | Function & Specification |

|---|---|

| High-Purity Analysis Gases | N₂ (99.999%+): Primary adsorbate for SSA. He (99.999%+): For dead volume calibration. N₂/He mixture (e.g., 30 mol%): For continuous flow (chemisorption) analyzers. |

| Calibration Standards | Certified reference materials (e.g., alumina, silica) with traceable SSA. Used for instrument validation and method qualification in regulated environments (e.g., pharma). |

| Sample Cells/Tubes | Glass or metal tubes of known volume. Must be scrupulously clean to prevent contamination affecting adsorption. |

| Degas Station | Separate unit or integral to analyzer. Provides controlled heating under vacuum or inert flow to remove surface contaminants (H₂O, VOCs) prior to analysis. |

| Liquid Coolant | Liquid Nitrogen (LN₂) at 77 K: Standard cryogen for N₂ adsorption. Liquid Argon (87 K): Alternative for microporous materials to improve resolution. |

| Regeneration Gas | Inert Gas (e.g., N₂, Ar): For cooling samples under inert atmosphere post-degas to prevent re-adsorption of contaminants. |

Experimental Protocol: BET Surface Area Measurement via Volumetric Method

Protocol Title: Static Volumetric Gas Adsorption for BET Surface Area Determination.

1. Principle: Precisely measure the amount of pure N₂ gas adsorbed onto a degassed solid sample at a series of controlled relative pressures (P/P₀) at 77 K. Construct an adsorption isotherm, apply the BET transform in the linear region (typically 0.05-0.30 P/P₀), and calculate the monolayer capacity (n_m) to derive SSA.

2. Materials & Equipment:

- Volumetric (Manometric) Gas Sorption Analyzer.

- Components listed in Table 3.

- Microbalance (for precise sample weighing).

- Sample preparation station.

3. Pre-Analysis Procedure: 1. Sample Preparation: Weigh an appropriate mass (targeting total surface area >5 m² for analyzer) into a clean, dry sample tube. 2. Sample Degassing: Attach tube to degas station. Apply vacuum (e.g., <10⁻³ mbar) and/or inert gas purge while heating to a material-specific temperature (e.g., 150°C for many oxides, 300°C for zeolites) for a defined duration (typically 2-12 hours). Critical: Temperature must not induce sample decomposition. 3. Cooling & Weighing: Cool sample under inert atmosphere (N₂ or He). Precisely weigh the degassed sample+tube assembly to determine degassed sample mass. 4. System Evacuation: Mount the sample tube onto the analyzer's designated port. The analyzer manifold and sample are evacuated to ultra-high vacuum (<10⁻⁶ mbar) to remove all traces of gas.

4. Analysis (Adsorption Isotherm) Workflow:

Diagram Title: BET Isotherm Data Collection Workflow

5. Post-Analysis & Data Processing Protocol: 1. BET Transform: For the adsorption branch data, plot (\frac{P/P0}{n(1-P/P0)}) vs. (P/P0) as per the linear BET equation. 2. Linearity Check: Identify the linear region, conventionally between 0.05 and 0.30 P/P₀. The correlation coefficient (R) should be >0.999. IUPAC recommends that the term (C(P/P0)) must be positive. 3. Calculate nm and C: Perform linear regression on points in the linear region. Intercept = (1/(nm C)), Slope = ((C-1)/(nm C)). Solve for (nm) and (C). 4. Calculate SSA: Apply the SSA equation using the cross-sectional area (\sigma) (0.162 nm² for N₂). Report result in m²/g with the used P/P₀ range and C value.

Table 4: Example BET Data Reduction from a Reference Silica

| Relative Pressure (P/P₀) | Quantity Adsorbed (cm³/g STP) | BET Transform Y-value |

|---|---|---|

| 0.050 | 36.5 | 0.00146 |

| 0.100 | 39.8 | 0.00281 |

| 0.150 | 42.5 | 0.00417 |

| 0.200 | 45.0 | 0.00556 |

| 0.250 | 47.8 | 0.00699 |

| 0.300 | 51.1 | 0.00840 |

Regression (0.05-0.30 P/P₀): Slope = 0.0267, Intercept = 0.00018, R² = 0.9999. Calculated n_m = 37.3 cm³/g STP, C = 149. SSA = (37.3 * 6.022e23 * 1.62e-19) / (Sample Mass g) = 364 m²/g.

The Brunauer-Emmett-Teller (BET) theory is the cornerstone of surface area and porosity characterization for solid materials. Within a broader thesis on BET method advancements, precise definition and application of key terms—monolayer capacity, cross-sectional area, and pore type classification—are critical for accurate data interpretation, particularly in pharmaceutical development where surface properties dictate drug adsorption, stability, and release kinetics.

Key Terms: Definitions and Quantitative Data

Monolayer Capacity (nₘ)

The monolayer capacity is the amount of adsorbate (typically nitrogen at 77 K) required to form a single, complete molecular layer on the surface of a solid. It is the fundamental derived quantity from the BET equation, from which the total surface area is calculated.

BET Equation:

1 / [n((P₀/P)-1)] = (1/(nₘC)) + ((C-1)/(nₘC))*(P/P₀)

Where: n = quantity adsorbed, P/P₀ = relative pressure, nₘ = monolayer capacity, C = BET constant.

Cross-Sectional Area (σ)

The average area occupied by a single adsorbate molecule in the completed monolayer. For nitrogen at 77 K, the universally accepted value is 0.162 nm². The choice of molecule and its assigned cross-sectional area significantly impacts the calculated surface area.

Pore Type Classification (IUPAC)

Pores are classified based on their internal width (diameter for cylindrical pores).

Table 1: IUPAC Pore Classification and Characterization Methods

| Pore Type | Pore Width (Diameter) | Primary Characterization Method | Typical Adsorption Isotherm Shape (N₂ at 77K) |

|---|---|---|---|

| Micropore | < 2 nm | Dubinin-Radushkevich, Horvath-Kawazoe, t-plot | Type I |

| Mesopore | 2 - 50 nm | Barrett-Joyner-Halenda (BJH), DFT, NLDFT | Type IV, Hysteresis loops |

| Macropore | > 50 nm | Mercury Intrusion Porosimetry (MIP) | Type II or III (near P/P₀ = 1) |

Table 2: Common Probe Molecules and Their Cross-Sectional Areas

| Adsorbate Gas | Analysis Temperature (K) | Cross-Sectional Area (σ, nm²) | Typical Application |

|---|---|---|---|

| Nitrogen (N₂) | 77 | 0.162 | Standard BET, mesoporosity |

| Argon (Ar) | 87 | 0.142 | Microporosity, DFT studies |

| Krypton (Kr) | 77 | 0.202 | Very low surface area materials (< 1 m²/g) |

| Carbon Dioxide (CO₂) | 273 | 0.187 | Ultramicropores (< 0.7 nm) |

Experimental Protocols

Protocol 3.1: Determination of BET Surface Area and Monolayer Capacity (Static Volumetric Method)

Purpose: To calculate the specific surface area of a mesoporous pharmaceutical excipient (e.g., silica).

Materials:

- Degassed solid sample (~0.2-0.5 g)

- BET Surface Area Analyzer (e.g., Micromeritics 3Flex, Quantachrome Nova)

- Liquid nitrogen Dewar

- High-purity (≥99.999%) N₂ gas

- He gas for free space measurement

Procedure:

- Sample Preparation: Weigh a clean, dry sample tube with sample. Degas the sample at an appropriate temperature (e.g., 150°C for silica) under vacuum for a minimum of 12 hours to remove physisorbed contaminants.

- Cool-down: Backfill the sample tube with helium, seal, and transfer to the analysis port. Immerse the sample in a liquid nitrogen bath (77 K) to establish cryogenic temperature.

- Free Space Measurement: Introduce a known amount of helium into the sample tube. Helium is not adsorbed at 77K and measures the dead volume (free space) of the system.

- Adsorption Analysis: Evacuate the helium. Introduce incremental doses of N₂ gas onto the sample at 77 K. Allow equilibrium after each dose (∆P < 0.01 torr/min). Measure the equilibrium pressure and quantity adsorbed.

- Data Collection: Continue until a relative pressure (P/P₀) of at least 0.3 is reached. For BET analysis, use data typically in the P/P₀ range of 0.05 - 0.30.

- BET Transformation: Plot

1 / [n((P₀/P)-1)]vs.P/P₀according to the BET equation. Perform linear regression. - Calculation:

- Slope (s) =

(C-1)/(nₘC) - Intercept (i) =

1/(nₘC) - Solve for nₘ:

nₘ = 1/(s + i) - Calculate Surface Area (S):

S = (nₘ * N_A * σ) / m, where N_A is Avogadro's number and m is sample mass.

- Slope (s) =

Protocol 3.2: Pore Size Distribution Analysis via BJH Method (Adsorption Branch)

Purpose: To determine mesopore size distribution from N₂ adsorption isotherm.

Procedure:

- Full Isotherm: Continue Protocol 3.1 to obtain a full adsorption-desorption isotherm up to P/P₀ ~0.99.

- Thickness Curve: Apply a statistical thickness curve (e.g., Harkins-Jura) to calculate the thickness t of the adsorbed film on the pore walls at each P/P₀.

- Core Radius: At a point during desorption (or adsorption), the core radius r_c is calculated from the Kelvin equation:

r_k = -2γV_m / (RT ln(P/P₀)), where γ is surface tension and Vm is molar volume of liquid N₂. The pore radius *rp = r_k + t*. - Incremental Pore Volume: Calculate the volume of liquid N₂ desorbed between two pressure steps. This volume is ascribed to pores with a radius defined by the Kelvin equation for that pressure step, corrected for the multilayer thickness on the walls of larger pores.

- Cumulative & Differential Plot: Generate a plot of cumulative pore volume vs. pore width and the differential pore size distribution (dV/dlog(w) vs. width).

Visualizations

Diagram 1: BET Analysis Workflow

Diagram 2: Pore Classification & Analysis Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for BET Surface Area and Porosity Analysis

| Item | Function / Description | Example Product/Catalog |

|---|---|---|

| High-Purity N₂ Gas (Grade 5.0 or better) | Primary adsorbate for standard BET and mesopore analysis. Impurities (e.g., H₂O, CO₂) distort isotherms. | Available from industrial gas suppliers (Airgas, Linde). |

| Liquid Nitrogen | Cryogen to maintain sample at 77 K during analysis. Requires proper Dewar for handling and transfer. | Standard laboratory supply. |

| High-Purity He Gas | Used for dead volume (free space) measurement and sample transfer. | Available from industrial gas suppliers. |

| Reference Material (Certified BET Standard) | Calibrates instrument and validates protocol. Often non-porous alumina or silica with known surface area. | NIST SRM 1898, NIST SRM 2000. |

| Sample Tubes with Fill Rods | Hold the solid sample during degassing and analysis. Fill rods minimize dead volume for low-surface-area samples. | Manufacturer-specific (Micromeritics P/N 512-53801-01). |

| Degassing Station | Separate vacuum system with heating to prepare samples by removing adsorbed species prior to analysis. | Micromeritics VacPrep, Anton Paar FlowPrep. |

| Cold Trap (Optional) | Protects vacuum pump and manifold from condensable vapors during sample degassing. | Used with liquid nitrogen or Peltier coolers. |

| Microbalance | Precisely weighs small sample masses (0.05-0.5 g) for accurate specific surface area calculation. | Mettler Toledo XP6, Sartorius Cubis. |

Within the broader research on the Brunauer-Emmett-Teller (BET) method for surface area measurement, the selection of an appropriate probe gas is paramount. This application note details the physicochemical rationale for the standardization of nitrogen at 77K as the primary probe gas for physisorption-based surface area analysis. We provide a comparative analysis of alternative gases, detailed experimental protocols for BET surface area measurement, and a discussion on applications, particularly in pharmaceutical development where surface area is a critical quality attribute (CQA) for active pharmaceutical ingredients (APIs) and excipients.

The BET theory requires an inert gas that undergoes physical adsorption (physisorption) on a solid surface under controlled conditions. The choice of probe gas directly influences the measured surface area value, reproducibility, and instrument design. Standardization enables reliable comparison of data across laboratories and industries, which is essential for material characterization in catalysis, nanotechnology, and pharmaceutical sciences.

Quantitative Comparison of Common Probe Gasses

The table below summarizes key properties of gases considered for BET surface area analysis.

Table 1: Comparative Properties of Probe Gasses for BET Analysis

| Probe Gas | Common Analysis Temperature (K) | Cross-Sectional Area (Ų/molecule) | Saturation Pressure (P₀) Range (Torr) | Relative Cost & Safety | Key Advantages & Limitations |

|---|---|---|---|---|---|

| Nitrogen (N₂) | 77 (LN₂ bath) | 16.2 | ~760 | Low, inert | Standard. Ideal isotherm shape, widely available, established databases. Limited for ultra-low surface area. |

| Argon (Ar) | 77 (LN₂ bath) 87 (LAr bath) | 14.2 (77K on non-porous) ~13.8 (87K) | ~215 (87K) | Low, inert | Useful for microporous materials, avoids quadrupole moment issues of N₂. Requires proper P₀ measurement. |

| Krypton (Kr) | 77 (LN₂ bath) | 20.2 (common value) | ~2.5 | High, inert | For low surface area (< 1 m²/g). Higher sensitivity due to low P₀. Cross-sectional area is substrate-dependent. |

| Carbon Dioxide (CO₂) | 273 (ice bath) | 17.0 (at 273K) | ~26,000 | Low, asphyxiant | Used for ultramicroporosity characterization. Higher temperature avoids diffusion limitations. |

The Rationale for Nitrogen at 77K as the Standard

- Optimal Isotherm Shape: At 77K, N₂ provides a Type II (non-porous/macroporous) or Type IV (mesoporous) isotherm with a well-defined monolayer formation point (Point B), which is crucial for accurate BET analysis.

- Practicality: Liquid nitrogen (LN₂) is readily available, relatively inexpensive, and provides a stable, reproducible temperature of 77K.

- Well-Defined Properties: The cross-sectional area of the N₂ molecule (16.2 Ų) is empirically established and widely accepted. Its saturation pressure (P₀) is near ambient at 77K, allowing for easy and accurate measurement.

- Extensive Databases: Decades of use have resulted in vast libraries of reference isotherms for diverse materials, enabling comparative studies.

Detailed Protocol: BET Surface Area Measurement via N₂ at 77K

Title: Determination of Specific Surface Area of a Pharmaceutical API using Static Volumetric N₂ Physisorption at 77K.

Principle: A known amount of gas (N₂) is dosed onto a degassed sample at 77K. The quantity adsorbed at equilibrium is measured at a series of relative pressures (P/P₀). The BET equation is applied to the linear region of the isotherm (typically 0.05-0.30 P/P₀) to calculate the monolayer adsorbed volume, which is converted to surface area.

Materials & Equipment (The Scientist's Toolkit):

Table 2: Essential Research Reagent Solutions and Materials

| Item | Function/Description |

|---|---|

| High-Purity Nitrogen Gas | (>99.99% purity). The primary probe gas for adsorption. |

| Liquid Nitrogen (LN₂) | Cryogen to maintain sample analysis station at constant 77K. |

| Helium Gas | (>99.99% purity). Used for dead space volume (void volume) measurement and as a carrier gas in some systems. |

| Sample Tubes (with rods) | Typically made of borosilicate glass or stainless steel. Must be clean, dry, and of known tare weight. |

| Micromeritics ASAP 2460 or equivalent | Automated surface area and porosity analyzer. |

| High-Vacuum System | Capable of achieving at least 10⁻³ Torr for sample degassing. |

| Analytical Balance | Capable of weighing to ±0.01 mg. |

| Degas Station | Separate or integrated station for sample preparation. |

| Sample Saver or Filler Rod | Reduces the dead volume in the sample tube, improving measurement accuracy for low-surface-area samples. |

Pre-Treatment (Degassing) Protocol:

- Weighing: Accurately weigh a clean, dry sample tube. Add an appropriate mass of sample (target total adsorption volume > 5 cm³/g STP). Re-weigh to determine exact sample mass.

- Loading: Secure the sample tube onto the degas port of the analyzer or a separate degas station.

- Heating: Apply a controlled heating ramp (typically 10°C/min) under vacuum to a predefined degas temperature. Critical: The temperature must be below the sample's melting/decomposition point and be validated (e.g., 100°C for many APIs, 300°C for stable oxides). Consult material-specific literature.

- Hold: Maintain the temperature and vacuum (typically <10 µmHg) for a specified duration (often 2-12 hours) to remove physically adsorbed contaminants (water, vapors).

- Cooling & Backfill: After degassing, allow the sample to cool to ambient temperature under continued vacuum. Isolate and backfill the sample tube with inert gas (He or N₂).

- Transfer: Carefully transfer the sealed sample tube to the analysis port of the instrument.

Analysis Protocol:

- Installation: Install the sample tube onto the analysis port. Immerse the sample tube in a Dewar filled with LN₂ to maintain 77K throughout the analysis.

- Evacuation: Evacuate the sample tube to remove the backfill gas.

- Free Space Measurement: Introduce a known amount of helium into the sample tube. As He is not adsorbed at 77K, its expansion provides a measurement of the system's "dead volume" (void space).

- Adsorption Analysis: Evacuate the He. The instrument then performs a series of N₂ dose-equilibration-pressure measurement steps. Small, incremental doses of N₂ are introduced. The system pressure is monitored until equilibrium is reached (pressure change < a predefined threshold per unit time). The amount adsorbed is calculated from the pressure change using gas laws.

- Data Collection: This process is repeated across a predefined relative pressure (P/P₀) range, typically from ~10⁻⁵ up to 0.995, generating the adsorption branch of the isotherm.

- Desorption (Optional): For porosity analysis, the process is reversed by slowly removing N₂ to generate the desorption branch.

Data Analysis Protocol (BET Surface Area):

- Extract equilibrium adsorption data (Volume adsorbed at STP, V, vs. P/P₀).

- Apply the BET equation in its linear form:

(P/P₀) / [V(1 - P/P₀)] = 1/(V_m * C) + (C - 1)/(V_m * C) * (P/P₀)where V_m is the monolayer volume and C is the BET constant. - Plot

(P/P₀) / [V(1 - P/P₀)]vs.P/P₀for the linear region (typically 0.05-0.30 P/P₀). - Determine the slope

s = (C - 1)/(V_m * C)and intercepti = 1/(V_m * C)from linear regression. - Calculate

V_m = 1 / (s + i). - Calculate the specific surface area (S):

S = (V_m * N_A * σ) / (m * V_{molar})whereN_Ais Avogadro's number,σis the cross-sectional area of N₂ (16.2 x 10⁻²⁰ m²),mis the sample mass (g), andV_{molar}is the molar volume at STP (22414 cm³/mol).

Visualizing the BET Workflow and Gas Selection Logic

Diagram Title: BET Surface Area Analysis Workflow & Gas Selection

Diagram Title: Logic for N₂ at 77K as the Standard Probe Gas

1.0 Introduction: Context Within BET Method Research

The Brunauer-Emmett-Teller (BET) theory is the cornerstone of specific surface area (SSA) analysis for porous materials in catalysis, drug formulation, and nanomaterials. However, its application is governed by stringent assumptions: multilayer adsorption of inert gases (typically N₂ at 77 K) on energetically homogeneous surfaces with no lateral interactions. This research note, part of a broader thesis on advancing surface area metrology, details the quantitative and qualitative conditions where these assumptions fail, leading to significant analytical error.

2.0 Quantitative Limitations: Data Summary

Table 1: Common Material Classes and BET Application Limits

| Material Class / Condition | Typical Pore Size / Feature | Key Limitation & Error Magnitude | Recommended Diagnostic |

|---|---|---|---|

| Microporous Materials (Zeolites, MOFs) | < 2 nm | Micropore filling violates the BET multilayer model. Overestimates SSA by 20-100%. | Use t-plot or NLDFT methods. Check linear region of BET plot (n=1). |

| Mesoporous Materials with High Adsorbate-Affinity | 2-50 nm | Strong fluid-wall interactions cause premature capillary condensation. Underestimates SSA by 10-30%. | Analyze adsorption branch with BJH/KJS; review adsorbate choice. |

| Non-Porous or Macroporous Low-Energy Surfaces | > 50 nm | Weak adsorbate-surface interaction leads to poor monolayer formation. C-values < 20 indicate unreliability. | Use adsorbates with higher affinity (Kr at 77 K). |

| Chemically Heterogeneous Surfaces (Functionalized APIs) | N/A | Energetic heterogeneity invalidates constant heat of adsorption. C-value is an average, SSA error variable. | Perform isosteric heat of adsorption analysis. |

| Flexible or "Breathing" Frameworks | Variable | Hysteresis and pore opening alter the adsorption mechanism. SSA is path-dependent. | Model entire adsorption/desorption isotherm. |

Table 2: BET Validity Criteria from IUPAC Recommendations (2015)

| Criterion | Valid Range | Interpretation of Deviation |

|---|---|---|

| Applied Relative Pressure (P/P₀) Range | 0.05 - 0.30 (often narrower) | Extension beyond indicates inappropriate fitting. |

| BET Transform Plot Correlation (R²) | > 0.9995 | Lower R² suggests poor linearity, model misfit. |

| C Constant from BET Plot | Positive and "Reasonably High" | Negative C indicates misapplication; very low C (<20) suggests weak adsorption. |

| Monolayer Capacity (nₘ) Intercept | Must be positive | Negative intercept is physically meaningless, indicates failure. |

3.0 Experimental Protocols for Diagnosing BET Theory Failure

Protocol 3.1: Assessing BET Plot Linearity and Validity Range

Objective: To determine the appropriate relative pressure range for BET analysis and identify deviations from linearity. Materials: High-resolution volumetric or gravimetric sorption analyzer, high-purity (99.999%) adsorbate gas (N₂, Ar, Kr), sample cell, degassing station. Procedure:

- Pre-treat sample per relevant standard (e.g., ISO 9277:2022).

- Collect a high-resolution adsorption isotherm (≥ 30 data points) for N₂ at 77 K from P/P₀ = 1e-7 to 0.995.

- Transform data into the BET equation linear form: ( \frac{P/P₀}{n(1-P/P₀)} = \frac{1}{nm C} + \frac{C-1}{nm C}(P/P_0) )

- Plot ( \frac{P/P₀}{n(1-P/P₀)} ) vs. ( P/P_0 ).

- Systematically vary the selected pressure range (e.g., 0.05-0.15, 0.05-0.20, 0.05-0.25, 0.05-0.30). For each range, calculate the correlation coefficient (R²), the intercept, and the C constant.

- Diagnostic: The valid range is the one yielding a linear plot (R² > 0.9995) with a positive intercept. The calculated nₘ (monolayer capacity) should remain stable across adjacent, valid ranges.

Protocol 3.2: Comparative Analysis Using Alternative Adsorbates

Objective: To detect surface energy heterogeneity and micropore effects by comparing isotherms from different probe gases. Materials: Sorption analyzer capable of cryogenic (77 K, 87 K) and/or temperature-controlled measurements, N₂, Ar (87 K), CO₂ (273 K). Procedure:

- Using the same pre-treated sample aliquot, perform three adsorption experiments: a. Standard N₂ isotherm at 77 K. b. Ar isotherm at 87 K (Ar boiling point). c. CO₂ isotherm at 273 K (ice bath).

- Apply the BET method to the N₂ and Ar isotherms within their respective valid ranges (from Protocol 3.1).

- For CO₂, apply a Dubinin-Radushkevich or NLDFT model suited for micropore analysis at 273 K.

- Diagnostic: A >20% discrepancy between the SSA from N₂ and Ar suggests significant surface energy heterogeneity. A significantly higher SSA from CO₂ vs. N₂ indicates predominant microporosity inaccessible to N₂ at 77 K.

4.0 Visualizing BET Theory Breakdown and Diagnostic Pathways

Diagram 1: Diagnostic Flowchart for BET Applicability (100 chars)

5.0 The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Advanced Surface Area Analysis

| Item | Function/Benefit | Application Note |

|---|---|---|

| High-Purity N₂ Gas (99.999%) | Standard BET adsorbate. Impurities (e.g., H₂O) skew low-pressure data. | Essential for all BET measurements. Use with molecular sieve traps. |

| High-Purity Kr Gas (99.995%) | Low saturation pressure (P₀) enhances sensitivity for low-SSA materials (< 1 m²/g). | Critical for drug substance (API) and non-porous material analysis. |

| Ar Gas (99.999%) & Liquid Argon | Ar at 87 K (saturated with solid) avoids quadrupole moment of N₂, probing surface energy differently. | Diagnosing surface heterogeneity; standard for microporosity analysis. |

| CO₂ (99.99%) & Ice Bath (273 K) | Higher temperature and kinetic energy allow CO₂ to access ultramicropores (< 0.7 nm). | Complementary analysis for carbonaceous materials, MOFs, zeolites. |

| Reference Material (e.g., Alumina) | Certified surface area standard for instrument validation and method calibration. | Mandatory for QC, ensuring inter-laboratory reproducibility (ISO 17025). |

| Non-Porous Silica (e.g., LiChrospher) | Used to generate reference "t-curves" for t-plot analysis, deconvoluting micro/mesoporosity. | Required for accurate micropore volume and external surface area determination. |

| Automated Degassing Station | Provides controlled, reproducible sample pretreatment (temperature, vacuum, time). | Eliminates pre-adsorbed contaminants, a major source of error. |

Step-by-Step BET Protocol & Pharmaceutical Use Cases

Within the context of advancing BET (Brunauer-Emmett-Teller) method research for surface area and porosity analysis, the selection of analytical equipment is paramount. The core distinction lies between volumetric (or manometric) and gravimetric adsorption analyzers. This application note details their principles, comparative protocols, and specific applications in pharmaceutical development, where precise surface area measurement of active pharmaceutical ingredients (APIs) and excipients is critical for bioavailability and stability.

Core Principles & Comparative Analysis

Volumetric Analyzers determine gas adsorption by precisely measuring pressure changes in a calibrated volume system. A known quantity of adsorbate gas is dosed, and the amount adsorbed is calculated from the pressure drop using gas laws.

Gravimetric Analyzers directly measure the mass change of the sample during gas adsorption using a highly sensitive microbalance. The amount adsorbed is measured gravimetrically, often accounting for buoyancy effects.

Table 1: Quantitative Comparison of Volumetric vs. Gravimetric Analyzers for BET Surface Area Measurement

| Parameter | Volumetric Analyzer | Gravimetric Analyzer |

|---|---|---|

| Primary Measurement | Pressure & Volume (Gas Laws) | Mass Change (Microbalance) |

| Typical Resolution | ~0.01 m²/g | ~0.001 m²/g (with superior balance) |

| Sample Mass Range | 50 mg - 2 g | 10 mg - 1 g (smaller typical) |

| Degas Temperature | Up to 450°C | Usually ≤ 150°C (balance limit) |

| Buoyancy Correction | Required, via void volume calibration | Required, more complex |

| Adsorbate Flexibility | High (N₂, Ar, Kr, CO₂) | High, but vapor compatibility crucial |

| Key Advantage | Robust, high-temperature analysis, industry standard for BET | Direct mass measurement, superior for vapor studies |

| Key Limitation | Indirect measurement, dead volume critical | Sensitive to vibrations, lower temp limit |

Application Protocols

Protocol 1: Standard BET Surface Area Analysis of a Mesoporous API using a Volumetric Analyzer

Objective: To determine the specific surface area of a model API (e.g., Mesoporous Silica) using N₂ adsorption at 77 K via a volumetric system.

Research Reagent Solutions & Essential Materials:

- Analyte Gas (N₂, 99.999% purity): Primary adsorbate for BET analysis at 77 K.

- Degassing Station: For sample pre-treatment to remove physisorbed contaminants.

- Liquid Nitrogen Dewar: To maintain cryogenic (77 K) analysis temperature.

- High-Vacuum System: To achieve and maintain necessary vacuum (<10⁻³ mbar) for analysis.

- Reference Cells & Calibration Rods: For precise system volume calibration.

- Ultra-High Purity Helium (He, 99.999%): For free space (void volume) measurement.

Procedure:

- Sample Preparation: Accurately weigh (~100-200 mg) sample into a pre-tared analysis tube.

- Sample Degassing: Secure tube to degas port. Heat sample to 150°C under vacuum (<10⁻² mbar) for a minimum of 6 hours to remove adsorbed moisture and volatiles.

- Cool & Backfill: Isolate sample under vacuum, cool to ambient, and backfill with dry helium.

- Sample Tube Transfer: Transfer the sealed sample tube to the analysis port of the volumetric analyzer.

- System Evacuation: Evacuate the sample and manifold to ultra-high vacuum (<10⁻³ mbar).

- Free Space Measurement: Immerse sample cell in liquid N₂. Admit small doses of He and measure equilibrium pressure to calculate the cell's cold free space volume.

- Adsorption Isotherm: Evacuate He. Begin N₂ adsorption analysis by dosing precise gas quantities and recording equilibrium P/P₀. Collect data across the relative pressure range 0.05 to 0.30 for BET analysis and up to 0.99 for full isotherm.

- Data Processing: Use instrument software to apply BET equation to the 0.05-0.30 P/P₀ data range, ensuring a positive C constant and a linear fit with a correlation coefficient >0.9999.

Protocol 2: Water Vapor Sorption Analysis of a Hydrophilic Polymer using a Gravimetric Analyzer

Objective: To measure the water adsorption isotherm of a polymer at 25°C to inform excipient stability and hydration state.

Research Reagent Solutions & Essential Materials:

- Vapor Generation System: Precise control of relative humidity (RH) via mass flow controllers or pressure variation.

- Microbalance (≤ 0.1 µg resolution): Core component for mass measurement.

- Temperature-Controlled Water Bath: Maintains precise analyzer temperature (±0.1°C).

- Buoyancy Calibration Weights: For accurate system buoyancy correction.

- High-Purity Nitrogen Carrier Gas: For generating dry and RH-controlled atmospheres.

Procedure:

- Sample & Tare Preparation: Load sample (~20-50 mg) into a pan on the microbalance hang-down wire. Load a counterweight tare on the reference side.

- System Stabilization: Seal the analysis chamber. Evacuate or purge with dry N₂. Stabilize system at 25.0°C and 0% RH until a stable baseline mass is achieved (drift <0.001 mg/min).

- Buoyancy Correction Run: Perform a blank buoyancy calibration run using inert weights under identical temperature and pressure conditions.

- Sorption Cycle: Program a dynamic vapor sorption (DVS) method. Typically, stepwise increments of 10% RH from 0% to 90% RH, holding at each step until equilibrium (dm/dt < 0.01%/min over 10 min).

- Desorption Cycle: Reverse the RH steps from 90% down to 0% to assess hysteresis.

- Data Processing: Software corrects raw mass data for buoyancy using the calibration file. Plot equilibrium mass uptake vs. %RH to generate the adsorption/desorption isotherm. Surface area can be estimated if a monolayer is evident.

Visualization of Method Selection & Workflow

BET Analyzer Selection Decision Tree

Volumetric vs. Gravimetric Core Pathways

Within the broader thesis on advancing the Brunauer-Emmett-Teller (BET) method for accurate surface area analysis of porous pharmaceuticals, meticulous sample preparation is the most critical, yet often overlooked, determinant of success. The pre-adsorption protocol, specifically the outgassing (or degassing) step, directly dictates data quality by removing physisorbed contaminants without altering the material's intrinsic porous structure. This application note details contemporary, evidence-based best practices for outgassing temperature, time, and protocols, targeting researchers in drug development where material integrity is paramount.

Fundamental Principles and Impact on BET Analysis

Outgassing prepares a solid sample for surface area analysis by removing adsorbed species (e.g., water vapor, solvents, atmospheric gases) from its pores and surface. Inadequate outgassing leads to underestimated surface area and pore volume, while excessive conditions can induce sintering, phase changes, or chemical decomposition, resulting in structural collapse and erroneous data. The core objective is to achieve a "clean" and stable surface under high vacuum or flowing inert gas, representative of the material's true state.

Quantitative Guidelines: Temperature and Duration

The optimal outgassing temperature is intrinsically linked to a material's thermal stability and the nature of the adsorbates. The following table synthesizes current recommendations from instrument manufacturers and peer-reviewed literature.

Table 1: Recommended Outgassing Parameters for Common Pharmaceutical Materials

| Material Class | Typical Recommended Temperature Range (°C) | Typical Recommended Time (hours) | Critical Notes & Rationale |

|---|---|---|---|

| Metal-Organic Frameworks (MOFs) | 80 - 150 | 6 - 24 | Temperature MUST remain below framework collapse/decomposition point (TGA analysis is essential). Use gentle heating rates (1-5°C/min). |

| Mesoporous Silica (e.g., MCM-41, SBA-15) | 200 - 300 | 6 - 12 | High temperatures required to remove chemisorbed water from silanol groups. Stability is generally high. |

| Active Pharmaceutical Ingredients (APIs) / Organic Crystals | 25 - 50 (Ambient) | 8 - 24 | Use ultra-gentle, vacuum-only degassing at ambient temperature to prevent polymorphic transition or melting. |

| Carbonaceous Materials (Activated Carbon, Graphite) | 250 - 350 | 8 - 12 | Robust materials; high temperatures needed to desorb strong contaminants. Verify absence of oxidation under flowing gas. |

| Polymer-Based Carriers | 25 - 80 (Below Tg) | 10 - 24 | Temperature must be kept significantly below the glass transition temperature (Tg) to prevent structural relaxation and pore collapse. |

| Metal Oxides (e.g., Alumina, Titania) | 150 - 250 | 6 - 10 | Standard pretreatment for inorganic oxides. Time varies with specific surface area. |

General Protocol: A common safe-start protocol for unknown but thermally sensitive materials is degassing at 80°C for 12 hours under dynamic vacuum. The ultimate criterion is a stable, low outgassing rate (e.g., pressure rise < 5 μbar/min upon valve closure to sample).

Detailed Experimental Protocols

Protocol A: Standard Outgassing for Thermally Stable Porous Materials

Objective: To prepare mesoporous silica or stable metal oxides for BET surface area and BJH pore size distribution analysis.

Materials & Equipment:

- BET Surface Area and Porosimetry Analyzer with degassing port.

- Sample tube with sealed-end bulb.

- Microbalance (accuracy ±0.01 mg).

- Furnace or heating mantle with programmable controller.

- High-vacuum system (capable of <10^-3 mbar).

- Liquid nitrogen for cold trap.

Procedure:

- Weighing: Accurately weigh the clean, empty sample tube. Add 50-200 mg of sample. Re-weigh to determine exact sample mass.

- Mounting: Secure the sample tube to the degassing station. Attach a cold trap filled with liquid nitrogen between the sample and vacuum pump to capture volatiles.

- Initial Evacuation: Apply gentle vacuum at room temperature for 30 minutes to remove loosely bound adsorbates.

- Heating: Program the heater to ramp to the target temperature (e.g., 250°C for silica) at a rate of 3°C per minute.

- Isothermal Hold: Maintain the target temperature under continuous dynamic vacuum for 6-12 hours.

- Cool-down & Backfill: After the hold period, turn off the heater and allow the sample to cool to ambient temperature under continuous vacuum. Once cool, backfill the sample tube with ultra-pure, dry helium or nitrogen gas.

- Sealing: Immediately cap the sample tube to prevent re-adsorption. It is now ready for analysis.

Protocol B: Mild Degassing for Thermally Labile Pharmaceutical Solids

Objective: To prepare a moisture-sensitive API or polymer carrier without inducing phase changes.

Procedure:

- Weighing: Follow Step 1 from Protocol A.

- Mounting: Attach the sample tube to the degassing station with a cold trap.

- Extended Ambient Degassing: Apply a high vacuum (<10^-3 mbar) at room temperature (25-40°C) for a minimum of 18 hours. No active heating is applied.

- Stability Test: Isolate the sample from the pump by closing a valve. Monitor the pressure rise over 5 minutes. A rate below 2-5 μbar/min indicates sufficient degassing.

- Completion: If the rate is acceptable, proceed to cool-down and backfill as in Protocol A (Steps 6-7). If not, continue degassing.

Visualization of the Decision Workflow

Title: Decision Workflow for Selecting Outgassing Protocol

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Sample Preparation

| Item | Function in Outgassing/BET Preparation |

|---|---|

| High-Purity Sample Tubes (with bulbs) | Contain the sample during degassing and analysis; the bulb design minimizes dead volume. |

| Ultra-High Purity (UHP) Nitrogen or Helium Gas (99.999%) | Used for backfilling degassed samples to prevent re-adsorption prior to analysis. |

| Liquid Nitrogen Cold Trap | Protects the vacuum pump and captures condensable vapors (water, solvents) during degassing. |

| Temperature-Programmable Degas Station | Provides controlled, reproducible heating under vacuum or inert gas flow. |

| Microbalance (±0.01 mg) | Enables accurate sample mass measurement, critical for final surface area calculation (m²/g). |

| Vacuum Grease (High-Temp, Low-Vapor) | Ensures airtight seals on joints; must withstand degassing temperature without outgassing itself. |

| TGA/DSC Instrument | Critical pre-screening tool to determine material thermal stability and safe outgassing temperature limits. |

| Glass Wool or Plugs | Used to prevent sample particulates from being entrained into the analysis manifold during degassing. |

The determination of specific surface area (SSA) via the Brunauer-Emmett-Teller (BET) method is a cornerstone of material characterization in pharmaceutical development, impacting critical attributes from drug carrier performance to catalyst efficiency and powder flow. This application note, framed within a broader thesis on BET methodology, details the experimental protocols for data collection during the adsorption isotherm measurement—the foundational step from which all subsequent analysis derives. The precision of this phase dictates the validity of the final SSA calculation.

Core Protocol: The Physisorption Isotherm Experiment

Objective: To measure the volume of nitrogen gas adsorbed by a solid sample across a defined range of relative pressures (P/P₀) at cryogenic temperature (typically 77.35 K using liquid nitrogen).

Detailed Methodology:

A. Pre-Measurement Sample Preparation (Activation)

- Weighing: Accurately weigh a clean, dry sample tube with the solid sample. The optimal sample mass depends on the expected SSA (see Table 1).

- Degassing: Mount the sample tube on a degassing station.

- Apply vacuum and heat (temperature and duration are material-specific) to remove physically adsorbed contaminants (e.g., water vapor, atmospheric gases).

- Common protocol for molecular sieves or metal-organic frameworks: 150-300°C under vacuum for 6-12 hours.

- For thermally sensitive pharmaceuticals: Use ambient to 50°C under vacuum for 4-8 hours.

- Outgassing Verification: Monitor pressure rise upon isolating the sample (leak test) to confirm complete removal of adsorbed species.

B. Isotherm Data Collection

- Cooling: Transfer the degassed sample to the analysis station and immerse in a cryogenic bath (liquid N₂).

- Dosing & Equilibrium: The analyzer introduces controlled doses of high-purity N₂ gas into the sample cell.

- Pressure Measurement: After each dose, the system monitors pressure until equilibrium is established (change < a predefined threshold over time).

- Adsorbed Quantity Calculation: The volume of gas adsorbed is calculated using manometric (volumetric) or gravimetric principles from the equilibrium pressure.

- Incremental Pressure Increase: The relative pressure (P/P₀) is incrementally increased from high vacuum (≈10⁻⁵) to near saturation (≈0.99-0.995) to collect the adsorption branch. A subsequent stepwise decrease yields the desorption branch.

Critical Measurement Points & Data Quality Indicators:

- Monolayer Completion (Point B): The inflection point on the isotherm where the monolayer is statistically filled.

- Hysteresis Loop: The disparity between adsorption and desorption branches indicates mesoporosity (2-50 nm pores). Its shape informs pore geometry (e.g., ink-bottle, slit-like).

- Saturation Plateau: At high P/P₀, micropores (<2 nm) and mesopores are filled via capillary condensation.

Data Presentation: Key Parameters & Quality Criteria

Table 1: Recommended Sample Mass Based on Expected Surface Area

| Expected BET Surface Area (m²/g) | Recommended Sample Mass (g) | Rationale |

|---|---|---|

| > 100 (e.g., MOFs, activated carbon) | 0.05 - 0.10 | Avoids excessive total adsorption, maintains instrument sensitivity. |

| 10 - 100 (e.g., catalysts, silica) | 0.10 - 0.30 | Balances signal strength with manageable dead volume. |

| 1 - 10 (e.g., some APIs, coarse powders) | 0.50 - 1.00 | Ensures measurable adsorption volume relative to system volume. |

| < 1 (e.g., dense ceramics) | ≥ 2.00 | Maximizes the absolute amount of gas adsorbed for reliable detection. |

Table 2: Critical Isotherm Data Quality Checklist

| Parameter | Target/Checkpoint | Purpose & Consequence of Deviation |

|---|---|---|

| Degassing Temperature | Must be below sample decomposition temp. | Prevents chemical alteration; incomplete degassing leads to underestimated adsorption. |

| Equilibrium Time | Must be sufficient for each point (typically 5-60s). | Non-equilibrium data invalidates the assumption underlying the BET theory. |

| Number of Data Points | 5-8 points in the BET linear range (0.05-0.30 P/P₀). | Fewer points reduce regression reliability; points outside range violate BET assumptions. |

| C-Constant (from BET plot) | Positive value (typically 50-250). | Negative or very low C suggests inappropriate sample or analysis range, invalidating result. |

| Saturation Pressure (P₀) | Measured continuously near the sample. | Accurate P₀ is critical for correct P/P₀ calculation; use of fixed value introduces error. |

The Scientist's Toolkit: Essential Materials & Reagents

Table 3: Key Research Reagent Solutions & Materials

| Item | Function & Criticality |

|---|---|

| High-Purity (≥99.999%) N₂ Gas | The adsorbate. Impurities (e.g., hydrocarbons, H₂O) competitively adsorb, skewing isotherm data. |

| High-Purity He Gas | Used for free space (dead volume) measurement. Impurities affect volume calibration. |

| Liquid Nitrogen (LN₂) | Provides constant 77K bath for N₂ physisorption. Level must be maintained for stable temperature. |

| Vacuum Grease (Apiezon type) | Seals joints on sample tubes and manifolds. Must be low-volatility to prevent outgassing interference. |

| Quantachrome or Micromeritics Sample Tubes | Calibrated glass cells of known tare weight and volume. Must be scrupulously clean. |

| Non-Porous Reference Material (e.g., Alumina) | Used for system calibration and periodic validation of instrument performance. |

| Glass Wool or Plugs | To contain fine powder samples during degassing, preventing entrainment. |

Visualizing the BET Isotherm Workflow & Analysis Logic

Diagram Title: BET Isotherm Data Collection & Analysis Workflow

Diagram Title: Logic Flow for Validating BET Analysis from Isotherm Data

Within a comprehensive thesis on the Brunauer-Emmett-Teller (BET) method for surface area measurement, the correct linearization of adsorption isotherm data and subsequent calculation form the critical, interpretative core. The BET equation transforms raw physisorption data into the monolayer adsorbed gas volume (Vm) and the material-specific surface area. Misapplication at this stage, particularly regarding the selection of the linear pressure range, is a prevalent source of error that undermines the validity of the entire analysis. These application notes provide definitive protocols for the accurate linearization and calculation procedure, ensuring data integrity for researchers in material science and pharmaceutical development.

Theoretical Framework: The BET Linearization

The multi-layer adsorption theory is expressed in its linearized form as: [ \frac{P/P0}{n(1 - P/P0)} = \frac{1}{nm C} + \frac{C - 1}{nm C} (P/P_0) ] Where:

- (P): Equilibrium pressure

- (P_0): Saturation pressure of adsorbate at experimental temperature

- (n): Quantity of gas adsorbed at (P)

- (n_m): Monolayer capacity

- (C): BET constant related to adsorption enthalpy

A plot of ( \frac{P/P0}{n(1 - P/P0)} ) versus (P/P0) should yield a straight line in the appropriate relative pressure range. The slope ((s)) and intercept ((i)) are used to calculate (nm) and (C). [ nm = \frac{1}{s + i}, \quad C = \frac{s}{i} + 1 ] The total specific surface area ((S{BET})) is then: [ S{BET} = \frac{nm NA \sigma}{m} ] Where (NA) is Avogadro's number, (\sigma) is the cross-sectional area of the adsorbate molecule (0.162 nm² for N₂ at 77 K), and (m) is the sample mass.

Critical Protocol: Establishing the Valid Linear Range

The IUPAC and ISO standards dictate that the BET plot is only valid for data points where the term (n(1-P/P0)) continuously increases with (P/P0). The recommended linear relative pressure ((P/P_0)) range is typically 0.05 to 0.30. However, this must be validated for each material.

Detailed Experimental Methodology

Procedure:

- Data Acquisition: Obtain at least 5-7 adsorption data points in the (P/P_0) range of 0.01 to 0.30 using a calibrated volumetric or gravimetric sorption analyzer.

- Initial Transformation: For each data point ((P/P0), (n)), calculate the y-coordinate for the BET plot: (y = \frac{P/P0}{n(1 - P/P_0)}).

- Iterative Linear Regression: a. Start with data points in the range 0.05-0.30. b. Perform a least-squares linear regression. Calculate the correlation coefficient (R²), slope ((s)), and intercept ((i)). c. Verify that the calculated (C) value is positive. d. Apply the "Roquerol Criteria": i. The quantity (n(1-P/P0)) must increase monotonically with (P/P0) over the selected points. ii. The monolayer capacity (n_m) calculated must correspond to a point on the isotherm within the selected range. e. If criteria fail, systematically narrow the upper limit (e.g., to 0.25, then 0.20) and repeat regression until all criteria are satisfied.

- Calculation: Using the final validated slope and intercept, calculate (nm), (C), and ultimately (S{BET}).

Quantifiable Criteria for Linearity Validity

Table 1: Summary of BET Linearization Validation Criteria and Outcomes

| Criterion | Optimal/Valid Condition | Consequence of Deviation |

|---|---|---|

| Relative Pressure Range | 0.05 ≤ P/P₀ ≤ 0.30 (Guideline) | Range must be narrowed per Roquerol criteria. |

| Correlation Coefficient (R²) | > 0.9995 for high accuracy | Lower R² indicates poor fit, invalid range, or microporosity. |

| BET Constant (C) | Positive value, typically 50-200 for mesoporous materials. | Negative intercept/C indicates invalid range or micropore filling. |

| Monotonic Increase | (n(1-P/P_0)) must always increase with P/P₀ over selected range. | Failure indicates the upper pressure limit is too high. |

Visualization: BET Analysis Workflow

Title: BET Surface Area Calculation and Validation Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for BET Surface Area Analysis

| Item | Function & Specification |

|---|---|

| High-Purity Adsorbate Gas | Typically N₂ (99.999%+) or Kr for low surface area samples. Provides the molecular probe for adsorption measurement. |

| UHP Helium or Hydrogen | Used for dead-volume calibration and sample preconditioning (purge gas). Must be 99.999% pure. |

| Reference Material | Certified standard (e.g., alumina, carbon black) with known surface area. Used for instrument and method validation. |

| Sample Tubes with Rods | Precision glassware for holding sample. Must be scrupulously clean and degassed to prevent contamination. |

| Liquid Nitrogen Dewar | Maintains a constant 77 K bath temperature for N₂ adsorption. Requires a stable, level holder. |

| Microbalance (Gravimetric) | For precise sample mass measurement pre- and post-degassing (if using gravimetric method). |

| Temperature Sensor | Accurately monitors the liquid nitrogen bath temperature for precise P₀ determination. |

| Regenerable Desiccant | Protects the analyzer manifold from moisture contamination during analysis and sample transfer. |

Within the context of a broader thesis on BET method for surface area measurement research, this application note details its critical role in pharmaceutical development. Precise surface area and porosity data are essential for predicting and controlling the performance, stability, and manufacturability of drug products.

Application Note 1: API Characterization and Polymorph Control

The specific surface area of an Active Pharmaceutical Ingredient (API) directly influences dissolution rate, a key determinant of bioavailability. BET analysis is indispensable for characterizing different polymorphic and morphological forms generated during crystallization and milling processes.

Table 1: BET Surface Area Data for API Polymorphs

| API Lot & Processing Method | Polymorph Form | BET Surface Area (m²/g) | Average Pore Diameter (nm) |

|---|---|---|---|

| Crystallization Batch A | Form I | 0.45 ± 0.03 | Non-porous |

| Crystallization Batch B | Form II | 0.68 ± 0.05 | Non-porous |

| Jet-Milled API (from Form I) | Form I | 4.32 ± 0.15 | Non-porous |

| Spray-Dried Dispersion | Amorphous | 8.91 ± 0.20 | 18.5 |

Protocol 1: BET Analysis of API Polymorphs

- Sample Preparation: Accurately weigh 500-1000 mg of API into a clean, pre-tared analysis tube. Use a larger sample mass for low-surface-area crystals.

- Degassing: Seal the tube and degas the sample using a Smart VacPrep or equivalent. Apply a vacuum at 25°C for 1 hour, then ramp to 40°C (or below polymorph transition temp) for a minimum of 6 hours to remove physisorbed contaminants.

- Analysis: Transfer the tube to a surface area analyzer (e.g., Micromeritics 3Flex, Anton Paar NovaTouch). Immerse the sample cell in a liquid nitrogen bath (77 K).

- Data Collection: Perform a 5-point BET analysis with nitrogen adsorbate across a relative pressure (P/P₀) range of 0.05 to 0.30.

- Calculation: Use the instrument software to apply the BET equation to the adsorption isotherm data, reporting surface area in m²/g. Perform t-plot or DFT methods to assess microporosity.

BET Workflow for API Analysis

The Scientist's Toolkit: API Characterization

| Item | Function |

|---|---|

| High-Resolution BET Analyzer | Measures low-pressure gas adsorption with high accuracy for precise surface area calculation. |

| Smart VacPrep Degasser | Removes adsorbed volatiles without altering sample morphology via controlled temperature and vacuum. |

| 9 mm Large-Rod Sample Tubes | Accommodates larger sample masses for low-surface-area crystalline APIs to improve signal-to-noise. |

| Ultra-High Purity (UHP) N₂ & He Gases | UHP N₂ is the adsorbate; UHP He is used for dead volume calibration. Impurities skew results. |

| Liquid Nitrogen Dewar & Level Sensor | Maintains constant 77 K temperature for cryogenic adsorption measurements. |

Application Note 2: Excipient Screening for Tablet Formulation

The functionality of direct compression excipients like microcrystalline cellulose (MCC) and silica is governed by surface area and porosity, affecting compaction, flow, and API-excipient interactions.

Table 2: BET Data for Common Tablet Excipients

| Excipient (Brand) | Grade | BET Surface Area (m²/g) | Total Pore Volume (cm³/g) | Primary Function |

|---|---|---|---|---|

| Microcrystalline Cellulose | PH-101 | 1.1 ± 0.1 | 0.004 | Diluent/Binder |

| Microcrystalline Cellulose | PH-200 | 0.9 ± 0.1 | 0.003 | Diluent (Improved Flow) |

| Colloidal Silicon Dioxide | Aerosil 200 | 200 ± 25 | 0.35 | Glidant/Anti-caking |

| Lactose Monohydrate | Inhalac 230 | 0.4 ± 0.05 | 0.001 | Diluent/Filler |

| Magnesium Stearate | Non-bovine | 5.8 ± 0.5 | 0.02 | Lubricant |

Protocol 2: Porosity Analysis of Excipient Blends

- Sample Preparation: Gently blend API with key excipients (e.g., MCC, silica) for 10 minutes in a turbula mixer. Weigh 300-600 mg of the blend into an analysis tube.

- Degassing: Degas at 40°C for 4 hours under vacuum to remove moisture without inducing polymorphic changes in any component.

- Full Isotherm Analysis: Perform a full N₂ adsorption-desorption isotherm from P/P₀ ~0.01 to 0.99.

- Hysteresis Analysis: Examine the adsorption-desorption hysteresis loop to identify pore shape (ink-bottle, slit-shaped).

- DFT/BJH Calculation: Apply Density Functional Theory (DFT) or Barrett-Joyner-Halenda (BJH) models to the desorption branch to calculate pore size distribution from 1-100 nm.

Excipient Properties Affect Final Product

Application Note 3: Inhalation Powder Aerodynamic Performance

For Dry Powder Inhalers (DPIs), the aerodynamic performance of carrier-based formulations (e.g., lactose with API) is controlled by surface adhesion forces, which correlate with carrier surface area and nano-roughness.

Table 3: BET Data vs. Performance of Inhalation Lactose

| Lactose Carrier Grade | BET Surface Area (m²/g) | Fines Content (%) | Emitted Dose (% label claim) | Fine Particle Fraction (<5 µm) |

|---|---|---|---|---|

| Inhalac 70 (Base) | 0.3 | 0.5 | 78.2 ± 2.1 | 21.5 ± 1.8 |

| Inhalac 70 (Sieve Classified) | 0.4 | 2.5 | 85.5 ± 1.5 | 32.8 ± 2.0 |

| Engineered Porous Lactose | 12.5 | <0.1 | 92.1 ± 1.0 | 48.5 ± 1.5 |

Protocol 3: Surface Area Analysis of DPI Formulations

- Sample Handling: Use a glovebox under controlled humidity (RH <20%) to handle hygroscopic inhalation powders. Weigh 200-400 mg carefully.

- Low-Temperature Degassing: Degas at 25°C for 12 hours to avoid sintering lactose or altering the API-carrier interface. Use a low outgassing rate.

- Low-Pressure Multipoint BET: Perform a 7-point BET analysis in the P/P₀ range 0.01-0.20. Use Kr adsorption for very low surface areas (<1 m²/g) if necessary.

- Complementary Morphology: Analyze the same sample via mercury porosimetry (for larger inter-particle voids) or atomic force microscopy (AFM) to correlate BET data with nano-roughness.

- Correlation: Plot Fine Particle Fraction (FPF) data from next-generation impactor (NGI) studies versus BET surface area to establish a predictive relationship.

Surface Area Drives DPI Performance

The accurate characterization of porous materials is foundational to their advanced application. The Brunauer-Emmett-Teller (BET) method for surface area measurement provides the critical quantitative framework for evaluating the performance of Metal-Organic Frameworks (MOFs) and mesoporous silica. Within a thesis on BET method development, this article details specific applications where precise surface area and pore volume data directly correlate to functional efficacy in drug delivery and catalysis. These application notes and protocols are designed for researchers leveraging BET data to engineer next-generation functional materials.

Application Notes

MOFs for Targeted Drug Delivery

The ultra-high surface area (often > 2000 m²/g) and tunable pore chemistry of MOFs, as quantified by BET analysis, make them ideal for high-capacity, stimuli-responsive drug carriers. BET isotherms can differentiate between micropores (for drug hosting) and mesopores (for larger biomolecule transport), guiding material selection.

Mesoporous Silica Nanoparticles (MSNs) for Controlled Release

Ordered mesoporous silica (e.g., MCM-41, SBA-15) exhibits well-defined pore sizes (2-10 nm) and high surface areas (∼1000 m²/g), enabling controlled drug loading and release kinetics. BET surface area and Barrett-Joyner-Halenda (BJH) pore size distribution are mandatory quality control metrics for batch consistency in pharmaceutical development.

MOFs and Mesoporous Materials as Catalyst Supports

High surface area maximizes active site dispersion, while pore architecture dictates reactant/product diffusion. BET analysis correlates material properties with catalytic turnover frequency (TOF) and stability. Shape-selective catalysis is particularly dependent on precise pore size measurements derived from BET and related methods.

Table 1: Quantitative Comparison of Representative Materials

| Material | Typical BET Surface Area (m²/g) | Typical Pore Volume (cm³/g) | Primary Pore Size (nm) | Key Application Example |

|---|---|---|---|---|

| MOF-5 (IRMOF-1) | 3000 - 3800 | 1.0 - 1.3 | ~1.2 (Micro) | High-capacity drug loading (e.g., Ibuprofen) |

| ZIF-8 | 1300 - 1800 | 0.6 - 0.7 | ~0.34 (Micro) | pH-responsive drug delivery (e.g., Doxorubicin) |

| UiO-66 | 1000 - 1500 | 0.4 - 0.6 | ~0.6 (Micro) | Anticancer pro-drug activation |

| MCM-41 | 800 - 1200 | 0.8 - 1.2 | 2 - 4 (Meso) | Sustained small-molecule release |

| SBA-15 | 600 - 1000 | 0.8 - 1.2 | 5 - 10 (Meso) | Macromolecular (e.g., protein/antibody) delivery |

| Pt@MOF-199 Catalyst | 900 - 1200 (after loading) | 0.4 - 0.5 | 0.9 (Micro) | Benzene oxidation to phenol |

| Pd@SBA-15 Catalyst | 500 - 700 (after loading) | 0.7 - 1.0 | 6 - 8 (Meso) | Heck cross-coupling reactions |

Experimental Protocols

Protocol 1: Drug Loading and In Vitro Release from Mesoporous Silica (MCM-41)

Objective: To load a model drug (e.g., Ibuprofen) into MCM-41 and characterize its release profile in simulated physiological buffers.

Materials: See "Research Reagent Solutions" table.

Method:

- Activation of Carrier: Degas 100 mg of MCM-41 at 120°C under vacuum for 12 hours to remove adsorbed species. Record pre-loading BET surface area.

- Drug Loading: Prepare a 30 mg/mL solution of Ibuprofen in hexane. Incubate the activated MCM-41 with the drug solution (10 mL) at room temperature for 24 hours with gentle shaking.

- Washing & Drying: Separate the particles by centrifugation (10,000 rpm, 10 min). Wash the pellet twice with 5 mL of fresh hexane to remove surface-adsorbed drug. Dry the resulting drug-loaded MSNs (MSN-IBU) under vacuum overnight.

- Loading Efficiency: Determine drug loading by Thermogravimetric Analysis (TGA) or by quantifying the concentration of drug remaining in the supernatant via UV-Vis spectroscopy.

- In Vitro Release Study: a. Suspend 20 mg of MSN-IBU in 50 mL of Phosphate Buffered Saline (PBS, pH 7.4) in a jacketed vessel at 37°C with constant stirring. b. At predetermined time intervals (0.25, 0.5, 1, 2, 4, 6, 8, 24 h), withdraw 1 mL of release medium and filter through a 0.22 µm syringe filter. c. Analyze the filtrate by HPLC or UV-Vis to determine drug concentration. Replenish the vessel with 1 mL of fresh pre-warmed PBS after each sampling. d. Plot cumulative drug release (%) vs. time.

Validation: Post-loading BET analysis should show a significant reduction in surface area and pore volume, confirming successful pore occupation.

Protocol 2: Synthesis and Catalytic Testing of a Pd@SBA-15 Heterogeneous Catalyst

Objective: To impregnate SBA-15 with Palladium nanoparticles and evaluate its performance in a model Suzuki-Miyaura cross-coupling reaction.

Materials: See "Research Reagent Solutions" table.

Method:

- Wet Impregnation: a. Dissolve 0.1 mmol of Palladium(II) acetate in 20 mL of acetone. b. Add 1.0 g of calcined SBA-15 (BET surface area pre-characterized) to the solution. Stir at room temperature for 6 hours. c. Remove solvent by rotary evaporation. d. Reduce the Pd²⁺ to Pd⁰ by calcining in a 5% H₂/Ar gas stream at 300°C for 2 hours. The final material is Pd@SBA-15.

- Catalyst Characterization: Perform BET analysis on Pd@SBA-15. Compare surface area, pore volume, and pore size distribution to the parent SBA-15 to assess pore blocking.