Catalyst Characterization in Drug Development: Essential Data, Methods, and Insights from CatTestHub

This article provides a comprehensive guide for researchers and drug development professionals on catalyst material characterization.

Catalyst Characterization in Drug Development: Essential Data, Methods, and Insights from CatTestHub

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on catalyst material characterization. It covers foundational principles of heterogeneous catalysts and their role in API synthesis, explores advanced analytical techniques like BET, XRD, and TEM, offers troubleshooting strategies for common catalyst performance issues, and details validation protocols for comparing catalyst batches. The guide synthesizes current methodologies to enable informed catalyst selection and process optimization, accelerating robust pharmaceutical manufacturing.

Understanding Catalyst Materials: Core Properties and Their Impact on Pharmaceutical Synthesis

Within the comprehensive research paradigm of CatTestHub, the systematic characterization of catalyst materials is paramount for rational design in chemical synthesis, energy conversion, and pharmaceutical manufacturing. The efficacy of a heterogeneous catalyst is fundamentally governed by three interdependent characteristics: its accessible Surface Area, the intricate network of its Porosity, and the density and nature of its Active Sites. This whitepaper provides an in-depth technical guide to defining these core properties, presenting current methodologies, quantitative benchmarks, and integrated protocols essential for researchers and development professionals.

Surface Area: The Foundation of Catalytic Accessibility

The total surface area per unit mass of a catalyst is the primary determinant of its potential activity, as it dictates the available platform for reactant adsorption. The Brunauer-Emmett-Teller (BET) theory remains the standard for calculating specific surface area from physical gas adsorption data, typically using nitrogen at 77 K.

Experimental Protocol: BET Surface Area Analysis via N₂ Physisorption

- Sample Preparation: Approximately 0.1-0.5 g of catalyst is degassed under vacuum (or flowing inert gas) at an elevated temperature (e.g., 150-300°C, material-dependent) for 3-12 hours to remove adsorbed contaminants.

- Adsorption Measurement: The degassed sample is cooled to cryogenic temperature (liquid N₂, 77 K). Precise volumes of high-purity N₂ gas are dosed onto the sample, and the equilibrium pressure is measured after each dose.

- Data Analysis: The adsorbed volume (at STP) is plotted vs. relative pressure (P/P₀). The linear region of this isotherm (typically 0.05-0.3 P/P₀) is fitted to the BET equation:

(P / (V_a(P_0 - P))) = (1 / (V_m * C)) + ((C - 1) / (V_m * C)) * (P / P_0)where (Va) is the adsorbed volume, (Vm) is the monolayer volume, and (C) is the BET constant. The specific surface area (S{BET}) is calculated from (Vm). - Reporting: Results are reported in m²/g. The value of C provides qualitative insight into the strength of adsorbate-adsorbent interaction.

Table 1: Typical BET Surface Area Ranges for Common Catalyst Classes

| Catalyst Class | Typical BET Surface Area Range (m²/g) | Common Support/Composition |

|---|---|---|

| Activated Carbon | 500 - 1500 | Microporous carbon |

| Zeolites | 200 - 800 | Aluminosilicate frameworks |

| Mesoporous Silica (e.g., SBA-15) | 500 - 1000 | SiO₂ |

| Alumina (γ-Al₂O₃) | 100 - 300 | Al₂O₃ |

| Titania (TiO₂) | 30 - 100 | TiO₂ |

| Metal-Organic Frameworks (MOFs) | 1000 - 7000 | e.g., HKUST-1, UiO-66, MIL-101 |

| Supported Metal Catalysts | 50 - 300 | Metal nanoparticles on Al₂O₃, SiO₂, etc. |

Porosity: Governing Mass Transport and Selectivity

Porosity defines the size, shape, volume, and connectivity of the void spaces within a catalyst. The International Union of Pure and Applied Chemistry (IUPAC) classifies pores as microporous (< 2 nm), mesoporous (2-50 nm), and macroporous (> 50 nm).

Experimental Protocol: Pore Size Distribution via NLDFT/QSDFT

- Data Collection: A full adsorption-desorption isotherm is measured, often using N₂ at 77 K or Ar at 87 K (for ultramicropores).

- Model Application: The isotherm is analyzed using advanced computational models like Non-Local Density Functional Theory (NLDFT) or Quenched Solid Density Functional Theory (QSDFT), which provide more accurate pore size distributions than classical methods (e.g., BJH) for micro- and mesopores.

- Output: The cumulative pore volume and differential pore size distribution (dV/dlog(D) vs. D) are generated, identifying the dominant pore modes.

- Hysteresis Analysis: The shape of the adsorption-desorption hysteresis loop (IUPAC types H1-H4) informs about pore geometry (e.g., cylindrical, slit-shaped, ink-bottle).

Table 2: Porosity Characteristics and Their Catalytic Implications

| Pore Type | Size Range | Primary Characterization Method | Catalytic Role & Implication |

|---|---|---|---|

| Micropores | < 2 nm | N₂/Ar physisorption, NLDFT/QSDFT | Molecular sieving, shape selectivity, high surface area. Potential diffusion limitations. |

| Mesopores | 2 - 50 nm | N₂ physisorption, BJH/NLDFT | Enhanced mass transport, reduced diffusion resistance. Ideal for liquid-phase reactions. |

| Macropores | > 50 nm | Mercury Intrusion Porosimetry (MIP) | Facilitates bulk fluid transport to the catalyst interior (secondary pore network). |

Active Sites: The Engine of Catalytic Function

Active sites are specific, localized atomic configurations where the chemical reaction is catalyzed. Their nature (acidic, basic, metallic, redox), density, and strength define catalyst activity, selectivity, and stability.

Experimental Protocol: Quantifying Acid Site Density by NH₃-TPD

- Acid Site Probing: The catalyst sample is pretreated in an inert gas flow (He, 500°C, 1 hr). It is then saturated with an acidic probe molecule like ammonia (NH₃) at 100-150°C.

- Physisorbed NH₃ Removal: Weakly held (physisorbed) NH₃ is flushed away by flowing inert gas at the adsorption temperature.

- Programmed Desorption: The temperature is ramped linearly (e.g., 10°C/min) to ~700°C under inert flow. Desorbed NH₃ is detected quantitatively, typically by a thermal conductivity detector (TCD) or mass spectrometer (MS).

- Data Analysis: The desorption profile (amount vs. temperature) is deconvoluted into peaks corresponding to sites of different acid strengths (weak, medium, strong). The total area under the curve gives the total acid site density (μmol NH₃/g).

Table 3: Common Techniques for Active Site Characterization

| Technique | Property Measured | Typical Probe/Measurement | Information Gained |

|---|---|---|---|

| Temperature-Programmed Desorption (TPD) | Site density, strength | NH₃ (acidity), CO₂ (basicity), H₂ (metal dispersion) | Quantity and strength distribution of active sites. |

| Chemisorption | Active metal surface area, dispersion | H₂, CO, O₂ titration | Density of surface metal atoms, average particle size. |

| Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) | Chemical nature of sites | Probe molecules (CO, NO, pyridine) | Identifies site types (e.g., Lewis vs. Brønsted acid, metal coordination). |

| X-ray Photoelectron Spectroscopy (XPS) | Surface composition, oxidation state | X-ray irradiation | Elemental and chemical state of surface atoms (<10 nm depth). |

Integrated Characterization Workflow in CatTestHub Research

A robust characterization strategy within CatTestHub involves a sequential, multi-technique approach to correlate macroscopic performance with microscopic properties.

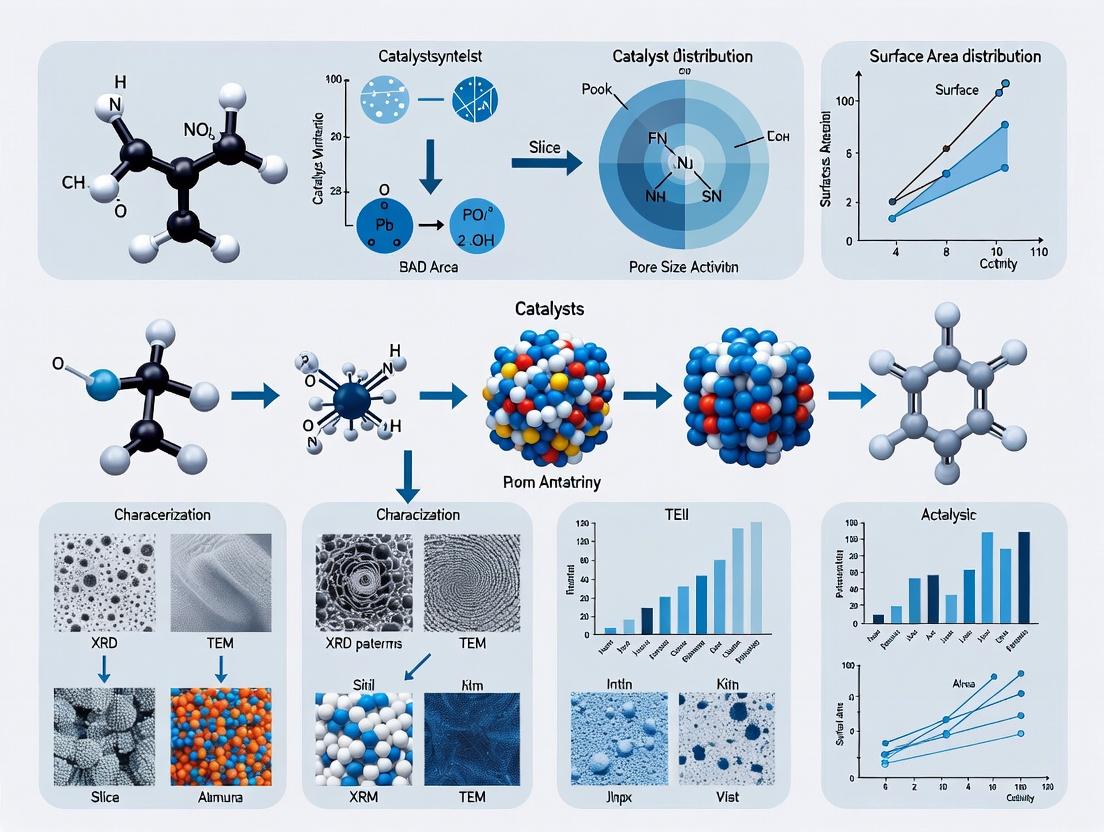

Diagram Title: Integrated Catalyst Characterization Workflow

The Scientist's Toolkit: Essential Reagent Solutions & Materials

Table 4: Key Research Reagents and Materials for Catalyst Characterization

| Item / Reagent Solution | Function / Purpose in Characterization |

|---|---|

| High-Purity Gases (N₂, Ar, He, 5% H₂/Ar, 10% CO/He) | Adsorbate (N₂, Ar) and carrier/purging gases (He) for physisorption; reactive gases (H₂, CO) for chemisorption and TPR/TPD experiments. |

| Ammonia (NH₃) / Carbon Dioxide (CO₂) Calibration Mixtures | Quantitative calibration standards for acid/base site measurement via Temperature-Programmed Desorption (TPD). |

| Pyridine, CO, or NO Probe Molecules (IR Grade) | Molecular probes for spectroscopic identification (e.g., DRIFTS) of specific active site types (Lewis/Brønsted acidity, metal sites). |

| Micromeritics TriStar or Quantachrome Autosorb Series | Automated gas sorption analyzers for performing BET surface area and pore size distribution measurements. |

| Catalytic Reactor System (Fixed-Bed, Tubular) | Bench-scale setup for evaluating catalytic performance (activity, selectivity, stability) under controlled conditions. |

| Reference Catalyst Materials (e.g., NIST Standard) | Certified materials with known surface area/porosity for validation and calibration of instrumentation and methods. |

| Inert Support Materials (SiO₂, Al₂O₃, Carbon) | High-surface-area supports for synthesizing and testing supported metal or oxide catalysts. |

The precise definition of surface area, porosity, and active sites forms the indispensable triad for understanding and engineering advanced catalysts. As exemplified by the CatTestHub research framework, integrating data from these characterization pillars enables the construction of predictive structure-activity relationships. This systematic approach is critical for accelerating the development of next-generation catalysts tailored for efficiency and selectivity in pharmaceuticals and fine chemicals.

The Role of Heterogeneous Catalysts in Active Pharmaceutical Ingredient (API) Synthesis

Heterogeneous catalysis is a cornerstone of modern Active Pharmaceutical Ingredient (API) synthesis, offering distinct advantages in selectivity, catalyst recovery, and process efficiency. Within the research framework of CatTestHub catalyst material characterization data, the rational design and application of these catalysts are driven by deep structural and performance analytics. This whitepaper provides a technical guide on their pivotal role, supported by current data, experimental protocols, and essential research tools.

Key Applications and Quantitative Performance Data

Heterogeneous catalysts are employed across critical API synthesis steps, including asymmetric hydrogenation, cross-coupling, and oxidation. The following table summarizes performance metrics for prominent catalyst classes, as derived from recent literature and CatTestHub benchmark studies.

Table 1: Performance Metrics of Heterogeneous Catalysts in Representative API Synthesis Reactions

| Catalyst Type | Support Material | Target Reaction | Typical Yield (%) | Selectivity (ee or %) | Key Advantage | Common Challenge |

|---|---|---|---|---|---|---|

| Pd Nanoparticles | Carbon / Alumina | Suzuki-Miyaura Cross-Coupling | 92-99 | >99% (chemoselectivity) | Excellent recyclability (5-10 cycles) | Pd leaching (<1 ppm target) |

| Immobilized Organocatalyst (e.g., Proline) | Silica / Polymer | Asymmetric Aldol Reaction | 70-90 | 80-95% ee | No metal contamination | Lower activity vs. homogeneous |

| Pt / PtO₂ (Adams' catalyst) | - | Aromatic Ring Hydrogenation | >95 | >99% (chemoselectivity) | Robust, high activity | Over-reduction risk |

| Chiral Modified Ni (Raney-type) | - | Asymmetric Hydrogenation of β-ketoesters | 85-98 | 88-96% ee | Cost-effective for chiral synthesis | Sensitivity to modifier loading |

| Zeolite (e.g., H-BEA) | - | Friedel-Crafts Acylation | 85-98 | >98% (regioselectivity) | Shape selectivity, no AlCl₃ waste | Pore diffusion limitations |

Core Experimental Protocols

Protocol: Evaluating a Heterogeneous Pd/C Catalyst in a Suzuki-Miyaura Coupling

Objective: To synthesize a biaryl intermediate and assess catalyst activity, leaching, and reusability.

Materials: Pd/C (5 wt%), aryl halide, arylboronic acid, base (K₂CO₃), solvent (toluene/water mix), schlenk line, HPLC/MS for analysis.

Procedure:

- Reaction Setup: In a flame-dried schlenk tube under N₂, combine aryl halide (1.0 mmol), arylboronic acid (1.2 mmol), K₂CO₃ (2.0 mmol), and solvent (10 mL, 4:1 toluene/H₂O).

- Catalyst Addition: Add Pd/C catalyst (0.5 mol% Pd relative to halide). Purge the headspace with N₂.

- Reaction Execution: Heat the mixture to 80°C with vigorous stirring. Monitor reaction completion by TLC or HPLC at regular intervals (typically 2-8 hours).

- Work-up & Analysis: Cool the mixture. Separate the catalyst by hot filtration through a celite pad. Extract the product, dry over MgSO₄, and concentrate. Analyze yield and purity by NMR and HPLC.

- Leaching Test: Analyze the cooled, catalyst-free filtrate by ICP-MS to quantify dissolved Pd.

- Reusability Study: Wash the recovered catalyst thoroughly with solvent, dry under vacuum, and repeat steps 1-4 with fresh reagents for up to 5 cycles. Plot yield vs. cycle number.

Protocol: Characterizing Catalyst Surface Properties via N₂ Physisorption (BET)

Objective: To determine the surface area, pore volume, and pore size distribution of a solid catalyst—a core CatTestHub characterization step.

Materials: Catalyst sample (~0.2g), degassing station, BET surface area analyzer (e.g., Micromeritics), liquid N₂.

Procedure:

- Sample Preparation: Pre-weigh a clean sample tube. Add catalyst. Attach to the degassing station.

- Degassing: Heat the sample under vacuum (e.g., 150°C for 6 hours) to remove adsorbed moisture and contaminants.

- Analysis: Transfer the degassed sample tube to the analyzer port. Immerse in liquid N₂. The instrument automatically measures the volume of N₂ adsorbed at varying relative pressures.

- Data Processing: Use the Brunauer–Emmett–Teller (BET) model on the adsorption isotherm data in the relative pressure (P/P₀) range of 0.05-0.30 to calculate the specific surface area. Pore size distribution is derived using the Barrett-Joyner-Halenda (BJH) method on the desorption branch.

Visualization of Workflows

Diagram 1: Heterogeneous Catalytic Cycle in API Synthesis

Diagram 2: CatTestHub Catalyst R&D & Testing Pipeline

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Heterogeneous Catalyst Research in API Synthesis

| Item / Reagent Solution | Function in Research | Typical Specification / Note |

|---|---|---|

| Metal Precursors (e.g., Pd(OAc)₂, H₂PtCl₆, Ni(NO₃)₂) | Source of active metal for catalyst synthesis. | High purity (>99.9%) to minimize impurity effects. |

| Porous Supports (e.g., Activated Carbon, SiO₂, Al₂O₃, TiO₂) | Provide high surface area, stabilize metal nanoparticles, influence selectivity. | Defined mesh size, pre-calcined, surface functionalization possible. |

| Chiral Modifiers (e.g., Cinchonidine, (R)-Binap) | Induce enantioselectivity on metal surfaces (e.g., for asymmetric hydrogenation). | High enantiomeric purity critical for reproducible results. |

| Coupling Reagents Kit (Aryl halides, Boronic acids/esters) | For cross-coupling reaction screening (Suzuki, Heck). | Variety of electronic and steric properties for substrate scope study. |

| Leaching Test Kits (ICP-MS standards, Chelating resins) | Quantify metal contamination in reaction products (critical for API purity). | Allows detection down to ppb levels. |

| Dedicated Hydrogenation Reactor (Parr type, H-Cube) | Safe, controlled environment for high-pressure hydrogenation reactions. | Enables precise control of P, T, and flow (continuous systems). |

| Solid-Phase Extraction (SPE) Cartridges | Rapid separation of product from catalyst fines in liquid-phase reactions. | Silica or alumina-based; used in high-throughput screening. |

Within the comprehensive research framework of the CatTestHub catalyst material characterization database, a systematic understanding of major catalyst classes is paramount. This whitepaper provides an in-depth technical guide to three foundational categories: Supported Metals, Zeolites, and Metal Oxides. These materials form the backbone of heterogeneous catalysis, critical to applications ranging from chemical synthesis and petroleum refining to pharmaceutical intermediate production and environmental remediation. The performance of these catalysts is intrinsically linked to their physicochemical properties, which is why rigorous characterization protocols, as standardized within CatTestHub, are essential for linking structure to function.

Supported Metal Catalysts

Supported metal catalysts consist of active metal nanoparticles (e.g., Pt, Pd, Rh, Ni) dispersed on a high-surface-area support (e.g., Al2O3, SiO2, TiO2, CeO2). The support stabilizes the nanoparticles, prevents sintering, and can participate in catalytic cycles via strong metal-support interactions (SMSI).

Key Characterization Data & Protocols

Table 1: Quantitative Characterization Metrics for Supported Metal Catalysts

| Property | Typical Measurement Technique | Target Range/Value (Example: Pt/Al2O3) | Relevance to Catalytic Function |

|---|---|---|---|

| Metal Loading | Inductively Coupled Plasma - Optical Emission Spectroscopy (ICP-OES) | 0.5 - 5 wt.% | Directly influences active site density. |

| Metal Dispersion | CO Chemisorption, H2 Chemisorption | 30 - 80% | Fraction of surface metal atoms; key for activity & cost-efficiency. |

| Particle Size | Transmission Electron Microscopy (TEM), X-ray Diffraction (XRD) Scherrer Analysis | 1 - 10 nm | Smaller particles increase surface area but can alter selectivity. |

| Surface Area (BET) | N2 Physisorption (BET Method) | 100 - 300 m²/g (support) | Higher area promotes better metal dispersion. |

| Acidity | NH3-Temperature Programmed Desorption (TPD) | Variable, depending on support | Influences bifunctional catalysis and reaction pathways. |

| Redox Properties | H2-Temperature Programmed Reduction (TPR) | Reduction peak temperature(s) | Indicates reducibility and metal-support interaction strength. |

Experimental Protocol: CO Chemisorption for Metal Dispersion

- Sample Preparation (~200 mg): Load catalyst into a U-shaped quartz tube reactor.

- Pre-treatment: Heat to 150°C under He flow (30 mL/min) for 1 hour to remove physisorbed water. Then, reduce in flowing 5% H2/Ar (30 mL/min) at a specified temperature (e.g., 300°C for Pt) for 2 hours. Cool to 35°C under inert gas.

- Pulse Chemisorption: At 35°C, inject calibrated pulses of 10% CO/He mixture into the He carrier gas flowing to the sample. The eluted CO is measured by a thermal conductivity detector (TCD).

- Calculation: Dispersion (%) = (Total moles of CO chemisorbed * Stoichiometry factor * Atomic weight of metal) / (Weight of sample * Metal loading fraction) * 100. (Assumes a CO:Metalsurface stoichiometry, often 1:1 for Pt).

Research Reagent Solutions

Table 2: Essential Research Toolkit for Supported Metal Catalyst Studies

| Reagent/Material | Function/Explanation |

|---|---|

| Precursor Salts | e.g., H2PtCl6, Pd(NO3)2, Ni(NO3)2. Source of the active metal for impregnation synthesis. |

| High-Purity Gases | 5% H2/Ar (reduction), 10% CO/He (chemisorption), Ultra-high purity He, O2. Essential for pre-treatment and characterization. |

| Porous Oxide Supports | γ-Al2O3, SiO2 (Davisil), TiO2 (P25), CeO2. Provide the high-surface-area scaffold. |

| Quantitative Standard Solutions | e.g., 1000 ppm Pt in HNO3 for ICP-OES calibration. Critical for accurate metal loading analysis. |

| Chemical Probes | CO, NH3, pyridine. Used in chemisorption and spectroscopy to quantify active sites and acidity. |

Zeolite Catalysts

Zeolites are microporous, crystalline aluminosilicates with well-defined channels and cages. Their catalytic activity stems from Brønsted acid sites generated by the presence of aluminum in the silicate framework. Shape selectivity is a defining feature.

Key Characterization Data & Protocols

Table 3: Quantitative Characterization Metrics for Zeolite Catalysts

| Property | Typical Measurement Technique | Target Range/Value (Example: H-ZSM-5) | Relevance to Catalytic Function |

|---|---|---|---|

| Si/Al Ratio | X-ray Fluorescence (XRF), ICP-OES | 10 - ∞ (Silicalite-1) | Determines acid site density and hydrothermal stability. |

| Crystalline Phase & Purity | X-ray Diffraction (XRD) | Match to reference patterns (e.g., MFI) | Confirms correct framework structure and absence of impurities. |

| Acidity (Type & Strength) | NH3-TPD, Pyridine FTIR | Strong acid site density: 0.2 - 1.0 mmol NH3/g | Brønsted vs. Lewis acid distribution; strength impacts reaction pathways. |

| Microporous Surface Area | N2 Physisorption (t-plot method) | 300 - 500 m²/g | Primary area for shape-selective reactions. |

| Pore Volume | N2 Physisorption | 0.15 - 0.20 cm³/g (micro) | Accessible volume for reactants/products. |

Experimental Protocol: NH3-Temperature Programmed Desorption (TPD)

- Sample Preparation (~100 mg): Load zeolite into reactor. Pre-treat at 500°C under He/O2 flow to clean the surface.

- NH3 Adsorption: Cool to 100°C. Expose to a stream of 5% NH3/He for 30-60 minutes to achieve saturation. Flush with He at the same temperature to remove physisorbed NH3.

- Desorption: Heat the sample in flowing He at a constant ramp rate (e.g., 10°C/min) to 600-700°C. Monitor desorbed NH3 with a TCD or mass spectrometer.

- Analysis: The TCD signal is plotted vs. temperature. Peaks correspond to acid sites of different strengths. Quantification is done by calibrating the TCD signal and integrating the peak areas.

Research Reagent Solutions

Table 4: Essential Research Toolkit for Zeolite Catalyst Studies

| Reagent/Material | Function/Explanation |

|---|---|

| Structure-Directing Agents (SDAs) | e.g., Tetrapropylammonium hydroxide (TPAOH) for ZSM-5. Directs the crystallization of specific zeolite frameworks during synthesis. |

| Silica & Alumina Sources | e.g., Tetraethyl orthosilicate (TEOS), Sodium aluminate. The inorganic precursors for zeolite synthesis. |

| Acid/Base Probes | Ammonia (NH3), Pyridine, 2,6-di-tert-butylpyridine (DTBPy). For quantifying total acidity, distinguishing Brønsted/Lewis sites, and probing accessibility. |

| Model Reactant Feedstocks | n-Heptane, iso-octane, methanol. Used in catalytic testing (e.g., cracking, isomerization, MTH) to evaluate performance and selectivity. |

| Ion-Exchange Solutions | e.g., NH4NO3, NaCl. Used to convert as-synthesized zeolites into their active protonic (H+) or other cationic forms. |

Metal Oxide Catalysts

Metal oxide catalysts include single oxides (e.g., Al2O3, TiO2), mixed oxides (e.g., V2O5-WO3/TiO2 for SCR), and reducible oxides (e.g., CeO2, Fe2O3). They often function via acid-base or redox mechanisms.

Key Characterization Data & Protocols

Table 5: Quantitative Characterization Metrics for Metal Oxide Catalysts

| Property | Typical Measurement Technique | Target Range/Value (Example: V2O5-WO3/TiO2) | Relevance to Catalytic Function |

|---|---|---|---|

| Surface Area | N2 Physisorption (BET) | 50 - 150 m²/g | Critical for dispersing active phases and providing reaction sites. |

| Crystalline Phase | X-ray Diffraction (XRD) | Anatase TiO2, Monoclinic WO3 | Determines thermal stability and intrinsic activity of the support/phase. |

| Acidity/Basicity | NH3-TPD, CO2-TPD | Acid/Base site density (mmol/g) | Key for acid-base catalyzed reactions (e.g., dehydration, aldol condensation). |

| Redox Properties | H2-TPR, O2-TPD | Reduction peak temperatures, O2 desorption profiles | Indicates lattice oxygen mobility and availability for redox cycles. |

| Surface Composition | X-ray Photoelectron Spectroscopy (XPS) | V4+/V5+ ratio, W/Ti atomic ratio | Reveals oxidation states and dispersion of surface active species. |

Experimental Protocol: H2-Temperature Programmed Reduction (TPR)

- Sample Preparation (~50 mg): Load oxide catalyst into reactor. Pre-treat in flowing 5% O2/He at 400°C for 1 hour to ensure a consistent oxidized state.

- Reduction Step: Cool to 50°C under inert gas. Switch to a reducing gas mixture (e.g., 5% H2/Ar, 30 mL/min) and stabilize the baseline on the TCD.

- Temperature Ramp: Heat the sample at a constant rate (e.g., 10°C/min) to 800-900°C while monitoring H2 consumption via the TCD.

- Analysis: The negative TCD signal (H2 consumption) is plotted vs. temperature. The number, position, and area of reduction peaks provide information on the reducibility of different oxide species and their interaction strength.

Comparative Workflow & Data Integration in CatTestHub

The characterization of these catalyst classes follows a logical, integrated workflow that feeds into the CatTestHub database for structure-property-performance mapping.

Diagram 1: Catalyst Characterization and Modeling Workflow

Supported metals, zeolites, and metal oxides represent three indispensable pillars of heterogeneous catalysis, each with distinct structural motifs and governing principles for activity and selectivity. The path to rational catalyst design, as championed by the CatTestHub initiative, requires the rigorous application of standardized characterization protocols—from chemisorption and physisorption to temperature-programmed techniques and spectroscopic analysis. The quantitative data derived from these methods, when structured into comparable formats and integrated into a unified research database, enables the development of predictive models that accelerate catalyst discovery and optimization across chemical, energy, and pharmaceutical industries.

How Physical and Chemical Properties Dictate Catalytic Activity and Selectivity

This whitepaper, framed within the CatTestHub catalyst material characterization data research thesis, delineates the fundamental principles through which intrinsic physical and chemical properties of catalytic materials govern their activity and selectivity. By integrating quantitative structure-property relationships (QSPRs) with experimental validation protocols, we provide a technical guide for researchers and drug development professionals to rationalize catalyst design and selection.

Catalytic performance is a multivariate function of material properties. Key descriptors include surface area, pore architecture, acid-base character, oxidation state, coordination environment, and electronic structure. The CatTestHub framework systematizes the correlation of these descriptors with catalytic outcomes from high-throughput experimentation.

Quantitative Property-Performance Relationships

The following table synthesizes critical property-activity-selectivity relationships for heterogeneous and homogeneous catalysts, derived from curated CatTestHub datasets.

Table 1: Influence of Physical and Chemical Properties on Catalytic Outcomes

| Property Category | Specific Descriptor | Impact on Activity | Impact on Selectivity | Typical Measurement Technique |

|---|---|---|---|---|

| Textural | BET Surface Area (m²/g) | Directly proportional to active site density for structure-insensitive reactions. | Low influence alone; modifies diffusional constraints. | N₂ Physisorption |

| Textural | Pore Diameter (nm) | Micropores (<2 nm) can limit mass transfer, reducing apparent activity. | Dictates product shape selectivity in zeolites (e.g., xylene isomer separation). | NLDFT/PBET analysis of sorption isotherms |

| Structural | Crystallite Size (nm) | For metals, activity per gram often peaks at 2-5 nm (maximized edge/corner sites). | Size dictates facet exposure, influencing reaction pathway (e.g., CO₂ hydrogenation to CH₄ vs. CO). | XRD Scherrer analysis, TEM |

| Electronic | d-Band Center (eV) | Volcano relationship for adsorption energy of key intermediates (e.g., O* in ORR). | Determines preference for activating specific functional groups. | XPS, UPS, DFT Calculation |

| Chemical | Acid Site Density (μmol/g) | Linear increase for acid-catalyzed reactions (e.g., cracking) until diffusion limits. | Strong Brønsted acids favor carbocation pathways (e.g., cracking); Lewis acids favor redox pathways. | NH₃/CO₂-TPD, Pyridine FTIR |

| Chemical | Oxidation State (e.g., Mⁿ⁺) | Optimal value for redox cycles (e.g., Ce³⁺/Ce⁴⁺ in oxidation catalysts). | Determines electrophilicity/nucleophilicity, guiding chemoselectivity. | XANES, XPS |

| Geometric | Coordination Number | Lower coordination (e.g., step sites) often correlates with stronger adsorption, higher activity. | Influences enantioselectivity in chiral metal complexes or surfaces. | EXAFS, STM |

Experimental Protocols for Characterization and Testing

Protocol 1: Integrated Physicochemical Characterization Workflow (CatTestHub Standard) Objective: To obtain a comprehensive descriptor set for a solid catalyst.

- Degassing: Activate 100-200 mg sample under vacuum (10⁻³ mbar) at 300°C for 3 hours.

- Textural Analysis (N₂ Physisorption): Perform adsorption-desorption isotherm at 77 K using a volumetric analyzer. Calculate BET surface area (P/P₀ = 0.05-0.30) and pore size distribution via NLDFT.

- Chemical State Analysis (XPS): Transfer sample under inert atmosphere. Acquire survey and high-resolution spectra using Al Kα source. Calibrate to adventitious C 1s at 284.8 eV. Quantify surface elemental composition and oxidation states via peak deconvolution.

- Acid Site Characterization (NH₃-TPD): Pre-treat sample in He at 500°C. Adsorb NH₃ at 100°C. Desorb with a 10°C/min ramp to 700°C in He flow, quantifying desorbed NH₃ via TCD.

Protocol 2: Catalytic Performance Evaluation in a Fixed-Bed Reactor Objective: To measure activity and selectivity under controlled conditions.

- Catalyst Loading: Sieve catalyst to 250-355 μm. Dilute 50 mg with 500 mg inert SiC in a tubular quartz reactor to ensure isothermal operation.

- In-situ Activation: Heat to 500°C (10°C/min) under 50 sccm H₂, hold for 2 hours.

- Reaction Testing: Adjust to reaction temperature (e.g., 300°C). Introduce feed gas (e.g., CO: H₂: Ar = 1:2:1) at a total flow of 40 sccm (WHSV variable). Maintain system pressure at 20 bar.

- Product Analysis: After 1 hour stabilization, analyze effluent via online GC-MS equipped with TCD and FID detectors. Quantify using external calibration curves.

- Calculation:

- Conversion (%) = [(Molesin - Molesout) / Moles_in] * 100 (for key reactant).

- Selectivity to Product i (%) = [Molesi produced / Σ(Molesall products)] * 100.

- Turnover Frequency (TOF, s⁻¹) = (Molecules converted per second) / (Number of active sites).

Visualization of Relationships and Workflows

Title: From Material Properties to Catalytic Performance

Title: CatTestHub Integrated Catalyst R&D Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalyst Characterization and Testing

| Item / Reagent | Function / Purpose | Key Consideration |

|---|---|---|

| High-Purity Gases (H₂, O₂, He, N₂, 10% NH₃/He) | Activation, reaction feeds, carrier gas, and probe molecules for TPD. | Moisture and oxygen traps (<1 ppm) are critical for sensitive materials. |

| Reference Catalysts (e.g., NIST-supported metals, standard zeolites) | Benchmarking activity and validating experimental setups. | Ensures inter-laboratory data comparability within CatTestHub. |

| Porous Silica & Alumina Supports | High-surface-area, inert supports for creating model dispersed metal catalysts. | Controlled pore size and surface chemistry (e.g., acidic vs. neutral). |

| Metal Precursor Salts (e.g., H₂PtCl₆, HAuCl₄, Ni(NO₃)₂) | Synthesis of supported catalysts via impregnation. | Choice of anion (chloride vs. nitrate) affects dispersion and contamination. |

| Probe Molecules (Pyridine, CO, NH₃, NO) | FTIR and TPD studies to quantify acid site type and strength or metal dispersion. | Spectroscopic grade purity to avoid misleading adsorption features. |

| Inert Diluent (SiC, α-Al₂O₃ granules) | Ensures isothermal conditions in fixed-bed reactors by improving heat transfer. | Must be chemically inert under reaction conditions and sieved to match catalyst size. |

| Calibration Gas Mixtures | Quantitative analysis of reactor effluent by GC-TCD/FID. | Custom mixtures should match expected product/feed composition for accuracy. |

| Anhydrous Solvents (THF, Toluene) | For synthesis of organometallic catalysts and homogeneous catalysis studies. | Strict drying (over molecular sieves) to prevent hydrolysis of sensitive complexes. |

The rational design of catalysts with targeted activity and selectivity is predicated on a deep, data-driven understanding of the fundamental physical and chemical property descriptors. The CatTestHub research paradigm, through systematic characterization, standardized testing, and centralized data aggregation, provides the essential framework to elucidate these complex relationships and accelerate the development of next-generation catalytic materials.

Catalyst deactivation represents a critical economic and technical challenge in pharmaceutical process development, directly impacting yield, purity, and cost-effectiveness. Within the CatTestHub catalyst material characterization data research thesis, understanding these mechanisms is paramount for designing robust, scalable, and sustainable synthetic routes. This guide provides an in-depth examination of the primary deactivation pathways, their diagnosis, and mitigation strategies, contextualized with current experimental data and protocols.

Core Deactivation Mechanisms

Catalyst deactivation in pharmaceutical synthesis typically occurs via three primary pathways: poisoning, fouling/coking, and thermal degradation/sintering. The predominance of a mechanism depends on the catalyst material, reaction conditions, and process stream composition.

Table 1: Primary Catalyst Deactivation Mechanisms in Pharmaceutical Processes

| Mechanism | Typical Causes | Common in Catalyst Types | Reversibility |

|---|---|---|---|

| Poisoning | Strong chemisorption of impurities (e.g., S, N, P, heavy metals, catalyst byproducts) blocking active sites. | Homogeneous (metal complexes), Heterogeneous (Pd/C, Pt, enzymes). | Often irreversible. |

| Fouling/Coking | Physical deposition of organic species (e.g., high-MW polymers, carbonaceous deposits) on the surface or pores. | Heterogeneous (zeolites, acidic/basic catalysts, metal oxides). | Partially reversible via oxidative regeneration. |

| Thermal Degradation / Sintering | Loss of active surface area due to crystallite growth or support collapse at high temperature. | Heterogeneous (supported metals, nanoparticles). | Irreversible. |

| Active Site Leaching | Dissolution of the active metal species into the reaction medium. | Supported metals (e.g., Pd/C, Pt/Al2O3) in liquid phase. | Irreversible for the catalyst batch. |

| Phase Transformation | Change in the active crystalline or oxidation state to an inactive form. | Metal oxides, sulfides, and certain alloys. | Often irreversible. |

Table 2: Quantitative Impact of Common Poisons on a Model Pd/C Hydrogenation Catalyst

| Poisoning Agent | Concentration (ppm) | Relative Activity Loss (%) | Key Characterizing Technique (CatTestHub) |

|---|---|---|---|

| Sulfur (as Thiophene) | 10 | ~95 | XPS, ICP-MS |

| Lead (Pb²⁺) | 50 | ~80 | ICP-MS, STEM-EDX |

| Carbon Monoxide (CO) | 100 | ~70 (reversible) | In situ DRIFTS |

| Mercaptans | 20 | ~90 | GC-MS, XPS |

Experimental Protocols for Deactivation Analysis

Protocol: Accelerated Deactivation Test for Heterogeneous Catalysts

- Objective: To simulate and quantify long-term deactivation in a controlled, abbreviated timeframe.

- Materials: Fixed-bed reactor system, online GC/MS, candidate catalyst (e.g., 0.5g), model pharmaceutical reaction feedstock, potential poison spike solution.

- Procedure:

- Condition the catalyst under standard reaction conditions (e.g., 100°C, 20 bar H₂) for 2 hours.

- Establish baseline conversion and selectivity via hourly sampling/analysis over 4 hours.

- Introduce a controlled concentration of a suspected poison (e.g., 50 ppm sulfur) into the feedstock or cycle between reaction and harsh conditions (e.g., thermal spikes).

- Monitor conversion (X) as a function of time on stream (TOS). Calculate deactivation constant (k_d) from the slope of ln(X) vs. TOS.

- Characterize spent catalyst via N₂ physisorption (BET), TEM, and XPS (aligned with CatTestHub protocols).

Protocol: Leaching Test for Supported Metal Catalysts

- Objective: To determine the extent of active metal loss into the reaction medium.

- Materials: Batch reactor, catalyst (e.g., Pd/C), reaction solvent and substrates, ICP-MS/OES.

- Procedure:

- Perform the target reaction (e.g., coupling) under standard conditions.

- Upon reaction completion, cool the mixture and separate the catalyst via hot filtration through a 0.45 µm membrane under inert atmosphere.

- Immediately analyze the clear filtrate for metal content using ICP-MS.

- Correlate leached metal concentration with catalyst activity loss in subsequent reuse cycles.

Visualization of Deactivation Pathways & Analysis

Diagram 1: Primary Catalyst Deactivation Pathways and Diagnosis

Diagram 2: Catalyst Deactivation Analysis Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Catalyst Deactivation Studies

| Item | Function in Deactivation Studies | Example/Catalog Reference |

|---|---|---|

| Model Poison Compounds | Spiking agents to simulate impurity feed and study poisoning kinetics. | Thiophene (S-poison), Quinoline (N-poison), Triphenylphosphine (P-poison). |

| Thermogravimetric Analysis (TGA) Standards | Calibrating instruments for accurate coke burn-off and temperature-programmed oxidation (TPO) measurements. | Calcium oxalate monohydrate, Nickel metal. |

| ICP-MS Multi-Element Standard Solutions | Quantifying trace metal leaching and poisoning element accumulation on catalyst. | Custom blends for Pd, Pt, Ni, Pb, As, etc., at ppb-ppm levels. |

| Certified Reference Catalyst Materials | Benchmarking performance and validating characterization data within the CatTestHub ecosystem. | EUROCAT Pd/Al₂O³, NIST-supported metal standards. |

| In Situ DRIFTS Cells | For real-time monitoring of surface adsorbates and intermediate species leading to fouling. | High-temperature, high-pressure reaction cells with ZnSe windows. |

| Porous Membrane Filters (0.2 µm) | For rigorous hot filtration tests to separate catalyst from solution for leaching analysis. | PTFE or nylon membranes compatible with organic solvents. |

Advanced Characterization Techniques: From BET and XRD to In-Situ Analysis for Catalyst Profiling

This technical guide provides a foundational framework for characterizing catalyst materials within the CatTestHub research initiative, focusing on surface area and porosity—critical parameters governing activity, selectivity, and stability in catalytic and pharmaceutical applications.

Theoretical Foundations

Surface area and porosity analysis quantitatively describes a solid's accessible surface and void spaces. The Brunauer-Emmett-Teller (BET) theory is the standard for calculating specific surface area from gas adsorption isotherms, typically using nitrogen at 77 K. Pore Size Distribution (PSD) is derived from the same isotherm data using models like the Barrett-Joyner-Halenda (BJH) method for mesopores (2-50 nm) or Density Functional Theory (DFT)/Non-Local DFT (NLDFT) for micropores (<2 nm) and mesopores.

Key Quantitative Parameters & Data

The following table summarizes the core quantitative parameters derived from physisorption analysis, essential for CatTestHub catalyst benchmarking.

Table 1: Core Parameters from Physisorption Analysis

| Parameter | Symbol | Typical Units | Description | Relevance to Catalyst Performance |

|---|---|---|---|---|

| BET Surface Area | SBET | m²/g | Area accessible to adsorbate gas molecules. | Higher area often correlates with increased active site availability. |

| Total Pore Volume | Vp | cm³/g | Total volume of pores, typically at P/P₀ ~0.99. | Influences mass transport and loading capacity. |

| Micropore Volume | Vmicro | cm³/g | Volume of pores < 2 nm (from t-plot or DFT). | Crucial for size-selective catalysis and gas storage. |

| Mesopore Volume | Vmeso | cm³/g | Volume of pores 2-50 nm (often Vp - Vmicro). | Facilitates diffusion of larger reactants/products. |

| Average Pore Width | davg | nm | 4Vp/SBET (for cylindrical model). | General indicator of pore size scale. |

| Peak Pore Size | dpeak | nm | Maximum in PSD curve. | Indicates the most frequent pore diameter. |

Experimental Protocols

Sample Preparation Protocol

Aim: To remove contaminants and adsorbed species without altering the material's texture.

- Weighing: Accurately weigh a clean, dry sample tube with the sample (mass tailored to expected surface area).

- Degassing: Secure the tube to the degas port of the analyzer.

- Heating: Apply heat (temperature and duration are material-specific; e.g., 150-300°C for many metal oxides, under vacuum or flowing inert gas).

- Duration: Degas for a minimum of 3 hours, or until a stable outgassing rate is achieved.

- Cooling: Cool to ambient temperature under continued vacuum or inert flow.

BET Surface Area Measurement (Static Volumetric Method)

Aim: To acquire a nitrogen adsorption isotherm at 77 K and calculate SBET.

- Installation: Transfer the degassed sample tube to the analysis station.

- Immersion: Lower the sample into a liquid nitrogen Dewar (77 K) bath.

- Dosing: Introduce controlled, incremental doses of high-purity N₂ gas into the sample manifold.

- Equilibrium: After each dose, monitor pressure until equilibrium is reached (typical ΔP/P < 0.01%).

- Adsorption: Record the quantity adsorbed at each relative pressure (P/P₀). Continue up to P/P₀ ~0.3.

- Desorption: Optionally, measure the desorption branch by removing doses.

- Calculation: Apply the BET equation in the linear relative pressure range (usually 0.05-0.30 P/P₀). The slope and intercept yield the monolayer capacity, from which SBET is calculated using the cross-sectional area of N₂ (0.162 nm²).

Pore Size Distribution via the BJH Method

Aim: To derive mesopore size distribution from the adsorption or desorption isotherm branch.

- Full Isotherm: Continue the adsorption measurement from Protocol 3.2 up to P/P₀ ~0.99.

- Desorption Branch: Acquire a detailed desorption isotherm.

- Thickness Model: Apply a statistical thickness model (e.g., Halsey, Harkins-Jura) to calculate the adsorbed layer thickness t at each pressure.

- Core Radius Calculation: As pressure decreases during desorption, the condensed nitrogen in pores evaporates. The Kelvin equation relates the pressure to the radius of the evaporating liquid core (rk).

- Pore Volume Increment: The volume desorbed between two pressure steps is assigned to pores with a characteristic radius given by rp = rk + t.

- PSD Plot: Iterative calculation yields a cumulative and differential pore volume vs. radius plot.

Diagram 1: Physisorption Analysis Workflow

Diagram 2: Data Interpretation Pathway

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials

| Item | Function in BET/PSD Analysis |

|---|---|

| High-Purity Analysis Gases (N₂, Ar, Kr) | N₂ at 77 K is standard; Ar at 87 K for low-surface-area materials; Kr at 77 K for very low surface areas (< 1 m²/g). |

| Cryogenic Fluid (Liquid N₂ or Ar) | Maintains the constant temperature bath (77 K or 87 K) required for controlled physisorption. |

| Sample Tubes with Fill Rods | Hold the sample; fill rods reduce dead volume for more accurate measurements on low-surface-area samples. |

| Non-Porous Reference Materials | Used for buoyancy correction and validation of instrument free space measurements. |

| Certified Surface Area Reference Materials | e.g., NIST-traceable alumina, carbon black. Essential for calibrating and validating the entire measurement protocol. |

| Degassing Station | Removes adsorbed contaminants from samples via heating under vacuum or inert flow prior to analysis. |

| Quantachrome or Micromeritics ASAP Software | Industry-standard software suites for instrument control, data acquisition, and application of BET, BJH, DFT, etc. |

| DFT/NLDFT Kernel Libraries | Model-specific theoretical adsorption isotherms for advanced, material-specific micropore and mesopore analysis. |

Within the research framework of the CatTestHub initiative, the comprehensive characterization of catalyst materials is paramount. Precise identification of crystalline phases and atomic-scale structure determination are critical for establishing structure-property relationships in heterogeneous catalysts, supported metal nanoparticles, and zeolitic frameworks. X-Ray Diffraction (XRD) stands as the cornerstone technique for this purpose. This whitepaper provides an in-depth technical guide on applying XRD for phase and structure identification, contextualized for catalyst development research.

Fundamental Principles of XRD for Phase Identification

XRD operates on Bragg's Law: nλ = 2d sinθ, where constructive interference of X-rays scattered by crystalline planes yields a characteristic diffraction pattern. The positions (2θ angles) and intensities (I) of the peaks form a unique fingerprint for each crystalline phase.

Key Quantitative Parameters for Phase Analysis

The following table summarizes core quantitative data extracted from XRD patterns for phase identification in catalyst materials.

Table 1: Key Quantitative XRD Parameters for Phase Analysis

| Parameter | Symbol/Unit | Description | Typical Value Range for Catalysts | Primary Use in CatTestHub Context |

|---|---|---|---|---|

| Diffraction Angle | 2θ (degrees) | Angle between incident and diffracted beam. | 5° – 120° | Indexing patterns, identifying phase via d-spacing. |

| d-spacing | d (Å) | Interplanar spacing calculated via Bragg's Law. | 0.5 – 30 Å | Matching to crystallographic databases (ICDD, ICSD). |

| Relative Intensity | I/I₁ (%) | Peak intensity normalized to strongest peak. | 0 – 100% | Qualitative and quantitative phase analysis. |

| Full Width at Half Maximum | FWHM, β (degrees or radians) | Peak breadth at half its maximum height. | 0.05° – 2° (2θ) | Estimating crystallite size via Scherrer equation. |

| Crystallite Size | D (nm) | Average size of coherently diffracting domains. | 1 – 200 nm | Characterizing nanoparticle catalysts, monitoring sintering. |

| Lattice Parameter | a, b, c (Å) | Unit cell dimensions from whole-pattern fitting. | Varies by material (e.g., Al₂O₃: a~4.75 Å) | Detecting strain, solid solutions, thermal expansion. |

Experimental Protocols for Catalyst Characterization

Protocol A: Sample Preparation for Powder XRD (Catalyst Powders)

Objective: Obtain a representative, randomly oriented, flat specimen.

- Grinding: Gently grind the catalyst powder (approx. 0.5-1.0 g) in an agate mortar and pestle to reduce preferred orientation and ensure particle size <10 µm.

- Loading: For a standard aluminum holder, place the powder into the sample cavity. Use a glass slide or razor blade to pack and scrape the excess material flush with the holder surface, creating a smooth, level area for analysis.

- Handling: For air-sensitive catalysts (e.g., reduced metal catalysts), perform all steps in an inert atmosphere glovebox and use an airtight sample holder with a dome or Kapton film seal.

- Mounting: Secure the sample holder onto the XRD stage, ensuring it is correctly aligned in the sample plane.

Protocol B: Routine Phase Identification Scan

Objective: Rapid acquisition of a pattern for qualitative phase analysis.

- Instrument Setup: Cu Kα radiation (λ = 1.5418 Å), voltage: 40 kV, current: 40 mA.

- Scan Parameters: Continuous scan mode. 2θ range: 5° to 80°. Step size: 0.02° 2θ. Counting time: 0.5 – 2 seconds per step. Divergence slits: 1°.

- Data Collection: Initiate scan. Monitor real-time pattern for unexpected features.

- Post-Measurement: Apply basic smoothing and Kα2 stripping. Perform background subtraction.

Protocol C: High-Resolution Scan for Crystallite Size/Strain Analysis

Objective: Acquire high-quality data for line profile analysis.

- Instrument Setup: Long fine-focus Cu X-ray tube. Use a receiving slit (e.g., 0.1 mm) or a crystal analyzer to improve angular resolution.

- Scan Parameters: Step-scan mode. 2θ range: focused on a specific peak or region of interest (e.g., 30°-40° for Pt (111)). Step size: 0.01° 2θ. Counting time: 5 – 20 seconds per step.

- Data Collection: Ensure excellent counting statistics. Repeat scan for improved signal-to-noise if necessary.

- Analysis: Use Scherrer equation (D = Kλ / (β cosθ), where K~0.9, β is FWHM in radians) for crystallite size estimation. For advanced microstructural analysis, employ whole-pattern fitting (Rietveld refinement).

Structure Solution and Refinement (Rietveld Method)

For novel catalyst phases, full structure determination is possible. The Rietveld method refines a theoretical diffraction pattern, calculated from a structural model, to fit the observed pattern.

Table 2: Typical Refinement Parameters & Figures of Merit in Rietveld Analysis

| Parameter | Description | Target Value (Good Fit) | Role in Catalyst Characterization |

|---|---|---|---|

| R-pattern (Rp) | Residual between observed and calculated patterns. | < 10% | Overall fit quality indicator. |

| R-weighted pattern (Rwp) | Weighted residual; most significant figure of merit. | < 15% | Minimized during refinement. |

| R-expected (Rexp) | Statistically expected residual based on data quality. | - | Used to calculate GoF. |

| Goodness-of-Fit (GoF) | χ² = (Rwp / Rexp)². | Close to 1.0 | Balance between model complexity and fit. |

| Lattice Parameters (a, b, c) | Refined unit cell dimensions. | ±0.001 Å precision | Detecting lattice expansion/contraction from dopants or defects. |

| Atomic Coordinates (x, y, z) & Occupancies | Positions and site populations of atoms. | Chemically sensible | Determining active site geometry, cation distribution. |

| Isotropic/Anisotropic Displacement Parameters (Biso/Uij) | Measure of atomic vibration/static disorder. | Positive, reasonable values | Probing local disorder or thermal motion. |

Rietveld Refinement Workflow for Structure Solution

The Scientist's Toolkit: Research Reagent Solutions for XRD Analysis

Table 3: Essential Materials & Reagents for XRD Catalyst Analysis

| Item | Function / Purpose | Critical Considerations for CatTestHub |

|---|---|---|

| Agate Mortar & Pestle | To grind and homogenize catalyst powder, minimizing preferred orientation. | Essential for preparing uniform samples; agate prevents contamination. |

| Standard Reference Material (e.g., NIST SRM 674b, SiO₂) | For instrument calibration (angle, intensity, line shape). | Mandatory for ensuring data comparability across different instruments and studies. |

| Zero-Background Holder (e.g., Silicon single crystal) | Holds a thin layer of powder on a non-diffracting substrate. | Ideal for small sample quantities (<50 mg) common in catalyst research. |

| Airtight Sample Holder with Kapton Film | Encapsulates air- or moisture-sensitive samples (e.g., reduced metal catalysts). | Preserves the catalyst's active state during measurement. |

| Internal Standard (e.g., ZnO, Al₂O₃ Corundum) | Mixed with sample to calibrate position and enable quantitative phase analysis (QPA). | Used for accurate lattice parameter determination and QPA validation. |

| Rietveld Refinement Software (e.g., GSAS-II, TOPAS, MAUD) | For full-pattern fitting, structure refinement, and microstructural analysis. | Required for extracting detailed structural parameters from complex catalyst patterns. |

| Crystallographic Database (ICDD PDF-4+, ICSD) | Digital library of reference diffraction patterns and crystal structures. | Core resource for phase identification; subscriptions are essential. |

XRD Data Acquisition & Analysis Pipeline

Advanced Applications in Catalyst Research

- In Situ/Operando XRD: Monitoring phase transitions, reduction/oxidation, and active phase formation under realistic gas atmospheres and temperature.

- Pair Distribution Function (PDF) Analysis: Probing local structure and disorder in nanocrystalline or amorphous catalyst components.

- Thin-Film & Grazing Incidence XRD (GI-XRD): Analyzing catalyst coatings and model supported catalyst systems.

- High-Throughput XRD: Rapid screening of catalyst libraries for phase composition in combinatorial discovery projects.

XRD remains an indispensable, non-destructive tool for the CatTestHub research portfolio, providing definitive crystallographic insights. From routine phase identification to sophisticated structure-property elucidation via Rietveld refinement, mastery of XRD protocols and analysis empowers researchers to deconvolute the complex structures underpinning catalytic performance, driving rational catalyst design.

Within the CatTestHub catalyst material characterization data research framework, correlating nanoscale morphology with elemental composition is paramount. Scanning and Transmission Electron Microscopy (SEM/TEM) coupled with Energy-Dispersive X-ray Spectroscopy (EDS) provide the foundational techniques for this analysis. This whitepaper details the core methodologies, protocols, and data interpretation strategies essential for advanced catalyst development, directly impacting fields from chemical synthesis to pharmaceutical catalysis.

Core Techniques and Instrumentation

Scanning Electron Microscopy (SEM)

SEM generates high-resolution images of a sample's surface morphology by scanning a focused electron beam across it and detecting secondary or backscattered electrons. It is ideal for studying catalyst particle size, distribution, and surface topography at micro to nanoscale resolutions.

Transmission Electron Microscopy (TEM)

TEM transmits a high-energy electron beam through an ultrathin specimen, providing atomic-resolution imaging, diffraction patterns, and lattice structure information. It is critical for analyzing internal structure, crystal defects, and nanoparticle crystallinity in catalyst materials.

Energy-Dispersive X-ray Spectroscopy (EDS)

An analytical technique used with both SEM and TEM, EDS detects X-rays emitted from a sample when bombarded by the electron beam. Each element produces characteristic X-rays, enabling qualitative and quantitative elemental analysis and spatial mapping.

Table 1: Key Specifications and Capabilities of SEM/TEM-EDS

| Parameter | SEM-EDS Typical Range | TEM-EDS Typical Range | Primary Function in Catalyst Analysis |

|---|---|---|---|

| Resolution | 0.5 nm – 5 nm | 0.05 nm – 0.2 nm | Morphology & lattice imaging |

| Accelerating Voltage | 0.1 kV – 30 kV | 80 kV – 300 kV | Penetration & excitation volume |

| Elemental Detection | Beryllium (Be) – Uranium (U) | Lithium (Li) – Uranium (U) | Light/heavy element identification |

| Mapping Spatial Resolution | ~1 µm – 10 nm | <1 nm – 5 nm | Elemental distribution |

| Quantitative Accuracy | ±1-5 wt% (standardized) | ±2-10 wt% (thin-film) | Composition measurement |

Experimental Protocols for Catalyst Characterization

Protocol: Sample Preparation for Catalyst Nanoparticles

Objective: To prepare a representative, electron-transparent specimen for TEM and contamination-free for SEM.

- Dispersion: Suspend 1 mg of catalyst powder in 10 mL of high-purity ethanol or isopropanol. Sonicate for 15-30 minutes using a bath or probe sonicator to break agglomerates.

- Deposition (TEM): Pipette 5-10 µL of the well-dispersed suspension onto a lacey carbon-coated copper TEM grid. Allow to dry in a clean, low-dust environment.

- Deposition (SEM): Pipette 10-20 µL onto a cleaned silicon wafer or conductive carbon tape mounted on an aluminum stub. Allow to dry.

- Conductive Coating (SEM): For non-conductive catalysts, apply a 5-10 nm thick coating of sputtered carbon or gold/palladium using a precision etching coating system to prevent charging.

Protocol: EDS Elemental Mapping and Point Analysis in SEM

Objective: To correlate morphology with elemental distribution on catalyst surfaces.

- Instrument Setup: Insert sample into high-vacuum chamber. Select accelerating voltage (typically 10-20 kV) to optimize X-ray excitation and spatial resolution.

- Area Selection: Acquire a secondary electron (SE) or backscattered electron (BSE) image at a magnification suitable to visualize features of interest (e.g., 50,000x).

- Spectrum Acquisition: Define a region of interest (ROI). Acquire a full EDS spectrum with a dead time of 20-40% and a minimum of 100,000 total counts for qualitative identification.

- Elemental Mapping: Select the characteristic X-ray lines for each element of interest (e.g., Pt Lα, Co Kα). Perform a raster scan over the ROI with a dwell time of 100-500 ms/pixel and a pixel resolution of 256x256 or 512x512. Use pulse pile-up correction and dead time correction.

- Quantification: Use standardless (built-in factory standards) or standards-based quantification (ZAF or φ(ρZ) matrix correction) on selected areas or points to obtain weight% and atomic% composition.

Protocol: High-Resolution STEM-EDS Mapping

Objective: To achieve atomic-scale correlation of structure and composition in catalyst nanoparticles.

- Instrument Setup: Use a probe-corrected Scanning Transmission Electron Microscope (STEM). Align the microscope for high-angle annular dark-field (HAADF) imaging. Set the probe current to 50-200 pA for sufficient X-ray counts.

- Spectrometer Calibration: Ensure the EDS detector (e.g., windowless silicon drift detector) is optimally positioned and calibrated for light element detection.

- Data Acquisition: Acquire a simultaneous HAADF image and EDS spectrum image. Use a pixel dwell time of 1-10 ms/pixel. For core-shell nanoparticles, ensure the scan is sufficiently fast to minimize sample drift but long enough for adequate counts.

- Data Processing: Use advanced software to perform background subtraction, deconvolution of overlapping peaks (e.g., Pt Mβ and Co Kα), and elemental map generation. Apply multivariate statistical analysis (e.g., Principal Component Analysis) for low-signal maps.

Data Presentation and Analysis

Table 2: Quantitative EDS Analysis of a Bimetallic Pt-Co Catalyst (CatTestHub Sample CT-234)

| Analysis Type | Region | Pt (at%) | Co (at%) | O (at%) | C (at%) | Notes |

|---|---|---|---|---|---|---|

| Point Analysis | Nanoparticle Core | 52.1 ± 1.5 | 47.3 ± 1.6 | 0.6 ± 0.2 | - | Alloyed core |

| Point Analysis | Nanoparticle Surface | 90.5 ± 2.1 | 8.2 ± 1.8 | 1.3 ± 0.3 | - | Pt-rich shell |

| Area Analysis | Whole Particle (5 avg) | 68.7 ± 3.2 | 30.1 ± 2.9 | 1.2 ± 0.5 | - | Bulk composition |

| Line Scan | Across 10 nm particle | Gradient | Inverse Gradient | Constant ~1% | - | Confirms core-shell structure |

Visualizing Workflows and Relationships

Diagram 1: Correlative Microscopy Workflow for CatTestHub

Diagram 2: Electron-Sample Interactions & Data Output

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SEM/TEM-EDS Catalyst Analysis

| Item | Function & Specification | Application Note |

|---|---|---|

| Lacey Carbon TEM Grids | Provides ultra-thin, conductive support film with holes for unobstructed imaging. Copper, 300 mesh. | Essential for high-resolution TEM of nanoparticles; prevents background interference. |

| High-Purity Silicon Wafers | Flat, conductive, and clean substrate for SEM sample mounting. | Preferred over carbon tape for quantitative surface analysis to avoid carbon background. |

| High-Purity Solvents (Isopropanol, Ethanol) | For dispersing catalyst powders without leaving residue. HPLC grade or better. | Critical for preventing contamination that can obscure EDS signals, especially for light elements. |

| Conductive Silver Paint/Epoxy | Electrically bonds sample to stub, preventing charging. | Use sparingly to avoid outgassing in high vacuum and contaminating analysis area. |

| Sputter Coater with Au/Pd or C Target | Applies nanometer-thin conductive layer to non-conductive samples. | Carbon is preferred for EDS as it minimizes interference with metal peaks; Au/Pd offers finer grain. |

| EDS Standard Reference Materials | Certified thin-film or bulk standards for quantification (e.g., Mn, Cu, SiO₂). | Required for accurate quantitative analysis; verifies system calibration. |

| Cryo-Preparation System | For preparing beam-sensitive or liquid-containing catalyst samples. | Preserves the native state of catalysts supported on polymers or metal-organic frameworks. |

This whitepaper serves as an in-depth technical guide to core surface chemistry characterization techniques, developed within the research framework of CatTestHub, a platform dedicated to catalyst material characterization data. Understanding the surface composition, functional groups, and reactivity of materials is fundamental for researchers in catalysis and pharmaceutical development. This document details the operational principles, experimental protocols, and data interpretation for X-ray Photoelectron Spectroscopy (XPS), Fourier-Transform Infrared Spectroscopy (FTIR), and Temperature-Programmed Desorption, Reduction, and Oxidation (TPD, TPR, TPO).

X-ray Photoelectron Spectroscopy (XPS)

XPS is a quantitative technique that measures the elemental composition, empirical formula, chemical state, and electronic state of elements within the top 1-10 nm of a material surface.

Experimental Protocol:

- Sample Preparation: Solid samples are typically mounted on a conductive stub using double-sided tape or inserted into a powder holder. Samples must be ultra-high vacuum (UHV) compatible.

- Loading & Evacuation: The sample is introduced into a load-lock chamber, which is then evacuated to a pressure of ~10⁻⁷ mbar before transfer to the main analysis chamber (UHV, ~10⁻¹⁰ mbar).

- Spectrum Acquisition: The sample is irradiated with a monochromatic X-ray beam (e.g., Al Kα, 1486.6 eV). Emitted photoelectrons are analyzed for their kinetic energy by a hemispherical electron energy analyzer.

- Data Analysis: The binding energy (BE) is calculated (BE = hν - KE - Φ). Spectra are calibrated using adventitious carbon (C 1s at 284.8 eV) or a known metal peak. Peak fitting is performed using appropriate software (e.g., CasaXPS, Avantage).

Key Quantitative Data (Example):

| Element | Peak | Binding Energy (eV) | Atomic % | Chemical State Assignment |

|---|---|---|---|---|

| C | 1s | 284.8 | 45.2 | C-C/C-H (Adventitious) |

| C | 1s | 286.3 | 12.1 | C-O |

| O | 1s | 530.1 | 30.5 | Metal Oxide (O²⁻) |

| O | 1s | 531.7 | 9.8 | Hydroxyl/Carbonate |

| Ti | 2p₃/₂ | 458.5 | 2.4 | Ti⁴⁺ in TiO₂ |

Fourier-Transform Infrared Spectroscopy (FTIR)

FTIR spectroscopy identifies surface functional groups and adsorbed species by measuring the absorption of infrared light, which causes vibrational transitions in molecular bonds.

Experimental Protocol (Diffuse Reflectance Infrared Fourier-Transform Spectroscopy - DRIFTS):

- Background Collection: A spectrum of a clean, non-absorbing reference material (e.g., KBr) is collected as a background.

- Sample Loading: The catalyst powder is mixed with KBr (typically 1-5 wt%) and loaded into a DRIFTS cell.

- In-situ Treatment: The cell allows for in-situ pretreatment (e.g., heating in He, O₂, H₂) to clean and condition the sample surface.

- Spectrum Acquisition: Infrared light is directed onto the sample, and the diffusely reflected light is collected by a parabolic mirror and directed to a mercury-cadmium-telluride (MCD) detector. An interferogram is generated and Fourier-transformed to produce a spectrum.

- Analysis: Absorption peaks are assigned to specific vibrational modes (e.g., ν(O-H) at ~3700-3200 cm⁻¹, ν(C=O) at ~1700 cm⁻¹).

Key Research Reagent Solutions & Materials:

| Item | Function |

|---|---|

| KBr (Potassium Bromide) | Infrared-transparent matrix for diluting solid samples in DRIFTS. |

| Alumina/Silica Wafers | Supports for preparing thin films of samples for transmission FTIR. |

| Pyridine-d₅ | Probe molecule for identifying Brønsted and Lewis acid sites via characteristic ring vibration modes. |

| CO Gas (⁵% in He) | Probe molecule for identifying metal sites and their coordination (e.g., linear, bridged, carbonyl bands). |

| High-Pressure/Temperature DRIFTS Cell | Enables operando studies of catalysts under realistic reaction conditions. |

FTIR-DRIFTS Experimental Workflow

Temperature-Programmed Methods (TPD, TPR, TPO)

These techniques probe the reactivity of surface species by monitoring gas-phase composition while heating the sample in a controlled gas flow.

Experimental Protocol (Generic TPD/TPR/TPO):

- Sample Preparation: A known mass (50-100 mg) of catalyst is loaded into a U-shaped quartz microreactor.

- Pretreatment: The sample is cleaned/pre-conditioned by heating in an inert gas (He, Ar) or reactive gas.

- Adsorption/Saturation: The sample is exposed to a probe gas (NH₃ for acidity, CO₂ for basicity, H₂ for reducible species, O₂ for oxidizable species) at a specific temperature, followed by purging with inert gas to remove physisorbed molecules.

- Temperature Ramp: The sample is heated at a constant linear rate (e.g., 10 °C/min) under a steady inert (TPD) or reactive (TPR/TPO) gas flow.

- Detection: The effluent gas is monitored continuously by a thermal conductivity detector (TCD) and/or a mass spectrometer (MS). The MS tracks specific mass-to-charge ratios (m/z) to identify desorbing species.

- Data Analysis: The peak temperature (Tmax) indicates the strength of adsorption/reaction. The area under the peak is proportional to the quantity of species.

Key Quantitative Data Comparison:

| Method | Probe Gas | Carrier Gas | Detects | Information Gained |

|---|---|---|---|---|

| TPD | NH₃, CO₂, H₂O | Inert (He, Ar) | Desorbed probe molecules | Acid/Base site strength & density, Adsorption energy |

| TPR | H₂ (⁵% in Ar) | Reducing (H₂/Ar) | H₂ consumption | Reducibility, Reduction temperature, Metal dispersion |

| TPO | O₂ (⁵% in He) | Oxidizing (O₂/He) | O₂ consumption or CO₂ production | Carbon/coke burn-off temperature, Oxidizability |

Temperature-Programmed Analysis System

Integrated Characterization within CatTestHub Framework

At CatTestHub, data from these techniques are synergistically combined to build a comprehensive picture of a catalyst material.

- XPS provides the surface chemical composition and oxidation states.

- FTIR identifies the types of functional groups and adsorbed intermediates.

- TPD/TPR/TPO quantifies the density, strength, and reactivity of active sites.

Integrated Surface Analysis for Catalyst Modeling

XPS, FTIR, and temperature-programmed methods form the cornerstone of modern surface chemistry analysis. When applied systematically, as within the CatTestHub data research paradigm, they deliver indispensable, complementary insights into the physicochemical properties that govern material performance. For researchers in catalyst and drug development, mastering these techniques is crucial for rational design, optimization, and understanding of active surfaces.

The fundamental goal of catalysis research is to bridge the gap between idealized model studies and industrially relevant performance. Traditional ex-situ characterization, performed before and after a reaction, often fails to capture the true active state of a catalyst, missing metastable intermediates, structural dynamics, and surface reconstructions that occur only under working conditions. This limitation forms a critical knowledge gap within the CatTestHub catalyst material characterization data research initiative, which seeks to build comprehensive, dynamic datasets that link atomic-scale structure to macroscopic function.

In-situ (under static, reactive conditions) and operando (under working conditions with simultaneous activity measurement) characterization techniques have emerged as the cornerstone of modern catalyst analysis. By applying spectroscopic, scattering, and microscopic probes during reaction, researchers can establish definitive structure-activity relationships. This whitepaper serves as a technical guide to the core methodologies, experimental protocols, and data interpretation strategies in this transformative field.

The following table summarizes the primary in-situ/operando techniques, their key measurables, and typical temporal and spatial resolutions.

Table 1: Core In-Situ/Operando Characterization Techniques for Catalysis

| Technique | Acronym | Primary Information | Typical Pressure Range | Temporal Resolution | Spatial Resolution | Key for CatTestHub |

|---|---|---|---|---|---|---|

| X-ray Absorption Spectroscopy | XAS (XANES/EXAFS) | Oxidation state, local coordination, bond distances | UHV - 100 bar | Seconds - Minutes | ~mm (bulk-sensitive) | Tracks electronic & geometric structure evolution. |

| In-Situ X-Ray Diffraction | XRD | Crystalline phase, particle size, lattice strain | UHV - 100 bar | Seconds - Minutes | ~µm (long-range order) | Monitors phase transformations & sintering. |

| Ambient Pressure XPS | AP-XPS | Surface composition, chemical states | UHV - 25 mbar | Minutes | ~10s of µm | Probes topmost atomic layers under gas exposure. |

| In-Situ Transmission Electron Microscopy | TEM/STEM | Particle morphology, atomic structure, dynamics | UHV - 1 bar (with cell) | Milliseconds - Seconds | Sub-Ångström | Visualizes structural dynamics at atomic scale. |

| Operando Infrared Spectroscopy | IR (DRIFTS, PM-IRRAS) | Surface adsorbates, reaction intermediates | UHV - 100 bar | Milliseconds - Seconds | ~10s of µm | Identifies molecular intermediates & active sites. |

| Operando Raman Spectroscopy | Raman | Molecular vibrations, phase identification | UHV - 100 bar | Seconds - Minutes | ~1 µm | Detects oxide phases, carbon species (coking). |

| Mass Spectrometry (Coupled) | MS | Gas-phase products, reaction rates | Any | Milliseconds | N/A | Essential for quantitative activity/selectivity data. |

Experimental Protocols for Key Methodologies

Protocol 1: Operando XAS Coupled with Mass Spectrometry for a CO Oxidation Catalyst

- Objective: To correlate the reduction state of a Pt/CeO₂ catalyst with its activity for CO oxidation.

- Setup: A plug-flow capillary reactor (ID ~1-2 mm) containing catalyst powder is placed in the X-ray beam. Heating is provided by a hot-air blower. Gas feed (e.g., 1% CO, 1% O₂ in He) is controlled by mass flow controllers.

- Procedure:

- Collect reference XANES spectra for Pt foil and PtO₂.

- Under inert flow (He), heat catalyst to 300°C and collect initial spectrum.

- Switch to reactive gas mixture. Initiate simultaneous data collection: a) Quick-EXAFS scans (every 30-60 seconds). b) Online MS monitoring of m/z = 28 (CO) and 44 (CO₂).

- Perform a temperature-programmed reaction ramp (e.g., 50-300°C at 5°C/min) while maintaining continuous XAS and MS data acquisition.

- Post-process: Linear combination fitting (LCF) of XANES spectra using Pt⁰ and Pt²⁺ references to quantify oxidation state. Integrate MS peaks to calculate CO conversion. Plot oxidation state vs. temperature vs. conversion.

Protocol 2: In-Situ TEM Study of Nanoparticle Sintering

- Objective: To visualize the thermal sintering dynamics of supported Pd nanoparticles under gaseous environment.

- Setup: Use a commercial in-situ TEM gas cell holder. Load a microfabricated SiNₓ chip coated with Pd/SiO₂ catalyst.

- Procedure:

- Establish high vacuum in TEM column and locate nanoparticles at room temperature.

- Introduce 20 mbar of H₂ into the cell via the holder's gas manifold.

- Acquire a series of high-angle annular dark-field (HAADF-STEM) images at a set interval (e.g., every 10 seconds).

- Ramp the integrated heater to 500°C at a controlled rate, continuing image acquisition.

- Analyze image sequences: Track individual particle coordinates to measure diffusion. Use image analysis software to measure particle size distributions over time, quantifying coalescence and growth mechanisms.

Protocol 3: Operando DRIFTS for Mechanistic Study of Methanol Synthesis

- Objective: To identify surface species and intermediates during CO₂ hydrogenation over a Cu/ZnO/Al₂O₃ catalyst.

- Setup: A DRIFTS reactor cell with ZnSe windows, connected to a gas manifold and online MS/GC.

- Procedure:

- Pre-reduce catalyst in situ under H₂ at 250°C.

- Cool to reaction temperature (e.g., 220°C) under inert gas and collect a background spectrum.

- Switch to feed gas (e.g., CO₂:H₂ = 1:3). Continuously collect IR spectra (e.g., 64 scans at 4 cm⁻¹ resolution every minute).

- Simultaneously sample effluent gas to MS/GC for quantification of CO, CH₃OH, H₂O.

- Process spectra by subtracting the background. Assign key bands: formate (HCOO⁻) at ~1350, 1580 cm⁻¹; methoxy (CH₃O-) at ~1100 cm⁻¹; gaseous CO at ~2100 cm⁻¹. Plot temporal evolution of intermediate intensities versus product formation rate.

Visualization of Workflows and Relationships

Diagram 1: Operando Data Generation & Integration Workflow

Diagram 2: Technique-Specific Challenges & Solutions

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials & Components for In-Situ/Operando Experiments

| Item | Function & Importance | Typical Specification / Example |

|---|---|---|

| Micro-Reactor Cell | Houses catalyst under controlled P/T while allowing probe access. Defines pressure limits and dead volume. | Silica/quartz capillary for XRD/XAS; stainless steel with KBr windows for IR; MEMS chip for TEM. |

| Gas Delivery System | Provides precise, stable, and contaminant-free reactive gas mixtures. Critical for steady-state measurements. | Mass Flow Controllers (MFCs) with ±1% accuracy; heated gas lines to prevent condensation; in-line filters. |

| Calibration References | Essential for quantitative analysis of spectroscopic data (XAS, XPS, Raman). | Metal foils (Pt, Au, Ni) for XAS energy calibration; standard samples (Si wafer, Cu sheet) for XPS/Raman shift. |

| Porous Catalyst Support | High-surface-area, chemically inert (under conditions) material for dispersing active phases. | High-purity γ-Al₂O₃, SiO₂, TiO₂, or CeO₂ powders (e.g., BET > 100 m²/g). |

| High-Temperature Adhesive | Immobilizes catalyst powder in the measurement cell without contaminating or reacting. | High-purity ceramic bonds or colloidal silica suspensions. |

| Calibrated Thermocouple | Accurate temperature measurement at the catalyst bed. Largest source of error if misplaced. | Type K (Chromel-Alumel) or Type C (W-Re) thermocouple, placed directly in contact with the sample. |

| Online Analytical Standard | For calibrating the quantitative output of gas analyzers (MS, GC). | Certified gas mixture (e.g., 1000 ppm CO₂ in N₂, ±1% cert.) for converting MS signal to partial pressure. |

Diagnosing Catalyst Performance Issues: A Guide to Deactivation, Selectivity Loss, and Batch Variability

Within the framework of the CatTestHub catalyst material characterization data research thesis, understanding and mitigating catalyst deactivation is paramount. This whitepaper provides an in-depth technical analysis of the four primary failure modes: sintering, coking, poisoning, and attrition. These mechanisms represent significant economic and operational challenges in catalysis-driven industries, from pharmaceutical synthesis to bulk chemical production. The systematic characterization and data standardization championed by CatTestHub are critical for developing predictive models and robust catalyst designs.

Fundamental Mechanisms and Quantitative Analysis

Sintering

Sintering, or thermal degradation, involves the loss of active surface area via crystallite migration and coalescence or via atomic migration (Ostwald ripening). It is primarily driven by high temperatures, often exacerbated by steam.

Table 1: Quantitative Impact of Sintering on Common Catalysts

| Catalyst System | Typical Operating Temp (°C) | Onset Temp for Sintering (°C) | Surface Area Loss (%) after 100h at Onset Temp | Common Stabilizers |

|---|---|---|---|---|

| Pt/Al₂O₃ | 400-550 | ~600 | 40-60 | La₂O₃, BaO |

| Pd/CeO₂-ZrO₂ | 400-600 | ~800 | 30-50 | Rare earth oxides |

| Ni/Steam Reforming | 700-900 | ~500* | 50-70 | MgO, Al₂O₃ |

| Co-FTS | 200-240 | ~250 | 20-40 | Pt promoters, Al₂O₃ support |

*Nickel sinters at lower relative temperatures due to high mobility.

Coking

Coking refers to the deposition of carbonaceous species (polymers, filaments, graphite) on the catalyst surface, blocking active sites. It is common in hydrocarbon processing.

Table 2: Coking Rates and Characteristics

| Reaction Type | Catalyst | Typical Conditions | Coke Formation Rate (gcoke/gcat·h) | Primary Coke Morphology | Reversibility |

|---|---|---|---|---|---|

| Steam Cracking | Ni/MgAl₂O₄ | 800°C, low pO₂ | 0.05-0.2 | Filamentous Carbon | Partially (via steam gasification) |