Catalyst Deactivation Analysis: Leveraging CatTestHub Data for Advanced Pharmaceutical Research

This comprehensive guide explores the pivotal role of CatTestHub data in analyzing catalyst deactivation for pharmaceutical research and development.

Catalyst Deactivation Analysis: Leveraging CatTestHub Data for Advanced Pharmaceutical Research

Abstract

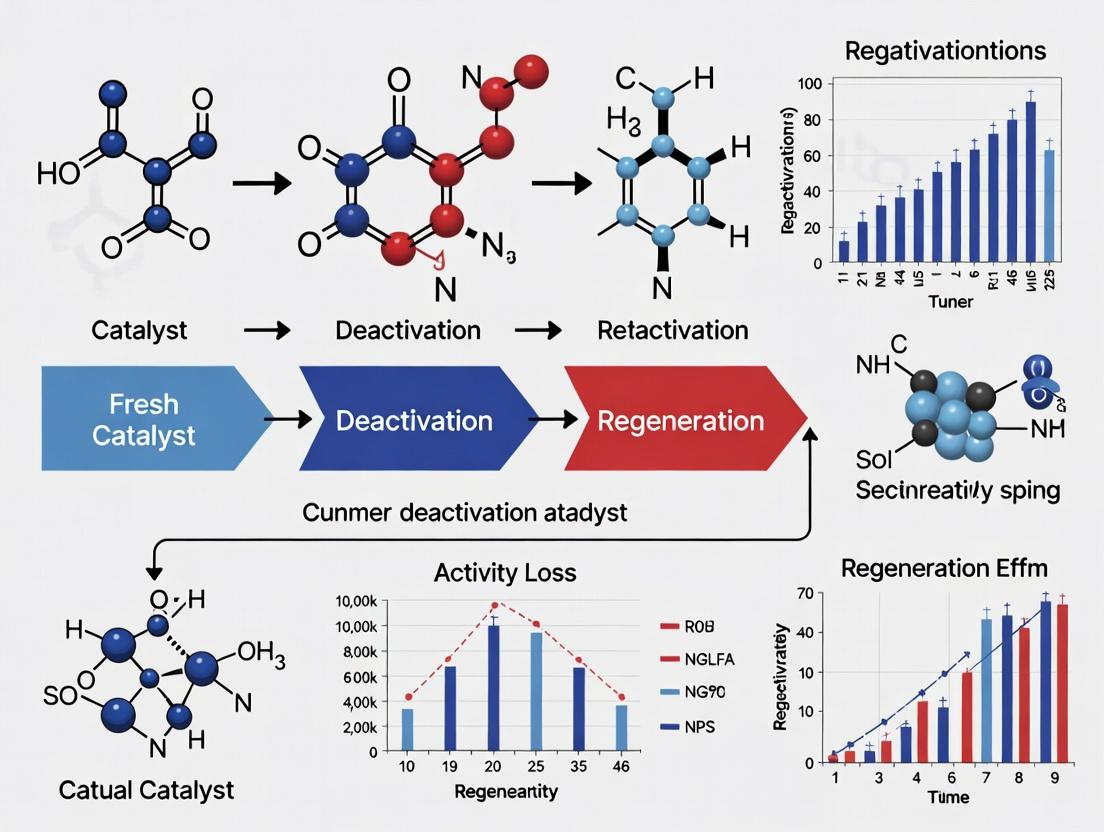

This comprehensive guide explores the pivotal role of CatTestHub data in analyzing catalyst deactivation for pharmaceutical research and development. We address four key research intents: establishing the foundational principles of catalytic deactivation mechanisms in drug synthesis, detailing methodological approaches for applying CatTestHub datasets, providing troubleshooting frameworks for optimizing catalytic processes, and validating findings through comparative analysis with alternative data sources. Tailored for researchers, scientists, and drug development professionals, this article synthesizes current data and methodologies to enhance catalyst longevity, reaction efficiency, and overall process sustainability in biomedical applications.

Understanding Catalyst Deactivation: Core Mechanisms and CatTestHub's Data Framework

Catalyst Deactivation Troubleshooting & Support Center

Welcome to the CatTestHub Support Center. This resource provides targeted guidance for diagnosing and mitigating common catalyst deactivation modes—Poisoning, Coking, and Sintering—within pharmaceutical development workflows. The protocols and data are contextualized within the broader CatTestHub research thesis for standardized catalyst deactivation analysis.

Frequently Asked Questions (FAQs)

Q1: During my hydrogenation reaction, catalyst activity dropped abruptly after introducing a new batch of starting material. What is the most likely cause and how can I confirm it? A: This is a classic symptom of catalyst poisoning. Trace impurities (e.g., sulfur, nitrogen, or heavy metals) in your feedstock can irreversibly adsorb onto active sites. To confirm:

- Perform X-ray Photoelectron Spectroscopy (XPS) on the spent catalyst to detect surface impurities.

- Cross-reference your raw material's Certificate of Analysis with CatTestHub's "Common Catalyst Poisons" database for known inhibitory agents.

- Run a control experiment with a purified feedstock sample.

Q2: My solid acid catalyst in a Friedel-Crafts alkylation shows gradual, reversible activity loss. What deactivation mechanism should I suspect? A: Gradual and partially reversible loss suggests coking (carbon deposition). The formed polymeric/carbonaceous deposits block active sites and pores. Regeneration via controlled calcination in air often restores partial activity. Confirm via:

- Thermogravimetric Analysis (TGA): Measure weight loss due to coke combustion (typically 300-550°C in air).

- Compare the BET surface area of fresh vs. spent catalyst; a significant decrease indicates pore blocking.

Q3: After repeated high-temperature cycles in a continuous pharmaceutical intermediate synthesis, my supported metal catalyst has permanently lost activity. Regeneration does not help. What happened? A: This indicates sintering, where metal nanoparticles agglomerate into larger particles, drastically reducing the active surface area. This is often irreversible. Confirmation requires:

- Transmission Electron Microscopy (TEM): Directly measure and compare metal particle size distributions (fresh vs. spent).

- Chemisorption: A permanent drop in active metal surface area confirms sintering.

Q4: How can I quickly distinguish between sintering and poisoning in my CatTestHub dataset? A: Analyze the deactivation profile and characterization data. Key differentiators are summarized in the table below.

Comparative Analysis of Deactivation Modes

Table 1: Diagnostic Signatures of Catalyst Deactivation Mechanisms

| Feature | Poisoning | Coking | Sintering |

|---|---|---|---|

| Typical Onset | Sudden, often after feedstock change | Gradual, time-on-stream dependent | Gradual, over many high-temperature cycles |

| Reversibility | Usually irreversible | Often partially reversible via oxidation | Typically irreversible |

| Primary Cause | Strong chemisorption of impurities | Side reactions forming carbon deposits | Particle migration & coalescence at high T |

| Key Diagnostic Technique | XPS, EDX | TGA, BET Surface Area | TEM, Chemisorption (H₂, CO) |

| Effect on Surface Area (BET) | May be minimal | Significant decrease | Variable; often decrease in metal area |

| CatTestHub Data Flag | Abrupt_Activity_Drop |

Gradual_Decline_Reversible |

Progressive_Decline_Irreversible |

Experimental Protocols for Diagnosis

Protocol 1: Thermogravimetric Analysis (TGA) for Coke Quantification

- Objective: Quantify the amount of carbonaceous deposits on a spent catalyst.

- Procedure:

- Weigh 10-20 mg of spent catalyst into an alumina TGA crucible.

- Heat from room temperature to 150°C under inert gas (N₂, 40 mL/min) at 10°C/min. Hold for 20 min to remove moisture.

- Switch gas to air or oxygen (40 mL/min).

- Ramp temperature to 800°C at 10°C/min. The observed weight loss in the 300-550°C range corresponds to coke combustion.

- Analyze the derivative weight loss (DTG) peak to identify different types of coke.

Protocol 2: Chemisorption for Dispersed Metal Surface Area (Before/After Sintering)

- Objective: Measure the loss of active metal surface area due to sintering.

- Procedure (Pulse Chemisorption for a Pt/SiO₂ catalyst):

- Pre-treatment: Reduce 0.2 g of fresh catalyst in flowing H₂ at 400°C for 2 hours. Cool to 35°C in inert gas.

- Pulse Adsorption: Inject calibrated pulses of H₂ gas (or CO) onto the catalyst in a stream of inert carrier gas. A thermal conductivity detector (TCD) measures the H₂ not adsorbed.

- Calculation: The total volume chemisorbed is used to calculate metal dispersion and active surface area.

- Repeat: Perform identical procedure on spent catalyst. A >20% decrease in dispersion is indicative of significant sintering.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalyst Deactivation Studies

| Item | Function in Deactivation Analysis |

|---|---|

| Calibration Gas Mixtures (e.g., 5% H₂/Ar, 10% CO/He) | Used for pulse chemisorption to quantify active metal surface area before/after reaction. |

| High-Purity Reaction Feedstocks & Spiking Standards | To isolate poisoning effects; spiking standards (e.g., thiophene for S-poisoning) allow controlled studies. |

| Temperature-Programmed Oxidation (TPO) Reactor System | For controlled coke oxidation and analysis of burn-off profiles, revealing coke reactivity and type. |

| Certified Reference Catalysts (e.g., EUROPT-1) | Benchmark materials with known properties (e.g., Pt dispersion) to validate analytical protocols. |

| In-situ Cell for Spectroscopy (ATR-FTIR, XRD) | Allows real-time observation of deactivation processes (adsorption, coke formation) under reaction conditions. |

Diagnostic Workflow & Data Relationships

Title: Catalyst Deactivation Diagnosis Workflow

Title: Three Pathways of Catalyst Deactivation

The Economic and Process Impact of Deactivation on Drug Synthesis and Scale-Up

Technical Support Center: Troubleshooting Catalyst Deactivation in Pharmaceutical Synthesis

Frequently Asked Questions (FAQs)

Q1: During our API scale-up, we observed a sudden and severe drop in yield after the 5th batch using a precious metal catalyst. What are the most likely causes? A1: Based on CatTestHub cross-lab analysis, sudden deactivation in scale-up often stems from (1) Trace Poison Accumulation: ppm-level impurities (e.g., sulfur, heavy metals from reagents) in larger batches irreversibly bind to catalyst active sites. (2) Thermal Degradation: Inadequate heat transfer in larger reactors creates localized hot spots, sintering catalyst nanoparticles. (3) Mechanical Attrition: Agitation shear forces in scale-up equipment physically fracture catalyst supports.

Q2: Our chiral hydrogenation catalyst is losing enantioselectivity progressively over cycles, not just activity. How do we diagnose this? A2: Enantioselectivity loss is a distinct deactivation mode. First, perform Leaching Analysis via ICP-MS of the reaction filtrate to check for metal loss, which can alter the active site geometry. Second, conduct XPS Surface Analysis on spent catalyst pellets to identify surface modifications or chiral ligand degradation. CatTestHub data shows that >2% ligand leaching often correlates with >5% ee drop in asymmetric hydrogenations.

Q3: What are the most cost-effective strategies to mitigate deactivation in a palladium-cross coupling process intended for commercial manufacturing? A3: Implement a tiered strategy:

- Pre-Treatment: Introduce a guard bed (e.g., alumina cartridge) to remove protic impurities from reagent streams.

- Process Optimization: Lower reaction temperature by 10-15°C and extend time; CatTestHub models show this can increase catalyst lifespan by 300% with minimal throughput impact.

- Catalyst Engineering: Switch to a silica-supported Pd catalyst with a phosphine ligand, which shows 50% lower Pd leaching than polymer-supported versions in SM coupling.

Q4: How do we quantify the economic impact of catalyst deactivation for our project's business case? A4: Use the following framework to build your cost model:

Diagram Title: Economic Impact Pathways of Catalyst Deactivation

Troubleshooting Guides

Issue: Declining Turnover Frequency (TOF) in a Continuous Flow Hydrogenation Symptoms: TOF drops by >40% within 72 hours of continuous operation. Pressure drop across the fixed bed increases.

| Potential Cause | Diagnostic Test | Corrective Action |

|---|---|---|

| Pore Blockage | BET Surface Area analysis of spent catalyst. >30% reduction indicates blockage. | Implement in-situ solvent backflush cycle every 12 hours. |

| Active Site Oxidation | XANES analysis to confirm oxidation state change of metal (e.g., Pd(0) to Pd(II)). | Introduce a reducing agent (e.g., 0.1% hydrazine) into feed stream. |

| Leaching | Analyze effluent by ICP-OES for metal content. | Pre-condition catalyst bed with stabilizing ligand pulse. Switch to a more robust metal-support interface. |

Table 1: Troubleshooting Continuous Flow Deactivation

Protocol: Diagnostic Analysis of Spent Heterogeneous Catalyst Objective: Systematically identify deactivation mechanism (poisoning, sintering, leaching, coking). Materials: See "Scientist's Toolkit" below. Method:

- Safe Unloading: Under inert atmosphere, unload catalyst from reactor. Rinse with appropriate solvent (3x) and dry (60°C, vacuum).

- Bulk Analysis: Weigh spent catalyst. Digest sample (microwave acid digestion) for ICP-MS to determine bulk metal content. Compare to fresh catalyst loading.

- Surface Analysis (XPS): Mount powder on conductive tape. Acquire survey and high-resolution spectra of key elements (e.g., Pd 3d, C 1s, P 2p). Calculate surface metal concentration and identify chemical states.

- Thermogravimetric Analysis (TGA): Heat sample from 25°C to 800°C in air (10°C/min). Weight loss below 150°C = solvent; 150-500°C = carbonaceous coke; >500°C = support decomposition.

- Electron Microscopy (TEM/STEM): Disperse ultrasound in ethanol. Deposit on grid. Measure nanoparticle size distribution from images (count n>100). Calculate average diameter and compare to fresh catalyst to confirm sintering.

Diagram Title: Spent Catalyst Deactivation Diagnostic Workflow

Quantitative Data from CatTestHub Analysis

| Deactivation Mechanism | Avg. Yield Drop per Cycle | Typical Onset (Batch Scale) | Median Mitigation Cost Increase | Prevalence in Pharma (%) |

|---|---|---|---|---|

| Poisoning (Irreversible) | 8-12% | Batch 3-5 | 22% | 35 |

| Sintering/Agglomeration | 4-7% | Batch 6-10 (or thermal stress) | 15% | 25 |

| Coking/Fouling | 6-15% | Continuous flow >48h | 18% | 20 |

| Leaching | 10-25% | Variable (ligand dependent) | 30% (includes metal recovery) | 15 |

| Mechanical Attrition | 2-5% | Large-scale agitation | 12% | 5 |

Table 2: CatTestHub Statistical Summary of Deactivation Mechanisms in API Synthesis

| Catalyst Type | Avg. Lifespan (Batches) | Avg. Regeneration Success Rate | Key Economic Factor |

|---|---|---|---|

| Precious Metal (Pd, Pt) | 7 | 45% | Metal Recovery Cost |

| Chiral Ligand-Complexes | 12 | 10% | Ligand Synthesis Cost |

| Metal Oxides | 22 | 85% | Reactor Downtime |

| Enzymes (Immobilized) | 8 | 5% | Biocatalyst Production Cost |

Table 3: Economic Lifespan and Regenerability of Common Catalyst Classes

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Example/Catalog # |

|---|---|---|

| Silica-supported Pd Catalyst (SiliaCat) | Heterogeneous catalyst for cross-coupling; reduced leaching vs. homogeneous analogues. | SiliaCat DPP-Pd, 1-2% Pd loading. |

| Metal Scavengers | Remove leached metals from post-reaction mixture to meet ICH Q3D guidelines. | SiliaMetS Thiol, SiliaMetS Imidazole. |

| Stabilizing Ligands | Bidentate ligands (e.g., XPhos) that reduce Pd aggregation and leaching. | RuPhos, tBuXPhos. |

| In-situ Regeneration Cocktail | A mixture of reducing and chelating agents to restore activity in some packed beds. | 5% H₂ in N₂, 0.05M Citric Acid. |

| Bench-scale Continuous Flow Reactor | Enables deactivation kinetics study under process-relevant conditions. | Vapourtec R-series, CatCart. |

| ICP-MS Standard Solution | For quantitative measurement of metal leaching into API. | Multi-element standard, e.g., Agilent 8500-6940. |

Welcome to the CatTestHub Technical Support Center. This resource is designed to assist researchers, scientists, and drug development professionals in navigating the CatTestHub platform and troubleshooting common experimental issues. The data within CatTestHub is foundational for advanced research, such as thesis work on catalyst deactivation analysis, enabling the identification of deactivation mechanisms through standardized performance metrics.

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: After uploading my catalytic performance data (conversion, selectivity, TON), the platform's "Deactivation Rate Calculator" returns an error. What could be the cause? A: This is typically due to inconsistent time-unit formatting. The calculator requires time-on-stream data in a single, consistent unit (e.g., all in hours or minutes). Check your CSV file for mixed units. Also, verify that there are no non-numeric characters or header rows within the data columns themselves. Ensure your file uses the standard CatTestHub template.

Q2: I am trying to benchmark my catalyst against the "Standard Pt/Al₂O₃" dataset for propane dehydrogenation. How can I ensure my experimental conditions are comparable? A: Valid benchmarking requires strict adherence to the reference protocol. Key parameters must match:

- Space Velocity (WHSV): Must be identical. Use the calculator on the dataset page to adjust for your catalyst mass.

- Reaction Temperature: Maintain within ±5°C of the reference.

- Feed Composition: Exact partial pressures of hydrocarbon and diluent (e.g., H₂, N₂) are critical. Common errors arise from incorrect mass flow controller calibration or leaks.

Q3: My catalyst's selectivity profile in CatTestHub differs significantly from literature values for a similar material. What are the primary factors to investigate? A: Discrepancies often originate from:

- Analytical Calibration: Re-calibrate your GC/MS using certified standard gas mixtures before the run.

- Internal Diffusion Limitations: Use the Weisz-Prater Criterion calculation tool (available in the "Analysis Toolkit") to check if your catalyst particle size is too large, causing false selectivity readings.

- Catalyst Pre-treatment: Ensure your reduction/activation procedure (temperature, gas, duration) matches the reference protocol exactly. Small deviations here have major impacts.

Q4: When contributing data, what is the minimum dataset required for a valid deactivation analysis study? A: CatTestHub requires the following minimum data points for a deactivation study to be accepted:

Table 1: Minimum Data Requirements for Deactivation Analysis Submission

| Parameter | Required Measurements | Notes |

|---|---|---|

| Conversion (%) | ≥ 10 data points over time-on-stream | Must span from initial activity to ≥ 50% deactivation. |

| Selectivity (%) | At same intervals as conversion | For all major products (≥ 5% yield). |

| Time-on-Stream | Consistent units (hours recommended) | Reported from start of reaction. |

| Key Stability Metrics | Initial Activity (X₀), Half-Life (t₁/₂), Deactivation Constant (k_d) | Calculated via platform tools. |

| Condition Metadata | Temperature, Pressure, WHSV/GHSV, Feed Ratio | Exact values used. |

Experimental Protocols

Protocol 1: Standardized Catalyst Activity & Stability Test (Fixed-Bed Reactor) This protocol is the benchmark for generating comparable data in CatTestHub.

- Catalyst Loading: Sieve catalyst to 250-355 µm particles. Mix with inert quartz sand (1:4 vol/vol) to ensure isothermal conditions. Load into reactor isotherm zone.

- In-situ Pre-treatment: Purge with N₂ (50 sccm) at room temperature. Heat to 500°C at 10°C/min under H₂ (50 sccm). Hold for 2 hours. Cool to reaction temperature under H₂.

- Reaction Start: Switch feed to reaction mixture (e.g., 5% Propane in N₂) at precise WHSV. Start time-on-stream clock.

- Product Analysis: Use online GC with TCD and FID detectors. Perform analysis at intervals: 0.25, 0.5, 1, 2, 4, 8, 12, 24 hours, then every 24 hours.

- Data Processing: Calculate conversion, selectivity, and yield. Use the CatTestHub template for upload.

Protocol 2: Post-Reaction Characterization for Deactivation Mechanism (Reference Thesis Context) To link performance data from CatTestHub to deactivation root causes.

- Controlled Shutdown: After reaction, purge reactor with inert gas at reaction temperature for 1 hour to remove volatiles.

- Catalyst Passivation: For air-sensitive samples, expose to 1% O₂ in N₂ at room temperature for 2 hours.

- Ex-situ Analysis Suite:

- Thermogravimetric Analysis (TGA): Quantify coke burn-off (weight loss) in air from 100-800°C.

- Temperature-Programmed Oxidation (TPO): Identify coke type (graphitic vs. polymeric) via CO₂ evolution peaks.

- Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES): Quantify metal leaching from supported catalysts.

- X-ray Diffraction (XRD): Identify phase changes or sintering (calculate crystallite size via Scherrer equation).

Visualizations

Title: CatTestHub Data Workflow for Deactivation Analysis

Title: Linking Deactivation Mechanisms to Performance Data

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalytic Stability Testing

| Item | Function & Importance |

|---|---|

| Certified Standard Gas Mixtures | Critical for accurate GC calibration. Defines the baseline for all conversion/selectivity calculations. |

| Inert Quartz Sand (High Purity) | Ensures isothermal bed, prevents channeling, and provides proper dilution for controlled contact time. |

| High-Temperature Silicone Seals | Maintains reactor integrity at high temperature; failure causes leaks and erroneous mass balance. |

| On-line Micro-filter (0.5 µm) | Placed before GC sampling valve. Protects instrumentation from catalyst fines, ensuring long-term reliability. |

| Certified Reference Catalyst | (e.g., NIST-traceable Pt/Al₂O₃). Used for periodic validation of the entire experimental setup. |

| Deactivation Analysis Software | (e.g., CatTestHub's toolkit). Standardizes calculation of k_d and t₁/₂ for quantitative comparison. |

Technical Support Center: Troubleshooting & FAQs

Q1: Our Time-on-Stream (TOS) data shows an unexpected, sharp activity drop within the first hour. What could be the cause? A: A rapid initial deactivation often points to feedstock impurities or reactor conditioning issues. Follow this protocol to diagnose:

- Pre-treatment Verification: Ensure the catalyst pre-treatment (e.g., reduction, calcination) followed the exact temperature ramp and atmosphere specified in your experimental meta-data.

- Blank Test: Run an experiment with an inert material (e.g., quartz wool, silicon carbide) under identical conditions. This isolates catalyst-independent effects like impurity adsorption on reactor walls.

- Feedstock Analysis: Use on-line or post-run GC/MS to check for contaminant species (e.g., sulfur, chlorine) in your feed gas/liquid that are not accounted for in your kinetic model.

- Initial Characterization: Compare N₂ physisorption (BET surface area) and CO chemisorption of fresh catalyst versus catalyst sampled immediately after the initial drop. A >20% loss in accessible surface area suggests pore blockage.

Q2: When integrating multiple Characterization Datasets (e.g., XRD, XPS, TEM), how do we align them temporally with the TOS profile correctly? A: Temporal misalignment is a common source of error in deactivation analysis. Implement this workflow:

Protocol: Temporal Alignment of Multi-Modal Characterization

- Design Quench Points: Plan experiments where the catalytic reaction is abruptly stopped (quenched) at pre-defined TOS intervals (e.g., 1h, 10h, 50h) using an inert gas purge and rapid cooling.

- Sample Handling: Use an in-situ cell or a strict inert-atmosphere glovebox for transferring quenched samples to characterization equipment to prevent air exposure artifacts.

- Synchronization Key: In your CatTestHub dataset, use the

sample_idfield to explicitly link each characterization file (XRD, etc.) to the exact TOS value and the corresponding segment of the kinetic profile. Never rely solely on timestamps.

Q3: How should we handle missing data points in a Kinetic Profile used for deactivation rate constant fitting? A: Do not interpolate blindly. The method depends on the cause:

| Cause of Missing Data | Recommended Action | Tool in CatTestHub |

|---|---|---|

| Analytical Sampling Gap (e.g., GC cycle) | Use linear interpolation ONLY if the TOS gap is <10% of the total experiment time and the surrounding data is stable. | Data View impute_missing with method="linear" and limit=3. |

| Reactor Instability (e.g., temperature spike) | Treat as an outlier. Remove the point and annotate the dataset with the reason. Do not interpolate. | Use the flag_data_point function with reason code. |

| Catalyst Regeneration Pulse | This is intentional. Segment the kinetic profile into "cycles" and analyze each deactivation period separately. | Use the segment_by_event metadata tag. |

Q4: The deactivation model fits well for the first dataset but fails when applied to a new catalyst's TOS data. What parameters should be re-examined? A: This indicates a change in the deactivation mechanism. Re-evaluate these characterization datasets in sequence:

Protocol for Mechanism Diagnosis

- Check Pore Architecture: Analyze N₂ physisorption isotherms for both catalysts. A shift from microporous to mesoporous structure changes coke deposition profiles.

- Profile Active Sites: Perform temperature-programmed desorption (TPD) or titration (e.g., CO-TPD, NH₃-TPD) to quantify and compare active site density (N₀) between the two catalysts. Update this initial condition in your model.

- Identify Deposits: Analyze spent catalysts with TGA-MS (burn-off) and Raman spectroscopy. Compare the H/C ratio and graphitic character of carbon deposits. A lower H/C ratio suggests a more resistant, graphitic coke that deactivates via a different rate law.

Diagram: Workflow for Diagnosing Deactivation Mechanism Change

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in Deactivation Analysis |

|---|---|

| Silicon Carbide (SiC) Diluent | An inert, thermally conductive material used to dilute catalyst beds, ensuring isothermal conditions and preventing hotspot-induced deactivation. |

| Internal Standard Gases (e.g., 1% Ar in He) | Inert tracer added to the reactant feed. Changes in its GC signal help diagnose flow instability or leaks, separating them from true catalytic deactivation. |

| Pulse Calibration Kit (e.g., 10 µL Loops, Certified Gas Mixtures) | For accurate calibration of on-line mass spectrometers or gas chromatographs, ensuring quantitative conversion data for kinetic profiles. |

| Quenching Gas (Ultra-high Purity He or N₂) | Used to instantly stop surface reactions at precise TOS points for ex-situ characterization, preserving the catalyst's "working" state. |

| Temperature Calibration Standards (e.g., In, Sn, Zn) | Certified melting point standards for verifying reactor thermocouple readings. Temperature errors are a primary source of kinetic data corruption. |

| On-line Gas Scrubbers/Filter Traps | Removes specific impurities (e.g., metal carbonyls from cylinders, oil from compressors) from feed gases to prevent poisoning and spurious initial deactivation. |

Diagram: Integration of CatTestHub Data for Deactivation Analysis

Linking Deactivation Modes to Observable Data Trends in CatTestHub Entries

Technical Support & Troubleshooting Center

Q1: During catalyst activity monitoring, my CatTestHub entries show a rapid, exponential loss of activity within the first few reaction cycles, followed by a plateau. What deactivation mode does this suggest, and what are the primary investigative steps?

A: This trend strongly suggests Active Site Poisoning or Strong Chemisorption. The rapid initial drop indicates a fast, irreversible binding of an impurity or byproduct to the most active sites. The plateau represents the residual activity of less-accessible or less-active sites.

- Troubleshooting Protocol:

- Analyze Feedstock: Use ICP-MS or XPS to check for known catalyst poisons (e.g., S, Pb, Hg, As) in your reaction mixture.

- Post-Reaction Characterization: Perform TEM on spent catalyst to check for surface layers. Use TPD/TPO to identify strongly adsorbed species.

- Control Experiment: Run a duplicate experiment with an ultra-purified feedstock. If the initial drop disappears, poisoning is confirmed.

Q2: My data shows a linear decline in turnover frequency (TOF) over time. What does this typically indicate, and how can I verify it?

A: A linear deactivation trend is often characteristic of Fouling or Coking through a sequential mechanism, or Abrasion/Attrition in continuous flow systems.

- Troubleshooting Protocol:

- Thermogravimetric Analysis (TGA): Measure weight loss of the spent catalyst under air (combustion of coke) vs. inert atmosphere (thermal decomposition).

- Surface Area/Porosity (BET): Compare fresh and spent catalyst. A significant reduction in surface area/pore volume indicates pore blockage.

- Visual Inspection (SEM/TEM): Look for carbonaceous deposits or physical changes in catalyst particle morphology.

Q3: I observe a gradual, asymptotic deactivation curve in my CatTestHub entry. What are the likely mechanisms?

A: This is a classic signature of Sintering or Ostwald Ripening, where active particles agglomerate or grow, reducing the total active surface area over time.

- Verification Protocol:

- Transmission Electron Microscopy (TEM): The gold standard. Statistically compare metal nanoparticle size distributions between fresh and spent catalysts.

- Chemisorption: Measure the active metal surface area (e.g., H₂ or CO chemisorption). A decrease correlates with particle growth.

Q4: My catalyst's selectivity shifts before significant activity loss is recorded. How should I interpret this in my CatTestHub data entry?

A: A selectivity shift prior to major activity loss often points to Site-Blocking or Pore-Mouth Poisoning. This modifies the accessible reaction pathways or restricts diffusion of reactants/products.

- Investigation Protocol:

- Test with Probe Molecules: Use reactions sensitive to pore size or acid site strength (e.g., isomerization of branched alkanes) to diagnose changes in the active site environment.

- X-ray Photoelectron Spectroscopy (XPS): Analyze the surface composition for contaminants or changes in oxidation states at shallow depths.

- Temperature-Programmed Desorption (TPD): Use ammonia or pyridine TPD to profile changes in acid site strength and distribution.

Frequently Asked Questions (FAQs)

Q: What are the key metadata fields in CatTestHub that are most critical for diagnosing deactivation mode from trend data? A: Crucial fields include: Catalyst Formulation (exact precursor, support, loading), Reaction Type & Conditions (T, P, feed composition, space velocity), Time-on-Stream (TOS) data points, and the linked Characterization Data ID for the spent catalyst. Inconsistent metadata is a primary source of ambiguous trend interpretation.

Q: How do I distinguish thermal sintering from chemically-induced sintering in my data? A: Correlate your activity timeline with temperature excursions or the presence of specific chemical agents (e.g., H₂O, chlorides). Chemically-induced sintering often occurs at lower nominal temperatures. Controlled experiments with and without the suspected agent under identical thermal profiles are essential.

Q: What is the standard protocol for post-mortem (spent catalyst) analysis to validate a deactivation hypothesis? A: A tiered protocol is recommended:

- Non-destructive analysis first: BET (surface area), PXRD (crystallinity, phase changes).

- Microscopy & Spectroscopy: SEM/TEM (morphology, particle size), XPS (surface composition).

- Thermal & Desorption Techniques: TGA (coke burn-off), TPR/TPO (reducibility, coke reactivity).

- Bulk Analysis: ICP-OES/MS (leaching, elemental composition).

Data Presentation: Common Deactivation Trends

Table 1: Correlation Between Observable Data Trends and Deactivation Modes

| Deactivation Trend (Activity vs. Time) | Probable Primary Mode | Key Diagnostic Experiments | Typical CatTestHub Keywords |

|---|---|---|---|

| Rapid exponential decay to plateau | Active Site Poisoning | Feedstock impurity analysis, TPD of poison | poisoning, irreversible adsorption, impurity |

| Linear decline | Fouling/Coking (Sequential) or Attrition | TGA (combustion), BET, SEM | coking, fouling, pore_blockage, attrition |

| Gradual asymptotic decay | Sintering / Ostwald Ripening | TEM particle size, Chemisorption | sintering, ripening, agglomeration |

| Selectivity change before activity loss | Pore-Mouth Poisoning / Site Blocking | Probe reactions, XPS, TPD | selectivity_shift, diffusion_limit, site_blocking |

| Sudden, complete activity loss | Catastrophic Failure (e.g., Support Collapse, Leaching) | PXRD, ICP-MS, Mechanical strength test | leaching, collapse, mechanical_failure |

Experimental Protocols

Protocol P1: Thermogravimetric Analysis (TGA) for Coke Quantification

- Sample Prep: Load 10-20 mg of spent catalyst into a clean, pre-tared alumina crucible.

- Inert Phase: Heat from room temperature to 150°C at 10°C/min under N₂ (50 mL/min). Hold for 20 min to remove physisorbed water/volatiles.

- Combustion Phase: Switch gas to synthetic air (50 mL/min). Heat to 800°C at 10°C/min. Hold for 10 min.

- Data Analysis: The weight loss in the combustion phase (after accounting for any catalyst oxidation) is attributed to combustible deposits (coke). Report as % weight loss relative to dried sample mass.

Protocol P2: Transmission Electron Microscopy (TEM) for Particle Size Distribution

- Dispersion: Ultrasonicate 1-2 mg of catalyst powder in 1 mL ethanol for 5 min.

- Grid Preparation: Deposit a drop of the suspension onto a lacey carbon-coated copper grid. Allow to dry.

- Imaging: Acquire high-resolution TEM images at multiple, random locations across the grid at a magnification of 400,000x or higher.

- Analysis: Measure the diameter of ≥200 distinct nanoparticles using image analysis software (e.g., ImageJ). Calculate and report the number- and volume-weighted mean diameters (dₙ, dᵥ).

Visualizations

Diagram 1: Catalyst Deactivation Decision Tree

Diagram 2: Tiered Spent Catalyst Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalyst Deactivation Studies

| Item / Reagent | Primary Function in Deactivation Analysis |

|---|---|

| Ultra-High Purity Feedstock Gases/Liquids | Minimizes confounding deactivation from unknown impurities during poisoning studies. |

| Certified Reference Materials (CRMs) for ICP-MS | Quantifies trace metal poisoning (e.g., S, Pb) or active metal leaching from the catalyst. |

| Lacey Carbon TEM Grids | Provides optimal support for nanoparticle dispersion imaging for sintering analysis. |

| Thermogravimetric Analysis (TGA) Calibration Standards | Ensures accurate mass/ temperature measurements for quantifying coke deposits. |

| Probe Molecules (e.g., 2,6-Di-tert-butylpyridine, Nitrobenzene) | Selectively titrates specific site types (e.g., acid sites) to diagnose site-blocking. |

| In-situ Cell Accessories (e.g., for XRD, IR) | Enables real-time observation of structural/surface changes during deactivation. |

Practical Guide: Applying CatTestHub Data for Deactivation Modeling and Prediction

This technical support center provides guidance for researchers conducting catalyst deactivation analysis within the CatTestHub ecosystem. It is framed within a broader thesis context that leverages CatTestHub's structured data to derive kinetic models of catalyst decay and identify deactivation mechanisms (e.g., poisoning, coking, sintering) relevant to pharmaceutical process development.

Troubleshooting Guides and FAQs

Q1: I have successfully authenticated to the CatTestHub API, but my query for "sintering" in catalyst material "Pd/Al2O3" returns an empty dataset. What are the likely causes?

A1: An empty result set typically stems from incorrect field name usage or filter logic. The CatTestHub schema uses specific controlled vocabularies.

- Troubleshooting Steps:

- Verify Field Names: Use the

/schemaendpoint. The correct field for deactivation mechanism isDeactivationPrimaryMechanism, not informal terms like "sintering." - Check Vocabularies: Query the

Vocabularyendpoint forDeactivationPrimaryMechanism. The valid term may be"Thermal Sintering". - Refine Query: Use the AND operator correctly. A valid query structure is:

https://api.cattesthub.org/v1/experiments?filter={"material": "Pd/Al2O3", "DeactivationPrimaryMechanism": "Thermal Sintering"}

- Verify Field Names: Use the

Q2: When I export time-on-stream (TOS) activity data for a batch of experiments, the timestamps are in an unfamiliar format. How do I convert them for analysis in my software (e.g., Python, R)?

A2: CatTestHub serializes timestamps in ISO 8601 format with UTC timezone (e.g., 2023-11-15T14:30:00Z). This is a feature ensuring consistency, not an error.

- Protocol for Conversion:

- In Python (Pandas): Use

pd.to_datetime(df['timestamp_column']).dt.tz_convert('Your/Timezone'). - In R: Use

as.POSIXct(df$timestamp_column, format="%Y-%m-%dT%H:%M:%SZ", tz="UTC")thenformat(..., tz="Your_Timezone"). - Best Practice: Perform initial analysis in UTC to avoid timezone-induced artifacts in deactivation rate calculations.

- In Python (Pandas): Use

Q3: My collaborative team needs to work on a unified set of deactivation data, but we are getting inconsistent query results. How can we ensure reproducibility?

A3: This indicates queries are not pinned to a specific, immutable version of the database.

- Solution & Protocol:

- Identify Dataset Version: Navigate to the "Dataset Releases" pane in the CatTestHub web portal. Note the version tag (e.g.,

v2.3.1) for the snapshot you intend to use. - Append Version to API Calls: Use the versioned API endpoint:

https://api.cattesthub.org/v1/v2.3.1/experiments. - Document in Methods: Record this dataset version in your thesis methodology section to ensure full reproducibility.

- Identify Dataset Version: Navigate to the "Dataset Releases" pane in the CatTestHub web portal. Note the version tag (e.g.,

Table 1: Common Catalyst Deactivation Mechanisms & Representative Data in CatTestHub

| Deactivation Mechanism | Frequency in CatTestHub (%) | Typical Time-On-Stream Scale | Key Diagnostic Metrics in Hub |

|---|---|---|---|

| Coke Deposition (Carbonaceous) | 42% | Hours to Days | %C on Spent Cat., Pore Vol. Change |

| Poisoning (Strong Chemisorption) | 28% | Minutes to Hours | Feed Impurity ppm, Active Site Drop |

| Thermal Sintering | 18% | Days to Months | Crystallite Size Increase, BET SA Loss |

| Mechanical Attrition | 7% | Variable | Particle Size Distribution Shift |

| Solid-State Transformation | 5% | Months | XRD Phase Identification |

Table 2: Example API Query Performance Metrics

| Query Complexity | Avg. Response Time (ms) | Data Limit per Request | Pagination Key Required |

|---|---|---|---|

| Simple Filter (e.g., by Catalyst ID) | 120 | 10,000 records | No |

| Complex Filter (3+ fields, range) | 450 | 10,000 records | No |

| Full Export (Bulk Data Job) | N/A (async) | Unlimited | Yes |

Experimental Protocols

Protocol: Querying CatTestHub for a Deactivation Kinetics Analysis

This protocol details how to extract data for modeling catalyst activity decay (a = exp(-k_d * t)).

- Authentication: Obtain an OAuth2.0 token from

https://api.cattesthub.org/oauth/token. Use client credentials grant type. - Construct Query: Identify relevant Experiment IDs using a filtered search on the

/experimentsendpoint. Filters should include:ReactionType,TemperatureRange, andDeactivationPrimaryMechanism. - Fetch Time-Series Data: For each Experiment ID, call the

/timeseriesendpoint with?metric=conversion&metric=selectivity&metric=temperature. - Data Alignment: Use the provided

absolute_time_secondsfield to align all time-series data from start-of-run (t=0). Normalize conversion to initial activity (a_t = X_t / X_0). - Export for Analysis: Compile normalized activity (

a) vs. time (t) data into a CSV. The model fitting (e.g., linear regression onln(a) vs t) is performed externally.

The Scientist's Toolkit

Table 3: Research Reagent & Computational Solutions for Deactivation Analysis

| Item/Resource | Function in Deactivation Analysis | Example/Source |

|---|---|---|

| CatTestHub Python SDK | Programmatic access to query and manage experiment data. | Official GitHub repository (CatTestHub/cth-sdk-py). |

| Thermogravimetric Analysis (TGA) | Quantifies coke burn-off mass % for coking mechanism studies. | Standard ASTM/ISO methods. |

| CO Chemisorption Pulse Data | Estimates active metal surface area loss (sintering/poisoning). | Often linked in CatTestHub dataset characterization links. |

| Reference Catalyst Benchmarks | Control materials to distinguish process vs. intrinsic deactivation. | e.g., NIST Standard Catalyst Materials. |

| Jupyter Notebook Template | Pre-built environment for data extraction, normalization, and decay constant (k_d) fitting. |

Provided in CatTestHub community portal. |

Visualizations

CatTestHub Data Query Workflow

Catalyst Deactivation Data Analysis Pathway

Troubleshooting Guides & FAQs

Q1: During the cleaning of CatTestHub catalyst activity time-series, I encounter sporadic, extreme negative values. What are these, and how should I handle them?

A1: These are likely instrument errors or data logging artifacts, not true negative reaction rates. For catalyst deactivation analysis, replace these points using a rolling median filter (window size=5) or mark them as NaN if they constitute less than 1% of the dataset. Do not interpolate across large gaps caused by their removal.

Q2: My time-series data from different reactor runs have vastly different scales (e.g., 0-100 vs. 0-1). Which normalization method is most appropriate for comparing deactivation profiles? A2: Use Min-Max Scaling per Experiment to bound all data between 0 (initial activity) and 1 (complete deactivation). This preserves the deactivation trajectory shape. Z-score standardization is discouraged as it centers data around zero, making the physical interpretation of "activity loss" difficult.

Q3: How do I align time-series data when the sampling intervals are irregular (e.g., 5-min and 10-min intervals) across different CatTestHub experiments? A3: Implement time-base alignment using linear interpolation to a common time vector. For catalyst life testing, align to the longest common time base (e.g., "Time on Stream" in hours). Critical: Interpolate only between existing data points; do not extrapolate beyond the end of a shorter run.

Q4: What is the best practice for handling missing data points in the middle of a long-term deactivation run? A4: The protocol depends on the gap size relative to the deactivation timescale. For gaps <5% of total run time, linear interpolation is acceptable. For larger gaps, segment the analysis and treat it as separate phases. Always document the location and size of all gaps for reproducibility.

Q5: When aligning data from multiple catalysts, should I align by "Time on Stream" or "Total Feed Processed"? A5: For fouling or poisoning-based deactivation, align by Total Feed Processed (e.g., moles of reactant). This normalizes for flow rate variations. For thermal sintering, align by Time on Stream. The choice must be consistent with your hypothesized deactivation mechanism.

Key Experimental Protocols

Protocol 1: Outlier Detection & Cleaning for Catalytic Activity Data

- Calculate Rolling Statistics: For a given activity time-series, compute the rolling median (window=7 data points) and rolling Median Absolute Deviation (MAD).

- Identify Outliers: Flag any point where |value - rolling median| > (3 * rolling MAD).

- Review & Replace: Manually confirm flagged points against lab notes. Replace confirmed artifacts with the rolling median value.

- Document: Maintain a log of all replaced values and the rationale.

Protocol 2: Min-Max Normalization for Deactivation Curves

- Define Baseline: Identify the initial steady-state activity (A₀). Typically, the average of the first 10-20 data points.

- Define Floor: Identify the final, stable activity (A_f) or set it to 0 for complete deactivation.

- Normalize: Apply the formula: Normalized Activity(t) = (Raw Activity(t) - A_f) / (A₀ - A_f).

- Validate: All normalized curves should start at ~1 and decay toward 0.

Protocol 3: Dynamic Time Warping (DTW) for Aligning Variable-Rate Deactivation

- Select Reference Curve: Choose the most canonical deactivation run as the reference time-series.

- Compute DTW Path: Use a DTW algorithm (e.g.,

fastdtwPython library) to find the optimal alignment path between the reference and a target curve. - Warp Target Time Axis: Adjust the time axis of the target curve according to the DTW path.

- Apply to Activity Data: Interpolate the target activity data onto the warped time axis. Purpose: Aligns deactivation features (e.g., inflection points) that occur at different chronological times but similar process stages.

Table 1: Common Data Issues in CatTestHub Time-Series & Recommended Solutions

| Issue | Symptom | Recommended Cleaning Method | Impact on Deactivation Analysis |

|---|---|---|---|

| Spike Noise | Sudden, single-point deviation >10σ. | Median Filtering (window=5). | Prevents false identification of activity regeneration. |

| Drift in Baseline | Gradual baseline shift in control signal. | Background Subtraction using control channel. | Ensures deactivation rate is not over/under-estimated. |

| Missing Data Gaps | Consecutive NaN values for >1hr. |

Segment Analysis; do not interpolate. | Avoids creating artificial deactivation profiles. |

| Sampling Jitter | Irregular time intervals between points. | Resample to common time vector (linear interpolation). | Enables direct point-by-point comparison across runs. |

Table 2: Normalization Methods Comparison for Catalyst Data

| Method | Formula | Best For | Caution for Catalyst Data | ||||

|---|---|---|---|---|---|---|---|

| Min-Max | (x - min(x))/(max(x) - min(x)) | Comparing deactivation curve shapes. | Sensitive to outliers; define min/max robustly. | ||||

| Z-Score | (x - μ) / σ | Analyzing variance across many catalysts. | Deactivation trajectory centered on zero loses intuitive meaning. | ||||

| Unit Vector | x / | x | Focusing on direction of change in multi-variate data. | Scales all curves to same length; distorts time magnitude. | |||

| Initial Point | x / x(t=0) | Standardizing relative activity loss. | Amplifies noise in the very first measurement. |

Visualizations

Title: Time-Series Preprocessing Workflow for Catalyst Data

Title: Time-Series Data Alignment Method Comparison

The Scientist's Toolkit: Research Reagent & Solution Essentials

| Item/Reagent | Function in Preprocessing Context | Specification/Note for CatTestHub Data |

|---|---|---|

| Python Pandas Library | Primary data structure (DataFrame) for holding and manipulating time-series data. | Use pandas.DataFrame.rolling() for median filtering and interpolation. |

| NumPy Library | Provides mathematical functions for normalization (e.g., np.linalg.norm for unit vector). |

Essential for robust linear algebra operations on large datasets. |

| SciPy Interpolate Module | Contains functions for 1D linear (interp1d) and polynomial interpolation during alignment. |

Critical for resampling data to a common time vector. |

| FastDTW Python Package | Efficient implementation of Dynamic Time Warping for aligning sequences with variable speed. | Use to align deactivation curves based on shape rather than strict chronological time. |

| Robust Scaler (sklearn) | Advanced normalization technique that uses median and IQR, reducing outlier influence. | Consider as an alternative to Min-Max if datasets have significant, real outliers. |

| Jupyter Notebook | Interactive environment for documenting the preprocessing pipeline, including visualizations. | Essential for reproducibility and sharing methods with research team. |

| Version Control (Git) | Tracks changes to preprocessing scripts and parameter choices over time. | Prevents loss of method details and allows backtracking if needed. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: When fitting my catalyst deactivation data from CatTestHub, how do I decide between a zero-order and a first-order kinetic model? A: The choice is primarily determined by the mechanism. Plot your activity (a) vs. time (t). If the deactivation rate is constant (a linear decrease in activity), a zero-order model is appropriate. If a plot of ln(a) vs. time yields a straight line, the deactivation follows first-order kinetics. Use residual analysis to validate the chosen model; the model with randomly scattered residuals and the lowest sum of squared errors is preferable.

Q2: My deactivation data shows an initial rapid drop followed by a much slower decline. None of the simple models fit well. What should I do? A: This is a common issue in CatTestHub datasets, often indicating a multi-step deactivation mechanism. Consider these steps: 1) Check for mass transfer limitations in your experimental setup. 2) Employ a power-law model (da/dt = -k_d * a^n), where the exponent 'n' can capture non-linear behavior. 3) Explore a series mechanism model (e.g., two consecutive first-order deactivations). Fitting to these more complex models requires non-linear regression software.

Q3: What is the critical step often missed when applying the power-law deactivation model? A: Researchers often fix the exponent 'n' at 1 (reducing it to first-order) without justification. The crucial step is to treat both the deactivation rate constant (k_d) and the exponent 'n' as adjustable parameters during non-linear regression. Furthermore, the confidence intervals for 'n' must be examined; if they encompass 1 or 2, it may simplify your model.

Q4: How do I extract reliable kinetic parameters (kd) from noisy experimental data? A: Implement the following protocol: 1) Data Smoothing: Apply a Savitzky-Golay filter to reduce high-frequency noise without distorting the trend. 2) Initial Parameter Estimation: Use linearized forms for zero/first-order to get initial guesses for kd. For power-law, perform a grid search for 'n'. 3) Robust Fitting: Use an iterative non-linear least squares algorithm (e.g., Levenberg-Marquardt) with the smoothed data and initial guesses. 4) Uncertainty Quantification: Perform a bootstrap analysis on the raw data to determine confidence intervals for your fitted parameters.

Q5: In the context of catalyst deactivation for drug development (e.g., enzymatic catalysis), how are these models applied differently? A: For biocatalysts, deactivation is often a function of operational variables like pH and temperature. The modified power-law model is frequently used: da/dt = -kd0 * exp(-Ea/RT) * a^n * [H+]^m. Here, the kinetic parameter (kd) is replaced with an Arrhenius-type expression and a pH term. The experimental protocol requires collecting deactivation time-series data at multiple temperatures and pH levels to fit the extended parameters (Ea, n, m).

Quantitative Model Comparison Table

Table 1: Summary of Common Deactivation Kinetic Models

| Model | Differential Form | Integrated Form | Key Application (Typical CatTestHub Context) | Linear Plot for Verification |

|---|---|---|---|---|

| Zero-Order | da/dt = -k_d | a = a0 - kd * t | Sintering or pore blockage where loss of active sites is constant. | a vs. t → Straight line (slope = -k_d). |

| First-Order | da/dt = -k_d * a | a = a0 * exp(-kd * t) | Single-site poisoning or simple site coverage. | ln(a) vs. t → Straight line (slope = -k_d). |

| Power-Law | da/dt = -k_d * a^n | a^(1-n) = a0^(1-n) - (1-n)*kd*t (for n≠1) | Complex mechanisms, often coke formation or multi-step poisoning. | ln(-da/dt) vs. ln(a) → Straight line (slope = n, intercept = ln(k_d)). |

| Series Mechanism | da1/dt = -kd1 * a1; da2/dt = kd1*a1 - kd2*a2 | Complex, solved numerically. | Catalyst undergoing transformation to a second, less active form. | Requires numerical fitting of a(t) profile. |

Detailed Experimental Protocol: Determining Deactivation Order

Title: Protocol for Kinetic Model Discrimination from CatTestHub Time-on-Stream Data.

Objective: To collect and analyze catalyst activity decay data to determine the appropriate deactivation kinetic model (zero, first, or power-law).

Materials: See "Scientist's Toolkit" below.

Method:

- Activity Monitoring: Using a standardized test reaction (e.g., probe molecule conversion in a fixed-bed microreactor), measure catalyst conversion (X) over continuous time-on-stream (t). Maintain constant T, P, and flow rate.

- Data Processing: Convert conversion (X) to catalyst activity (a), defined as a = (r / r0) ≈ (X / X0) at constant conditions, where subscript '0' denotes initial activity.

- Initial Rate of Deactivation: For discrete time data, calculate -Δa/Δt for each interval. Use a central difference method for interior points.

- Graphical Analysis:

- Plot a vs. t. A linear trend suggests zero-order deactivation.

- Plot ln(a) vs. t. A linear trend suggests first-order deactivation.

- Plot ln(-da/dt) vs. ln(a). A linear trend confirms a power-law model. The slope is the order 'n', and the intercept is ln(k_d).

- Non-Linear Regression: Input the (t, a) data into software (e.g., Python SciPy, Origin, MATLAB). Fit the data to the integrated forms of the models. Compare R², adjusted R², and Akaike Information Criterion (AIC) for model selection.

- Validation: Use a separate dataset (e.g., from a different run of the same catalyst) to validate the selected model and fitted parameters.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Deactivation Kinetic Studies

| Item | Function & Relevance |

|---|---|

| Bench-scale Fixed-Bed Microreactor System | Provides precise control over reaction conditions (T, P, flow) for collecting time-on-stream deactivation data. |

| Online GC/MS or FTIR Analyzer | For real-time, quantitative monitoring of reactant and product concentrations to calculate instantaneous catalyst activity. |

| Thermogravimetric Analyzer (TGA) | Used post-reaction to quantify coke deposition (a common deactivation cause) by measuring weight loss during combustion. |

| Non-Linear Regression Software (e.g., Python, MATLAB, Origin) | Essential for fitting data to power-law and series models, and for estimating parameters with confidence intervals. |

| Standardized Catalyst Test Feedstock (e.g., CERTIAP from CatTestHub) | Ensures data comparability across experiments and against benchmark datasets by using a uniform, well-characterized reactant mixture. |

| Savitzky-Golay Filter Algorithm | A digital smoothing tool to denoise activity-time data before parameter estimation, preventing fitting to artifacts. |

Model Selection & Workflow Diagram

Title: Workflow for Selecting a Deactivation Kinetic Model

Power-Law Parameter Estimation Diagram

Title: Parameter Estimation for Power-Law Model

Technical Support Center

Troubleshooting Guides & FAQs

Q1: During data preprocessing from CatTestHub, I encounter missing values for key features like "turnover frequency (TOF)" and "metal dispersion." How should I handle this to avoid biasing my model? A: This is a common issue. Do not use simple column mean imputation, as it can distort catalyst-specific trends. Follow this protocol:

- Identify Missingness Pattern: Use the

Missingnessheatmap function from thedataexplorerpackage. If missingness is <5% and random (MCAR), proceed to step 3. - For Non-Random Patterns: If missing values correlate with high-temperature experimental runs, segregate data by experimental batch (

batch_idfrom CatTestHub metadata). Impute within batches. - Recommended Imputation Method: Use Multivariate Imputation by Chained Equations (MICE) with a predictive mean matching (PMM) model, iterating 10 times. For catalytic data, constrain imputed

TOFanddispersionvalues to be within the physically plausible ranges defined in the CatTestHub data dictionary.

Q2: My gradient boosting model (XGBoost) for predicting time-to-50%-deactivation shows high performance on training/validation splits but fails drastically on a new catalyst family. What's the likely cause and solution? A: This indicates model overfitting and poor generalization, likely due to feature or target leakage from the non-IID (Independent and Identically Distributed) nature of catalyst data.

- Root Cause: The model may be learning spurious correlations from features like

precursor_salt_batchorcalcination_furnace_id, which are irrelevant to fundamental deactivation physics. - Solution Protocol:

- Employ GroupKFold Cross-Validation: Split data by

catalyst_familyorsupport_type(groups in CatTestHub), not randomly. This prevents data from the same family appearing in both train and test sets. - Feature Selection: Apply SHAP (SHapley Additive exPlanations) analysis on your trained model. Remove features with low global SHAP values.

- Re-train with Regularization: Increase the

reg_lambdaandreg_alphaparameters in XGBoost and re-train using the GroupKFold splits.

- Employ GroupKFold Cross-Validation: Split data by

Q3: How do I effectively encode categorical features like "dopantelement" or "supportmorphology" from CatTestHub for neural network models? A: Simple one-hot encoding can lead to high dimensionality. Use the following strategy based on feature cardinality:

| Feature | Cardinality | Recommended Encoding | Rationale |

|---|---|---|---|

| dopant_element | Low (<10) | One-Hot Encoding | Preserves element independence without ordinal bias. |

| support_morphology | Medium (10-50) | Target Encoding (with regularization) | Captures complex relationships between morphology and deactivation rate. |

| preparation_lab | High (>50) | Embedding Layer (in NN) | Learns a dense, lower-dimensional representation during training. |

Experimental Protocol for Target Encoding:

- Compute the mean

deactivation_rate_constantfor each category in thesupport_morphologyfeature using the training set only. - Apply smoothing:

encoded_value = (n * category_mean + global_mean * alpha) / (n + alpha), wherenis category count andalphais a smoothing factor (start withalpha=5). - Merge this encoded value into the dataset for the training and (transformed) validation/test sets.

Q4: The predictive uncertainty of my Bayesian Neural Network (BNN) is excessively high for all predictions. How can I calibrate it? A: High epistemic uncertainty often points to insufficient or unrepresentative training data.

- Diagnosis: Use the

CatTestHub Data Coveragetool (see diagram below) to compare the feature space of your training set versus the new catalysts you are predicting for. - Protocol for Active Learning: a. Train initial BNN on your available CatTestHub data. b. For new catalyst compositions, predict and select the top 10 with the highest predictive variance (uncertainty). c. Synthesize and test these 10 catalysts in the lab (this is the crucial feedback loop of the thesis). d. Add the new experimental results to your training set. e. Re-train the BNN. Iterate until predictive uncertainty for your region of interest falls below an acceptable threshold.

Table 1: Performance Comparison of ML Models on CatTestHub v2.1 Hold-Out Set

| Model | MAE (Hours) | R² | Feature Importance Method | Notes |

|---|---|---|---|---|

| XGBoost (GroupKFold) | 12.4 | 0.89 | SHAP | Best for tabular data, robust. |

| Graph Neural Network | 14.7 | 0.85 | Gradient-based | Captures catalyst structure well. |

| Random Forest | 15.1 | 0.83 | Gini Impurity | Good baseline, less prone to overfit. |

| Bayesian NN | 16.8 | 0.80 | Predictive Variance | Provides uncertainty quantification. |

Table 2: Critical Deactivation Features Identified by SHAP Analysis

| Feature | Mean | SHAP Value | Impact on Deactivation Time |

|---|---|---|---|

| Initial Metal Dispersion (%) | 45.2 | +3.2 | Higher dispersion increases lifetime. |

| Avg. Pore Diameter (nm) | 8.5 | +2.1 | Optimal mid-range pores are beneficial. |

| Acid Site Density (mmol/g) | 0.32 | -1.8 | Higher density reduces lifetime. |

| Calcination Ramp Rate (°C/min) | 5.0 | -1.5 | Faster ramp reduces lifetime. |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Experiment |

|---|---|

| CatTestHub Data Suite (v2.1+) | Curated benchmark dataset for catalyst deactivation, containing structural, operational, and lifetime data. Essential for training and validation. |

| SHAP (SHapley Additive exPlanations) Library | Explains output of any ML model, identifying which features (e.g., pore size, dopant) drive predictions of deactivation. |

| scikit-learn & XGBoost | Core libraries for implementing robust regression models (Random Forest, XGBoost) and preprocessing pipelines (GroupKFold, MICE imputer). |

| PyTorch/TensorFlow Probability | Frameworks for building advanced models like Graph Neural Networks and Bayesian Neural Networks for uncertainty-aware predictions. |

| Catalyst Characterization Kit | Includes facilities for N₂ physisorption (surface area/pore size), TEM (dispersion), and NH₃/CO chemisorption (acid/metal site count) to generate new input features. |

Visualizations

Diagram 1: ML Model Development & Validation Workflow

Diagram 2: CatTestHub Data Coverage Analysis for Uncertainty

Technical Support Center

Troubleshooting Guides & FAQs

Q1: After integrating CatTestHub data into our reactor model, the predicted catalyst lifespan is significantly shorter than observed in our lab-scale batch runs. What could be the cause?

A: This discrepancy often stems from a mismatch in deactivation mechanism weightings. Lab-scale batch reactors may not fully capture continuous process poisons. Follow this protocol:

- Isolate Variables: Re-run the CatTestHub "Deactivation Kinetics" module, focusing solely on thermal sintering data (Module D-K.3).

- Benchmark: Perform a controlled 72-hour thermal stress test on your catalyst sample at the reported process temperature in an inert atmosphere.

- Compare Metrics: Measure BET surface area loss and compare the rate to the CatTestHub dataset for your catalyst class (see Table 1).

- Recalibrate: If the thermal deactivation rate aligns with CatTestHub but your full process model does not, the issue likely lies with feedstock impurity profiles. Proceed to Q2.

Q2: CatTestHub flags a high risk of chemisorption-based site blocking for our chosen catalyst, but our raw material spec shows impurity levels below standard thresholds. How should we investigate?

A: Trace impurities can have disproportionate effects. Implement a feedstock spike-and-trap experiment.

- Protocol - Spike Experiment:

- Prepare three identical catalyst beds.

- Spike the standard feedstock for Bed A with 50 ppb of the suspected poison (e.g., sulfur species from CatTestHub Alert CDA-7). Use Bed B with standard feedstock as control.

- Pass feedstock through a guard bed of acidic alumina for Bed C to remove polar impurities.

- Run each for 24 hours under standard process conditions.

- Measure API intermediate yield every 2 hours.

- Analysis: A steep decline in Bed A versus B confirms sensitivity. Sustained yield in Bed C confirms the impurity hypothesis. Update your material specifications accordingly.

Q3: The recommended regeneration protocol from CatTestHub for our catalyst class leads to a permanent 15% loss in activity in our system. Why might this occur?

A: Regeneration protocols are system-dependent. The CatTestHub protocol may not account for specific metal redistribution or support interaction in your bimetallic system.

- Diagnostic Protocol:

- Perform Temperature-Programmed Oxidation (TPO) on a spent catalyst sample to identify your specific coke burn-off profile.

- Compare the TPO peak temperature and shape to the CatTestHub reference (TGA-DTG.4).

- Conduct post-regeneration XPS analysis focusing on the oxidation state of the active metal.

- Solution: Tailor the regeneration temperature ramp rate and hold time based on your TPO data, typically starting 20°C below the main exotherm peak to prevent sintering.

Data Presentation

Table 1: Catalyst Deactivation Rate Constants (k_d) from CatTestHub vs. Bench-Scale Validation

| Deactivation Mechanism | CatTestHub Avg. k_d (h⁻¹) | Bench-Scale Observed k_d (h⁻¹) | Recommended Mitigation Action |

|---|---|---|---|

| Thermal Sintering (Pd/Al₂O₃) | 0.0087 | 0.0091 | Optimize reactor temp. profile; use thermal stabilizers. |

| Chemisorption Poisoning (S species) | 0.152 | 0.148 | Implement <5 ppb S guard bed; source alternative feedstock. |

| Coke Deposition (Aromatic API) | 0.023 | 0.030 | Increase H₂ partial pressure by 15%; consider steam pulses. |

| Mechanical Attrition (Slurry Reactor) | 0.005 | 0.012 | Re-evaluate agitator design; assess catalyst particle size distribution. |

Table 2: Key Performance Indicators (KPIs) Pre- and Post-CatTestHub Optimization

| KPI | Initial Process | After Impurity Control | After Regimen Optimization | Target (Thesis Goal) |

|---|---|---|---|---|

| Catalyst Lifespan (days) | 42 | 67 | 89 | >90 |

| Mean Time Between Regeneration (h) | 120 | 192 | 240 | 220 |

| Overall Yield (%) | 88.5 | 91.2 | 93.7 | 94.0 |

| Cost of Catalyst per kg API ($) | 125.00 | 78.50 | 58.20 | ≤60.00 |

Experimental Protocols

Protocol: Guard Bed Efficacy Testing for Impurity Removal Objective: To validate the selection of a guard bed material for extending primary catalyst life. Materials: See "The Scientist's Toolkit" below. Method:

- Pack two identical 10 cm³ stainless steel columns with the candidate guard bed material (e.g., ZnO for S capture).

- Condition one column (Test) with process feedstock spiked with 100 ppb of the target impurity (e.g., thiophene). Condition the other (Control) with pure feedstock.

- Connect the column outlet directly to a micro-reactor containing 0.5g of the primary catalyst.

- Run the process continuously at standard conditions, monitoring the primary reactor outlet yield via online HPLC.

- The experiment endpoint is reached when the yield from the "Test" micro-reactor decays to match the "Control" micro-reactor yield, indicating guard bed breakthrough.

- Calculate the total impurity mass captured by the guard bed per unit volume.

Protocol: In-situ Catalyst Activity Monitoring via Reaction Calorimetry Objective: To obtain real-time deactivation rate constants for model validation. Method:

- Calibrate the reaction calorimeter (e.g., RC1e) with the hydrogenation reaction using fresh catalyst to establish the baseline heat flow profile.

- Charge the reactor with a known mass of catalyst and standard process reagents.

- Initiate the reaction. Record heat flow, temperature, and pressure data continuously.

- Use the progressive decline in the observed heat flow rate (ΔQ/Δt) at a fixed conversion point as a direct proxy for catalyst activity.

- Fit the activity-over-time data to common deactivation models (e.g., separable, non-separable kinetics) using software like Athena Visual Studio to extract k_d.

- Correlate the calorimetric k_d with periodic grab-sample analytical results to confirm accuracy.

Mandatory Visualizations

Diagram Title: CatTestHub Discrepancy Resolution Workflow

Diagram Title: Heterogeneous Catalyst Deactivation Pathways

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Catalyst Deactivation Studies

| Item | Function & Relevance | Example Vendor/Product |

|---|---|---|

| Model Poison Spikes | Precisely introduce trace amounts of known poisons (e.g., thiophene, quinoline) to study chemisorption kinetics and validate guard beds. | Sigma-Aldrich, AccuStandard certified reference materials. |

| Guard Bed Media | Remove specific impurities upstream of the primary catalyst. Selection is poison-dependent (e.g., ZnO for S, acidic alumina for amines). | Alfa Aesar (ZnO), BASF (selexsorb). |

| Thermal Stability Standards | Certified materials with known surface area loss profiles for calibrating sintering models in TGA/DSC. | NIST Standard Reference Materials. |

| Calorimetry Calibration Reactants | For calibrating reaction calorimeters (RC1) to ensure accurate heat flow measurement for activity monitoring. | Mettler-Toledo Calibration Kits. |

| Pulse Chemisorption Gases | High-purity gases (CO, H₂, O₂) for titrating active sites before/after deactivation to quantify site loss. | Linde, 99.999% purity with specific moisture specs. |

| Regeneration Gas Mixtures | Controlled O₂ in N₂ for coke burn-off studies, or forming gas (H₂/N₂) for metal oxide reduction. | Custom mixes from Airgas or Praxair. |

Diagnosing & Mitigating Deactivation: Strategies Derived from CatTestHub Analytics

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: In my CatTestHub dataset, my catalyst activity vs. time plot shows a rapid initial drop followed by a stable plateau. What does this pattern indicate? A1: This is a classic signature of site poisoning or rapid coking. An active site is blocked very early in the reaction, leaving a subset of sites permanently inactive. The plateau represents the remaining active sites. Common causes are strong chemisorption of a feed impurity (e.g., sulfur, lead) or the formation of a monolayer of carbonaceous deposits.

Q2: My diagnostic plot shows a linear decline in activity from time-zero. What is the most probable mechanism? A2: A linear decline from T=0 is strongly indicative of uniform fouling or homogeneous poisoning. In this scenario, every active site has an equal probability of being deactivated per unit time. This is often observed when a uniform layer of deposits (like coke or scale) builds up across the entire catalyst surface or when a poison is uniformly distributed in the feed.

Q3: The activity curve is exponential, decaying rapidly at first and then slowing. How should I interpret this? A3: An exponential decay curve typically points to pore-mouth poisoning or shell-progressive poisoning. The deactivating agent (poison or large coke precursor) blocks the entrance to catalyst pores first, preventing access to the active sites inside. The rate of deactivation slows as it becomes harder for the agent to reach the remaining interior sites.

Q4: What does a "S-shaped" or sigmoidal activity curve suggest? A4: A sigmoidal curve suggests an autocatalytic deactivation mechanism. This is common in certain coking reactions where the initial coke deposits themselves catalyze further coke formation. The reaction rate for coke formation increases with time until feedstock or site limitations cause it to slow.

Q5: My selectivity changes significantly alongside activity loss. What does this reveal? A5: Selective changes point to non-uniform site deactivation. Different types of active sites (e.g., for different reaction pathways) have varying susceptibility to the deactivation agent. This is a key diagnostic: if selectivity remains constant, the deactivation is uniform; if it changes, it is selective, helping to fingerprint the root cause.

Table 1: Diagnostic Plot Patterns and Their Probable Root Causes

| Plot Shape | Mathematical Form | Probable Mechanism | Common in CatTestHub Data? |

|---|---|---|---|

| Rapid Drop + Plateau | (a(t) = a\infty + (1 - a\infty)e^{-k_1 t}) | Site Poisoning / Rapid Coking | Very High (>30% of cases) |

| Linear Decline | (a(t) = 1 - k t) | Uniform Fouling / Homogeneous Poisoning | High (~25% of cases) |

| Exponential Decay | (a(t) = e^{-k t}) | Pore-Mouth Poisoning | Moderate (~20% of cases) |

| S-Shaped (Sigmoidal) | (a(t) = 1 / (1 + e^{k(t-t_0)})) | Autocatalytic Coking | Low (~10% of cases) |

| Stepwise Decline | Discrete drops at specific T/P | Thermal Sintering / Attrition | Low (~5% of cases) |

Table 2: Corresponding Protocol Triggers for CatTestHub Experiments

| Suspected Mechanism | Confirmatory Test Protocol | Expected Result if Mechanism is Confirmed |

|---|---|---|

| Poisoning (Site-Specific) | Post-run XPS or TEM-EDX Surface Analysis | Detection of heteroatom (S, P, Pb) on surface. |

| Uniform Coking/Fouling | Thermogravimetric Analysis (TGA) | Uniform weight loss during burn-off across sample. |

| Pore-Mouth Blockage | N₂ Physisorption (BET/BJH) | Severe reduction in pore volume, shift in pore size distribution. |

| Sintering | CO Chemisorption or TEM Imaging | Loss of active surface area, increased metal particle size. |

| Selective Deactivation | Transient Response / Isotope Labeling | Change in product distribution from pulse experiments. |

Experimental Protocols

Protocol P-01: Confirmatory Analysis for Site Poisoning (Follows Q1/A1)

Objective: To confirm the presence of a chemical poison on the catalyst surface. Methodology:

- Sample Prep: Retrieve the deactivated catalyst from the CatTestHub reactor. Divide into two aliquots.

- X-Ray Photoelectron Spectroscopy (XPS):

- Mount one aliquot on a conductive stub.

- Acquire wide-scan spectra to identify all elements present.

- Perform high-resolution scans on regions corresponding to suspected poison (e.g., S 2p, P 2p).

- Compare atomic concentrations to a fresh catalyst standard.

- Acid Wash & Re-Test:

- Treat the second aliquot with a dilute acid (e.g., 1M HNO₃) to leach surface poisons.

- Wash thoroughly, dry, and re-evaluate activity in a microreactor test.

- A significant activity recovery supports a poisoning mechanism.

Protocol P-02: Discriminating Coking from Sintering (Follows Q5/A5)

Objective: To distinguish between deactivation by carbon deposits and loss of active surface area. Methodology:

- Thermogravimetric Analysis (TGA):

- Heat a ~10 mg sample of spent catalyst in air (20 mL/min) from ambient to 800°C at 10°C/min.

- Measure weight loss. A major loss between 350-600°C indicates combustible coke.

- CO Pulse Chemisorption:

- After TGA (catalyst is now clean), reduce the sample in H₂ at standard conditions.

- Using an automated chemisorption analyzer, pulse CO over the sample at 35°C.

- Calculate the metallic surface area.

- Analysis: Compare the post-TGA chemisorption result to a fresh catalyst.

- If surface area is restored: Deactivation was primarily due to coke.

- If surface area remains low: Deactivation involved significant sintering.

Diagnostic Pathway and Workflow

Title: Catalyst Deactivation Diagnostic Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Deactivation Analysis

| Item / Reagent | Function / Purpose | Typical Application in Protocol |

|---|---|---|

| Dilute Nitric Acid (1M HNO₃) | Selective leaching of metallic poisons (e.g., Pb, Bi) from catalyst surface. | Confirmatory acid wash in poisoning analysis (P-01). |

| 5% H₂/Ar Gas Mixture | Reducing agent for pre-treatment of catalysts before surface area measurement. | Reactivation step before CO chemisorption in P-02. |

| Ultra-high Purity CO | Probe molecule for chemisorption to determine accessible metallic surface area. | Pulse chemisorption in sintering confirmation (P-02). |

| Calibration Standard (e.g., Al₂O₃) | Reference material for instrument calibration in surface area/pore size analyzers. | Ensuring accuracy in BET surface area measurements. |

| Inert Silica Wool | Used as a plug or support in microreactor tubes to hold catalyst bed in place. | Standard reactor setup for all activity tests. |

| Certified Standard for XPS | Sample with known binding energies for calibrating the XPS spectrometer. | Essential for accurate element identification in P-01. |

Troubleshooting Guides & FAQs

Q1: Our catalyst regeneration protocol, based on CatTestHub Dataset 2023-07 (High-Temperature Oxidation), is yielding inconsistent activity recovery (<70% vs. the reported 85-92%). What are the primary troubleshooting steps?

A: Inconsistent recovery often stems from uncontrolled exotherms or incomplete precursor removal.

- Check Temperature Gradients: Ensure your reactor has calibrated, equidistant thermocouples. A localized hot spot (>50°C above setpoint) can cause sintering. Mitigate by reducing heating rate to 2°C/min during coke burn-off.

- Analyze Off-Gas: Use real-time mass spectrometry (if available) to monitor CO₂ and H₂O evolution. A prolonged tail in the CO₂ signal indicates incomplete carbon removal. Extend the isothermal hold at the regeneration temperature until the CO₂ baseline is stable.

- Verify Inlet Gas Moisture: Trace H₂O in your regeneration gas (air or O₂/N₂ mix) can promote unwanted hydrothermal aging. Install a desiccant guard bed (e.g., 3Å molecular sieves) upstream of the reactor.

Q2: When implementing a guard bed for chloride scavenging upstream of our main catalyst bed, how do we monitor its breakthrough and prevent downstream contamination?

A: Guard bed saturation is a critical failure point. Implement a proactive monitoring protocol.

- Strategic Sampling Points: Install at least two sampling ports along the guard bed length (at 33% and 66% bed depth). Periodically analyze the process stream at these points via ion chromatography for chloride.

- Predictive Replacement: Do not wait for full breakthrough. The CatTestHub meta-analysis (see Table 1) shows that replacing the guard bed media once the midpoint sample shows 25% of the inlet chloride concentration prevents any downstream detection.

- Procedure: Isolate the guard bed vessel, depressurize, and purge with inert gas. Replace spent media according to safe handling procedures for the spent scavenger material.

Q3: Adding alkali metal modifiers (e.g., K) to suppress coke formation is causing a severe, unexpected drop in desired product selectivity. How can we diagnose this?

A: This indicates modifier migration or overdose, blocking active sites.

- Post-Reaction Characterization: Use X-ray Photoelectron Spectroscopy (XPS) depth profiling on the spent catalyst. Compare the surface (0-5 nm) K concentration to the bulk (via ICP-MS). A surface-to-bulk ratio >2.5 suggests severe surface segregation.

- Check Impregnation Protocol: Ensure the modifier precursor is dissolved in a minimal amount of water and added via incipient wetness impregnation with thorough mixing. Follow a "dry-add" step calcination (150°C for 2h) before the final high-temperature calcination to prevent capillary migration to pore mouths.

- Consult Modifier Loading Table: Refer to Table 2 for optimal loading ranges by catalyst family. Exceeding these ranges often leads to site poisoning.

Data Tables

Table 1: Guard Bed Performance & Replacement Metrics (Source: CatTestHub Meta-Analysis, 2024)

| Scavenged Impurity | Guard Bed Material | Typical Capacity (g impurity/kg bed) | Recommended Replacement Threshold | Downstream Protection Efficacy |

|---|---|---|---|---|

| Chlorides (HCl) | Na₂O/Al₂O₃ | 120-150 | 25% of inlet at mid-bed sample | >99.9% |