Catalytic Activity Comparison Against Standard Reference Materials: A 2025 Guide for Pharmaceutical Research

This article provides a comprehensive framework for researchers and drug development professionals to compare catalytic activity against Certified Reference Materials (CRMs).

Catalytic Activity Comparison Against Standard Reference Materials: A 2025 Guide for Pharmaceutical Research

Abstract

This article provides a comprehensive framework for researchers and drug development professionals to compare catalytic activity against Certified Reference Materials (CRMs). It covers the foundational role of CRMs like NIST Standard Reference Materials in ensuring measurement traceability and quality control for catalytic processes. The scope includes methodological approaches for activity testing, troubleshooting common homogeneity and stability issues, and validation strategies for comparative analysis. By synthesizing insights across these four intents, the article establishes best practices for using CRMs to validate analytical methods, calibrate instruments, and generate reliable, comparable data in biomedical catalysis, ultimately accelerating the development of safe and effective biological drugs.

Understanding Certified Reference Materials (CRMs): The Foundation of Reliable Catalytic Measurement

Defining Certified Reference Materials (CRMs) and Standard Reference Materials (SRMs)

Certified Reference Materials (CRMs) and Standard Reference Materials (SRMs) are specialized measurement standards essential for ensuring data quality, method validation, and metrological traceability in scientific research and industrial analysis. CRMs provide the highest level of accuracy and traceability for critical calibration and validation, while SRMs are a specific class of CRMs certified by the National Institute of Standards and Technology (NIST) to meet additional, stringent criteria.

Core Definitions and Hierarchical Relationship

Reference Material (RM): A material, sufficiently homogeneous and stable with respect to one or more specified properties, which has been established to be fit for its intended use in a measurement process [1] [2] [3]. RMs serve as controls in quality assurance but lack the comprehensive characterization of certified materials.

Certified Reference Material (CRM): A reference material characterized by a metrologically valid procedure for one or more specified properties, accompanied by a certificate that provides the value of the specified property, its associated uncertainty, and a statement of metrological traceability [1] [2] [4]. CRMs are produced by reference material producers (RMPs) operating a quality system compliant with ISO 17034 [1] [5].

Standard Reference Material (SRM): A certified reference material issued by NIST that satisfies additional NIST-specific certification criteria [2] [6] [7]. "Standard Reference Material" and "SRM" are registered trademarks of NIST [2] [6]. SRMs are physical standards that help users develop accurate measurement methods, calibrate instruments, and support quality assurance programs [8] [7].

The relationship between these materials is hierarchical, with SRMs representing a specialized subset of the broader CRM category, which in turn is a characterized subset of general-purpose RMs.

Comparative Analysis: CRMs vs. SRMs

The table below summarizes the key characteristics that differentiate CRMs from SRMs, highlighting the progression in metrological rigor.

Table 1: Key Characteristics of CRMs and SRMs

| Feature | Certified Reference Material (CRM) | Standard Reference Material (SRM) |

|---|---|---|

| Definition | Reference material with certified property values, uncertainty, and traceability [1] [2] [3]. | A CRM certified by NIST that meets additional NIST-specific criteria [2] [6]. |

| Certifying Body | Any Reference Material Producer (RMP) with an ISO 17034-compliant quality system [1]. | Exclusively the National Institute of Standards and Technology (NIST) [2] [7]. |

| Primary Documentation | Certificate (Reference Material Certificate) [2]. | Certificate or Certificate of Analysis [2]. |

| Traceability | Metrological traceability to an internationally recognized system (e.g., SI), where possible [1]. | Metrologically traceable to a higher-order reference system and deemed suitable for unbiased calibration/validation by NIST [2]. |

| Key Purpose | Method validation, assessment of bias, measurement uncertainty, instrument calibration [1] [9]. | Calibration, method development, quality assurance; facilitates commerce and supports trade [2] [7]. |

| Term Status | Generic term defined in international standards (e.g., ISO Guide 30) [2]. | Registered trademark of NIST [2] [6]. |

The choice between a general CRM and a specific SRM depends on the application's required level of certainty, regulatory context, and specific measurement goals. SRMs are often sought for their unparalleled authority in establishing measurement credibility in publications and regulatory submissions.

Experimental Protocols for Characterizing Reference Materials

The production and certification of CRMs, including SRMs, follow rigorous, standardized protocols to ensure homogeneity, stability, and accurate value assignment. These processes are detailed in ISO Guide 17034 and ISO Guide 35 [1] [3].

Material Preparation and Homogenization

The process begins with the collection or synthesis of a bulk material. For solid matrix materials, this often involves processing into a fine powder or paste to ensure homogeneity [3]. The material may be stabilized with additives (e.g., antimicrobials) or through lyophilization (freeze-drying) to enhance long-term stability [3]. The processed material is then bottled into individual units.

Homogeneity Testing

Homogeneity is assessed to ensure property values do not vary significantly between units. A common approach uses a balanced nested experimental design [3].

- Protocol: Select 10-30 units randomly from the entire batch. From each unit, take multiple sub-samples (e.g., 2-3). Measure the property of interest for all sub-samples in a randomized order.

- Data Analysis: Use analysis of variance (ANOVA) to separate the variation between units from the variation within units (measurement error). The between-unit standard deviation is quantified and must be sufficiently small for the material's intended use [3].

Stability Assessment

Stability is evaluated to ensure the material's properties remain unchanged over time, considering both long-term storage and transport conditions [1] [3]. Several study designs are employed:

- Real-time Studies: Units are stored at the recommended temperature and measured at intervals over time. Data is analyzed by linear regression to detect significant trends [3].

- Accelerated Studies: Units are stored at elevated temperatures to simulate aging. Data is fitted to a degradation model (e.g., Arrhenius model) to predict stability at storage temperature [3].

- Isochronous Studies: Units undergo different storage times but are all measured simultaneously against a stable reference, eliminating measurement drift as a variable [3].

Value Assignment and Certification

This is the core metrological procedure for assigning a certified value and its uncertainty.

- Protocol: The property value is determined using one or more primary (definitive) methods or by a network of independent, reference laboratories. Methods must be metrologically valid [1] [2].

- Uncertainty Calculation: The combined standard uncertainty includes components from property value characterization, homogeneity (from Step 2), and stability (from Step 3) [1].

- Certification: All data and methodologies are reviewed, and a certificate is issued. For an SRM, NIST authorizes the certified value with the highest confidence, meaning all known sources of bias have been investigated [2].

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key materials and reagents used in the characterization and application of reference materials for catalytic research.

Table 2: Essential Research Reagents for CRM Characterization and Use

| Reagent/Material | Primary Function | Application Context |

|---|---|---|

| High-Purity Solvents | Dissolution, dilution, and extraction of analytes from solid matrix CRMs [9]. | Sample preparation for chromatography and spectroscopy. |

| Primary Calibration Standards | Ultimate source of traceability; used with definitive methods to assign values to CRMs [9]. | Value assignment during CRM production. |

| Internal Standard Solutions | Correction for instrument response drift and matrix effects during analysis [9]. | Quantification via mass spectrometry (ICP-MS) or chromatography. |

| Matrix-Matched Modifiers | Modify sample matrix to improve analyte stability or signal response [9]. | Graphite furnace atomic absorption spectrometry (GF-AAS). |

| Spectrophotometric Filters (NTRM) | Calibration of absorbance/transmittance scales of spectrophotometers [2]. | Instrument performance verification. |

| Control Materials | Independent quality control check to validate the entire analytical process [1] [5]. | Daily or weekly quality control monitoring. |

Application in Catalytic Activity Research

In the context of comparing catalytic activity, CRMs and SRMs are indispensable for generating reliable and comparable data. Their application ensures that performance metrics, such as turnover frequency or reaction yield, are measured on a consistent and traceable scale.

- Calibration of Analytical Instruments: CRMs are used to calibrate instruments like gas chromatographs (GC) or inductively coupled plasma (ICP) spectrometers that quantify reaction products or catalyst metal content [1] [9]. This establishes metrological traceability for all subsequent measurements [1].

- Method Validation: A matrix CRM with a known concentration of a relevant analyte in a similar material (e.g., a catalyst support) is analyzed to validate a new testing procedure, proving the method's accuracy and precision [9].

- Commuting Comparative Studies: When different research groups use a common, well-characterized catalyst CRM (e.g., a powdered metal on a support with certified surface area and metal loading) as a benchmark, the catalytic activity data from various laboratories can be directly and meaningfully compared [3] [6]. This practice is fundamental to advancing reproducible research in catalysis.

For regulatory submissions in drug development, the use of SRMs from NIST or accredited CRMs provides the highest level of confidence to regulatory bodies, as it unequivocally demonstrates the traceability and validity of the critical measurements supporting the research [5].

The Critical Role of CRMs in Metrological Traceability and Quality Management (ISO/IEC 17025)

For testing and calibration laboratories, particularly those operating under ISO/IEC 17025:2017, measurement traceability is a fundamental requirement for assuring the quality and validity of results [10] [11]. Metrological traceability is defined as the "property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty" [12]. This establishes confidence that measurements agree with national or international standards within stated uncertainties, which is critical in fields like clinical chemistry, pharmaceutical development, and manufacturing, where decisions affect health, safety, and commerce [10].

Certified Reference Materials (CRMs) serve as a crucial link in this traceability chain. These materials are characterized by metrologically valid procedures for one or more specified properties, accompanied by a certificate that provides the property's value, its associated uncertainty, and a statement of metrological traceability [12]. For laboratories measuring catalytic activity, CRMs provide an anchor to higher-order references, enabling demonstration of measurement accuracy and method validation as required by clause 6.5 of ISO/IEC 17025:2017 [11].

Table: Key Definitions in Metrological Traceability

| Term | Definition | Relevance to ISO/IEC 17025 |

|---|---|---|

| Metrological Traceability | Property of a measurement result that can be related to a reference through a documented unbroken chain of calibrations [12] | Core requirement for ensuring measurement reliability and comparability (Clause 6.5) [11] |

| Certified Reference Material (CRM) | Reference material characterized by a metrologically valid procedure, with certificate providing value, uncertainty, and traceability statement [12] | Provides traceable link to reference standards for calibration and method validation [13] |

| Measurement Uncertainty | Parameter characterizing the dispersion of values that could reasonably be attributed to a measurand [10] | Must be estimated for all measurements and included in traceability chains [10] |

| Calibration Hierarchy | Sequence of calibrations from a reference to the final measuring system, where each calibration depends on the previous one [10] | Establishes the unbroken chain required for demonstrating traceability [10] |

ISO/IEC 17025:2017 Traceability Requirements and CRM Implementation

Traceability Mandates for Laboratories

The ISO/IEC 17025:2017 standard establishes specific requirements for metrological traceability that differ slightly between calibration and testing laboratories. For calibration laboratories, the standard mandates that equipment calibration programs must "ensure that calibrations and measurements made by the laboratory are traceable to the International System of Units (SI)" through an unbroken chain of calibrations linking them to primary standards [10]. These laboratories must use reference standards calibrated by bodies that can provide demonstrable traceability, and such standards must be used for calibration only [10].

For testing laboratories, the requirements are similarly rigorous but include a proportionality clause. The standard states that traceability requirements apply to measuring equipment "unless it has been established that the associated contribution from the calibration contributes little to the total uncertainty of the test result" [10]. In such cases, laboratories must provide objective evidence that the equipment can provide the needed measurement uncertainty [10]. This nuanced approach recognizes that not all measurements require the same level of traceability documentation, though CRMs remain essential for method validation and trueness control even when not part of the direct calibration chain [13].

Establishing Traceability Through CRMs

Certified Reference Materials provide one of the most practical mechanisms for laboratories to establish and maintain metrological traceability. According to NIST policy, traceability requires establishing an unbroken chain of calibrations to specified reference standards, typically national or international standards or realizations of SI units [12]. CRMs certified in accordance with ISO Guide 35 and produced under ISO 17034 accreditation fulfill this requirement by providing a documented link to higher-order references [13] [14].

Table: CRM Types and Their Traceability Functions

| CRM Type | Primary Function | Traceability Pathway | Example Materials |

|---|---|---|---|

| Primary Reference Materials | Calibration of reference measurement procedures | Direct link to SI units or international standards | Pure substance CRMs with purity certified against SI units |

| Matrix Reference Materials | Method validation, quality control, trueness verification | Established through characterization using reference methods | ERM AD456/IFCC (alpha-amylase in human tissue) [13] |

| Proficiency Testing Materials | Interlaboratory comparison, competence assessment | Value assignment through expert laboratory consensus | ERM-AD457k/IFCC (aspartate transaminase) [14] |

| Calibration Solutions | Instrument calibration, routine method calibration | Traceable to primary reference materials | Enzyme catalytic activity calibration solutions |

Comparative Analysis of Catalytic Activity CRMs in Clinical Research

Experimental Data and Certification Protocols

The certification of CRMs for catalytic activity follows rigorous experimental protocols designed to ensure traceability and reliability. The process for ERM AD456/IFCC (alpha-amylase) exemplifies this approach, where the starting material was pancreatic alpha-amylase purified from human tissue, diluted in buffered solution, lyophilized, and assessed for between-unit homogeneity and stability in accordance with ISO Guide 35 [13]. The material was characterized through an interlaboratory comparison of laboratories with demonstrated competence adhering to ISO/IEC 17025, with uncertainties calculated following the Guide to the Expression of Uncertainty in Measurement (GUM) [13].

Similarly, the recently certified ERM-AD457k/IFCC for aspartate transaminase (AST) catalytic activity concentration used recombinant AST cytosolic isoform originating from human liver expressed in Escherichia coli [14]. The certification involved homogeneity and stability assessments according to ISO 33405:2024, with characterization through an interlaboratory comparison of competent laboratories following ISO/IEC 17025:2017 [14]. In this study, ten out of twelve datasets were used to calculate the assigned value, demonstrating the selective rigor applied to data evaluation in reference material certification [14].

Table: Comparative Analysis of Catalytic Activity CRMs

| Parameter | ERM AD456/IFCC (Alpha-Amylase) | ERM-AD457k/IFCC (Aspartate Transaminase) |

|---|---|---|

| Catalytic Activity | Certified for alpha-amylase activity | Certified for aspartate transaminase activity |

| Source Material | Pancreatic alpha-amylase purified from human tissue | Recombinant AST from human liver expressed in E. coli |

| Physical Form | Lyophilized material from 1 mL solution in nitrogen-flushed vials | Lyophilized form of 1.0 mL AST solution in amber glass vials |

| Minimum Sample Size | 5 µL after reconstitution in 1 mL | 9 µL |

| Certification Basis | ISO 17034:2016 and ISO Guide 35:2017 | ISO 17034:2016 accreditation |

| Characterization Method | Interlaboratory comparison of ISO/IEC 17025 compliant labs | Interlaboratory comparison of competent laboratories |

| Primary Intended Use | Assessment of primary reference measurement procedure performance | Assessment of primary reference measurement procedure performance |

| Additional Applications | Trueness control, external quality control if commutability proven | Trueness control, external quality control if commutability proven |

Experimental Workflow for CRM Certification

The certification of reference materials for catalytic activity follows a meticulously designed experimental workflow that ensures traceability, reliability, and fitness for purpose. The process from material preparation to value assignment involves multiple validation steps with uncertainty estimation at each stage.

CRM Certification Workflow

Research Reagent Solutions for Catalytic Activity Studies

The experimental characterization of catalytic activity CRMs requires specific reagent solutions and reference materials to ensure accurate and traceable measurements. These materials form the foundation of reliable measurement systems in both reference methods and routine laboratory procedures.

Table: Essential Research Reagent Solutions for Catalytic Activity Measurement

| Reagent/Material | Function | Critical Specifications | Traceability Considerations |

|---|---|---|---|

| Certified Enzyme Reference Materials | Calibrate reference measurement procedures; verify method trueness | Certified value with expanded uncertainty; commutability with clinical samples | Direct traceability to IFCC reference methods via certification process [13] [14] |

| Buffer Solutions | Maintain optimal pH for enzyme activity; provide necessary cofactors | Certified pH with uncertainty; specified ionic strength; absence of interfering substances | pH traceable to primary pH standards; component purity traceable to SI units |

| Substrate Solutions | Provide specific reaction substrates for enzyme catalysis | Purity certification; absence of inhibitors or contaminants; solution stability | Chemical purity traceable to primary chemical reference materials |

| Calibrators | Establish calibration curve for instrument response | Value assignment traceable to CRMs; demonstrated commutability | Unbroken metrological traceability chain to highest available reference [10] |

| Quality Control Materials | Monitor measurement procedure performance over time | Assigned values with acceptable ranges; stability documentation | Traceability to CRMs or reference measurement procedures |

Metrological Traceability Pathways in Catalytic Activity Measurement

Establishing and maintaining metrological traceability requires a systematic approach that connects routine measurements to international standards through an unbroken chain of comparisons. The pathway from sample measurement to international standards involves multiple steps, each contributing to the overall measurement uncertainty.

Traceability Pathway for Catalytic Activity

Certified Reference Materials play an indispensable role in establishing and maintaining metrological traceability for catalytic activity measurements in ISO/IEC 17025 accredited laboratories. The rigorous certification processes followed for materials like ERM AD456/IFCC and ERM-AD457k/IFCC demonstrate how proper characterization, homogeneity testing, stability monitoring, and uncertainty estimation create the foundation for reliable measurements in clinical chemistry and pharmaceutical research [13] [14]. As regulatory requirements for data quality continue to intensify across drug development and clinical diagnostics, the proper implementation of CRMs within a traceability framework remains essential for laboratories seeking to demonstrate technical competence and generate legally defensible results. The experimental data and certification protocols reviewed provide a template for how reference materials serve as critical tools for method validation, quality control, and demonstrating equivalence of measurement results across different platforms and laboratories.

In the field of catalysis research, Certified Reference Materials (CRMs) serve as foundational tools for ensuring measurement accuracy, method validation, and result comparability. CRMs are reference materials characterized by a metrologically valid procedure for one or more specified properties, accompanied by a certificate that provides the value of the specified property, its associated uncertainty, and a statement of metrological traceability [15]. The use of CRMs is particularly critical in catalysis studies, where precise determination of catalytic activity, selectivity, and stability directly impacts research outcomes and technology development.

Catalysis research relies on CRMs across multiple applications: instrument calibration to ensure measurement accuracy over time, validation of new analytical methods, routine quality control to monitor analytical performance, and proficiency testing to ensure consistency across different laboratories [15]. The growing emphasis on sustainable catalysis, including the development of single-atom catalysts and the replacement of precious metals with more abundant alternatives, has further increased the importance of reliable reference materials in the field [16]. This guide systematically compares the three primary types of CRMs relevant to catalysis research—pure substances, matrix materials, and physico-chemical standards—to assist researchers in selecting appropriate materials for their specific applications.

CRM Type 1: Pure Substance CRMs

Definition and Applications

Pure substance CRMs consist of highly pure chemical reagents or proportionally prepared mixtures with well-defined compositional properties [17]. In catalysis research, these materials serve as primary calibrators for analytical instruments, standards for creating calibration curves, and reference points for evaluating method accuracy. Their primary function is to establish metrological traceability when determining the concentration of specific catalysts, reactants, or products in experimental systems.

Pure substance CRMs are particularly valuable in homogeneous catalysis and for quantifying reaction products in heterogeneous systems. When used to create standard curves, these CRMs enable researchers to establish the linear relationship between instrumental response and analyte concentration, providing a common basis for comparing results across different laboratories and experimental conditions [17]. Their certified purity and composition make them indispensable for quantifying catalytic performance metrics, including conversion efficiency, product yield, and reaction kinetics.

Key Providers and Specifications

Several prominent manufacturers supply pure substance CRMs suitable for catalysis research. Supelco offers CRMs produced in accordance with ISO 17034 and characterized under ISO/IEC 17025 standards, ensuring metrological traceability [18]. Their product lines include Cerilliant and TraceCERT CRMs suitable for various analytical platforms used in catalysis research, including chromatography, mass spectrometry, and quantitative NMR. Similarly, Certipur reference materials provide high-purity standards for inorganic analysis, including single-element standards for AAS, IC, and ICP techniques commonly employed in catalyst characterization [18] [19].

Alfa Chemistry provides another source of pure substance CRMs, offering materials with documented molecular weights and CAS numbers for precise identification [17]. These materials function as measuring tools that play an indispensable role in calibrating measuring instruments, evaluating measurement methods, and quality control in catalytic research. The certification process for these materials includes rigorous testing for homogeneity, stability, and characterization with specified uncertainties, making them suitable for demanding applications in catalysis research and development.

Experimental Applications in Catalysis

Protocol for Calibrating Analytical Instruments:

- CRM Selection: Choose a pure substance CRM with a matrix similar to the analyte and a certified value encompassing the expected concentration range in catalytic experiments.

- Solution Preparation: Precisely weigh and dilute the CRM to prepare at least five standard solutions of varying concentrations, covering the analytical range of interest.

- Instrument Calibration: Analyze each standard solution in triplicate using the target analytical method (e.g., GC, HPLC, ICP-MS).

- Calibration Curve: Plot the instrument response against the certified concentration values for each standard. Calculate the regression equation and correlation coefficient (R²).

- Verification: Analyze an independent CRM as an unknown to verify calibration accuracy. The measured value should agree with the certified value within statistical uncertainty.

Protocol for Catalyst Quantification Using Standard Curves:

- CRM Preparation: Use pure substance CRMs to prepare a series of standard solutions encompassing the expected concentration range of the target analyte (e.g., reaction product).

- Sample Processing: Process catalytic reaction samples using the same method as the CRM standards.

- Analysis: Analyze both standards and samples using the calibrated instrument.

- Quantification: Calculate analyte concentration in samples by interpolating the instrument response from the CRM-based standard curve.

- Validation: Include quality control samples spiked with known amounts of CRM to monitor analytical recovery and precision.

CRM Type 2: Matrix CRMs

Definition and Applications

Matrix Certified Reference Materials (mCRMs) are carefully manufactured materials characterized by suitable homogeneity, stability, and traceability, with certified values and a specific matrix that closely mimics the composition and properties of real samples [15]. Unlike pure substance CRMs, mCRMs incorporate complex matrices such as environmental samples, biological materials, or engineered catalytic systems, making them essential tools for validating analytical methods where matrix effects could influence measurement accuracy.

In catalysis research, mCRMs are particularly valuable for studying supported catalysts, analyzing spent catalysts in complex media, and investigating catalytic processes in environmental or biological systems. These materials allow researchers to account for matrix-induced interferences, validate sample preparation procedures, and ensure the accuracy of measurements when analyzing real-world samples. Natural matrix CRMs, such as those developed by NIST including sediments, biological materials, and soils, provide reference points for environmental catalysis studies and the analysis of catalytic materials derived from complex sources [20].

Production and Certification

The production of mCRMs follows a meticulous, multi-stage process governed by strict international guidelines, primarily ISO 17034 and ISO/IEC 17025 [15]. This process begins with planning and material selection, where the need for a specific matrix CRM is defined based on analytical requirements. Material processing and preparation follow, aiming to achieve maximum homogeneity while preserving the matrix characteristics essential for realistic analytical challenges.

Homogeneity testing constitutes a critical phase in mCRMs production, ensuring that variations between different units of the material do not contribute significantly to measurement uncertainty. Stability testing follows, assessing the material's behavior under various storage conditions and timeframes. The characterization phase employs multiple analytical techniques to assign reference values, often through interlaboratory comparisons that involve experienced laboratories using different validated methods [20]. This approach diminishes potential methodological bias and contributes to continuous improvement of analytical capabilities. The final certification and documentation phase includes preparing a comprehensive certificate containing certified values, uncertainties, and intended use instructions, followed by post-certification monitoring to ensure ongoing reliability.

Experimental Applications in Catalysis

Protocol for Method Validation Using mCRMs:

- mCRM Selection: Choose a matrix CRM with properties similar to the catalytic samples under investigation (e.g., supported metal catalysts, environmental samples from catalytic processes).

- Sample Processing: Process the mCRM using the exact same analytical method applied to catalytic samples.

- Analysis: Analyze the mCRM alongside experimental samples using the validated instrumental method.

- Accuracy Assessment: Compare the measured value for the mCRM against its certified value. The result should fall within the certified uncertainty range.

- Method Adjustment: If significant bias is observed, investigate sources of error and refine the analytical method until satisfactory agreement with the certified value is achieved.

Protocol for Quality Control in Catalytic Studies:

- Batch Analysis: Include a matrix CRM in each analytical batch when processing multiple catalytic samples.

- Control Charting: Record measured values for the mCRM over time to establish control charts with warning and action limits.

- Process Monitoring: Use control charts to monitor analytical performance and identify potential issues with instruments or reagents.

- Corrective Action: Implement corrective measures when mCRM results exceed established control limits before proceeding with sample analysis.

CRM Type 3: Physico-chemical Standards

Definition and Applications

Physico-chemical property standards are CRMs certified for specific physical or chemical properties rather than compositional parameters [19]. These materials enable accurate calibration of instruments that measure properties highly relevant to catalysis research, including viscosity, density, pH, conductivity, melting point, and various spectroscopic characteristics. The calibration of analytical equipment with these standards represents a fundamental requirement for obtaining high-quality analytical data in catalysis research.

In catalysis studies, these standards support the characterization of catalyst materials, monitoring of reaction progress, and analysis of products. For instance, pH buffer CRMs maintain proper calibration of pH instrumentation used to monitor acidic or basic reaction conditions, while conductivity standards enable accurate measurement of ionic species in catalytic solutions. Melting point standards facilitate the characterization of catalytic products or organic intermediates, and viscosity standards support the analysis of liquid reaction media or products in catalytic processes involving polymers or heavy hydrocarbons.

Key Providers and Specifications

Sigma-Aldrich's Supelco portfolio offers comprehensive physico-chemical standards, including Certipur buffer solutions for pH calibration, melting point standards, and materials for calibrating instruments that measure viscosity, density, and refractive index [19]. These CRMs are produced in accordance with ISO 17034 and characterized following ISO/IEC 17025 standards, ensuring metrological traceability for physical property measurements.

The Certipur line of CRMs includes specialized materials for various analytical techniques relevant to catalysis research. Karl Fischer (KF) standards support accurate water determination in catalytic reactions where moisture content critically impacts performance. Volumetric standards enable precise calibration for titration methods used to quantify reactive sites on catalyst surfaces. Conductivity standards facilitate the calibration of instruments for monitoring ionic species in electrocatalytic systems or catalytic solutions. These physico-chemical standards undergo rigorous certification processes to ensure they deliver maximum accuracy, reliability, and convenience while maintaining consistency and avoiding costly reanalyses [19].

Experimental Applications in Catalysis

Protocol for pH-Sensitive Catalytic Reactions:

- Buffer Selection: Select Certipur pH buffer CRMs bracketing the expected pH range of the catalytic reaction.

- Instrument Calibration: Calibrate the pH meter using at least two buffer CRMs according to manufacturer instructions.

- Verification: Measure a third buffer CRM as an unknown to verify calibration accuracy.

- Reaction Monitoring: Use the calibrated instrument to monitor pH during catalytic reactions where acidity influences mechanism or kinetics.

- Documentation: Record calibration details including CRM batch numbers, calibration date, and verification results.

Protocol for Catalyst Surface Characterization:

- Standard Selection: Choose appropriate physico-chemical standards based on characterization technique (e.g., melting point standards for DSC calibration, viscosity standards for rheological measurements).

- Instrument Calibration: Calibrate characterization instruments using certified reference materials before analyzing catalyst samples.

- Quality Control: Periodically verify calibration during extended analysis sequences using control standards.

- Sample Analysis: Characterize catalyst materials using properly calibrated instruments.

- Data Interpretation: Compare results against certified values of quality control standards to ensure measurement reliability.

Comparative Analysis of CRM Types

Table 1: Comparison of Key Characteristics for Different CRM Types in Catalysis Research

| Characteristic | Pure Substance CRMs | Matrix CRMs | Physico-chemical Standards |

|---|---|---|---|

| Primary Application | Instrument calibration, standard curves, quantitative analysis | Method validation, quality control, matrix-effect assessment | Instrument calibration for physical property measurements |

| Certified Values | Chemical composition, purity, concentration | Composition in specific matrices, element concentrations | Physical properties (pH, viscosity, melting point, conductivity) |

| Complexity | Single component or simple mixtures | Complex matrices mimicking real samples | Defined physical or chemical properties |

| Measurement Traceability | SI units through gravimetry and volumetry | SI units through characterization by multiple methods | SI units through certified reference instruments |

| Key Producers | Supelco, Cerilliant, TraceCERT, Alfa Chemistry | NIST, LGC Standards, BAM, IRMM, NMIJ | Certipur, Aquastar |

| Relevant Techniques | Chromatography, MS, NMR, AAS, ICP-MS | Environmental analysis, bioanalysis, catalyst characterization | pH meters, viscometers, refractometers, melting point apparatus |

| Uncertainty Sources | Purity, homogeneity, stability | Matrix effects, heterogeneity, sample preparation | Measurement technique, environmental conditions, instrument stability |

Table 2: Selection Guide for CRM Types Based on Catalysis Research Applications

| Research Application | Recommended CRM Type | Specific Examples | Key Considerations |

|---|---|---|---|

| Catalyst Synthesis & Characterization | Pure Substance CRMs, Physico-chemical Standards | Metal salt CRMs for catalyst preparation, melting point standards for product identification | Purity verification, quantitative preparation, identity confirmation |

| Reaction Monitoring & Quantification | Pure Substance CRMs | Organic compound CRMs for calibration curves, internal standards | Linear dynamic range, compatibility with detection system |

| Environmental Catalysis | Matrix CRMs | Natural matrix CRMs (sediments, soils), water analysis CRMs | Matrix-matched calibration, recovery studies, interference assessment |

| Electrocatalysis | Physico-chemical Standards, Pure Substance CRMs | Conductivity standards, pH buffers, high-purity electrolyte CRMs | Ionic strength control, potential calibration, impurity effects |

| Heterogeneous Catalyst Testing | Matrix CRMs, Pure Substance CRMs | Supported catalyst CRMs, reactant/product CRMs | Diffusion limitations, active site accessibility, product distribution |

| Quality Assurance Programs | Matrix CRMs | Proficiency testing materials, interlaboratory study materials | Method comparability, bias detection, performance demonstration |

Experimental Design and Protocols

Workflow for CRM Selection and Application

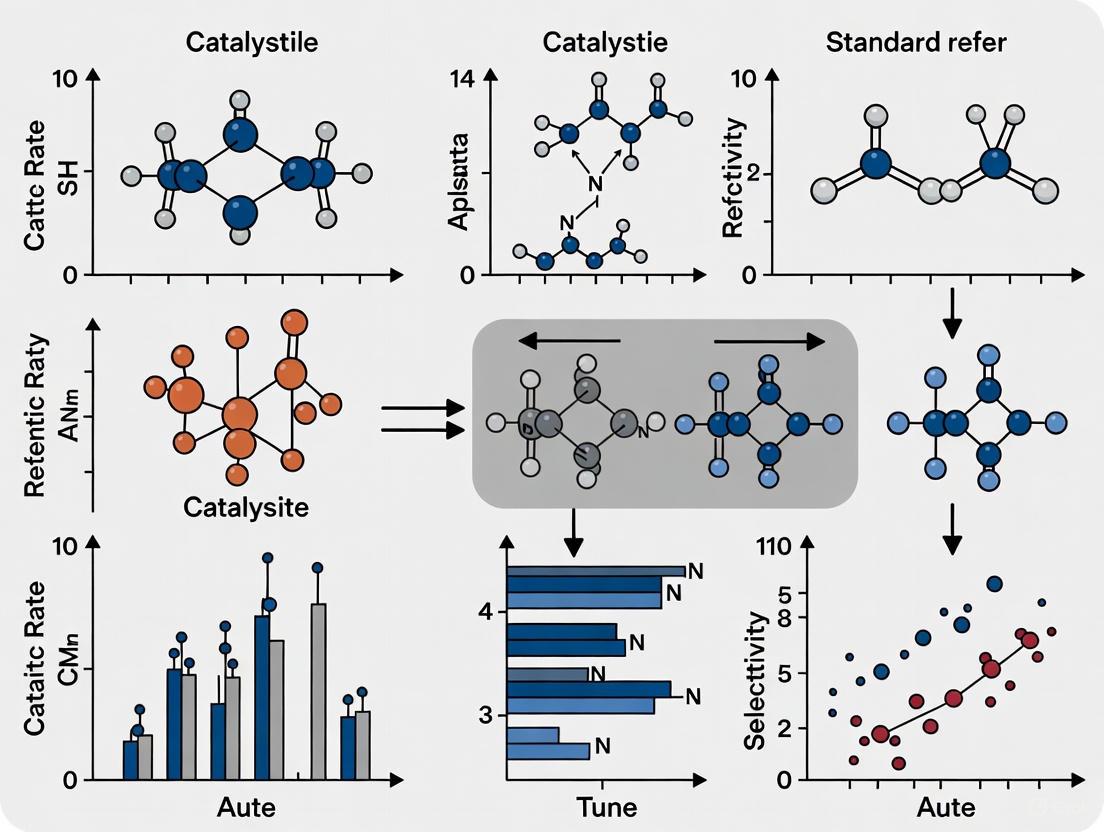

The following workflow diagram illustrates the systematic process for selecting and applying appropriate CRMs in catalysis research:

CRM Selection Workflow

Advanced CRM Applications in Sustainable Catalysis

The development of sustainable catalytic processes presents unique challenges for analytical chemistry and CRM applications. Research focused on replacing precious metals with more abundant elements requires rigorous comparison against standardized references [16]. The European Union's Critical Raw Materials (CRMs) assessment identifies elements with supply risks, influencing catalyst design strategies toward dematerialization—using smaller amounts of catalytic materials while maintaining or enhancing functionality [16].

Protocol for Comparing Novel Catalysts Against Reference Materials:

- Reference System Selection: Identify appropriate CRMs corresponding to the target catalytic system (e.g., precious metal CRMs for comparison with alternative catalysts).

- Standardized Testing Conditions: Establish reaction conditions using validated methods and physico-chemical standards for parameter control (temperature, pressure, pH).

- Parallel Testing: Conduct catalytic experiments with both novel materials and reference systems under identical conditions.

- Quantitative Analysis: Use pure substance CRMs to quantify reaction products and calculate performance metrics (conversion, selectivity, yield).

- Statistical Comparison: Apply appropriate statistical tests to determine significant differences in catalytic performance.

- Uncertainty Evaluation: Account for measurement uncertainties in both reference and novel catalyst systems when drawing conclusions.

Table 3: Essential Research Reagent Solutions for Catalysis Research

| Reagent Category | Specific Examples | Primary Function | Key Providers |

|---|---|---|---|

| Pure Substance CRMs | Single-element standards, organic compound CRMs, high-purity metals | Quantitative calibration, reference values for catalytic activity comparison, preparation of working standards | Supelco [18], TraceCERT [18], Alfa Chemistry [17] |

| Matrix CRMs | Environmental sediments, biological tissues, engineered catalyst materials | Method validation for complex samples, quality control, matrix-effect assessment | NIST [20], LGC Standards, BAM, IRMM [15] |

| Physico-chemical Standards | pH buffers, melting point standards, conductivity standards, viscosity standards | Instrument calibration for physical property measurements, method standardization | Certipur [19], Aquastar [18] |

| ISO 17034-Certified Producers | Accredited reference material manufacturers | Ensuring metrological traceability, quality assurance, regulatory compliance | Various internationally recognized producers [15] |

| CRM Databases | COMAR, CNRM | Locating specialized CRMs, identifying alternative sources, accessing certificate information | BAM, Chinese National Sharing Platform [15] |

The integration of appropriate Certified Reference Materials into catalysis research protocols significantly enhances data reliability, facilitates meaningful comparisons between laboratories, and supports the development of robust catalytic technologies. By systematically selecting CRMs based on analytical requirements and following validated experimental protocols, researchers can advance catalytic science with greater confidence in their analytical results. The growing emphasis on sustainable catalysis and critical raw material management further underscores the importance of reliable reference materials in guiding the development of next-generation catalytic systems [16].

For researchers in drug development and catalytic activity studies, Certified Reference Materials (CRMs) are indispensable tools for ensuring measurement validity, regulatory compliance, and scientific reproducibility. CRMs function as metrological anchors, providing a definitive link between laboratory measurements and internationally recognized standards. According to ISO definitions, a CRM is a reference material characterized by a metrologically valid procedure for one or more specified properties, accompanied by a certificate providing the value of the specified property, its associated uncertainty, and a statement of metrological traceability [21]. The credibility of these materials rests upon three foundational pillars: homogeneity, stability, and a certified value with well-defined uncertainty. This guide explores these key properties through an analytical lens, providing a structured comparison for scientific professionals selecting and utilizing CRMs in catalytic activity research.

Defining the Core Properties of CRMs

Homogeneity

Homogeneity refers to the uniformity of the property values across all individual units of a CRM batch. It ensures that any variation between units is negligible compared to the measurement uncertainty, guaranteeing that any single vial used in an experiment is representative of the entire batch. In practice, even carefully prepared materials can exhibit minor variations. The homogeneity study quantifies this between-unit variation, which is then incorporated into the overall uncertainty budget of the certified value [22]. For catalytic activity measurements, using a non-homogeneous CRM could introduce significant bias when comparing results across different laboratories or over time.

Stability

Stability denotes the CRM's ability to maintain its certified property value within specified limits throughout its shelf life under defined storage and handling conditions. Stability is assessed for both long-term storage (shelf life) and short-term transport conditions [1]. Materials can degrade due to chemical, physical, or biological processes, which is why CRMs have a defined validity period and strict storage requirements. For instance, reducing water activity to a level between 0.15 and 0.35 is a common strategy to minimize degradation in many materials [22]. Proper stability assessment protects researchers from drawing erroneous conclusions based on a degraded standard.

Certified Value and Uncertainty

The certified value is the property value—such as the catalytic activity concentration of an enzyme—authorized by the Reference Material Producer (RMP) and stated in the certificate. The accompanying measurement uncertainty is a quantitative parameter that characterizes the dispersion of values that could reasonably be attributed to the measurand [21] [1]. This uncertainty is not a guess; it is a rigorously calculated value that includes contributions from the characterization process, homogeneity assessment, and stability studies [1] [14]. This combined uncertainty provides a range within which the true value is believed to lie with a high level of confidence, which is critical for evaluating the fitness for purpose in high-stakes applications like drug development.

Experimental Protocols for Property Validation

Assessing Homogeneity

The protocol for homogeneity testing is designed to statistically distinguish between-unit variation from the method's inherent random error.

- Experimental Design: A minimum of 10 units are randomly selected from the entire production batch. From each selected unit, a minimum of two samples are analyzed under repeatability conditions (same operator, same instrument, short time interval) [22].

- Measurement Technique: The property of interest (e.g., catalytic concentration) is measured using a high-precision method, typically the primary reference measurement procedure (PRMP) for that analyte. For pancreatic α-amylase, this might be the IFCC reference procedure using a specific substrate like EPS [23].

- Statistical Analysis: Data is analyzed using one-way analysis of variance (ANOVA). The between-unit standard deviation (sbb) is calculated and compared to the method's standard deviation (s). If sbb is not significant compared to s, the material is considered homogeneous. The value of s_bb is then used in the uncertainty budget [22].

Evaluating Stability

Stability is monitored through studies that simulate different environmental conditions over time.

- Short-Term (Transport) Stability: Samples are exposed to elevated temperatures (e.g., 40°C, 60°C) for a period representing potential transit conditions. Measurements are taken before and after exposure and compared using a t-test or regression analysis to detect significant changes [1].

- Long-Term (Shelf-Life) Stability: A set of samples is stored under recommended conditions (e.g., -20°C, protected from light). Another set may be stored under accelerated stress conditions. These samples are periodically measured against a stable control (e.g., samples stored at -70°C) over the intended shelf life. A trend analysis is performed, and if a statistically significant trend is detected, its magnitude is incorporated into the uncertainty budget. The recent extension of certification for the "Japanese diet" CRM to 2035 is a direct result of such ongoing stability testing [24].

Assigning the Certified Value and Uncertainty

The process of value assignment and uncertainty calculation is the core of CRM certification.

- Value Characterization: The property value is determined through one of three metrologically valid procedures: (1) measurements by a single primary method (e.g., isotope dilution mass spectrometry), (2) measurements by two or more independent reference methods, or (3) a network of competent laboratories using validated methods in an interlaboratory comparison, as seen in the certification of ERM-AD457k/IFCC for aspartate transaminase [14].

- Uncertainty Budget Calculation: The combined standard uncertainty (uCRM) is calculated by combining the following components:

- uchar: Uncertainty of the value characterization.

- ubb: Uncertainty from between-unit homogeneity.

- uts: Uncertainty from long-term stability.

- u_ss: Uncertainty from transport stability.

The combined uncertainty is expressed as:

u_CRM = √(u_char² + u_bb² + u_ts² + u_ss²)[1].

Comparative Data and Analysis

The following tables synthesize the quantitative expectations and impacts of the three core properties, providing a clear framework for evaluation.

Table 1: Summary of Key Property Validation for CRMs

| Property | Validation Objective | Key Experimental Metrics | Impact on Certified Uncertainty |

|---|---|---|---|

| Homogeneity | Quantify unit-to-unit variation | Between-unit standard deviation (s_bb), ANOVA F-test | Contributes u_bb; critical for multi-use batches |

| Stability | Verify value persistence over time | Slope from trend analysis, significant change in t-test | Contributes u_ts and u_ss; defines shelf life |

| Certified Value | Establish a traceable reference point | Consensus value from characterization study, e.g., from interlaboratory comparison [14] | Foundation; uncertainty u_char is typically the largest budget component |

Table 2: Consequences of Compromised CRM Properties in Catalytic Research

| Compromised Property | Effect on Catalytic Activity Measurement | Downstream Risk in Drug Development |

|---|---|---|

| Homogeneity | Inconsistent calibration, increased replicate variability | Misclassification of compound potency, flawed structure-activity relationships |

| Stability | Drifting assay baselines, inaccurate sample quantification | Unreliable pharmacokinetic data, failure in bioequivalence studies |

| Certified Uncertainty | Underestimation of measurement error, false precision | Invalid clinical trial results, regulatory compliance issues |

Essential Research Reagent Solutions

The following toolkit outlines critical materials and standards required for rigorous catalytic activity research, emphasizing the role of CRMs.

Table 3: Research Reagent Solutions for Catalytic Activity Studies

| Reagent / Material | Function in Research | Key Consideration |

|---|---|---|

| Enzyme CRMs (e.g., AST, α-amylase) | Calibrate measurement systems; validate primary reference procedures [23] [14] | Must be commutable to prove it behaves like a real patient sample in the assay |

| Primary Reference Measurement Procedure (PRMP) Reagents | Provide the highest-order measurement capability for catalytic activity concentration [23] | Reagent purity and specification (e.g., substrate EPS, BSA) are critical for accuracy |

| Buffer Solutions & Matrix Modifiers | Maintain optimal pH and ionic strength; mimic sample matrix | Essential for ensuring CRM and sample behave identically during analysis |

| Quality Control Materials | Monitor assay performance over time (precision, drift) | Should be independent of the calibration standard to provide unbiased assessment |

Workflow for CRM Certification and Use

The path from production to practical use in the lab involves a rigorous, multi-stage process that integrates assessments of all three key properties, as shown in the following workflow.

CRM Certification and Utilization Workflow

The rigorous assurance of homogeneity, stability, and certified uncertainty elevates Certified Reference Materials from simple consumables to fundamental metrological tools. For scientists comparing catalytic activity against standard reference materials, a deep understanding of these properties is not merely academic—it is a practical necessity for designing robust experiments, interpreting data within its proper context of uncertainty, and ultimately building a reliable foundation for scientific and regulatory decisions. As the market for CRMs continues to grow, driven by stringent quality standards and laboratory accreditation [24], the demand for materials with demonstrably robust properties will only intensify, further cementing their role as the bedrock of trustworthy analytical science.

Standard Reference Materials (SRMs) and Certified Reference Materials (CRMs) are essential tools for validating analytical methods, ensuring measurement traceability, and guaranteeing data comparability across laboratories and international boundaries. For researchers in catalysis and drug development, these materials provide the foundational standards against which novel catalytic materials and processes can be rigorously evaluated. This guide objectively compares the products and capabilities of major CRM producers, focusing on the National Institute of Standards and Technology (NIST) in the United States, the Bundesanstalt für Materialforschung und -prüfung (BAM) in Germany, and other prominent international bodies. By examining their respective portfolios, certification approaches, and specialized applications, this overview provides catalytic activity researchers with critical insights for selecting appropriate reference materials to benchmark their experimental findings.

Comparative Analysis of Major CRM Producers

The table below summarizes the key characteristics, product specialties, and certification approaches of the major CRM producers, with a particular emphasis on materials relevant to catalytic and energy conversion research.

Table 1: Comparison of Major CRM Producers

| Producer | Key Specialties & Product Examples | Typical Certification Process | Relevance to Catalysis & Energy Research |

|---|---|---|---|

| NIST (USA) [25] [20] | - HER2 Genomic DNA for biotherapeutics (SRM 2373)- Environmental matrices (sediments, soils, biological tissues)- Radioactivity standards for environmental monitoring | Characterization through interlaboratory comparisons and definitive methods by expert laboratories [20]. | Provides standards for catalyst precursors, environmental emission monitoring, and validation of analytical methods used in catalyst characterization. |

| BAM (Germany) | Information on BAM was not available in the search results. | Information on BAM was not available in the search results. | Information on BAM was not available in the search results. |

| International Bodies (e.g., IAEA, IRMM) [20] | - IAEA-465 (Baltic Sea Sediment for radionuclides)- IRMM-426 (Wild Berries contaminated by Chernobyl)- Materials from Fukushima contamination studies | Large-scale international intercomparison exercises involving numerous expert laboratories worldwide [20]. | Ensures global comparability of data for environmental catalysis and the study of catalytic processes for environmental remediation. |

Detailed Producer Profiles and Catalytic Applications

National Institute of Standards and Technology (NIST)

NIST operates one of the world's most comprehensive SRM programs, providing materials crucial for quality assurance in pharmaceutical development, environmental monitoring, and advanced materials science.

Catalysis-Relevant Materials and Research Support: While NIST offers a vast catalog of over 1,300 SRMs, its direct offerings in catalytic materials are complemented by research from affiliated institutions. For instance, the Brunelli Group at The Ohio State University, which collaborates within the national research ecosystem, focuses on creating "atomically precise catalysts to enable selective and sustainable catalytic processes," including zeolites and mesoporous materials for converting biomass and CO2 into valuable chemicals [26]. This research alignment underscores the importance of standardized measurements in developing next-generation catalysts.

Certification Methodology: NIST employs a multi-faceted approach to certification. For many chemical and biological SRMs, this involves organizing international interlaboratory comparisons where expert laboratories worldwide analyze candidate materials using validated methods. The certified values are established based on a consensus of these results or through measurements using definitive methods by NIST itself [20]. This process ensures that the SRMs provide a reliable benchmark for validating analytical instruments and methods, including those used to characterize catalytic properties like surface area, metal dispersion, and elemental composition.

International Atomic Energy Agency (IAEA) and Other International Bodies

International organizations play a critical role in producing CRMs for niche applications, particularly those requiring a global consensus, such as tracking environmental radioactivity from nuclear accidents or weapons testing.

Exemplary Materials: The IAEA-465 Baltic Sea Sediment is a CRM certified for its content of anthropogenic radionuclides resulting from Cold War nuclear activities [20]. Similarly, IRMM-426 (from the Institute for Reference Materials and Measurements of the European Commission) is a wild berry material contaminated by the Chernobyl accident [20]. These materials are vital for validating the performance of catalysts designed for environmental remediation of radioactive contaminants.

Certification via Global Collaboration: The hallmark of these international CRMs is their development through extensive international intercomparison exercises [20]. A material is prepared by a recognized institution and distributed to dozens of experienced laboratories globally. Each laboratory employs its own validated procedures—whether gamma spectrometry for direct measurement or complex radioanalytical separations followed by alpha or mass spectrometry for pure alpha/beta emitters [20]. The collective data is statistically evaluated to assign certified values with stated uncertainties, ensuring global acceptance and data comparability.

Experimental Protocols for CRM Use in Catalytic Research

Protocol 1: Validating Analytical Methods for Catalyst Characterization

This protocol outlines the use of CRMs to validate the accuracy of analytical techniques used in characterizing catalytic materials.

- Selection: Choose a CRM with a matrix and analyte(s) similar to your catalyst (e.g., a silica-based CRM for mesoporous catalyst supports, or a metal-on-support CRM for active metal loading analysis).

- Calibration: Use the CRM to calibrate the analytical instrument (e.g., ICP-MS, XRF) according to the certificate's guidance.

- Analysis: Measure the CRM as an unknown sample alongside your catalytic materials using the same standardized procedure.

- Data Comparison: Compare your measured values for the CRM against its certified values. The results should agree within the stated uncertainties.

- Method Validation: If the results agree, the analytical method is considered validated for measuring your catalytic materials. Significant deviations indicate a need for procedural investigation and correction.

Protocol 2: Benchmarking Novel Catalyst Performance

This protocol describes how a CRM can be used as a baseline to benchmark the activity and selectivity of a newly developed catalyst in a specific reaction.

- Identify a Reference Reaction: Select a well-established model reaction relevant to your research, such as CO2 reforming of methane (CRM) over Ni-based catalysts [27].

- Establish a Control: If available, use a commercial catalyst or a well-characterized material as an internal control.

- Conduct Parallel Testing: Perform the catalytic reaction (e.g., CRM) under identical, controlled conditions (temperature, pressure, gas flow rates) for both the novel catalyst and the control.

- Quantify Key Metrics: Measure critical performance indicators such as conversion (%) of reactants (CH4, CO2), selectivity (%) towards desired products (H2, CO), and H2/CO ratio [27].

- Cross-Reference with Literature: Compare your control catalyst's performance data against published studies that may have used similar reference materials or standardized catalysts to contextualize your novel catalyst's performance.

The workflow for benchmarking a new catalyst against a standard, incorporating CRM use, is illustrated below.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table lists key reagents, materials, and instruments critical for conducting rigorous catalytic activity comparisons and CRM-based validation.

Table 2: Essential Research Reagents and Materials for Catalytic Research and Validation

| Item | Function/Application | Relevance to CRM Studies |

|---|---|---|

| Natural Matrix CRMs (e.g., Sediments, Soils) [20] | Method validation for analyzing catalyst precursors or environmental samples post-reaction. | Provides a known quantity of specific analytes (e.g., metals) to ensure analytical accuracy from sample digestion to final measurement. |

| Zeolite & Mesoporous Silica Materials [26] | High-surface-area supports for creating uniform, active catalytic sites. | Serve as model systems or benchmark materials for comparing the performance of newly synthesized porous catalysts. |

| Ni-Based Catalyst Precursors [27] | Active, non-noble metal components for CO2 reforming of methane (CRM) and other reactions. | Used as a baseline control material when benchmarking novel, more coke-resistant Ni-based catalysts. |

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) | Ultra-sensitive elemental analysis and quantification. | The primary technique for verifying the elemental composition of catalysts and CRMs, requiring validation with matrix-matched CRMs. |

| Gas Chromatography (GC) System | Separation and quantification of gas-phase reaction products (e.g., syngas from CRM). | Essential for determining catalyst selectivity and conversion during performance benchmarking. |

NIST and international bodies like the IAEA provide indispensable CRMs that form the bedrock of reliable measurement science in catalytic research. While NIST offers a wide array of materials certified through rigorous interlaboratory studies and definitive methods, international producers facilitate global data comparability, especially for environmental monitoring. For researchers measuring catalytic activity, the strategic use of these materials is not merely a procedural step but a critical practice that lends credibility, reproducibility, and international acceptance to their findings. Integrating CRMs into experimental workflows—from method validation to performance benchmarking—ensures that new discoveries in catalyst design are supported by data that is both accurate and traceable to international standards.

Methodological Guide: Applying CRMs to Catalytic Activity Testing and Calibration

In the field of catalytic research, selecting the appropriate catalyst is paramount for optimizing reaction efficiency and ensuring process sustainability. For the Carbon Dioxide Reforming of Methane (CRM)—a critical reaction for converting greenhouse gases into valuable syngas—this selection process is particularly complex. Researchers must navigate a landscape of diverse catalyst materials, each with distinct performance characteristics, stabilities, and affinities for specific reaction conditions. This guide provides an objective comparison of modern CRM catalysts, framing their performance against established material standards and providing the experimental protocols necessary for their evaluation. The aim is to equip scientists and development professionals with a structured framework for selecting the optimal catalytic material tailored to their specific CRM application and reactor matrix.

Performance Comparison of CRM Catalysts

The catalytic performance in CRM is influenced by a triad of factors: the active metal, the support material, and any promotional additives. The following tables summarize key performance metrics for various catalyst formulations, providing a basis for direct comparison.

Table 1: Performance of Ni-Based Catalysts with Different Supports and Promoters

| Catalyst Formulation | Support/Promoter Role | Experimental Temperature (°C) | CH4 Conversion (%) | Stability & Coke Resistance | Key Findings |

|---|---|---|---|---|---|

| Ni/CeO2–Al2O3/SiC Foam [28] | SiC foam: High thermal conductivity & mechanical strength. CeO2: Alkaline promoter, provides oxygen species [28]. | Not Specified | 68-70% | High; Prepared catalyst showed good stability [28]. | Achieved a thermochemical energy storage efficiency of 31.4% in a solar cavity reactor [28]. |

| Ni@SiO2@CeO2 [28] | Core-shell structure; CeO2 coating enhances activity and reduces coke [28]. | Not Specified | Performance improved 1.5x | Carbon deposition reduced by half [28]. | The core-shell design effectively limits sintering and carbon formation. |

| Ni/Ce0.9Gd0.1O2−δ [29] | Gd doping enhances Ni dispersion, reducibility, and oxygen storage capacity (OSC) [29]. | 240-300 (for MSR) | Highest in comparative test [29] | Excellent hydrothermal stability; low CO selectivity [29]. | Optimal Gd doping level creates a balance of redox properties and metal dispersion. |

| Ni-Mn-Cu/Al2Ox Spinel [29] | Mn doping enriches Mn3+ species, promotes oxygen vacancy formation [29]. | 240-300 (for MSR) | High (Mn2Cu2Al4Ox sample) | Low CO selectivity; excellent stability over 24h [29]. | Mn/Cu ratio optimizes redox properties and suppresses CO formation. |

| Ni/CeO2 [28] | CeO2 support with unique redox properties [28]. | Not Specified | Not Specified | Carbon formation increases with Ni crystal size, max at 20-30 nm [28]. | Highlights the critical need to control Ni particle size to mitigate deactivation. |

Table 2: Comparison of Noble Metal vs. Non-Noble Metal Catalysts for CRM

| Catalyst Type | Example | Advantages | Disadvantages & Deactivation Mechanisms |

|---|---|---|---|

| Noble Metal [27] | Rh, Ru, Pt, Pd | High catalytic activity, excellent stability, and superior anti-coking performance [27]. | High cost and scarce resources limit large-scale industrial application [28] [27]. |

| Non-Noble Metal (Ni-Based) [28] [27] | Ni on various supports (Al2O3, CeO2, SiC) | High activity comparable to noble metals; low cost and abundant reserves [28] [27]. | Susceptible to rapid deactivation from carbon deposition and thermal sintering of Ni particles [28] [27]. |

Essential Research Reagent Solutions

The experimental study of CRM catalysts requires a specific toolkit of materials and reagents. The following table details key components and their functions in the preparation and testing of these materials.

Table 3: Key Research Reagents and Materials for CRM Catalyst Studies

| Reagent/Material | Function in CRM Catalyst Research | Specific Example |

|---|---|---|

| SiC Foam [28] | Used as a structured catalyst support. Its high thermal conductivity and mechanical strength help achieve more uniform temperature distribution in the reactor [28]. | 30 ppi (pores per linear inch), 10 mm thickness [28]. |

| Cerium Oxide (CeO2) [28] | An alkaline promoter with unique redox properties and high active oxygen species, which can help gasify carbon deposits and enhance stability [28]. | Used in Ni/CeO2–Al2O3/SiC-foam catalyst [28]. |

| Pseudo-boehmite [28] | A precursor used to create a γ-Al2O3 layer on a support, which provides a high-surface-area anchor for active metal particles [28]. | Used to prepare AlOOH sol for impregnating SiC foam [28]. |

| Metal Nitrates [28] | Common precursors for depositing active metals (e.g., Ni) and promoters (e.g., Ce) onto catalyst supports via impregnation methods. | Ni(NO3)2·6H2O and Ce(NO3)3·6H2O [28]. |

| Ordered Mesoporous Silica [27] | Used as a catalyst support (e.g., SBA-16) for nano Nickel, providing high specific surface area and porosity to enhance catalytic performance [27]. | SBA-16 as a carrier for nano Nickel [28]. |

Experimental Protocols for Catalyst Evaluation

To ensure consistent and comparable results, researchers must adhere to standardized experimental protocols. The following sections detail key methodologies for preparing and evaluating CRM catalysts.

Catalyst Preparation Protocol: Impregnation of SiC Foam

The preparation of a structured Ni/CeO2–Al2O3/SiC-foam catalyst, as described in the search results, involves a multi-step impregnation process [28].

Workflow: Catalyst Preparation via Impregnation

Detailed Procedure:

- Support Pre-treatment: The starting material, SiC-foam (e.g., 30 ppi density, 10 mm thickness), is first calcined in air at 1000 °C for 2 hours to ensure thermal stability and remove impurities [28].

- Washcoating: The calcined SiC-foam is repeatedly impregnated with an AlOOH sol, which is prepared from pseudo-boehmite and nitric acid. After each impregnation, the sample is dried and then calcined at 800 °C to form a γ-Al2O3 layer on the foam structure [28].

- Active Metal Loading: The γ-Al2O3/SiC foam is then impregnated with an aqueous solution containing Ni(NO3)2·6H2O and Ce(NO3)3·6H2O.

- Final Processing: The impregnated foam is dried and subsequently calcined at 750 °C to decompose the nitrates and form the final active catalyst, now containing NiO and CeO2 [28].

- Characterization: The final catalyst should be characterized using techniques like X-ray diffraction (XRD) and scanning electron microscopy (SEM) to confirm morphology, structure, and successful loading of active components [28].

Catalytic Activity Testing Protocol

Testing the performance of a prepared CRM catalyst involves measuring its activity and stability under controlled reaction conditions.

Workflow: Catalytic Activity Testing

Detailed Procedure:

- Reactor System: The reaction is typically carried out in a fixed-bed or cavity reactor system. The catalyst is loaded into the reactor, and the system is checked for leaks [28].

- Catalyst Activation: Prior to the reaction, the catalyst is often reduced in situ with a hydrogen stream at high temperature (e.g., 750 °C) to convert the metal oxides (NiO) into active metallic sites (Ni⁰) [28].

- Setting Conditions: The reactor temperature is set to the desired level (CRM is typically conducted above 640 °C). The flow rates of the reactant gases (CH4 and CO2) are controlled using mass flow controllers to achieve a specific gas hourly space velocity (GHSV) and mole ratio [28].

- Reaction and Analysis: The reactant mixture is introduced to the reactor. The effluent gas stream is analyzed using online gas chromatography (GC) to determine the composition (H2, CO, CH4, CO2) and calculate conversion rates and product ratios [28].

- Stability Testing: The catalyst is tested under continuous operation for an extended period (e.g., 24 hours or more) to assess its stability and resistance to deactivation. The conversion rates and product yields are monitored over time [29].

The selection of a CRM catalyst is a deliberate process of matching material properties to the target reaction environment. While noble metals offer robust performance, advanced Ni-based catalysts on engineered supports like SiC foam or doped cerium oxides present a highly effective and commercially viable alternative. The critical factors for success are the careful control of Ni particle size to minimize sintering, the use of promoters and supports that provide mobile oxygen to combat coke formation, and the integration of the catalyst into a matrix that ensures efficient heat and mass transfer. By leveraging the standardized comparison data and experimental protocols outlined in this guide, researchers can make informed decisions to drive innovation in catalytic science and the sustainable conversion of greenhouse gases.

The development of new catalytic materials necessitates rigorous and standardized comparison against established references to contextualize performance claims. Benchmarking provides an external standard for evaluating quantifiable observables, helping researchers determine if a newly synthesized catalyst is genuinely more active than its predecessors or if a reported turnover rate is free from corrupting influences like diffusional limitations [30]. Without such standardized practices, the field risks encountering irreproducible results and inefficiencies in technology development. This guide outlines the established best practices for the experimental design of catalytic activity comparisons, providing a framework for researchers to generate reliable, comparable, and scientifically valid performance data.

The core challenge in catalysis research lies in moving beyond simple activity reports toward generating data that enables meaningful cross-comparison between different studies and laboratories [30]. A well-designed experiment must not only measure activity but also account for numerous variables that can influence the observed rate, including catalyst deactivation, heat and mass transfer limitations, and thermodynamic constraints [30]. By adopting a community-wide benchmarking approach, researchers can dramatically accelerate the development of more efficient catalytic processes for applications ranging from pharmaceutical synthesis to environmental protection.

Fundamental Principles of Experimental Design

The Role of Reference Catalysts

The first step in creating a reliable catalysis benchmark involves access to well-characterized and abundantly available catalysts [30]. These reference materials can be sourced from commercial vendors (e.g., Zeolyst, Sigma Aldrich), research consortia, or through reliable synthesis protocols that individual researchers can reproduce [30]. Historically, efforts like the Johnson-Matthey EuroPt-1, EUROCAT's EuroNi-1, and the World Gold Council's standard gold catalysts have served this purpose [30].

When selecting a reference catalyst, consider its relevance to your catalytic system and its well-documented performance across multiple laboratories. The use of common reference materials allows for direct comparison of new catalytic materials against an established standard, providing crucial context for the significance of reported performance improvements. For instance, in studies of Pd-based catalysts for Suzuki cross-coupling reactions, researchers often compare new catalyst formulations against established Pd on carbon (Pd/C) catalysts or other well-characterized supported Pd nanoparticles [31].

Controlling Experimental Variables

Precise control and reporting of experimental conditions are fundamental to obtaining reproducible catalytic activity data. Key variables that must be carefully controlled and documented include:

- Temperature: Both the reaction temperature and the method of temperature control should be specified. Many catalytic reactions exhibit Arrhenius-type behavior, where small temperature variations can significantly impact reaction rates [32].

- Pressure: For reactions involving gases, pressure must be carefully controlled and monitored. Studies have shown that hydrogen pressure significantly influences reaction rates in hydrogenation catalysis [32].

- Catalyst Loading: The mass or molar percentage of catalyst used in the reaction should be precisely reported, as this directly affects the observed reaction rate and turnover frequency [32].

- Reaction Time: The temporal profile of the reaction should be documented, as many catalysts deactivate over time [30].

- Mass Transfer Limitations: Experiments should be designed to ensure that the measured kinetics are free from mass transfer limitations. This can be verified by demonstrating that the reaction rate is independent of stirring speed and catalyst particle size [30].

Table 1: Key Experimental Variables to Control and Report in Catalytic Activity Studies

| Variable Category | Specific Parameters | Impact on Activity |

|---|---|---|

| Reaction Conditions | Temperature, Pressure, Time | Directly affects reaction kinetics and thermodynamics |

| Catalyst Properties | Loading, Particle Size, Dispersion | Influences active site availability and accessibility |

| Reactant Composition | Concentration, Solvent, Additives | Can modify reaction pathways and rates |

| System Parameters | Stirring Speed, Reactor Geometry | Affects mass and heat transfer limitations |

Standardized Testing Methodologies

Catalyst Characterization Protocols

Comprehensive characterization of catalyst materials before and after reactions is essential for meaningful activity comparisons. The structural evolution of catalysts during synthesis and under reaction conditions must be analyzed using multiple characterization techniques [33]. Standard characterization should include:

- Structural Analysis: X-ray diffraction (XRD) reveals information about the crystalline structure, phase composition, and crystallite size of catalytic materials [34] [33].

- Morphological Examination: Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide insights into the catalyst's morphology, particle size distribution, and structural features [34] [33]. High-resolution techniques like HAADF-STEM are particularly valuable for confirming atomic dispersion in single-atom catalysts [33].

- Surface Composition: X-ray photoelectron spectroscopy (XPS) determines the elemental composition and chemical states of surfaces [34] [33].

- Coordination Environment: X-ray absorption spectroscopy (XAS), including both XANES and EXAFS, provides detailed information about the local coordination environment of metal centers, which is crucial for understanding structure-activity relationships [33].