Computational Fluid Dynamics in CO2 Electrolysis: Advanced CFD Models for Mass Transfer Optimization and Reactor Design

This article provides a comprehensive guide to applying Computational Fluid Dynamics (CFD) for enhancing mass transfer in CO2 electrolyzers, critical for improving product selectivity and conversion rates.

Computational Fluid Dynamics in CO2 Electrolysis: Advanced CFD Models for Mass Transfer Optimization and Reactor Design

Abstract

This article provides a comprehensive guide to applying Computational Fluid Dynamics (CFD) for enhancing mass transfer in CO2 electrolyzers, critical for improving product selectivity and conversion rates. Targeted at researchers, scientists, and process engineers, we explore foundational multiphysics principles, methodological approaches for simulating gas-liquid-solid interfaces, strategies for troubleshooting common reactor inefficiencies, and frameworks for validating models against experimental data. The review synthesizes current methodologies to bridge the gap between simulation and practical reactor optimization for sustainable chemical synthesis and energy applications.

Understanding the Core Challenge: Why Mass Transfer Limits CO2 Electrolyzer Performance

The performance of CO2 electrolyzers is fundamentally constrained by the mass transfer of CO2 from the gas phase to the catalytic active sites. This bottleneck manifests in three interrelated physical phenomena: the solubility of CO2 in the electrolyte, the diffusion rate of dissolved CO2 through the electrode and boundary layers, and the intrinsic reaction kinetics at the catalyst surface. Computational Fluid Dynamics (CFD) simulation is a critical tool for decoupling and analyzing these factors to design systems with enhanced mass transfer, ultimately leading to higher current densities, selectivities, and energy efficiencies.

Quantitative Data on CO2 Transport & Kinetics

Table 1: Key Physical Properties Governing CO2 Availability

| Property | Typical Value (Aqueous, ~1M KOH/KHCO3) | Conditions (Temp, Pressure) | Impact on Bottleneck |

|---|---|---|---|

| CO2 Solubility | ~0.03 – 0.04 mol/L | 25°C, 1 atm CO2 | Low solubility limits maximum dissolved CO2 concentration (C*). |

| Diffusion Coefficient (D_CO2) | ~1.8 – 2.0 × 10⁻⁹ m²/s | 25°C, aqueous solution | Governs rate of transport through stagnant boundary layers. |

| Diffusivity in Gas Diffusion Layer (GDL) | ~0.01 – 0.1 × 10⁻⁹ m²/s | Effective, in porous media | Severe reduction vs. bulk; depends on porosity & tortuosity. |

| Typical Boundary Layer Thickness (δ) | 10 – 100 µm | Varies with flow geometry/rate | Key parameter for concentration gradient (ΔC/δ). |

| Henry's Law Constant (k_H) | ~30 – 35 mol/(L·bar) | 25°C for CO2 in water | Describes gas-liquid partitioning. |

Table 2: Reaction Kinetics & Performance Metrics

| Parameter | Typical Range | Measurement Method | Notes |

|---|---|---|---|

| Exchange Current Density (j₀) | 10⁻⁵ – 10⁻³ A/cm² | Tafel analysis | Intrinsic catalyst activity for CO2 reduction. |

| Limiting Current Density (j_L) | 10 – 200 mA/cm² | Linear Sweep Voltammetry | Mass-transfer-limited current, function of C* and δ. |

| Tafel Slope for CO formation | 120 – 140 mV/dec | Potentiostatic steady-state | Indicates rate-determining step (e.g., first electron transfer). |

| Faradaic Efficiency for C₂₊ | 50 – 85% | GC/NMR product analysis | Performance indicator; drops sharply at high current due to CO2 starvation. |

Application Notes & Protocols

Protocol: Experimental Determination of CO2 Mass Transfer Coefficient (kₘ)

Objective: Quantify the CO2 transport rate to the electrode surface under operational conditions.

Materials & Equipment:

- H-cell or flow electrolyzer with reference electrode.

- Potentiostat/Galvanostat.

- Ag/AgCl or Hg/HgO reference electrode.

- CO2-saturated electrolyte (e.g., 0.1M KHCO3).

- Inert gas (Ar or N2) supply.

- Gas Chromatograph (for verification).

Procedure:

- System Preparation: Fill the electrochemical cell with CO2-saturated electrolyte. Ensure a constant CO2 purge over the electrolyte to maintain saturation.

- Reduction of Non-reactive Species: Switch the electrolyte to one containing a non-reactive, fast-reducing species with known concentration and diffusivity (e.g., 5mM K₃Fe(CN)₆ in 1M KCl). Saturate with N2.

- Limiting Current Measurement: Perform a linear sweep voltammetry (LSV) scan from open circuit potential to a sufficiently negative potential where the reduction current plateaus (limiting current, i_lim,ref). Scan rate: 5-10 mV/s.

- Calculation of kₘ: For the well-known redox couple, the mass transfer coefficient is calculated: kₘ,ref = i_lim,ref / (nFAc_ref), where c_ref is bulk concentration.

- Estimation for CO2: Assuming similar hydrodynamic conditions, estimate kₘ,CO₂ using the ratio of diffusion coefficients: kₘ,CO₂ ≈ kₘ,ref * (D_CO₂ / D_ref)^(2/3).

- Validation: Perform LSV in CO2-saturated electrolyte at high overpotential to approximate the CO2 reduction limiting current. Compare with calculated value: i_lim,CO₂ ≈ nFA kₘ,CO₂ c_CO₂*.

Protocol: CFD Simulation Workflow for Mass Transfer Analysis

Objective: Develop a multiphysics CFD model to visualize concentration gradients and identify transport bottlenecks.

Workflow Steps:

- Geometry & Mesh Creation: Use CAD software to create a 2D or 3D model of the electrolyzer flow channel, Gas Diffusion Electrode (GDE), and catalyst layer. Generate a structured mesh with refinement at critical boundaries (GDE/electrolyte interface).

- Physics Setup:

- Fluid Flow: Define inlet flow rate, electrolyte properties (density, viscosity).

- Species Transport: Input dissolved CO2 concentration at the GDE/flow channel interface (from solubility). Set diffusion coefficients for all species (CO2, OH⁻, products).

- Electrochemical Reactions: Apply boundary conditions at the catalyst layer. Use Butler-Volmer kinetics with user-defined parameters (j₀, α, equilibrium potential) or a fixed current density boundary.

- Solver Settings: Use a steady-state, pressure-based solver. Employ coupled schemes for stability.

- Simulation & Analysis: Solve for velocity, pressure, and species concentration fields. Post-process to extract:

- CO2 concentration profile across the GDE and boundary layer.

- Local current density distribution.

- Identification of regions where CO2 concentration approaches zero (severe mass transfer limitation).

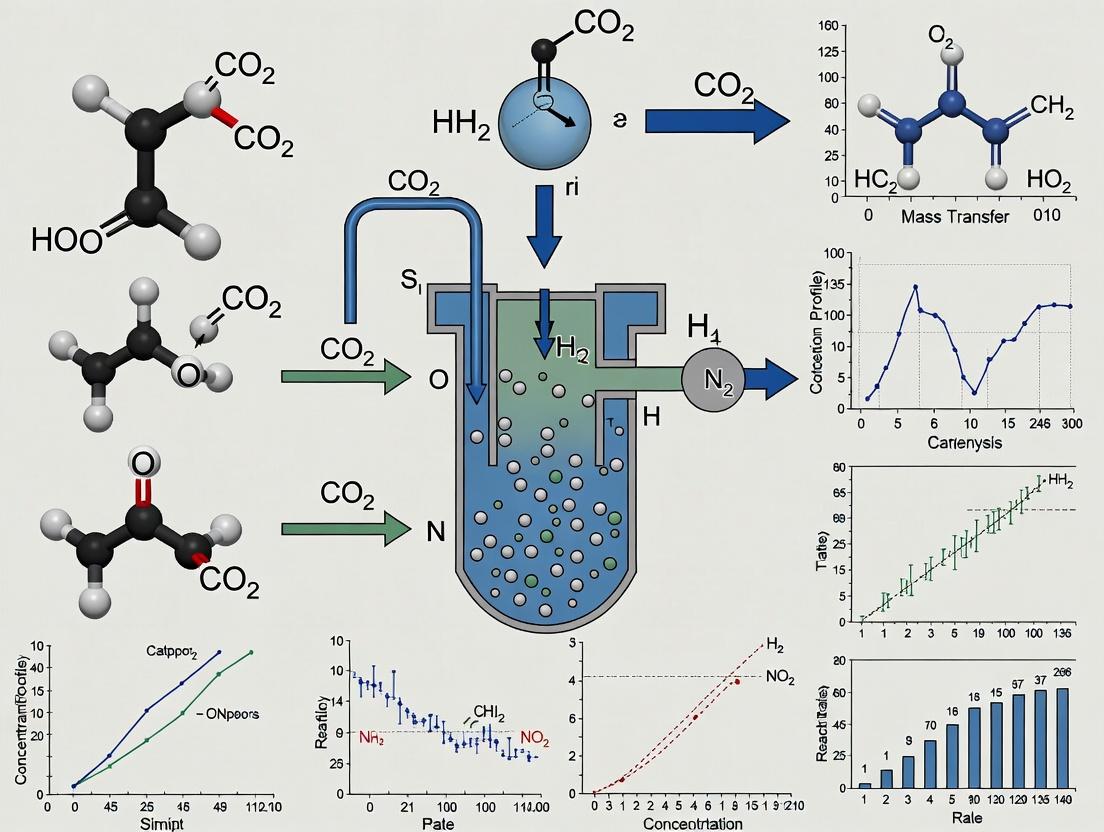

Visualization of Concepts and Workflows

Diagram 1: The sequential bottlenecks in CO2 electrolysis.

Diagram 2: CFD simulation workflow for mass transfer analysis.

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for CO2 Electrolysis Mass Transfer Studies

| Item | Function/Application | Key Considerations |

|---|---|---|

| Gas Diffusion Electrode (GDE) | Porous electrode enabling triphase (gas/electrolyte/catalyst) contact. | Hydrophobicity (PTFE content), microporous layer, catalyst integration method. |

| Ion-Exchange Membrane (Nafion, Sustainion) | Separates anode and cathode, conducts ions, prevents product crossover. | Selectivity (cation/anion), chemical stability, gas permeability. |

| 0.1M - 1M KHCO3 Electrolyte | Common aqueous electrolyte; bicarbonate acts as a local pH buffer and CO2 reservoir. | pH affects selectivity; concentration influences conductivity and CO2 solubility. |

| Standard Redox Couple (K₃[Fe(CN)₆]/K₄[Fe(CN)₆]) | Used for electrochemical active surface area (ECSA) and mass transfer calibration. | Well-defined, fast kinetics; use with supporting electrolyte (e.g., KCl). |

| Micro-reference Electrode (Ag/AgCl) | Provides stable, accurate potential measurement in small electrochemical cells. | Requires proper filling solution and frit maintenance. |

| Polytetrafluoroethylene (PTFE) Binder | Used in catalyst ink formulation to create hydrophobic pathways in the catalyst layer. | Ratio impacts hydrophobicity, catalyst adhesion, and mass transfer. |

| Porous Carbon Substrates (Sigracet, Freudenberg) | Commercial GDL substrates for constructing custom GDEs. | Variants differ in thickness, porosity, and hydrophobic treatment. |

Within the broader thesis on Computational Fluid Dynamics (CFD) simulation for mass transfer enhancement in CO₂ electrolyzers, the liquid-phase mass transfer coefficient (kL) is a critical parameter. It governs the rate at which reactants (e.g., CO₂) are transported from the bulk electrolyte to the electrode surface, directly limiting the achievable current density in diffusion-controlled regimes. This application note details the quantification of kL, its role in electrochemical performance, and protocols for its experimental determination, with a focus on applications in CO₂ reduction reaction (CO2RR) systems.

Core Principles and Quantitative Data

The limiting current density (ilim) for a reactant is defined by: ilim = n F kL Cb where n is the number of electrons, F is Faraday's constant, and Cb is the bulk concentration.

Table 1: Typical Mass Transfer Coefficients and Resulting Limiting Currents in Electrochemical Reactors

| Reactor Type | Typical kL Range (m/s) | Example Electrolyte | Calculated ilim for CO₂ (A/m²)* | Key Determining Factors |

|---|---|---|---|---|

| Planar Electrode (Stagnant) | 10⁻⁶ - 10⁻⁵ | 0.1M KHCO₃ | 0.4 - 4 | Natural convection, cell geometry |

| Rotating Disk Electrode (RDE) | 10⁻⁵ - 10⁻⁴ | 0.1M KHCO₃ | 4 - 40 | Rotation speed (ω), kinematic viscosity (ν) |

| Flow Cell (Channel Flow) | 10⁻⁵ - 10⁻³ | 1M KOH | 40 - 4000 | Flow velocity, channel height, diffusion layer |

| Gas Diffusion Electrode (GDE) | 10⁻³ - 10⁻² | AEM / CEM | 400 - 4000 | Porous structure, pressure, wetting |

Calculation assumes n=2, Cb≈0.03M for dissolved CO₂ (approx. saturation).

Table 2: Impact of Enhanced Mass Transfer on CO2RR Performance Metrics

| Enhanced kL Method | Reported kL (m/s) | Current Density Increase (%) (vs. baseline) | Effect on Faradaic Efficiency (FE) for C₂₊ Products | Reference Year |

|---|---|---|---|---|

| Pulsed Electrolysis | 2.1 x 10⁻⁴ | ~150% | Increased FE by ~20% | 2023 |

| Microstructured Electrodes | 5.8 x 10⁻⁴ | ~300% | Promoted C₂ pathway | 2024 |

| Superhydrophobic GDEs | 3.0 x 10⁻³ | ~600% | Suppressed HER, improved CO FE | 2023 |

| CFD-Optimized Flow Fields | 1.2 x 10⁻³ | ~400% | Enhanced uniformity, raised C₂₊ FE | 2024 |

Experimental Protocols for DeterminingkL

Protocol 3.1: Determination via Limiting Current on a Rotating Disk Electrode (RDE)

Objective: To determine the mass transfer coefficient (kL) using a well-defined hydrodynamic system. Principle: For an RDE, the Levich equation defines the limiting current: ilim = 0.620 n F A D2/3 ω1/2 ν-1/6 Cb, where kL can be derived as kL = ilim / (n F A Cb). Materials: See "Scientist's Toolkit" below. Procedure:

- Electrode Preparation: Polish a 5mm glassy carbon (GC) RDE tip to a mirror finish. Clean ultrasonically in ethanol and DI water.

- Redox System Setup: Prepare a 5 mM solution of potassium ferricyanide (K₃[Fe(CN)₆]) in 1.0 M potassium chloride (KCl) as a supporting electrolyte. Deoxygenate with N₂ for 20 minutes.

- Electrochemical Cell Assembly: Use a standard 3-electrode cell with the GC RDE as the working electrode, Pt wire as the counter electrode, and a saturated calomel electrode (SCE) as the reference.

- Linear Sweep Voltammetry (LSV): a. Set rotation speed to 400 rpm. b. Perform an LSV from +0.6 V to -0.1 V vs. SCE at a scan rate of 10 mV/s. c. Record the steady-state limiting current plateau (ilim).

- Variable Rotation Speed Study: a. Repeat Step 4 at rotation speeds of 400, 900, 1600, and 2500 rpm. b. Plot ilim vs. ω1/2 (Levich plot). The slope is used to verify the system's mass-transfer-controlled behavior.

- Calculation: Calculate kL at each rotation speed using the formula: kL = ilim / (n F A Cb), where n=1 for [Fe(CN)₆]³⁻ reduction, A is electrode area, and Cb is 5 mol/m³.

Protocol 3.2: Determination in a Flow Cell or CO₂ Electrolyzer

Objective: To measure the effective kL for CO₂ reduction in an operational flow electrolyzer. Principle: The limiting current for CO₂ reduction is measured under CO₂-saturated conditions where the reaction is mass-transfer-limited (typically at high overpotentials for CO or formate production). Materials: See "Scientist's Toolkit" below. Procedure:

- Cell Setup: Assemble a flow cell with a known active area Gas Diffusion Electrode (GDE) as the cathode, an anion exchange membrane (AEM), and a suitable anode (e.g., Ni foam).

- Electrolyte Saturation: Circulate 1.0 M KOH catholyte (CO₂-saturated) and anolyte separately. Ensure CO₂ is bubbled through the catholyte reservoir at a constant rate (e.g., 50 sccm) for >30 minutes to achieve saturation.

- Polarization Curve under Mass-Transfer-Limited Conditions: a. Set a constant electrolyte flow rate (e.g., 10 mL/min). b. Perform a slow cathodic potential sweep (e.g., 1 mV/s) from open circuit potential to a very negative potential (e.g., -1.5 V vs. RHE). c. Identify the potential region where the current plateaus, indicating mass transfer limitation (ilim,CO2).

- Calculation: Calculate the effective kL using kL = ilim,CO2 / (n F A Cb,CO2). Here, n is typically 2 (for CO or formate), A is the geometric area, and Cb,CO2 is the solubility of CO₂ in the electrolyte (e.g., ~0.03 M in 1M KOH at 25°C).

- CFD Validation: Use the measured kL and operating conditions (flow rate, geometry) as inputs and validation points for a conjugate mass-transfer CFD simulation of the flow channel.

Visualizations

Diagram 1: Relationship between kL, diffusion, and limiting current.

Diagram 2: CFD-driven research workflow for CO2 electrolyzer design.

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for kL and CO2RR Experiments

| Item | Function & Rationale |

|---|---|

| Rotating Disk Electrode (RDE) | Provides controlled, definable hydrodynamics for fundamental kL measurement via the Levich equation. |

| Potassium Ferricyanide (K₃[Fe(CN)₆]) | A stable, reversible redox couple with well-known diffusion coefficient, used as a standard for kL calibration. |

| Gas Diffusion Electrode (GDE) | Porous electrode that facilitates high kL by delivering gaseous CO₂ directly to the reaction site, avoiding low liquid solubility. |

| Anion Exchange Membrane (AEM) | Separates cathode and anode while allowing hydroxide (OH⁻) transport, critical for maintaining pH in alkaline CO2RR flow cells. |

| 1.0 M Potassium Hydroxide (KOH) Electrolyte | High-concentration alkaline electrolyte enhances CO₂ solubility (via carbonate formation) and reduces kinetic overpotentials. |

| CO₂ Gas (99.999%) with Mass Flow Controller | Provides consistent reactant supply; flow rate is a key variable for kL in flow cells and a CFD simulation input. |

| Potentiostat/Galvanostat with Rotation Control | Essential for performing LSV and chronoamperometry to measure limiting currents under controlled potentials. |

| 3D Printer / CNC Mill | For fabricating CFD-optimized flow field plates and custom cell components to test mass transfer enhancements. |

Within the thesis research on Computational Fluid Dynamics (CFD) for mass transfer enhancement in CO₂ electrolyzers, a multiphysics approach is indispensable. CO₂ reduction reaction (CO2RR) performance is governed by the intricate coupling of fluid dynamics (delivering CO₂ to the catalyst), species transport (of reactants and products), and electrochemistry (kinetics at the electrode surface). Optimizing these coupled phenomena is critical for improving current density, Faradaic efficiency, and product selectivity in next-generation electrolyzers.

Core Multiphysics Coupling Mechanisms

The system is described by a set of interdependent partial differential equations. The primary couplings are:

- Flow-Transport Coupling: The fluid flow field (velocity, pressure) directly advects chemical species. Conversely, local gas composition can affect fluid properties like density and viscosity, especially in gas diffusion electrode (GDE) configurations.

- Transport-Electrochemistry Coupling: Local concentrations of CO₂ and protons at the catalyst surface determine the local reaction rates via Butler-Volmer kinetics. The consumption/production of species creates steep concentration gradients that drive diffusion.

- Electrochemistry-Flow Coupling: Gas evolution reactions (e.g., O₂ at the anode, H₂ at the cathode) can alter local flow patterns and create two-phase flow regimes.

Application Notes: Key Phenomena and Simulation Strategies

Modeling Mass Transport Limitations in GDEs

In a Gas Diffusion Electrode (GDE), CO₂ gas flows through a porous transport layer (PTL) to reach the catalyst layer (CL) dissolved in a liquid electrolyte. The key challenge is resolving the species transport across the gas-liquid interface and through the liquid-filled catalyst layer.

Table 1: Key Transport Parameters and Typical Values in CO2RR GDE Models

| Parameter | Symbol | Typical Range/Value | Notes |

|---|---|---|---|

| CO₂ Diffusivity in Liquid | D_CO₂,l | 1.5 - 2.0 × 10⁻⁹ m²/s | Temperature and electrolyte dependent. |

| KHCO₃ Electrolyte Conc. | C_elec | 0.1 - 1.0 M | Affects conductivity and local pH. |

| Cathodic Kinetic Current Density | j₀ | 10⁻⁴ - 10⁻² A/m² | For common catalysts (e.g., Cu, Ag). |

| Limiting Current Density | j_lim | 10 - 250 mA/cm² | Dictated by CO₂ transport. Target for enhancement. |

| Gas Diffusion Layer Porosity | ε_GDL | 0.6 - 0.8 | Critical for gaseous transport. |

| Catalyst Layer Thickness | δ_CL | 5 - 50 μm | Thinner layers reduce ionic resistance but may limit catalyst loading. |

Protocol: Coupled CFD-Electrochemical Simulation Workflow

This protocol outlines the steps for setting up a transient, 2D/3D multiphysics simulation of a CO2RR flow cell.

A. Pre-processing and Geometry

- Geometry Creation: Draw the computational domain representing the flow channel, porous GDL, catalyst layer, membrane, and anode channel.

- Mesh Generation: Create a boundary-layer refined mesh near the catalyst layer and GDL/Channel interface to capture steep gradients. Target mesh independence.

B. Physics Setup

- Fluid Flow (Navier-Stokes): Activate the Laminar Flow or Turbulent Flow (k-ε) interface for the channel domains. For porous GDL, add a Brinkman Equations or Darcy's Law subnode.

- Species Transport (Maxwell-Stefan): Add a Transport of Diluted Species or Concentrated Species interface. For the GDE, define species (CO₂(aq), OH⁻, HCO₃⁻, CO₃²⁻, H₂, C₂H₄, etc.).

- Electrochemistry: Implement the Secondary Current Distribution or Tertiary Current Distribution interface. In the catalyst layer domain, define the electrode kinetics using a Butler-Volmer equation. For the cathode: [ j = j0 \left( \frac{C{CO₂}}{C{CO₂,ref}} \exp\left(\frac{-\alphac F \eta}{RT}\right) - \exp\left(\frac{\alphaa F \eta}{RT}\right) \right) ] Link the local overpotential (η) and species concentrations (CCO₂) as inputs.

- Couplings: Define the reaction rate in the species transport module as a source/sink term linked to the electrochemical current ((Si = \pm \frac{si j}{nF}), where (s_i) is the stoichiometric coefficient). Ensure the fluid properties are updated based on local composition.

C. Solving and Post-processing

- Solver Configuration: Use a fully coupled, transient solver with adaptive time stepping for stability.

- Post-processing: Extract key performance metrics: local current density distribution, species concentration profiles at the catalyst layer, and overall cell polarization curves.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for CO2RR Experimental Validation of Multiphysics Models

| Item | Function in Research | Example/Specification |

|---|---|---|

| Gas Diffusion Electrode (GDE) | Supports triple-phase boundary for high-rate CO2RR. | Carbon paper or cloth with microporous layer (MPL), coated with catalyst ink (e.g., Cu nanoparticles). |

| Ion-Exchange Membrane | Separates anode and cathode compartments, selectively transports ions (e.g., H⁺, K⁺). | Nafion 117 (proton exchange) or Sustainion (hydroxide exchange). |

| Aqueous Electrolyte | Provides ionic conductivity and defines local pH near catalyst. | 0.1M - 1M Potassium Bicarbonate (KHCO₃), pre-saturated with CO₂. |

| Reference Electrode | Enables accurate measurement of cathode potential vs. a standard. | Ag/AgCl (in 3M KCl) or reversible hydrogen electrode (RHE). |

| Microfluidic Flow Cell | Well-defined geometry for correlating CFD simulations with experimental data. | Polycarbonate or PTFE body with machined flow channels, integrated gaskets. |

| Online Gas Chromatograph (GC) | Quantifies gaseous reaction products (CO, H₂, C₂H₄, etc.) for Faradaic efficiency calculation. | Equipped with TCD and FID detectors, automated sampling loop. |

Visualization of Multiphysics Coupling and Workflow

Title: Multiphysics Coupling in CO2 Electrolyzer Models

Title: CFD-Electrochemistry Simulation Protocol Workflow

Within the broader thesis on Computational Fluid Dynamics (CFD) simulation for mass transfer enhancement in CO2 electrolyzers, reactor geometry is a critical variable. The design dictates the local environment at the catalyst surface, directly influencing key performance metrics like current density, Faradaic efficiency (FE), and stability. This application note details three dominant reactor configurations—Flow Cells, MEAs, and GDEs—providing quantitative comparisons and experimental protocols for their evaluation.

Comparative Analysis of Reactor Geometries

Table 1: Key Performance & Operational Characteristics of CO2 Electrolyzer Geometries

| Parameter | Flow Cell (Aqueous Catholyte) | Membrane Electrode Assembly (MEA) | Gas Diffusion Electrode (GDE) |

|---|---|---|---|

| Typical Current Density (mA/cm²) | 10 - 200 | 100 - 500 | 100 - 1,000+ |

| CO2 Delivery Method | Dissolved in liquid electrolyte | Humidified vapor via gas chamber | Direct gas phase to catalyst |

| Electrolyte Configuration | Liquid catholyte & anolyte | Ionomer in catalyst layer & membrane | Liquid anolyte, gas at cathode |

| Mass Transfer Limitation | High (low CO2 solubility) | Medium (humidification control) | Low (direct gas access) |

| Key Challenge | CO2 solubility & salt precipitation | Water & thermal management | Electrode flooding & salt creep |

| Primary Research Focus | Catalyst screening, mechanism study | System integration, stability | High current operation, product yield |

Table 2: Quantitative Data from Recent Representative Studies (2023-2024)

| Geometry | Catalyst | Key Product | Max FE (%) | Current Density (mA/cm²) | Stability (Hours) | Ref. Year |

|---|---|---|---|---|---|---|

| Flow Cell | Bi-derived catalyst | Formate | 95 | 150 | 50 | 2024 |

| MEA | Cu-N-C / PEM | CO | 85 | 300 | 100 | 2024 |

| GDE | Modified Cu | C2+ (Ethylene) | 65 | 800 | 150 | 2023 |

| GDE | Ag Nanocubes | CO | 92 | 1200 | 80 | 2023 |

Experimental Protocols

Protocol 1: Assembling & Testing a Gas Diffusion Electrode (GDE) Cell

Objective: To evaluate catalyst performance under high current density conditions using a standard 3-electrode GDE configuration.

Materials: Cathode GDE (catalyst coated on PTFE-treated carbon paper), Anode (Pt mesh/Ni foam), Reference electrode (Reversible Hydrogen Electrode, RHE), Anolyte (1 M KOH), Gas-tight electrochemical cell, CO2 mass flow controller, Potentiostat/Galvanostat, Gas chromatography (GC) system.

Procedure:

- Electrode Preparation: Cut the catalyst-coated GDE to the desired geometric area (e.g., 1 cm²). Ensure the catalyst layer faces the electrolyte chamber and the gas diffusion layer (GDL) faces the gas chamber.

- Cell Assembly: Assemble the electrochemical cell with the GDE pressed against a gasket to separate the cathodic gas chamber from the anodic liquid compartment. Secure the anode in the anolyte. Position the RHE reference electrode near the cathode via a Luggin capillary.

- System Purging: Prior to operation, purge the anolyte with inert gas (e.g., Ar) for 30 minutes to remove dissolved oxygen. Simultaneously, purge the cathode gas chamber with high-purity CO2 at a fixed flow rate (e.g., 20 sccm) for 20 minutes.

- Electrochemical Testing: Conduct linear sweep voltammetry (LSV) from open circuit potential (OCP) to more cathodic potentials under CO2 flow. Perform potentiostatic or galvanostatic electrolysis at target potentials/currents for a set duration (e.g., 1 hour).

- Product Analysis: Direct the outlet gas from the cathode chamber to an online GC for analysis of CO, CH4, C2H4, etc., at regular intervals. Use calibrated GC peaks and the known CO2 flow rate to calculate production rates and Faradaic efficiencies.

Protocol 2: Preparing a Membrane Electrode Assembly (MEA)

Objective: To fabricate a catalyst-coated membrane (CCM) for use in a zero-gap MEA electrolyzer.

Materials: Ionomer solution (e.g., Nafion), Catalyst powders (cathode: e.g., Cu, Ag; anode: IrO2), Proton exchange membrane (PEM, e.g., Nafion 115), Isopropyl alcohol (IPA), Deionized water, Ultrasonic spray coater or airbrush.

Procedure:

- Catalyst Ink Formulation:

- Cathode Ink: Weigh catalyst powder and ionomer (target 20-30 wt% ionomer in dry layer). Disperse in a solvent mixture (e.g., IPA/water 4:1). Sonicate in an ice bath for 30-60 minutes to form a homogeneous ink.

- Anode Ink: Repeat with anode catalyst (e.g., IrO2).

- Membrane Preparation: Pre-treat the PEM by boiling in 3% H2O2, DI water, 0.5 M H2SO4, and DI water again (1 hour each). Dry at 60°C.

- Coating (Spray Method): Secure the pretreated membrane on a heated vacuum table (80°C). Use an ultrasonic spray coater to apply the cathode ink onto one side of the membrane to achieve a target catalyst loading (e.g., 2 mg/cm²). Dry thoroughly. Flip and repeat with the anode ink on the opposite side.

- Hot-Pressing: Place the CCM between two pieces of PTFE film. Hot-press at 130°C and 50 kg/cm² for 3 minutes to enhance catalyst-ionomer-membrane adhesion.

- MEA Assembly: The CCM is then assembled between two gas diffusion layers (GDLs) or flow fields in a zero-gap cell fixture for testing.

Diagrams

GDE Cell Testing Workflow

MEA Catalyst Coated Membrane Fabrication

CFD Simulation Parameters by Reactor Geometry

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for CO2 Electrolyzer Research

| Material/Reagent | Primary Function | Critical Specification/Note |

|---|---|---|

| High-Purity CO2 (≥ 99.999%) | Reactant feed gas for reduction. | Must be O2-free to prevent catalyst oxidation. Use in-line filters. |

| Ionomer Solution (e.g., Nafion D521) | Binds catalyst particles, conducts protons/ions within the electrode. | Concentration (e.g., 5 wt%) and ionomer-to-catalyst ratio are critical variables. |

| Gas Diffusion Layer (GDL) | Supports catalyst, transports gas/reactants, removes products. | Hydrophobicity (PTFE content), thickness, and porosity define performance. |

| Proton Exchange Membrane (e.g., Nafion 115) | Separates electrodes, selectively transports ions (H⁺). | Requires pre-treatment (cleaning, protonation) for reproducible performance. |

| Potentiostat/Galcanostat with High Current | Applies precise potential/current and measures electrochemical response. | Must support current ranges >1A for high-current GDE testing. |

| Online Gas Chromatograph (GC) | Quantifies gaseous products (CO, C2H4, CH4, H2). | Requires methanizer for CO/CO2 detection. Calibration with standard gas mixtures is essential. |

| Catalyst Precursors (e.g., Cu(NO3)2, AgNO3) | Synthesis of tailored electrocatalysts. | Metal salt purity impacts catalyst reproducibility and impurity effects. |

| Alkaline Electrolyte (e.g., 1 M KOH) | Common anolyte providing high conductivity and facilitating water oxidation. | High purity (99.99% metals basis) to avoid trace metal contamination. |

Application Notes

Computational Fluid Dynamics (CFD) is an indispensable tool for modeling and optimizing CO₂ electrolyzers, which convert CO₂ into valuable chemicals and fuels. The core physics are captured by coupling the Navier-Stokes equations, species transport, and specialized electrochemical boundary conditions. This framework allows researchers to simulate complex mass, charge, and momentum transport phenomena that dictate device performance, including conversion efficiency, selectivity, and durability.

Key Governing Equations:

The simulation domain is governed by the following set of coupled partial differential equations:

- Navier-Stokes Equations: Describe the conservation of mass and momentum for the fluid (e.g., gas-liquid or liquid electrolyte) flow.

- Continuity: ∇ · (ρu) = 0 (for incompressible flow).

- Momentum: ρ(u · ∇)u = -∇p + ∇ · (μ(∇u + (∇u)^T)) + F (where F can include buoyancy or other body forces).

- Species Transport Equations: Describe the conservation of chemical species, including consumption and generation via electrochemical reactions.

- ∂(ρYi)/∂t + ∇ · (ρuYi) = -∇ · Ji + Ri, where Yi is the mass fraction, Ji is the diffusion flux, and R_i is the volumetric reaction rate.

- Electrochemical Boundary Conditions: Applied at electrode-electrolyte interfaces to model the conversion of species driven by local electrode potential and kinetics.

- Butler-Volmer Equation: Typically defines the current density as a function of overpotential: j = j₀ [exp(αa Fη/RT) - exp(-αc Fη/RT)].

- Species Flux: At the electrode boundary, the flux of a reactant/product is linked to the local current density: Ni = ± (si j)/(nF), where s_i is the stoichiometric coefficient.

Quantitative Data for Common CO₂ Electrolyzer Configurations:

Table 1: Typical Operating Parameters and Performance Metrics for Lab-Scale CO₂ Flow Electrolyzers

| Parameter | Gas Diffusion Electrode (GDE) Cell | H-Cell (Batch) | Membrane Electrode Assembly (MEA) Cell |

|---|---|---|---|

| Current Density (mA/cm²) | 100 - 500 | 10 - 50 | 200 - 1000 |

| CO₂ Single-Pass Conversion (%) | 5 - 30 | N/A (Batch) | 10 - 40 |

| Faradaic Efficiency for C₂+ (%) | 50 - 85 | 20 - 60 | 60 - 90 |

| Operating Temperature (°C) | 20 - 60 | 20 - 25 | 50 - 80 |

| Electrolyte pH | Alkaline (10-13) or Near-Neutral | Near-Neutral | Acidic or Alkaline |

| Characteristic Fluid Velocity (cm/s) | 1 - 10 (flow channel) | ~0 (stagnant) | 1 - 20 (flow fields) |

Table 2: Key Transport Properties for Common Species in Aqueous Electrolyte (25°C, 1M KHCO₃)

| Species | Diffusion Coefficient (×10⁻⁵ cm²/s) | Henry's Law Constant (M/bar) at 25°C | Typical Bulk Concentration (mol/m³) |

|---|---|---|---|

| CO₂ (aq) | 1.91 | 0.033 | 10 - 30 |

| HCO₃⁻ | 1.18 | N/A | 100 - 1000 |

| OH⁻ | 5.27 | N/A | 0.01 - 10 |

| K⁺ | 1.96 | N/A | 1000 |

| H₂ (g) | 5.13 (in H₂O) | 0.00078 | Product |

Experimental Protocols

Protocol 1: Setting Up a Baseline CFD Simulation for a CO₂ Flow Electrolyzer

Objective: To create a steady-state, isothermal 3D model of a flow channel adjacent to a Gas Diffusion Electrode (GDE) for CO₂ reduction to CO.

Materials & Software:

- Commercial (e.g., ANSYS Fluent, COMSOL Multiphysics) or open-source (OpenFOAM) CFD software.

- Geometry file (.stp, .igs) of the flow channel and GDE.

- Electrochemical parameters (exchange current density, transfer coefficients) from literature or experiment.

- Transport property database for species.

Procedure:

- Pre-processing & Meshing:

- Import the geometry. The domain should include the fluid flow channel and a thin porous electrode layer representing the GDE.

- Generate a computational mesh. Apply boundary layer refinement at the GDE surface to resolve steep concentration gradients. Aim for a mesh-independent solution (perform a mesh sensitivity study).

- Physics Setup:

- Solver: Select a pressure-based, steady-state solver.

- Models: Activate Laminar Flow (or k-ω SST for turbulent cases), Species Transport, and Electrochemistry modules.

- Materials: Define the fluid mixture (e.g., CO₂-saturated aqueous electrolyte). Input density, viscosity, and species diffusion coefficients from Table 2.

- Boundary Conditions:

- Inlet: Specify velocity/mass flow rate and species mass fractions.

- Outlet: Pressure-outlet.

- Channel Walls: No-slip wall.

- GDE Surface (Electrode): Apply a "Wall Reaction" or "User-Defined Function" boundary condition. a. Link the local species flux (e.g., for CO₂) to the current density via the Butler-Volmer equation: NCO₂ = - (j)/(nF). b. Define j = j₀ref * (CCO₂/CCO₂ref)^γ * [exp(αa Fη/RT) - exp(-αc Fη/RT)]. c. Set η = (φsolid - φelectrolyte) - Eeq, where φsolid is the applied electrode potential (fixed) and φelectrolyte is the local electrolyte potential (solved).

- Solution & Post-processing:

- Initialize and run the simulation until residuals converge (typically < 1e-6).

- Extract key results: current density distribution, CO₂ concentration profile along the GDE, outlet species concentrations, and overall conversion rate.

- Validate the model by comparing the simulated total current and outlet conversion to experimental data for a similar system.

Protocol 2: Simulating Transient Species Transport During Electrolyzer Startup

Objective: To model the time-dependent evolution of pH and intermediate species concentrations within the cathode diffusion layer.

Procedure:

- Modify Protocol 1 by switching the solver to Transient.

- At t=0, initialize the domain with a uniform bulk electrolyte composition (e.g., 1M KHCO₃, pH ~8).

- At the GDE boundary, implement additional reacting species (e.g., HCO₃⁻, OH⁻, CO) alongside CO₂. Include homogeneous reactions in the electrolyte bulk (e.g., CO₂ + OH⁻ ⇌ HCO₃⁻) as source terms in the species transport equations.

- Set a time step based on the characteristic diffusion time (Δx²/D) and solve.

- Monitor the local pH (calculated from OH⁻ and H⁺ concentration) near the electrode surface over time to identify regions prone to carbonate precipitation or HER competition.

Visualizations

Title: Coupled Physics Framework for CO2 Electrolyzer CFD

Title: CFD Simulation Workflow for an Electrolyzer

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for CO2 Electrolyzer CFD Modeling

| Item | Function in CFD Context |

|---|---|

| Electrolyte Property Database | Source for accurate density, viscosity, and species diffusivity as functions of temperature, concentration, and composition. Critical for realistic transport. |

| Electrochemical Kinetics Parameters | Experimentally measured or literature-derived exchange current density (j₀), transfer coefficients (α), and reaction orders (γ). These define the electrode boundary condition. |

| Micro-CT or SEM Image Data | Provides real porous electrode morphology (GDE, catalyst layer) for reconstructing realistic 3D geometries or informing effective transport properties (porosity, tortuosity). |

| Validated Reference Case (Literature) | A published experimental dataset (e.g., polarization curve, species conversion) for a specific cell geometry. Used to calibrate and validate the initial CFD model. |

| High-Performance Computing (HPC) Cluster | Necessary for solving large, transient, or 3D coupled problems with multiple species and reactions in a reasonable time. |

| Post-processing & Data Visualization Software | Tools (e.g., ParaView, MATLAB, Python/Matplotlib) to analyze complex 3D field data, extract averages/integrals, and create insightful plots and contours. |

Building Your Simulation: A Step-by-Step CFD Methodology for CO2 Electrolyzer Modeling

Geometry Creation and Meshing Strategies for Complex Electrode Structures

This document provides application notes and protocols for the generation of computational geometry and mesh for complex electrode structures, a critical step in the computational fluid dynamics (CFD) simulation of mass transfer in CO2 electrolyzers. The efficiency of these devices hinges on the intricate balance between electrochemical reactions and the transport of gaseous CO2, liquid electrolytes, and products. Realistic simulation of mass transfer enhancement mechanisms—such as those promoted by 3D porous electrodes, gas diffusion electrodes (GDEs), and structured flow fields—requires high-fidelity digital representations of these complex geometries. The strategies outlined herein are foundational to a broader thesis aimed at optimizing CO2 electrolyzer design through predictive CFD modeling.

Core Principles of Geometry Handling for Electrodes

Complex electrode structures present unique challenges: multi-scale features (from micrometer pores to millimeter channels), intricate porosity, and often stochastic or periodic arrangements. The core principles for geometry creation are:

- Feature Abstraction: Capturing the defining morphological characteristics critical for transport (tortuosity, pore size distribution, specific surface area) without modeling every physical imperfection.

- Scale Bridging: Employing representative elementary volumes (REVs) or porous media approximations to link micro-scale phenomena to device-scale performance.

- Watertight CAD: Ensuring geometric models are manifold (no gaps, overlaps, or self-intersections) to enable robust meshing.

Detailed Protocols for Geometry Generation

Protocol 3.1: Stochastic Reconstruction of Porous Electrodes

- Objective: Generate a 3D digital twin of a stochastic porous electrode (e.g., sintered particles, foam) based on experimental characterization data.

- Materials & Software:

- X-ray micro-computed tomography (µCT) scan data OR statistical descriptors (mean particle size, distribution, porosity).

- Image processing software (e.g., ImageJ, Dragonfly).

- Stochastic reconstruction code (e.g., QSGS, OpenPNM) or commercial software (GeoDict, Simpleware).

- Methodology:

- Data Input: If using µCT, import DICOM stack. Perform filtering (non-local means, median) and segmentation (Otsu, watershed) to binarize into solid and void phases.

- Alternative Statistical Input: If using statistical descriptors, define the volume domain and target porosity (φ).

- Reconstruction: For particle-based electrodes, use a random close-packing algorithm with Gaussian size distribution. For foams, use a Voronoi tessellation-based model followed by strut deposition.

- Validation: Calculate the effective porosity and pore size distribution of the digital model. Compare to experimental data (e.g., from mercury intrusion porosimetry). Iterate on reconstruction parameters until statistical agreement is achieved.

- Export: Export the final geometry as a watertight STL or STEP file.

Protocol 3.2: Parametric Design of Periodic Structured Electrodes

- Objective: Create a parameterized model of periodic electrode structures (e.g., mesh, felt, 3D-printed lattice) for design optimization studies.

- Materials & Software:

- CAD software with parametric capabilities (e.g., Siemens NX, SOLIDWORKS, FreeCAD) or scripting environment (Python with OpenCASCADE).

- Methodology:

- Define Unit Cell: Identify the smallest repeating geometric unit (e.g., a tetrakaidecahedron for foams, a weave pattern for mesh).

- Parameterize Key Dimensions: Create variables for critical dimensions (strut diameter

d, unit cell lengthL, pore window sizea). - Build Geometry: Construct the solid model of the unit cell using parametric sketches and features (sweeps, lofts, boolean operations).

- Array and Trim: Create a 3D array of the unit cell to form the electrode volume. Trim the array to the exact bounding dimensions of the flow channel or chamber.

- Export: Export the final periodic structure as a STEP file.

Meshing Strategies and Protocols

A high-quality mesh is non-negotiable for resolving boundary layers and concentration gradients within electrodes.

Protocol 4.1: Conformal Meshing for Detailed Feature Resolution

- Objective: Generate a high-resolution, body-fitted mesh for electrodes where the fluid-solid interface physics (e.g., local reaction rate) is the primary focus.

- Software: Advanced meshing tools (Ansys Meshing, SIMCENTER STAR-CCM+, snappyHexMesh).

- Methodology:

- Surface Preparation: Import CAD/STL. Run automatic geometry repair to heal tiny gaps and misalignments.

- Surface Meshing: Apply a curvature- and proximity-based sizing function. Ensure at least 3-5 elements across the smallest pore or strut diameter. Use triangular or polyhedral surface elements.

- Volume Meshing: For complex pores, use a tetrahedral core mesh with prism layers. For more regular structures, a generalized polyhedral mesh is advantageous. Critical: Apply 5-15 inflation/prism layers on all wetted walls with a growth rate of 1.2 to resolve near-wall gradients. Target a wall

y+< 1 for subsequent mass transfer simulations. - Quality Check: Enforce skewness < 0.85, aspect ratio < 20, and non-zero cell volume.

Protocol 4.2: Non-Conformal Meshing & Porous Media Approach

- Objective: Efficiently model the bulk region of a complex electrode where explicit geometric detail is less critical than capturing averaged transport effects.

- Software: Any CFD pre-processor with porous media model capabilities.

- Methodology:

- Create a Simplified Domain: Model the electrode region as a solid, simple volume (e.g., a rectangular block).

- Assign Porous Zone: In the CFD solver setup, assign this volume as a porous zone.

- Define Anisotropic Resistance: Calculate and input the permeability (

K) and Forchheimer coefficients (from Protocol 3.1 or literature) as a momentum sink. Use the form:S_i = -(μ/K * v_i + β * ρ * |v| * v_i). - Mesh the Simplified Domain: Use a regular hex-dominant or Cartesian mesh for high quality and low cell count.

- Coupling: Interface this porous region with conformally meshed free-flow channels (e.g., flow fields) using internal interfaces.

Table 1: Comparison of Meshing Strategies for Electrode Structures

| Strategy | Best For | Typical Cell Count | Pros | Cons |

|---|---|---|---|---|

| Conformal (Tetrahedral) | Stochastic pores, irregular foams | 10⁷ - 10⁹ | Captures exact geometry, accurate interfaces. | Extremely high cell count, long solve times. |

| Conformal (Polyhedral) | Periodic lattices, fiber felts | 10⁶ - 10⁸ | Lower cell count than tets, good convergence. | Complex surface prep required. |

| Non-Conformal (Porous Media) | System-scale modeling, packed beds | 10⁴ - 10⁶ | Very fast simulation, simple setup. | Loses local interfacial detail, requires homogenized properties. |

| Hybrid (Conformal+Porous) | GDEs with microporous layer (MPL) | 10⁵ - 10⁷ | Balances detail and efficiency. | Requires careful interface coupling. |

Diagram Title: Geometry and Meshing Decision Workflow for Electrode CFD

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Materials and Digital Tools for Electrode Geometry and Meshing

| Item / Solution | Function / Purpose | Example Product/Software |

|---|---|---|

| X-ray µCT Scanner | Non-destructive 3D imaging of internal electrode microstructure to obtain ground-truth geometry. | Zeiss Xradia 620 Versa, Bruker Skyscan 1272 |

| Image Processing Suite | To segment, filter, and analyze µCT data for geometric reconstruction and property calculation. | ImageJ/Fiji, ORS Dragonfly, Avizo |

| Stochastic Reconstruction Code | Generates 3D digital models from statistical descriptors when µCT is unavailable. | Quartet Structure Generation Set (QSGS), OpenPNM |

| Parametric CAD Software | For designing and modifying periodic, structured electrode architectures. | Siemens NX, Dassault SOLIDWORKS, FreeCAD |

| CFD Pre-processor with Advanced Mesher | To generate high-quality, conformal computational meshes from complex geometry. | Ansys Fluent Meshing, SIMCENTER STAR-CCM+, Pointwise |

| Porous Media Property Calculator | Determines homogenized permeability and inertial coefficients from digital models. | OpenFOAM's porousMediaSimpleFoam, in-house MATLAB/Python scripts |

| High-Performance Computing (HPC) Cluster | Essential for handling memory-intensive geometry processing and meshing of large domains. | Local Linux cluster, Cloud-based HPC (AWS, Azure) |

This application note serves the broader thesis on Computational Fluid Dynamics (CFD) simulation for mass transfer enhancement in CO2 electrolyzers. The core challenge involves accurately modeling the gas-liquid (e.g., CO2-electrolyte) interface and turbulent dispersion, which critically governs reactant availability at catalyst surfaces. Selecting an appropriate multiphase model is paramount. This document provides a detailed comparison, application protocols, and implementation guidelines for the two primary approaches: the Eulerian-Eulerian (EE) model and the Volume of Fluid (VOF) model.

Model Definition and Comparative Analysis

Table 1: Core Model Characteristics & Theoretical Basis

| Aspect | Eulerian-Eulerian (Multi-Fluid) Model | Volume of Fluid (VOF) Model |

|---|---|---|

| Fundamental Approach | Treats all phases as interpenetrating continua. Solves separate sets of Navier-Stokes equations for each phase, coupled by interfacial exchange terms. | Tracks the volume fraction of one (or more) fluid(s) across the domain. Solves a single set of momentum equations shared by all phases. |

| Interface Resolution | Does not explicitly resolve the interface. Uses correlations for interfacial area, drag, lift, and turbulence exchange. | Explicitly resolves the shape and location of the interface using a geometric (PLIC) or algebraic reconstruction scheme. |

| Phase Definition | Phases are defined statistically (e.g., volume fraction). Ideal for dispersed flows (bubbles, droplets). | Phases are defined by a sharp, tracked interface. Ideal for stratified, free-surface, or large-scale interfacial flows. |

| Computational Cost | Generally lower for high void fraction, dispersed flows. Scales with number of phases. | Generally higher, requiring fine mesh at the interface for accuracy. Mesh resolution dictates cost. |

| Primary Use Case in CO2 Electrolysis | Modeling dense bubble swarms in the electrolyte channel or gas diffusion electrode (GDE) backing layer. | Modeling specific bubble growth, detachment, and flow regime transitions near the catalyst layer or in microchannels. |

Table 2: Quantitative Data Summary for Model Selection in CO2 Electrolyzer Context

| Parameter | Favors Eulerian-Eulerian | Favors VOF | Typical Values/Correlations |

|---|---|---|---|

| Gas Volume Fraction (α_g) | High (>10%), dispersed | Low (<10%), segregated | EE: αg ~ 0.1-0.4 in bubble columns. VOF: αg < 0.1 at defined interface. |

| Bubble Diameter (d_b) vs. Mesh Size (Δx) | d_b << Δx (Sub-grid) | d_b >> Δx (Resolved) | EE: db ~ 10-500 µm, Δx ~ 100-1000 µm. VOF: db > 5*Δx. |

| Key Non-Dimensional Numbers | Stokes Number (St) << 1 | Weber Number (We), Capillary Number (Ca) | EE: Drag law (Schiller-Naumann, Grace). VOF: Surface tension model (CSF). |

| Mass Transfer Modeling | Built-in species transport per phase. Interfacial mass transfer via empirical coefficient (k_L). | Species transport in shared field. Interface mass transfer requires User-Defined Functions (UDFs) for Henry's Law equilibrium. | EE: k_La correlation (e.g., Higbie's penetration theory). VOF: Direct resolution of concentration boundary layer. |

Experimental & Simulation Protocols

Protocol 3.1: Setting Up an Eulerian-Eulerian Simulation for a Bubble Column Reactor (Analogous to Flow Electrolyzer)

- Objective: Predict global gas holdup, liquid velocity patterns, and species distribution.

- Software: ANSYS Fluent / Siemens Star-CCM+ / OpenFOAM.

- Steps:

- Geometry & Meshing: Create a 2D-axisymmetric or 3D column. Generate a structured hexahedral mesh. Cell size should be 3-5 times larger than the expected Sauter mean bubble diameter.

- Model Setup:

- Models: Enable Eulerian multiphase model with 2 phases: liquid (primary) and gas (secondary).

- Turbulence: Use the k-ε Dispersed or SST k-ω model with phase-dependent turbulence.

- Interfacial Forces: Enable Drag (Schiller-Naumann), Lift (Saffman-Mei), and Virtual Mass. For bubble coalescence/breakup, enable a Population Balance Model (PBM).

- Boundary Conditions:

- Gas Inlet: Velocity inlet or mass flow inlet with gas volume fraction = 1.

- Liquid Inlet: Velocity inlet with gas volume fraction = 0.

- Outlet: Pressure outlet with degassing condition for the gas phase.

- Walls: No-slip for liquid, free-slip for gas.

- Solution: Use a Coupled or Phase Coupled SIMPLE scheme. Initialize with a patched gas volume fraction at the inlet region.

Protocol 3.2: Setting Up a VOF Simulation for Bubble Growth at a Catalyst Pore

- Objective: Capture the dynamics of a single CO2 bubble nucleation, growth, and detachment.

- Software: ANSYS Fluent / OpenFOAM.

- Steps:

- Geometry & Meshing: Create a detailed 2D or 3D domain around a single pore/micro-cavity. Use an extremely fine, adaptive mesh refinement (AMR) at the interface. Minimum cell size should be 1/10 to 1/20 of the expected bubble diameter.

- Model Setup:

- Models: Enable Volume of Fluid model with 2 phases. Enable Implicit Body Force treatment.

- Interface Modeling: Select Geo-Reconstruct or Compressive scheme.

- Surface Tension: Enable Continuum Surface Force (CSF) model with wall adhesion.

- Turbulence: Often laminar for pore-scale simulation; otherwise, use a transitional model.

- Boundary Conditions:

- Catalyst Wall: Set constant gas flux (from electrochemical reaction) as a User-Defined Mass Source for the gas phase via a UDF.

- Domain Boundaries: Pressure outlets.

- Solution: Use a PISO or Coupled scheme with explicit time stepping. Use a very small time step to satisfy Courant number < 1.

Visualizations

Title: Decision Workflow for Multiphase Model Selection

Title: Comparative Simulation Setup Workflows for VOF vs. EE

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Computational & Physical Materials for Multiphase CFD Studies

| Item Name | Category | Function / Purpose in Research |

|---|---|---|

| OpenFOAM (v2306+) | CFD Software | Open-source toolbox for customized multiphase simulations; ideal for implementing novel mass transfer UDFs. |

| ANSYS Fluent (2024 R1+) | CFD Software | Industry-standard code with robust, validated EE and VOF solvers for production simulations. |

| High-Performance Computing (HPC) Cluster | Hardware | Essential for computationally intensive VOF or transient EE simulations with fine meshes. |

| Population Balance Model (PBM) Module | Software Add-on | Required for EE simulations to predict bubble size distribution due to coalescence and breakup. |

| User-Defined Function (UDF) Library | Code | Custom C/Python routines to define interfacial mass transfer, electrochemical reaction sources, or custom properties. |

| 0.5M KHCO3 Electrolyte (Physical Analog) | Physical Reagent | Common aqueous electrolyte in CO2 electrolysis; used for validating CFD models against experimental PIV/LIF data. |

| Polydisperse Glass Beads (50-200 µm) | Physical Reagent | Used in pseudo-2D experimental flow cells to mimic catalyst layer porosity for model validation. |

| High-Speed Camera & µPIV System | Experimental Equipment | Critical for capturing bubble dynamics and liquid velocity fields for direct comparison with VOF/EE results. |

Application Notes

This protocol details the implementation of electrochemical reaction mechanisms within computational fluid dynamics (CFD) simulations for CO₂ electrolyzer research. Accurate modeling of mass transfer with chemical reaction is paramount for designing electrodes and flow fields that enhance CO₂ conversion rates and product selectivity (e.g., towards C₂+ products like ethylene). The core challenge is translating discrete, localized electrochemical reactions into continuous source and sink terms within the governing transport equations solved by CFD solvers.

Theoretical Framework: Governing Equations with Reactions

In a CFD model of a gas diffusion electrode (GDE) in a CO₂ electrolyzer, the conservation of species i is governed by: [ \frac{\partial (\rho Yi)}{\partial t} + \nabla \cdot (\rho \vec{v} Yi) = \nabla \cdot (\rho D{i,eff} \nabla Yi) + Si ] where (Yi) is the mass fraction, (D{i,eff}) the effective diffusivity, and (Si) the source/sink term (kg m⁻³ s⁻¹) due to electrochemical reactions. The source term couples the fluid dynamics to the electrochemistry.

Butler-Volmer Kinetics as the Source Term Basis

For an elementary electron transfer reaction (O + ne^- \leftrightarrow R), the Butler-Volmer (BV) equation defines the current density i (A m⁻²): [ i = i0 \left[ \frac{CR}{CR^*} \exp\left(\frac{\alphaa F \eta}{RT}\right) - \frac{CO}{CO^*} \exp\left(-\frac{\alpha_c F \eta}{RT}\right) \right] ] where:

- (i_0): Exchange current density (A m⁻²)

- (Cj, Cj^*): Surface and bulk concentrations (mol m⁻³)

- (\alphaa, \alphac): Anodic and cathodic charge transfer coefficients

- (\eta): Activation overpotential (V)

- (F): Faraday constant (96485 C mol⁻¹)

- (R): Universal gas constant (8.314 J mol⁻¹ K⁻¹)

- (T): Temperature (K)

Conversion to Source Term: The volumetric source term for species i in a computational cell within the catalyst layer is: [ Si = \pm \frac{si Mi}{n F} \left( \frac{i A{v}}{L{CL}} \right) ] where (si) is the stoichiometric coefficient (positive for product, negative for reactant), (Mi) is the molar mass (kg mol⁻¹), (Av) is the specific electroactive area (m² m⁻³), and (L{CL}) is the catalyst layer thickness (m). The term ((i A{v}/L_{CL})) distributes the surface-based current density as a volumetric reaction rate.

Table 1: Key Parameters for CO₂-to-CO Reduction on Silver Catalyst

| Parameter | Symbol | Typical Value / Range | Units | Notes |

|---|---|---|---|---|

| Exchange Current Density | (i_0) | 1.0e-2 – 1.0e-1 | A m⁻² | Highly dependent on catalyst & local pH |

| Anodic Transfer Coefficient | (\alpha_a) | 0.5 – 0.7 | - | Assumed symmetric for simple ET |

| Cathodic Transfer Coefficient | (\alpha_c) | 0.3 – 0.5 | - | |

| Specific Electroactive Area | (A_v) | 1.0e5 – 1.0e7 | m² m⁻³ | Depends on catalyst loading & porosity |

| Catalyst Layer Thickness | (L_{CL}) | 5 – 50 | µm | |

| Reference CO₂ Concentration | (C{CO2}^*) | 0.033 – 1.2 | mol m⁻³ | Depends on pressure & electrolyte |

Table 2: Source/Sink Term Polarity for Common CO₂RR Species

| Species | Stoichiometry (CO production) | (S_i) Sign (Cathode) | Role |

|---|---|---|---|

| CO₂ | CO₂ + 2H⁺ + 2e⁻ → CO + H₂O | Negative (Sink) | Reactant |

| CO | Product of above reaction | Positive (Source) | Desired Product |

| H⁺ | Consumed in CO₂RR | Negative (Sink) | Affects local pH |

| OH⁻ | Generated via HER side reaction | Positive (Source) | Increases local pH |

| H₂ | 2H⁺ + 2e⁻ → H₂ | Positive (Source) | Side Product |

Protocol: Implementing BV Source Terms in a CFD Solver (e.g., OpenFOAM, ANSYS Fluent)

Objective: To incorporate the coupled mass transfer and electrochemical reaction in a 2D model of a CO₂ electrolyzer cathode GDE.

Workflow:

(Diagram Title: CFD-BV Implementation Workflow)

Step-by-Step Protocol:

Geometry Creation and Mesh Generation:

- Create a 2D computational domain representing the gas channel, gas diffusion layer (GDL), microporous layer (MPL), and catalyst layer (CL).

- Generate a structured mesh, ensuring high refinement in the CL (cell size ~0.1-1 µm) where gradients are steep. Maintain a mesh independence study.

Physics Setup:

- Activate a steady-state, pressure-based solver.

- Enable species transport equations for CO₂, CO, H₂, H⁺, OH⁻ (or a pH buffer ion).

- Set the fluid phase properties (density, viscosity) for the aqueous electrolyte in the CL and the gas mixture in the channel/GDL.

- Define effective diffusivities for each species in each porous layer (e.g., using Bruggeman correction: (D{i,eff} = Di \cdot \varepsilon^{1.5})).

Boundary and Initial Conditions:

- Gas Channel Inlet: Specify CO₂ mass fraction (or molar fraction), velocity, and temperature.

- Gas Channel Outlet: Pressure outlet.

- Catalyst Layer | Membrane Interface: Set ion concentrations/fluxes and electric potential (or current density).

- Walls: No-slip for flow, no-flux for species except at reactive surfaces.

- Initial Guess: Uniform CO₂ concentration in the domain, zero current.

User-Defined Function (UDF) for BV Source Terms:

- This is the critical step. Write a UDF (e.g., in C for ANSYS Fluent) that is hooked to the species transport equations as volumetric source terms.

UDF Pseudo-Code Logic:

Solution and Coupling:

- The UDF must be compiled and linked to the solver.

- The species equations and charge conservation equation are solved coupled or sequentially until convergence (residuals < 1e-6).

- Under-relaxation factors for species sources may need to be reduced (0.1-0.5) for stability.

Validation Protocol:

- Benchmarking: Compare simulated total current at a given cell voltage against experimental polarization curves from a well-characterized lab-scale CO₂ electrolyzer.

- Sensitivity Analysis: Perform parameter sweeps on (i0) and (Av). Calibrate these within physical ranges to match experimental data.

- Mesh Independence: Verify that key outputs (e.g., current density, CO₂ concentration at catalyst) change by <2% upon mesh refinement.

The Scientist's Toolkit: Research Reagent Solutions & Key Materials

Table 3: Essential Materials for Experimental Validation of CFD Models

| Item | Function in CO2 Electrolyzer Research | Example/Notes |

|---|---|---|

| Gas Diffusion Electrode (GDE) | Porous, conductive support providing triple-phase boundary for CO2RR. | Carbon-based GDL (e.g., Sigracet) with catalyst layer (e.g., sputtered Ag, Cu nanoparticles). |

| Ion-Exchange Membrane | Separates cathode and anode compartments, facilitates ion transport. | Cation Exchange Membrane (e.g., Nafion 117), Anion Exchange Membrane (e.g., Sustainion). |

| Electrolyte Solution | Medium for ion conduction; composition affects kinetics & selectivity. | 0.1M – 1.0 M KHCO3 (common for neutral/alkaline CO2RR). Purge with CO2 to saturate. |

| Reference Electrode | Measures local electrode potential vs. a standard. | Reversible Hydrogen Electrode (RHE) placed near the working electrode. |

| Micro-reference Electrode | For in-situ measurement of local pH or potential gradients. | Miniaturized Hg/Hg2SO4 or Ag/AgCl electrode; critical for model validation. |

| Gas Chromatograph (GC) | Quantifies gaseous product composition (CO, H2, C2H4, etc.). | Coupled online to electrolyzer outlet for real-time Faradaic Efficiency analysis. |

| Scanning Electrochemical Microscopy (SECM) | Maps local electrochemical activity and reactant concentration. | Used to experimentally validate simulated concentration/current distributions. |

(Diagram Title: CO2RR Kinetic Pathway with Mass Transfer)

Within the broader thesis on Computational Fluid Dynamics (CFD) simulation for mass transfer enhancement in CO₂ electrolyzers, accurate boundary condition (BC) setting is the cornerstone of model fidelity. This protocol details the application of three critical BCs: inlet flow rates (governing reactant supply), electrode potentials (driving reaction kinetics), and wall interactions (influencing species transport and bubble dynamics). Correct implementation is essential for simulating local concentration gradients, current density distribution, and overall device performance.

Key Boundary Condition Parameters and Data

The following tables summarize standard and advanced quantitative parameters for CO₂ electrolyzer CFD models, based on recent literature (2023-2024).

Table 1: Inlet Flow Rate and Composition Parameters

| Parameter | Typical Range | Common Value(s) in Research | Function & Impact |

|---|---|---|---|

| Inlet Flow Velocity | 1 – 50 mm/s | 5 – 20 mm/s | Governs convective CO₂ supply; high rates reduce concentration polarization but lower conversion per pass. |

| CO₂ Flow Rate (sccm/cm²) | 10 – 200 sccm/cm² | 20 – 50 sccm/cm² | Standardized measure of reactant flux. Critical for defining stoichiometry. |

| Electrolyte Co-Flow Rate | 0.1 – 5 mL/min | 0.5 – 2 mL/min (alkaline/neutral) | Carries ions, removes products (e.g., formate, ethylene), manages pH. |

| CO₂ Inlet Concentration | ~100% (gas-fed) or 0.1-0.5M (aqueous) | Saturated KHCO₃ (0.1M) | Defines maximum possible reactant concentration at catalyst surface. |

| Inlet Temperature | 20 – 30 °C | 25 °C | Affects fluid properties, kinetics, and gas solubility. |

Table 2: Electrode Potential and Kinetic Parameters

| Parameter | Typical Range | Application Note |

|---|---|---|

| Cathode Potential (vs. RHE) | -0.5 to -1.5 V | Primary driver for CO₂ Reduction Reaction (CO2RR). Applied as a constant potential BC. |

| Anode Potential | Often set as ground or counter-electrode | In full-cell models, the anode (OER) potential is solved implicitly. |

| Exchange Current Density (j₀) | 10⁻⁵ – 10⁻³ A/cm² (varies by catalyst) | Crucial for Butler-Volmer kinetics. Must be sourced from experimental Tafel plots. |

| Charge Transfer Coefficient (α) | 0.2 – 0.8 (often ~0.5) | Symmetry factor for cathodic reaction. |

| Reference Electrode Potential | Calculated for SHE or RHE | Essential for aligning model potential with experimental values. |

Table 3: Wall Boundary Interactions

| Boundary Type | Key Interaction Setting | Physical Meaning |

|---|---|---|

| Catalyst Surface (Wall) | Species BC: Flux = - (Reaction Rate). Electric BC: Potential = Fixed. | Site of electrochemical reactions. Species consumption/production linked to current via Faraday's law. |

| Gas Diffusion Layer (GDL) Wall | Slip/No-Slip: Partial slip often used. Species BC: Zero flux for ions; convective flux for gases. | Allows gas transport, blocks liquid/electrolyte. Wettability settings critical for bubble release. |

| Membrane/Wall Interface | Species BC: Zero flux for CO₂/gas products; flux for ions (H⁺, OH⁻, K⁺). | Ionic conductor, gas separator. Modeled as a porous wall or internal interface. |

| Channel Walls (Flow Field) | No-Slip Condition (standard). Wall Roughness: 0-5 µm. | Influences pressure drop, bubble adhesion, and flow profile. |

Experimental Protocols for Parameter Determination

Protocol 3.1: Determining Flow Rate for Mass Transfer-Limited Operation

- Objective: Establish the inlet flow rate that minimizes external mass transfer limitations for a given geometric design.

- Materials: Flow electrolyzer test cell, gas mass flow controllers (MFCs), liquid syringe pump, potentiostat.

- Method:

- Set the electrode potential to a value known to produce high current density (e.g., -1.2 V vs. RHE for C₂₊ products).

- Vary the CO₂ inlet flow rate systematically (e.g., 5, 10, 20, 50 sccm/cm²) while holding all other parameters constant.

- Record the steady-state current density at each flow rate.

- Plot current density vs. flow rate. The flow rate where the current density plateaus indicates the transition to kinetic control from mass transfer control.

- For CFD, use a flow rate just above this plateau to ensure sufficient reactant supply without excessive computational cost.

Protocol 3.2: Calibrating Electrode Kinetics for BC Input

- Objective: Extract exchange current density (j₀) and charge transfer coefficient (α) for use in the Butler-Volmer BC.

- Materials: Rotating disk electrode (RDE) setup or well-controlled microfluidic cell, potentiostat, reference electrode.

- Method:

- Perform linear sweep voltammetry (LSV) or chronoamperometry under well-defined, mass-transfer-unlimited conditions (e.g., high rotation speed in RDE, very high flow in microcell).

- Plot the Tafel curve: overpotential (η) vs. log10(|j|).

- The linear region of the Tafel plot yields the Tafel slope (b) and the intercept at η=0 gives log(j₀).

- Calculate α from the Tafel slope: b = 2.3RT/(αnF), where n is the number of electrons.

- Input j₀ and α into the CFD software's electrochemical BC module.

Protocol 3.3: Characterizing Wall Interactions via Bubble Adhesion Angle

- Objective: Quantify catalyst surface wettability to set appropriate wall adhesion parameters for bubble transport models.

- Materials: Catalyst-coated substrate, contact angle goniometer, electrolyte solution (e.g., 0.1M KHCO₃).

- Method:

- Place a small droplet (∼5 µL) of the electrolyte on the catalyst surface in air to measure the static contact angle (indicates hydrophilicity/hydrophobicity).

- For more relevant in-situ data, use a captive bubble method: submerge the catalyst in electrolyte and attach a CO₂ or H₂ gas bubble to the surface from below using a syringe.

- Measure the angle formed by the bubble at the three-phase (catalyst-electrolyte-gas) boundary.

- A low contact angle (<90°) indicates hydrophilic (wetting) surface, promoting bubble release. A high angle (>90°) indicates hydrophobic surface, promoting bubble adhesion and growth.

- Use this measured angle as input for the CFD model's wall adhesion parameter in multiphase (VOF or Euler-Euler) simulations.

Visualization of Workflow and Relationships

Title: Boundary Condition Workflow for CO2 Electrolyzer CFD

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 4: Key Reagents and Materials for BC Parameterization

| Item | Function in BC Context | Example/Note |

|---|---|---|

| High-Purity CO₂ Gas (≥99.999%) | Inlet reactant stream. Impurities (e.g., O₂) can alter cathode potential and kinetics. | Use with in-line purifiers. |

| Electrolyte Salts | Determines inlet ion concentration, conductivity, and pH. | KHCO₃ (0.1-1.0 M) common for neutral; KOH for alkaline. |

| Gas Mass Flow Controller (MFC) | Precisely sets and controls the inlet gas flow rate BC. | Critical for replicating defined flow regimes in CFD. |

| Potentiostat/Galvanostat | Applies the electrode potential BC and measures resulting current. | Used in both parameterization experiments and cell testing. |

| Reference Electrode (e.g., Ag/AgCl) | Provides stable potential reference to define cathode potential BC accurately. | All potentials converted to RHE for modeling consistency. |

| Catalyst Ink Materials | Fabricates the catalytic wall where reaction BCs are applied. | Catalyst powder, ionomer (e.g., Nafion), solvents (IPA/water). |

| Gas Diffusion Layer (GDL) | Defines a porous, partially wetting wall BC for gas/liquid separation. | Hydrophobic PTFE-coated carbon paper (e.g., Sigracet 39BB). |

| Contact Angle Goniometer | Quantifies surface wettability to define wall adhesion BC for bubbles. | Measures static or captive bubble contact angles. |

| Microfluidic Flow Cell | Well-defined geometry for precise BC validation and kinetic measurements. | Enables direct correlation between experiment and 2D CFD models. |

Within the broader thesis on Computational Fluid Dynamics (CFD) simulation for mass transfer enhancement in CO₂ electrolyzers, post-processing of simulation and experimental data is critical for deriving mechanistic insight. This protocol details methodologies for visualizing three key performance-determining phenomena: concentration gradients of reactive species (CO₂, OH⁻, HCO₃⁻), electrochemical current distribution, and the local pH environment at catalyst surfaces. These visualizations bridge high-fidelity simulations with experimental validation, guiding electrode and reactor design for improved selectivity and efficiency.

Core Quantitative Metrics & Data Presentation

The following parameters are fundamental for analysis. Table 1 summarizes typical target values and measurement techniques.

Table 1: Key Quantitative Metrics for CO₂ Electrolyzer Analysis

| Parameter | Typical Target Range / Value | Measurement/Simulation Technique | Significance |

|---|---|---|---|

| CO₂ Concentration at Catalyst | >10 mol/m³ (to avoid mass transport limitation) | CFD-PBE Simulation, Microsensor | Determines local availability for reduction. |

| Local pH at Cathode | 8 - 13 (depends on buffer, current) | CFD with Electrochemistry, Fluorescent Dyes, pH Microsensor | Affects C vs H₂ selectivity, catalyst stability. |

| Cathode Current Density | 100 - 500 mA/cm² (industry target) | Segmented Electrode, Simulation | Direct measure of reaction rate. |

| Current Distribution Uniformity | >80% (ideal) | Segmented Electrode, Potential Probe Scan | Indicates even catalyst utilization and local overpotential. |

| OH⁻ Generation Rate | 0.1 - 10 mmol/(cm²·s) | Derived from current & selectivity | Primary driver of pH gradient and carbonate formation. |

| HCO₃⁻/CO₃²⁻ Concentration | Variable, can exceed 1 M in boundary layer | Coupled CFD-Mass Transport Model | Impacts CO₂ availability and electrolyte conductivity. |

Experimental Protocols for Validation Data

Protocol: Mapping Local pH with Fluorescent Sensor Films

Objective: To experimentally measure the two-dimensional pH distribution within the cathode boundary layer of an operating flow electrolyzer. Materials: See Scientist's Toolkit. Procedure:

- Sensor Fabrication: Spin-coat a 50 µm layer of a pH-sensitive fluorescent dye (e.g., SNARF-1 derivative) embedded in a gas-permeable, ion-conductive polymer matrix (e.g., Nafion) onto a transparent window.

- Calibration: Prior to experiment, calibrate the fluorescence intensity ratio (Ex: 540 nm / Em: 580 nm vs 640 nm) against standard buffer solutions (pH 6-13) under identical temperature and ionic strength conditions.

- Cell Integration: Install the sensor window as part of the electrolyzer wall, providing a planar view of the cathode surface.

- Operando Imaging: Operate the electrolyzer at target current densities. Use a confocal fluorescence microscope or a calibrated CCD camera with appropriate excitation/emission filters to capture 2D fluorescence images.

- Data Processing: Convert captured intensity ratios to pH maps using the calibration curve. Superimpose pH contours onto cathode geometry.

- Validation: Compare experimental pH maps with CFD predictions of species transport coupled with the Nernst-Planck equation.

Protocol: Current Distribution Mapping via Segmented Electrode

Objective: To measure the spatial distribution of local current density across the catalyst surface. Materials: Segmented cathode (e.g., 10x10 array of isolated catalyst pads), multi-channel potentiostat/galvanostat, data acquisition system. Procedure:

- Electrode Assembly: Integrate the segmented cathode into the electrolyzer cell, ensuring uniform sealing and electrolyte flow over all segments.

- Connection: Connect each segment independently to a shared counter and reference electrode via the multi-channel potentiostat.

- Polarization: Operate the cell at a fixed overall cell potential or current.

- Simultaneous Measurement: Record the current from each individual segment simultaneously over a stable operating period (≥ 300 s).

- Analysis: Calculate local current density for each segment. Generate a 2D or 3D contour plot of current density vs. position. Calculate uniformity index: (1 - (σ/µ)) * 100%, where σ is standard deviation and µ is the mean segment current density.

- Correlation: Correlate areas of high/low current density with simulated local CO₂ concentration and overpotential.

Computational Post-Processing Protocols

Protocol: Extracting Concentration Gradients from CFD Results

Objective: To visualize species transport limitations from a converged CFD simulation. Software: ANSYS Fluent/COMSOL Multiphysics, ParaView/Teclplot. Procedure:

- Simulation Setup: Run a coupled CFD-Electrochemical model solving for flow, species transport (CO₂, K⁺, OH⁻, HCO₃⁻, CO₃²⁻), and electrode reactions.

- Plane Creation: In post-processor, define cutting planes perpendicular to the cathode surface, following streamlines from inlet to outlet.

- Profile Extraction: Extract molar concentration data for key species along lines normal to the cathode surface at multiple streamwise locations.

- Gradient Calculation: Compute the concentration gradient (dC/dy) at the catalyst surface (y=0) using a one-sided difference from the first two mesh nodes.

- Visualization: Generate filled contour plots on planes. Overlay streamlines colored by CO₂ mass fraction. Plot wall flux of CO₂ vs. position.

Protocol: Visualizing Local pH from Simulation Data

Objective: To compute and map pH from simulated ion concentrations. Procedure:

- Species Output: Ensure simulation outputs local concentrations of all ions involved in the carbonate system: [OH⁻], [HCO₃⁻], [CO₃²⁻].

- Charge Balance & pH Calculation: At each nodal point, solve the charge balance and carbonate equilibrium equations to compute [H⁺].

[K⁺] + [H⁺] = [OH⁻] + [HCO₃⁻] + 2[CO₃²⁻](simplified for KOH/KHCO₃ electrolytes). Use equilibrium constants (Kw, Ka1, K_a2) corrected for local ionic strength (Debye-Hückel). - pH Field: Calculate

pH = -log10([H⁺]). - Isosurface Generation: Create isosurfaces of specific pH values (e.g., pH 10, 11, 12) to visualize the alkaline boundary layer thickness and morphology.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Key Research Reagents & Materials

| Item | Function / Role | Example/Notes |

|---|---|---|

| pH-Sensitive Fluorophore (SNARF-1) | Embeds in sensor film; fluorescence ratio changes with pH. | Requires calibration. Must be stable under reduction potentials. |

| Gas-Permeable Ionomer (Nafion) | Matrix for sensor film; allows H⁺/OH⁻ transport while adhering to window. | Also used as binder in catalyst layers. |

| Segmented Electrode Chip | Enables spatially resolved current measurement. | Typically gold or carbon segments with isolated traces. |

| Micro-reference Electrode (e.g., Ag/AgCl) | Provides stable potential reference for local measurements. | Can be miniaturized for in-situ scanning. |

| Anion Exchange Membrane (AEM) | Separates compartments, selectively transports OH⁻/HCO₃⁻. | Critical for maintaining pH gradients. Material affects OH⁻ crossover. |

| 0.1 M KHCO₃ / 1 M KOH Electrolyte | Common aqueous electrolytes for CO₂ reduction. | Provides source of CO₂ (via equilibrium) and high conductivity. |

| CO₂ Mass Flow Controller | Delieves precise, reproducible CO₂ feed to the electrolyzer. | Essential for standardizing gas availability. |

| In-situ Raman Spectro-electrochemistry Setup | Probes local reaction intermediates and carbonate species. | Correlates pH/ concentration with catalyst state. |

Mandatory Visualizations: Workflows and Relationships

Diagram Title: CFD Post-Processing & Experimental Validation Workflow

Diagram Title: Computational pH Calculation Logic

Diagram Title: Cause-Effect Chain: From Current to pH to Performance

Diagnosing and Solving Mass Transfer Limitations: CFD-Driven Optimization Strategies

Identifying Common Flow Maldistribution and 'Dead Zone' Problems

Within computational fluid dynamics (CFD) simulations for mass transfer enhancement in CO2 electrolyzers, flow maldistribution and the formation of 'dead zones' (stagnant flow regions) are critical issues. These phenomena negatively impact reactant availability, product removal, and electrode durability, ultimately reducing Faradaic efficiency and cell longevity. This application note details common flow problems, quantification methods, and experimental protocols for validation, tailored for researchers in electrochemistry and related fields.

Common Flow Maldistribution Patterns & Quantitative Impact

Table 1: Common Flow Maldistribution Patterns in CO2 Electrolyzer Flow Fields

| Pattern Type | Description | Primary Cause | Typical Impact on CO2 Reduction Efficiency (from literature) |

|---|---|---|---|

| Channeling | Flow concentrates in a few preferred paths, bypassing large electrode areas. | Uneven compression, GDL porosity variations, manifold design. | Local current density variation >30%; overall efficiency drop of 10-25%. |

| U-turn / Recirculation Zones | Vortices form at sharp turns or sudden expansions, trapping reactants/products. | Abrupt geometric changes, high flow velocity disparities. | Can reduce effective electrode utilization by 15-40%; promotes local pH extremes. |

| Inlet/Outlet Dominance | Highest flow rates near inlet/outlet ports, with minimal flow in center. | Poor manifold distribution, insufficient flow resistance in channels. | Center region reactant starvation; efficiency losses of 20-35% in severe cases. |

| Under-rib Convection Starvation | Insufficient reactant flow through the gas diffusion layer (GDL) beneath channel ribs. | Low GDL permeability, insufficient pressure differential. | Under-rib areas operate at <50% of channel-adjacent reaction rates. |

Table 2: Dead Zone Characterization and Consequences