Decoding Catalyst Stability: A Practical Guide to Pourbaix Diagrams in Acidic Electrolytes

This comprehensive guide explores the critical role of Pourbaix diagrams in predicting and understanding electrocatalyst stability under harsh acidic conditions, crucial for applications like proton exchange membrane water electrolyzers (PEMWE)...

Decoding Catalyst Stability: A Practical Guide to Pourbaix Diagrams in Acidic Electrolytes

Abstract

This comprehensive guide explores the critical role of Pourbaix diagrams in predicting and understanding electrocatalyst stability under harsh acidic conditions, crucial for applications like proton exchange membrane water electrolyzers (PEMWE) and fuel cells. We begin with foundational electrochemical thermodynamics, explaining how to interpret potential-pH maps for metals, oxides, and novel catalyst materials. The article then details methodological approaches for constructing and applying these diagrams, including computational methods and in-situ validation techniques. We address common pitfalls in stability prediction and optimization strategies for real-world acidic environments. Finally, we compare computational predictions with experimental data, validating the diagram's power and limitations. Tailored for researchers and development professionals, this guide serves as an essential resource for designing durable catalysts for next-generation energy conversion and biomedical devices.

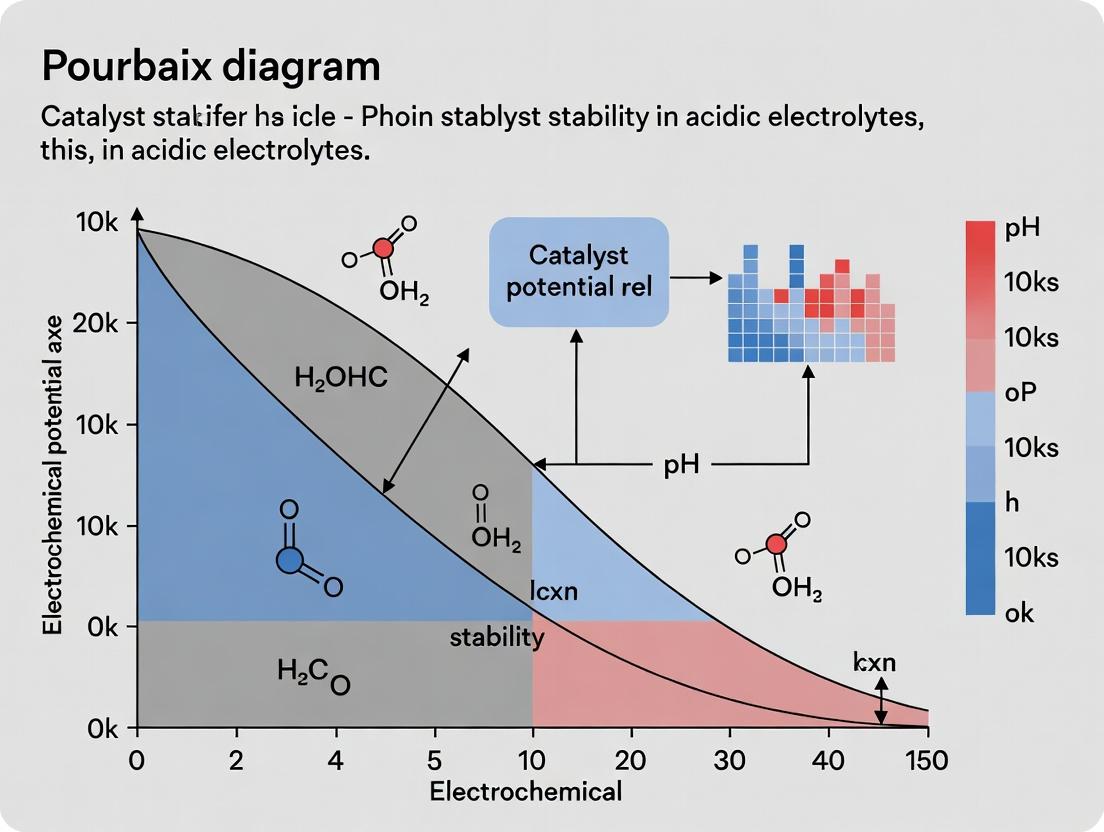

Pourbaix Diagrams Demystified: The Thermodynamic Blueprint for Acidic Catalyst Stability

Pourbaix diagrams, also known as potential-pH diagrams, are electrochemical phase maps that predict the thermodynamically stable phases of an element or compound as a function of electrode potential and solution pH. Within the context of broader research into catalyst stability in acidic electrolytes, these diagrams serve as an indispensable first-principles tool for predicting corrosion, passivation, and dissolution behavior. This whitepaper provides an in-depth technical guide to their construction, interpretation, and application in contemporary electrocatalysis research.

Fundamental Thermodynamic Basis

A Pourbaix diagram is constructed from the Nernst equation and the equilibrium constants for reactions involving the species of interest. The stability of a solid phase ( M ) in aqueous media is governed by three primary reaction types:

Redox Reactions (Potential-dependent): ( aA + mH^+ + ne^- \rightleftharpoons bB + cH_2O ) The Nernst equation applies: ( E = E^0 - \frac{0.0591}{n} \log Q ) at 298 K, where ( Q ) is the reaction quotient.

Acid-Base Reactions (pH-dependent): ( aA + mH^+ \rightleftharpoons bB ) The equilibrium is described by: ( \log K = \log([B]^b/[A]^a) - mpH ).

Solubility Reactions (Dependent on both): ( MmOn + 2nH^+ + 2ne^- \rightleftharpoons mM + nH_2O )

The lines on the diagram represent equilibria where the activities of the dissolved species are equal, typically set to a threshold like ( 10^{-6} ) M for practical "stability" against dissolution.

Table 1: Key Thermodynamic Parameters for Constructing a Pourbaix Diagram (Example: Platinum in Water)

| Reaction | ΔG° (kJ/mol) | E° vs. SHE (V) | Equilibrium Line Equation (E vs. pH) | Dominant Region |

|---|---|---|---|---|

| Pt²⁺ + 2e⁻ ⇌ Pt | 215.5 | ~1.18 | E = 1.18 + 0.0295 log[Pt²⁺] | Pt stable (low [Pt²⁺]) |

| PtO₂ + 4H⁺ + 4e⁻ ⇌ Pt + 2H₂O | -106.3 | 0.98 | E = 0.98 - 0.0591 pH | Pt stable (below line) |

| PtO₂ + 4H⁺ + 2e⁻ ⇌ Pt²⁺ + 2H₂O | -327.1 | 1.69 | E = 1.69 - 0.1182 pH + 0.0295 log[Pt²⁺] | PtO₂ / Pt²⁺ boundary |

| PtO₃²⁻ + 4H⁺ ⇌ PtO₂ + 2H₂O | - | - | log[PtO₃²⁻] = K - 4pH | PtO₂ / PtO₃²⁻ boundary |

Experimental Validation and Protocol for Catalyst Stability Mapping

Pourbaix diagrams predict thermodynamic stability, but kinetic factors dominate real catalyst performance. Experimental validation is critical.

Protocol: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for Dissolution Rate Measurement

Aim: Quantify the dissolution rate of a metallic catalyst (e.g., Pt, Ir) under potentiostatic control in acidic electrolyte (e.g., 0.1 M HClO₄).

Materials & Workflow:

- Electrochemical Cell: A 3-electrode cell with the catalyst-coated rotating disk electrode (RDE) as working electrode, reversible hydrogen electrode (RHE) as reference, and Pt mesh as counter.

- Electrolyte: High-purity 0.1 M HClO₄, deaerated with Argon for 30 min.

- Procedure: a. The electrolyte is held in a gas-tight cell with an outlet tube leading to the ICP-MS sample introduction system. b. Apply a constant potential (e.g., 1.0 V to 1.6 V vs. RHE) for a defined period (e.g., 2 hours). c. Use a peristaltic pump to continuously aspirate a small, constant stream (~0.5 mL/min) of the electrolyte from the cell directly into the ICP-MS nebulizer. d. The ICP-MS quantifies the concentration of dissolved metal ions (e.g., ( ^{195}\text{Pt}^+ )) in real-time with parts-per-trillion sensitivity. e. The dissolution rate (ng cm⁻² s⁻¹) is calculated from the steady-state concentration in the outlet, the flow rate, and the electrode geometric area.

- Data Correlation: Plot dissolution rate vs. applied potential. Compare "peaks" of dissolution to regions of predicted instability (e.g., Pt²⁺ stability field) on the Pourbaix diagram.

Protocol: In Situ X-ray Absorption Spectroscopy (XAS)

Aim: Determine the oxidation state and local coordination environment of catalyst atoms under operating conditions. Procedure:

- Prepare a catalyst thin film on a gas-diffusion layer or conductive polymer window.

- Mount in an in situ electrochemical XAS cell with X-ray transparent windows.

- Collect XANES (X-ray Absorption Near Edge Structure) spectra at specific potentials. The energy shift of the absorption edge indicates oxidation state (e.g., shift to higher energy for Pt(IV) vs. Pt(0)).

- Fit EXAFS (Extended X-ray Absorption Fine Structure) spectra to determine bond distances and coordination numbers, confirming the presence of oxide phases (Pt-O bonds) predicted by the Pourbaix diagram.

Diagram 1: Workflow for Validating Pourbaix Diagrams

Application to Catalyst Stability in Acidic Electrolytes

In proton exchange membrane water electrolyzers (PEMWE) and fuel cells (PEMFC), catalysts operate at low pH (≤1) and high anodic potentials (>1.5 V vs. RHE). The Pourbaix diagram for Ir, the state-of-the-art oxygen evolution reaction (OER) catalyst, reveals a critical insight: the stable phase is solid IrO₂, not metallic Ir. However, even IrO₂ can dissolve via formation of soluble Ir³⁺ or IrO₄²⁻ species at very high potentials or non-standard conditions.

Table 2: Stability Regions for Key Catalysts in Acidic Media (pH 0, 25°C)

| Catalyst | Stable Solid Phase (at OER potentials) | Soluble Species (Risk of Dissolution) | Key Stability Threshold (approx. vs. RHE) |

|---|---|---|---|

| Platinum (Pt) | Pt (metal) | Pt²⁺, PtO₃²⁻ (in very oxidizing, high pH) | Forms PtO₂ at >0.98 V; Pt dissolves as Pt²⁺ above ~1.1 V at high [H⁺]. |

| Iridium (Ir) | IrO₂ (oxide) | Ir³⁺, IrO₄²⁻ | Ir metal oxidizes to IrO₂ at ~0.92 V. IrO₂ may dissolve as Ir³⁺ at low potential or as IrO₄²⁻ at very high potential/pH. |

| Ruthenium (Ru) | RuO₂ (oxide) | Ru³⁺, RuO₄ | RuO₂ forms at ~0.79 V. High risk: RuO₂ oxidizes to volatile, soluble RuO₄ above ~1.4 V. |

| Gold (Au) | Au (metal) | Au⁺, Au³⁺ (complexed) | Stable metal phase up to ~1.5 V; dissolution requires complexing ions (e.g., Cl⁻). |

Advanced Considerations & Limitations

- Kinetics vs. Thermodynamics: Pourbaix diagrams are equilibrium maps. A predicted stable oxide (e.g., PtO₂) may form slowly, leaving the metal in a metastable state. Conversely, predicted dissolution may be negligibly slow.

- Complexing Agents & Anion Effects: Standard diagrams assume simple aqueous ions. Real electrolytes contain species (e.g., Cl⁻, SO₄²⁻) that complex metals, dramatically shifting stability fields. A separate diagram must be constructed for each defined electrolyte composition.

- Temperature & Crystallinity: Diagrams are typically for 25°C. High-temperature operation (e.g., 80°C in PEMFC) shifts equilibria. The crystalline phase of an oxide (e.g., anatase vs. rutile TiO₂) also has different stability.

Diagram 2: Factors Influencing Real Catalyst Stability

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Pourbaix & Catalyst Stability Studies

| Item | Function & Specification | Rationale |

|---|---|---|

| High-Purity Electrolyte | e.g., 0.1 M HClO₄ (TraceSELECT Ultra) | Minimizes impurity-induced dissolution or complexation. Perchlorate is weakly coordinating. |

| Reversible Hydrogen Electrode (RHE) | In-house or commercial, using same electrolyte. | Provides a potential reference tied to the solution's pH, essential for pH-potential diagrams. |

| Ultra-Pure Water | 18.2 MΩ·cm resistivity (from Milli-Q or similar). | Eliminates ionic contaminants that interfere with electrochemistry and ICP-MS analysis. |

| Single-Crystal Model Electrodes | e.g., Pt(111), Au(110) disks. | Provides a well-defined surface for fundamental studies linking structure to stability. |

| Nafion Binder Solution | 0.5% wt in low-alcohol solvent. | For preparing catalyst inks for thin-film working electrodes, ensuring proton conductivity. |

| ICP-MS Standard Solution | e.g., 1000 ppm Pt in 2% HNO₃. | For calibrating the ICP-MS to achieve quantitative, accurate dissolution measurements. |

| Calomel or Ag/AgCl Reference | Saturated KCl or 3 M NaCl filling solution. | Used when RHE is impractical; potential must be converted to RHE scale using pH. |

| Inert Gas Supply | Ultra-high purity Argon (≥99.999%). | For deaerating electrolytes to remove O₂, which interferes with redox measurements. |

This whitepaper provides a rigorous technical examination of the Nernst equation and Gibbs free energy, contextualized within research on catalyst stability using Pourbaix diagrams in acidic electrolytes. The principles discussed are foundational for interpreting electrochemical stability, dissolution potentials, and reaction spontaneity in proton-rich environments relevant to electrocatalysis and pharmaceutical development.

The stability and reactivity of catalytic materials in acidic media (e.g., PEM electrolyzers, biological compartments) are governed by electrochemical thermodynamics. The Gibbs free energy change (ΔG) of a reaction determines its spontaneity, while the Nernst equation quantitatively relates the reduction potential of an electrochemical half-cell to the standard electrode potential and the activities of the reacting species. In acidic electrolytes, the activity of H⁺ (pH) is a dominant variable.

The fundamental relationship is: ΔG = -nFE where n is the number of electrons transferred, F is Faraday's constant (96485 C/mol), and E is the cell potential. Under standard conditions (298.15 K, 1 bar, 1 M activity), this becomes ΔG° = -nFE°.

For a general reduction half-reaction: aOx + ne⁻ + cH⁺ ⇌ bRed + dH₂O The Nernst equation is expressed as:

[ E = E^{\circ} - \frac{RT}{nF} \ln \left( \frac{a{\text{Red}}^b \cdot a{\text{H}2\text{O}}^d}{a{\text{Ox}}^a \cdot a_{\text{H}^+}^c} \right) ]

At 298.15 K, using base-10 logs and assuming (a{\text{H}2\text{O}} \approx 1), this simplifies to:

[ E = E^{\circ} - \frac{0.0591}{n} \log \left( \frac{a{\text{Red}}^b}{a{\text{Ox}}^a} \right) - \frac{0.0591 \cdot c}{n} \text{pH} ]

The final term highlights the direct, linear dependence of potential on pH in acidic media, a cornerstone of Pourbaix diagram construction.

Quantitative Data: Key Thermodynamic Parameters

Table 1: Fundamental Constants and Conversion Factors

| Constant / Factor | Symbol | Value | Unit | Relevance |

|---|---|---|---|---|

| Faraday Constant | F | 96485.33212 | C mol⁻¹ | Converts moles e⁻ to charge |

| Gas Constant | R | 8.314462618 | J mol⁻¹ K⁻¹ | Relates energy, moles, & temp. |

| Standard Temp. | T | 298.15 | K | Reference temperature |

| Nernst Slope (298K) | (RT ln10)/F | 0.05916 | V | Prefactor in Nernst equation |

Table 2: Standard Reduction Potentials (E°) in Acidic Media (vs. SHE)

| Half-Reaction | E° (V) | Relevance to Catalyst Stability |

|---|---|---|

| 2H⁺ + 2e⁻ ⇌ H₂ | 0.000 (by definition) | Hydrogen evolution reaction (HER) reference |

| O₂ + 4H⁺ + 4e⁻ ⇌ 2H₂O | 1.229 | Oxygen reduction reaction (ORR) / water stability limit |

| Pt²⁺ + 2e⁻ ⇌ Pt(s) | ~1.18 | Platinum dissolution/redeposition |

| IrO₂(s) + 4H⁺ + 4e⁻ ⇌ Ir(s) + 2H₂O | ~0.98 | Iridium oxide stability for OER |

| Pd²⁺ + 2e⁻ ⇌ Pd(s) | 0.951 | Palladium dissolution potential |

Experimental Protocols for Key Measurements

Protocol: Determining the Reversible Potential via the Nernst Equation

Objective: To experimentally verify the Nernstian shift of a redox couple's potential with pH in acidic electrolyte. Materials: Electrochemical cell, working electrode (e.g., Pt disk), reference electrode (e.g., Ag/AgCl in 3M KCl), counter electrode (Pt mesh), potentiostat, buffer solutions (pH 0-6, 0.1 M ionic strength), analyte (e.g., 1 mM Quinone/Hydroquinone couple). Procedure:

- Prepare a series of acidic buffer solutions with precise pH values (e.g., 1.0, 2.0, 3.0, 4.0).

- Add an equal, low concentration (e.g., 1 mM) of both the oxidized and reduced forms of a reversible redox couple to each buffer.

- Assemble a three-electrode cell with the working electrode polished and cleaned.

- For each buffer, perform a low scan rate (e.g., 1 mV/s) cyclic voltammetry (CV) scan around the expected formal potential.

- Record the formal potential (E_f°) for each pH as the average of the anodic and cathodic peak potentials from the CV.

- Plot E_f° vs. pH. The slope should be -0.0591(c/n) V/pH, where *c is the number of H⁺ in the balanced half-reaction.

Protocol: Calculating ΔG for a Dissolution Reaction from Electrochemical Data

Objective: To calculate the Gibbs free energy change for a metal catalyst's dissolution (M → Mⁿ⁺ + ne⁻) in acidic media. Materials: Potentiostat, electrochemical cell, working electrode (catalyst of interest), relevant electrolyte, reference electrode. Procedure:

- Perform an anodic linear sweep voltammetry (LSV) scan (e.g., 0.5 mV/s) from the open circuit potential into the oxidative region.

- Identify the onset potential (E_onset) for a sustained anodic current, corresponding to M → Mⁿ⁺ + ne⁻.

- The reaction potential (Ereaction) under those specific conditions is approximated by Eonset.

- The ΔG for dissolution is calculated as: ΔG = nFE_reaction.

- To find the standard ΔG°, use the standard potential (E°_Mⁿ⁺/M) from literature: ΔG° = -nFE°.

- The activity of Mⁿ⁺ can then be related to the measured potential via the Nernst equation: Eonset ≈ E° + (RT/nF) ln(aMⁿ⁺).

Diagram: Relationship of Core Concepts in Acidic Stability

Diagram 1: Thermodynamic Control of Catalyst Stability in Acid

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Acidic Media Thermodynamics Research

| Reagent / Material | Function & Explanation |

|---|---|

| 0.1 M HClO₄ (Perchloric Acid) Electrolyte | Common acidic electrolyte for fundamental studies. Perchlorate anion has low specific adsorption, minimizing interference on electrode surfaces. |

| Saturated Calomel Electrode (SCE) or Ag/AgCl Reference | Stable reference electrode. Potential must be converted to the Standard Hydrogen Electrode (SHE) scale for thermodynamic analysis using a known offset (e.g., SCE = +0.241 V vs. SHE). |

| Nafion Membrane | Proton-exchange membrane used to separate electrode compartments while allowing H⁺ transport, mimicking PEM fuel cell/electrolyzer environments. |

| pH Buffers (e.g., Phosphate, Acetate, Sulfate) | Maintain constant proton activity (pH) during experiments, crucial for isolating pH effects as per the Nernst equation. |

| High-Purity Water (18.2 MΩ·cm) | Prevents contamination from ions that could alter electrochemical potentials or catalyze side reactions. |

| Quinhydrone (Quinone/Hydroquinone) | Reversible redox couple used as a internal potential standard to verify reference electrode potential or Nernstian behavior across pH. |

| Ultra-high Purity Inert Gas (Ar, N₂) | For deaerating electrolytes to remove dissolved O₂, which can interfere with measurements by introducing an additional redox couple (O₂/H₂O). |

The electrochemical stability of metal catalysts in acidic electrolytes is a cornerstone of modern electrochemical research, directly impacting fields from fuel cells to electrosynthesis. This guide contextualizes the key thermodynamic regions—immunity, corrosion, and passivation—within the framework of Pourbaix (E-pH) diagram analysis, a critical tool for predicting catalyst stability. Understanding these domains is essential for designing durable catalysts for proton-exchange membrane water electrolyzers (PEMWE) and acidic organic electrosynthesis, where harsh conditions prevail.

Thermodynamic Foundations: The Pourbaix Diagram

A Pourbaix diagram maps the thermodynamically stable phases of an element in an aqueous electrochemical system as a function of electrode potential (E) and pH. For metals in acidic electrolytes (typically pH < 7), three primary regions dictate stability.

Immunity: At sufficiently low potentials (highly reducing conditions), the metal remains in its metallic (M⁰) state, immune to oxidative dissolution. This is the ideal operational region for a stable catalyst. Corrosion: At higher potentials, the metal oxidizes to soluble ionic species (e.g., M²⁺(aq)), leading to catastrophic dissolution and catalyst degradation. Passivation: At even higher potentials, the metal may form an insoluble oxide or hydroxide layer (e.g., M₂O₃). This passive film can protect the bulk metal from further corrosion, but its stability (electronic conductivity, adherence) is critical for catalytic function.

Quantitative Stability Data for Key Catalytic Metals

The operational window for catalysts in acidic media (e.g., 0.1 M H₂SO₄, pH ~1) is defined by the hydrogen evolution reaction (HER, ~0 V vs. RHE) and oxygen evolution reaction (OER, ~1.23 V vs. RHE). Stability data for common metals are summarized below.

Table 1: Stability Regions of Select Metals in Acidic Electrolytes (vs. RHE, pH 0-1)

| Metal | Immunity Region (V vs. RHE) | Primary Corrosion Product | Passivation Region (V vs. RHE) | Passivation Layer | Key Catalyst Use |

|---|---|---|---|---|---|

| Platinum (Pt) | < ~0.8 - 1.1 | Pt²⁺ (minimal) | > ~1.1 | PtO₂ (thin, reversible) | HER, ORR, anode catalyst support. |

| Iridium (Ir) | < ~0.9 - 1.3 | IrO₂²⁺ (slow) | > ~1.3 | IrO₂ (conductive, stable) | OER catalyst. |

| Gold (Au) | < ~1.4 | Au⁺ (complexed) | > ~1.4 | Au₂O₃ (unstable) | ORR, inert substrate. |

| Copper (Cu) | < ~0.1 | Cu²⁺ | ~0.1 to ~0.6 | Cu₂O / CuO | CO₂ reduction (requires protection). |

| Nickel (Ni) | < ~0.1 | Ni²⁺ | > ~0.4 (pH-dependent) | NiO / Ni(OH)₂ | Not stable in strong acid. |

Table 2: Experimental Corrosion Rates in 0.5 M H₂SO₄ at 25°C

| Metal | Applied Potential (V vs. RHE) | Region | Measured Corrosion Rate (µA/cm²) | Equivalent Dissolution (ng/cm²·s) | Method |

|---|---|---|---|---|---|

| Polycrystalline Pt | 1.0 | Immunity/Onset Passivation | 0.01 - 0.05 | ~0.5 - 2.5 | ICP-MS |

| Polycrystalline Ir | 1.5 | Passivation | 0.1 - 0.3 | ~9.6 | ICP-MS |

| Polycrystalline Cu | 0.3 | Corrosion | > 100 | > 3300 | RDE Mass Loss |

Key Experimental Protocols for Stability Assessment

Protocol 1: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for Dissolution Measurement

- Objective: Quantify trace metal ion dissolution from an electrode during electrochemical cycling.

- Materials: Working electrode (catalyst on substrate), acidic electrolyte (e.g., 0.1 M HClO₄), electrochemical cell, ICP-MS.

- Procedure:

- Clean all cell components with aqua regia and ultrapure water (18.2 MΩ·cm).

- Fill cell with a known volume (e.g., 10 mL) of purified electrolyte.

- Perform electrochemical protocol (e.g., chronoamperometry, cyclic voltammetry).

- Post-experiment, collect the entire electrolyte volume.

- Acidify the sample with ultrapure HNO₃ to 2% v/v.

- Analyze using ICP-MS with external calibration standards.

- Calculate dissolution rate:

Rate (mol/s) = (Concentration (mol/L) * Volume (L)) / Time (s).

Protocol 2: In-situ Electrochemical Quartz Crystal Microbalance (EQCM)

- Objective: Monitor mass changes on an electrode in real-time with nanogram sensitivity.

- Materials: EQCM with Au-coated quartz crystal, catalyst coating station, potentiostat compatible with EQCM.

- Procedure:

- Coat the EQCM crystal with a thin, adherent layer of the catalyst material.

- Calibrate the frequency shift (Δf) to mass change (Δm) using Sauerbrey equation:

Δm = -C * Δf, where C is the sensitivity constant. - Immerse the crystal in the acidic electrolyte under potential control.

- Apply potential steps or sweeps while simultaneously recording current and frequency.

- A frequency increase indicates mass loss (dissolution); a decrease indicates mass gain (oxide formation or deposition).

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials and Reagents for Acidic Stability Studies

| Item | Function / Rationale | Key Consideration for Stability Studies |

|---|---|---|

| Perchloric Acid (HClO₄), Ultra Pure | Common electrolyte (0.1 M). Low specific adsorption minimizes anion interference. | Highly oxidative when hot/concentrated. Must be used with extreme caution and proper training. |

| Sulfuric Acid (H₂SO₄), Ultra Pure | Common electrolyte (0.5 M). Relevant to PEMWE conditions. | Sulfate anions can adsorb on some metals, influencing reactivity and oxide formation. |

| Hydrochloric Acid (HCl), TraceMetal Grade | Electrolyte for specific studies; used for cleaning. | Chloride anions aggressively promote corrosion and complex metal ions, altering stability regions. |

| Aqua Regia (3:1 HCl:HNO₃) | Powerful oxidizing mixture for cleaning glassware and etching electrodes. | Extremely hazardous. Must be prepared fresh in a fume hood; never store. |

| High-Purity Water (18.2 MΩ·cm) | Solvent for all electrolytes. Reduces impurity-driven side reactions. | Use from a certified ultrapure system; resistivity is a key quality indicator. |

| Nafion Perfluorinated Resin | Binder for catalyst inks on rotating disk electrodes (RDEs). | Can introduce sulfonic acid groups/local acidity; use consistent, minimal amounts (e.g., 0.02-0.1% wt). |

| Single-Crystal Metal Electrodes (Pt, Au, etc.) | Model systems with well-defined surfaces. | Enable fundamental studies linking stability to specific crystallographic facets. |

| Indium Tin Oxide (ITO) or Fluorinated Tin Oxide (FTO) Glass | Transparent conducting substrate for spectroelectrochemistry. | Allows in-situ optical monitoring of corrosion/passivation (e.g., UV-Vis). |

Within the context of Pourbaix diagram catalyst stability research for acidic electrolytes (e.g., PEM electrolyzers, acidic CO₂ reduction), understanding the non-equilibrium solubility of metal ions and solid phases under high proton activity is paramount. Standard solubility product constants (K_sp) fail under highly acidic, non-equilibrium conditions where proton-coupled dissolution kinetics and the formation of soluble aquo- and chloro-complexes dominate. This guide details the mechanisms, experimental protocols, and material considerations essential for researchers investigating catalyst durability and metal ion contamination in acidic media.

Mechanisms of Proton-Coupled Dissolution

Under high [H⁺], two primary pathways enhance the solubility of metal oxides, hydroxides, and even some sparingly soluble salts:

2.1. Direct Proton Attack: M–O–M + H⁺ → M–OH–M⁺ (surface protonation) M–OH–M⁺ + H⁺ → 2M⁺ + H₂O (lattice cleavage) This pathway is critical for oxide catalysts (e.g., IrO₂, RuO₂) in oxygen evolution reaction (OER).

2.2. Ligand-Assisted Dissolution: In chloride-containing acidic electrolytes (common in many industrial processes), dissolution is accelerated: MxOy + yH⁺ + zCl⁻ → MCl_z^(y-2z) + (y/2)H₂O This leads to stable complexes like [PtCl₆]²⁻ or [PdCl₄]²⁻, drastically increasing effective solubility.

Key Experimental Protocols

3.1. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for Solubility Quantification Protocol:

- Electrolyte Preparation: Prepare 0.1 M H₂SO₄ (or other relevant acid) with/without 0.1 M NaCl. Purge with Ar to remove dissolved CO₂.

- Material Exposure: Add 100 mg of catalyst powder (e.g., 20 wt% Pt/C, IrO₂ nanopowder) to 50 mL of electrolyte in a PTFE vial.

- Conditioning: Place in a temperature-controlled shaker at 80°C (simulating accelerated conditions) for 24-168 hours.

- Separation: After exposure, filter the suspension through a 20 nm alumina membrane syringe filter.

- Acidification: Acidify the filtrate with 2% ultrapure HNO₃.

- Analysis: Analyze via ICP-MS against a calibration curve. Use internal standards (e.g., ¹¹⁵In, ¹⁸⁷Re) for signal drift correction. Data Output: Total dissolved metal concentration (ppb or µg/L).

3.2. Electrochemical Flow Cell Coupled to ICP-MS (EC-ICP-MS) Protocol:

- Cell Setup: Integrate a flow-through electrochemical cell (with a known catalyst-coated working electrode) directly upstream of the ICP-MS nebulizer.

- Electrolyte Flow: Use a peristaltic pump to circulate acidic electrolyte (e.g., 0.05 M H₂SO₄) at 0.5 mL/min.

- Potential Control: Hold the working electrode at a fixed potential relevant to operation (e.g., 1.8 V vs. RHE for OER).

- Time-Resolved Monitoring: The ICP-MS records real-time dissolution signals (e.g., ¹⁹⁵Pt, ¹⁹³Ir) synchronized with electrochemical data. Data Output: Dissolution rate (ng cm⁻² s⁻¹) as a function of applied potential.

Table 1: Solubility of Selected Catalyst Materials in Acidic Electrolyte (0.1 M H₂SO₄, 80°C, 24h)

| Material | Phase | Measured Total Dissolved Metal (µg/L) | Log(K_sp) of Corresponding Hydroxide |

|---|---|---|---|

| Platinum | Pt(0) / PtO₂ | 15.2 (Pt) | ~ -38 (Pt(OH)₂) |

| Iridium Dioxide | IrO₂ | 842.7 (Ir) | ~ -12 (Ir(OH)₄) |

| Ruthenium Dioxide | RuO₂ | 12,450 (Ru) | ~ -6 (Ru(OH)₄) |

| Gold | Au(0) | < 0.1 (Au) | - |

| Titanium (substrate) | TiO₂ (anatase) | 8.5 (Ti) | ~ -29 (Ti(OH)₄) |

Table 2: Effect of Chloride on Dissolution Rate (EC-ICP-MS at 1.4 V vs. RHE)

| Catalyst | Electrolyte | Dissolution Rate (ng cm⁻² s⁻¹) |

|---|---|---|

| Pt Nanoparticles | 0.1 M HClO₄ | 0.001 |

| Pt Nanoparticles | 0.1 M HClO₄ + 10 mM NaCl | 0.157 |

| IrO₂ thin film | 0.05 M H₂SO₄ | 0.012 |

| IrO₂ thin film | 0.05 M H₂SO₄ + 10 mM NaCl | 0.089 |

Visualization of Pathways and Workflows

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Acidic Solubility Studies

| Item | Function & Specification | Critical Note |

|---|---|---|

| Ultrapure Acids | For electrolyte prep and sample acidification. Trace metal grade HNO₃, H₂SO₄, HClO₄. | Baseline metal contamination must be < 1 ppt for target analytes. |

| High-Purity Salts | For supporting electrolyte and complexation studies (e.g., NaCl, Na₂SO₄). 99.999% purity. | Minimizes introduction of competing cationic impurities. |

| PTFE Vials & Filters | All sample digestion, storage, and filtration must use PTFE or PFA materials. | Precludes leaching of silicate from glass and adsorption onto glass walls. |

| ICP-MS Calibration Standards | Multi-element standard solutions, customized for catalyst metals (Pt, Pd, Ir, Ru, Au, Ti, etc.). | Must be matrix-matched to the acidic electrolyte. |

| Certified Reference Material (CRM) | e.g., NIST 1643f (Trace Elements in Water). | Used for validating ICP-MS method accuracy and recovery. |

| Membrane Filters | Anodized alumina or polyethersulfone (PES) syringe filters, 20 nm pore size. | For complete separation of nanoparticulate catalyst from dissolved species. |

| Potentiostat & Electrochemical Cell | For controlled potential experiments. Cell must be all-PTFA or PEEK with minimal metal parts. | Avoids corrosion of cell components contributing to background signal. |

This whitepaper addresses a central pillar of a broader thesis on Pourbaix Diagram Catalyst Stability in Acidic Electrolytes Research. The design of durable, active catalysts for applications in proton-exchange membrane electrolyzers, fuel cells, and electrosynthesis necessitates a rigorous understanding of material stability under operating conditions. A critical challenge is identifying the stable chemical phases of catalytic active sites under low pH (high proton activity) and applied potential. This guide details the theoretical framework, experimental protocols, and analytical tools required to pinpoint these critical points of stability, where the catalytically active phase persists without dissolution or passivation.

Theoretical Framework: Pourbaix Diagrams at Low pH

The Pourbaix diagram (potential-pH diagram) is an electrochemical phase map that plots the thermodynamically stable phases of an element or compound as a function of electrode potential (E) and pH. At low pH (< 4), the high concentration of H⁺ ions shifts equilibria, making dissolution to aqueous cations (e.g., Mⁿ⁺) a dominant deactivation pathway for many metals.

Key Regions at Low pH:

- Immunity: The metallic (M⁰) phase is stable. The catalyst remains in its reduced, metallic form.

- Corrosion/Dissolution: The aqueous ion (Mⁿ⁺) is the stable species. The active site leaches into the electrolyte, leading to irreversible catalyst loss.

- Passivation: A solid oxide, hydroxide, or hydrous oxide (MₓOᵧ, M(OH)₂) is stable. This can form a protective layer or a catalytically inactive barrier.

The "critical point" for a catalytic active site is often the boundary between the Immunity and Passivation regions, where the surface may be optimally active and stable. The boundary between Immunity and Corrosion is a critical failure point.

Key Quantitative Data & Stability Thresholds

Recent computational and experimental studies provide critical data for common catalytic elements in acidic media (pH 0-3, 25°C). The following tables summarize stability thresholds.

Table 1: Thermodynamic Stability of Selected Catalytic Elements at pH = 0

| Element | Stable Metallic Phase (Immunity) Potential Range (vs. SHE) | Primary Dissolution Product (Corrosion) | Passivating Oxide Phase |

|---|---|---|---|

| Platinum (Pt) | E > ~0.98 V | Pt²⁺, PtO₂²⁻ (at high E) | PtO₂ (above ~0.98 V) |

| Iridium (Ir) | E > ~0.926 V | Ir³⁺, IrO₃²⁻ (at high E) | IrO₂ (above ~0.926 V) |

| Ruthenium (Ru) | E > ~0.68 V | Ru³⁺, RuO₄²⁻ | RuO₂ (above ~0.68 V, unstable to OER) |

| Palladium (Pd) | E > ~0.92 V | Pd²⁺ | PdO (above ~0.92 V) |

| Gold (Au) | E > ~1.50 V | Au⁺, Au³⁺ | Au₂O₃ (above ~1.50 V) |

Table 2: Experimentally Observed Dissolution Rates in 0.1 M HClO₄ at 1.2 V vs. RHE

| Catalyst Material | Dissolution Rate (ng cm⁻² h⁻¹) | Dominant Mechanism | Reference (Year) |

|---|---|---|---|

| Pt nanoparticles (5 nm) | 15 - 25 | Transient during oxide formation/reduction | Cherevko et al. (2014) |

| IrO₂ (film) | < 1 | Steady-state, potential-dependent | Geiger et al. (2018) |

| RuO₂ (film) | 250 - 500 | Severe during OER, forms volatile RuO₄ | Geiger et al. (2018) |

| Pd nanoparticles | 80 - 120 | Continuous, especially during oxide formation | Povia et al. (2021) |

Experimental Protocols for Identification

In Situ/Operando X-ray Absorption Spectroscopy (XAS)

Objective: Determine the oxidation state and local coordination geometry of the active site under working conditions.

Detailed Protocol:

- Cell Preparation: Use a custom-designed electrochemical flow cell with X-ray transparent windows (e.g., Kapton, carbon).

- Electrode Fabrication: Deposit catalyst ink (catalyst powder, Nafion ionomer, isopropanol) onto a porous carbon paper or a glassy carbon disc. Loadings typically 0.1-1.0 mg catalyst cm⁻².

- Electrolyte & Setup: Use 0.1 M HClO₄ (high purity) as the acidic electrolyte. A standard three-electrode setup is used: catalyst as working electrode, reversible hydrogen electrode (RHE) as reference, and Pt mesh as counter electrode.

- Data Acquisition:

- Secure the cell in the XAS beamline.

- Apply a series of constant potentials (e.g., 0.4 V to 1.6 V vs. RHE) representing the operational window.

- At each potential hold, acquire both X-ray Absorption Near Edge Structure (XANES) and Extended X-ray Absorption Fine Structure (EXAFS) spectra.

- Simultaneously record electrochemical current.

- Data Analysis: Fit XANES spectra to linear combinations of reference spectra (e.g., metal foil, metal oxide) to quantify phase composition. Fit EXAFS spectra to obtain bond distances and coordination numbers.

Online Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

Objective: Quantify dissolution of catalyst material in real-time with ultra-high sensitivity.

Detailed Protocol:

- System Configuration: Integrate the electrochemical cell outlet directly into the nebulizer of the ICP-MS via PTFE tubing. A peristaltic pump maintains a constant electrolyte flow (e.g., 0.2 mL min⁻¹).

- Electrode & Cell: Use a rotating disc electrode (RDE) configuration to ensure homogeneous mass transport. The cell must be gas-tight and purged with inert gas (Ar).

- Experimental Sequence:

- Begin with electrolyte flow and ICP-MS stabilization while holding potential at open circuit voltage (OCV).

- Initiate a potential program (e.g., cyclic voltammetry, chronoamperometry at fixed potentials).

- The ICP-MS continuously monitors selected isotope signals (e.g., ¹⁹⁵Pt, ¹⁹³Ir, ¹⁰¹Ru) with a time resolution of ~1-10 seconds.

- Calibration: Perform post-experiment calibration by injecting standard solutions of known concentration into the electrolyte stream.

Electrochemical Stability Assessment via Cyclic Voltammetry

Objective: Rapidly screen for electrochemical signatures of dissolution, oxide formation/reduction, and phase transitions.

Detailed Protocol:

- Electrode Preparation: Use a thin-film rotating ring-disc electrode (RRDE). The catalyst is coated on the glassy carbon disc. The Pt ring is used to detect dissolved species (collection experiments).

- Stability Protocol:

- Record initial stable cyclic voltammogram (CV) in a non-activating window (e.g., 0.05 - 0.4 V vs. RHE) to establish baseline.

- Perform accelerated stress tests (AST) by scanning repeatedly over a wide potential range (e.g., 0.05 - 1.6 V vs. RHE at 500 mV s⁻¹ for 1000 cycles).

- Periodically return to the initial non-activating window to record CVs and monitor changes in electrochemically active surface area (ECSA) via hydrogen underpotential deposition (Hupd) or oxide stripping charge.

- Analysis: The loss of ECSA and changes in oxide formation/reduction peaks indicate corrosion or phase transformation.

Visualization of Methodologies

Diagram 1: Experimental Workflow for Identifying Critical Points

Diagram 2: Low pH Stability Decision Pathway

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function/Description | Critical Specification |

|---|---|---|

| High-Purity HClO₄ (e.g., 70%, TraceSELECT) | Standard acidic electrolyte. Low chloride and metal impurities prevent misleading corrosion data. | < 1 ppb total metallic impurities. |

| Reversible Hydrogen Electrode (RHE) | The reference electrode for all potential measurements in acidic media. Provides a pH-independent reference scale. | Must be calibrated frequently in clean electrolyte. |

| Nafion Ionomer Solution (5% wt) | Binds catalyst particles to the electrode substrate and provides proton conductivity. | Dilute to 0.05-0.5% wt in alcohol for ink preparation. |

| X-ray Transparent Window Film (e.g., Kapton) | Forms the window of operando electrochemical cells for XAS and XRD, minimizing X-ray absorption. | High chemical resistance, specific thickness (e.g., 25 µm). |

| ICP-MS Tuning Solution (e.g., 1 ppb Ce, Co, Li, Tl, Y) | Optimizes ICP-MS instrument sensitivity and mass calibration before dissolution experiments. | Must contain elements covering low, mid, and high mass ranges. |

| Isotopically Enriched Catalyst Tracers | Used in model studies to differentiate between dissolution from different catalyst components or layers via ICP-MS. | e.g., ¹⁹⁴Pt, ¹⁰⁵Pd. |

| Single-Crystal Metal Electrodes (Pt(hkl), Au(hkl), etc.) | Provide atomically defined surfaces as model systems to understand fundamental phase stability without nanoparticle complexity. | Orientation accuracy within 0.5°. |

From Theory to Bench: Building and Applying Pourbaix Diagrams for Acid-Stable Catalyst Design

Within the context of research on catalyst stability in acidic electrolytes, Pourbaix diagrams are indispensable predictive tools. These potential-pH maps define the domains of thermodynamic stability for metals, their oxides, hydroxides, and dissolved ions. For electrocatalyst design—particularly for reactions like the oxygen evolution reaction (OER) in proton exchange membrane electrolyzers—the diagram identifies potential-pH conditions where the catalyst remains stable or may corrode, guiding material selection and operational parameter optimization.

Theoretical Foundation

The Pourbaix diagram is constructed from the Nernst equation and mass-balance constraints. The key governing equations are:

For redox reactions not involving H⁺ or OH⁻:

E = E⁰ - (0.05916/n) * log(Q)at 298.15 K.For reactions involving H⁺:

E = E⁰ - (0.05916*m/n)*pH - (0.05916/n) * log(Q), where m is the number of H⁺ ions.For pH-dependent hydrolysis/precipitation: A horizontal, vertical, or sloped line represents the equilibrium boundary.

The overall stability field is determined by comparing the Gibbs free energy of formation (ΔGf⁰) for all possible species.

Step-by-Step Construction Methodology

Step 1: Define the System and Gather Data

Select the element (e.g., Pt, Ir, Ni) and all plausible species in aqueous systems (e.g., M, M₂O₃, M⁺, MO₄²⁻). Gather standard Gibbs free energy of formation (ΔGf⁰) data for each species from reliable thermodynamic databases like the NIST JANAF tables or CRC Handbook. Recent computational databases (e.g., Materials Project) can supplement experimental data.

Table 1: Exemplary Thermodynamic Data for Iridium at 298.15 K

| Species | State | ΔGf⁰ (kJ/mol) | Reference / Notes |

|---|---|---|---|

| Ir | s | 0.0 | Defined reference |

| IrO₂ | s | -188.5 | Key oxide for OER catalysts |

| Ir³⁺ | aq | +130.5 | Assumed value for demonstration |

| IrO₄²⁻ | aq | +150.2 | Assumed value for demonstration |

| H₂O | l | -237.18 | Required for all aqueous equilibria |

Step 2: Enumerate All Relevant Reactions

Formulate balanced electrochemical and chemical reactions for each phase boundary. For Ir in water, critical reactions include:

- IrO₂ + 4H⁺ + 4e⁻ ⇌ Ir + 2H₂O (Reduction of oxide)

- Ir³⁺ + 3e⁻ ⇌ Ir (Metal ion reduction)

- IrO₂ + 4H⁺ + 2e⁻ ⇌ Ir³⁺ + 2H₂O (Oxide dissolution)

- IrO₄²⁻ + 8H⁺ + 6e⁻ ⇌ Ir + 4H₂O (Oxoanion reduction)

- 2IrO₂ + 2H₂O ⇌ 2IrO₄²⁻ + 4H⁺ + 4e⁻ (Oxide to oxoanion)

Step 3: Calculate Equilibrium Equations

Calculate the standard potential (E⁰) for each electrochemical reaction using ΔG⁰rxn = -nFE⁰. Express the equilibrium condition as E = f(pH, log[activity]).

Table 2: Derived Equilibrium Equations for the Ir-H₂O System

| Reaction No. | Equilibrium Equation (E vs. SHE) | Boundary Type |

|---|---|---|

| 1 | E = 1.02 - 0.0591*pH | Sloped (Ir/IrO₂) |

| 2 | E = 0.45 - 0.0591*log[Ir³⁺] | Horizontal (Ir³⁺/Ir) |

| 3 | E = 1.08 - 0.1182pH + 0.0197log[Ir³⁺] | Sloped (IrO₂/Ir³⁺) |

| 4 | E = 0.97 - 0.0788pH + 0.00985log[IrO₄²⁻] | Sloped (Ir/IrO₄²⁻) |

| 5 | E = 1.04 - 0.0788pH - 0.0197log[IrO₄²⁻] | Sloped (IrO₂/IrO₄²⁻) |

Note: Calculations assume a dissolved species activity of 10⁻⁶ M, a typical threshold for corrosion.

Step 4: Plot Boundaries and Define Stability Regions

Using the equations from Table 2, plot lines on an E (y-axis, V vs. SHE) vs. pH (x-axis, 0-14) grid. The intersection of lines defines triple points. The region with the lowest Gibbs free energy for a given (E, pH) coordinate is the dominant species.

Step 5: Incorporate the Stability Domain of Water

Superimpose the water stability lines:

- Upper limit (O₂ evolution): E = 1.23 - 0.0591*pH

- Lower limit (H₂ evolution): E = 0.00 - 0.0591*pH Catalyst operation must consider overpotentials beyond these lines.

Experimental Protocol: Validating Diagram Predictions

To verify the predicted corrosion boundaries for a catalyst (e.g., IrO₂ film on a Ti substrate) in acidic electrolyte (0.5 M H₂SO₄, pH ~0.3).

Materials:

- Working Electrode: Sputtered IrO₂ on Ti disk (0.196 cm²).

- Counter Electrode: Pt mesh.

- Reference Electrode: Reversible Hydrogen Electrode (RHE) in the same electrolyte.

- Electrolyte: 0.5 M H₂SO₄, purged with N₂.

- Instrumentation: Potentiostat, ICP-MS.

Procedure:

- Electrochemical Setup: Assemble a 3-electrode cell. Record open circuit potential (OCP) for 30 min.

- Potentiodynamic Scan: Perform a slow anodic scan (0.1 mV/s) from OCP to 1.8 V vs. RHE. Monitor current for oxidation/dissolution.

- Potentiostatic Hold: Hold the electrode at a series of fixed potentials (e.g., 1.4 V, 1.6 V, 1.8 V vs. RHE) for 2 hours each. Continuously monitor current.

- Solution Analysis: After each hold, collect a 5 mL aliquot of electrolyte. Analyze via ICP-MS to quantify dissolved Ir concentration.

- Data Correlation: Plot measured Ir dissolution rate (from ICP-MS) vs. applied potential. Compare the onset potential for significant dissolution to the predicted boundary between IrO₂ and IrO₄²⁻ or Ir³⁺ on the constructed Pourbaix diagram.

Visualizing the Construction Workflow

Title: Pourbaix Diagram Construction and Validation Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for Pourbaix Analysis & Validation

| Item | Function/Brief Explanation |

|---|---|

| High-Purity Deionized Water (18.2 MΩ·cm) | Prevents contamination in electrolyte preparation for accurate potential measurement. |

| Ultrapure Acids/Bases (e.g., H₂SO₄, HClO₄, KOH) | For precise pH control and electrolyte formulation. |

| Reversible Hydrogen Electrode (RHE) | The essential reference electrode in aqueous electrochemistry; its potential scales with pH. |

| Inert Gas Supply (Argon, Nitrogen) | For deaerating electrolytes to remove interfering O₂. |

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) Standards | Calibration standards for quantitative analysis of dissolved metal ions from corrosion. |

| Standard Thermodynamic Database (e.g., NIST JANAF, HSC Chemistry) | Source of reliable ΔGf⁰, S⁰, and Cp data for calculations. |

| Electrochemical Cell (3-electrode) | With separated compartments to prevent contamination of reference electrode. |

Within the broader thesis investigating catalyst stability in acidic electrolytes for applications such as proton exchange membrane electrolyzers and fuel cells, Pourbaix diagrams serve as indispensable thermodynamic maps. These diagrams plot the stable phases of an element or material as a function of applied potential and pH. Traditional experimental construction is laborious and often impractical for novel, multi-element materials. Density Functional Theory (DFT) provides a powerful computational framework to predict these diagrams ab initio, accelerating the discovery and screening of corrosion-resistant, electrochemically stable catalysts for harsh acidic environments.

Theoretical Foundation: From DFT to Pourbaix Diagram

The Pourbaix diagram is constructed from the minimization of Gibbs free energy. For an electrochemical system, the relevant thermodynamic potential is the grand canonical potential. DFT calculates the electronic energy of solid and gaseous species, which is then corrected to Gibbs free energy using vibrational, rotational, and translational contributions (for molecules) and the computational hydrogen electrode (CHE) model for proton/electron transfers.

Key Equation (CHE Model): The free energy of a proton-electron pair (H⁺ + e⁻) is referenced to half that of H₂ gas at standard conditions: G(H⁺ + e⁻) = 1/2 G(H₂). The effect of potential (U) and pH is incorporated via: ΔG = ΔG⁰ - neU + _kBT * ln(10) * pH where _ne is the number of electrons transferred.

Diagram Construction Protocol:

- DFT Calculations: Perform geometry optimization and energy calculations for all considered solid phases (pure elements, oxides, hydroxides, etc.), aqueous ions, and water/gas molecules (H₂, O₂).

- Free Energy Corrections: Apply zero-point energy, thermal, and entropic corrections to DFT total energies to obtain G(298 K, 1 bar).

- Aqueous Ion Reference: The free energy of aqueous ions is typically anchored to experimental solvation energies or calculated using implicit solvation models (e.g., VASPsol).

- Phase Stability Determination: For each (U, pH) coordinate, calculate the formation free energy for all possible phases and select the most stable one.

- Boundary Calculation: Solve for the (U, pH) lines where the stability of two phases is equal.

Table 1: Key DFT Parameters for Pourbaix Diagram Construction

| Parameter | Typical Setting/Value | Purpose/Justification |

|---|---|---|

| Exchange-Correlation Functional | PBE, RPBE, SCAN, HSE06 | Determines electron-electron interaction accuracy. PBE is common for solids. |

| Plane-Wave Cutoff Energy | 400-600 eV | Basis set size; ensures convergence of total energy. |

| k-point Mesh Density | Γ-centered, ~30 Å⁻¹ resolution | Samples Brillouin zone for bulk solids. |

| Pseudopotential | Projector Augmented-Wave (PAW) | Represents core electrons efficiently. |

| Energy Convergence Criterion | ≤ 1×10⁻⁵ eV/atom | Ensures electronic step precision. |

| Force Convergence Criterion | ≤ 0.01 eV/Å | Ensures ionic relaxation accuracy. |

| Solvation Model | VASPsol, implicit solvent | Estimates aqueous ion and surface hydration energies. |

| Reference for H⁺/e⁻ | Computational Hydrogen Electrode (CHE) | Links electron/proton chemical potential to H₂. |

Computational Workflow for DFT-Pourbaix Generation

The following diagram outlines the standard computational pipeline.

Diagram 1: DFT Pourbaix Calculation Workflow

Experimental Validation Protocol for Computational Diagrams

DFT-calculated diagrams require experimental validation, particularly for novel materials.

Protocol: In-situ Electrochemical Stability Mapping

- Electrode Preparation: Synthesize the novel material (e.g., via hydrothermal, sol-gel, or sputtering). Deposit as a thin film or prepare an ink for coating onto an inert rotating disk electrode (e.g., glassy carbon).

- Electrochemical Cell Setup: Use a standard three-electrode cell with the material as working electrode, a reversible hydrogen electrode (RHE) as reference (critical for pH correction), and a Pt mesh counter electrode. Use a N₂ or Ar-purged acidic electrolyte (e.g., 0.5 M H₂SO₄, pH ~0.3).

- Potentiostatic Hold Experiment:

- Set the cell potential to a value within a predicted stable region (e.g., 0.8 V vs. RHE). Hold for 1-2 hours while monitoring current.

- Use Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to analyze electrolyte for dissolved metal ions.

- Ex-situ characterize the electrode surface post-hold via X-ray Photoelectron Spectroscopy (XPS) and Scanning Electron Microscopy (SEM).

- Cyclic Voltammetry (CV) Stability Screening: Cycle the potential across a range spanning predicted phase boundaries (e.g., 0.05 to 1.5 V vs. RHE, 50 mV/s). Observe changes in CV shape over 100-1000 cycles, indicating corrosion or phase transformation.

- Correlate Data: Compare dissolution rates (from ICP-MS) and surface composition changes (from XPS) with the predicted stable/ unstable regions from the DFT-Pourbaix diagram.

Table 2: Quantitative Experimental Validation Data for Hypothetical Novel Anode Catalyst (M₁M₂Oₓ) in 0.5 M H₂SO₄

| Applied Potential (V vs. RHE) | DFT-Predicted Stable Phase | ICP-MS Dissolution Rate (ng cm⁻² h⁻¹) M₁ / M₂ | Post-Hold XPS Surface Phase | Experimental Stability Verdict |

|---|---|---|---|---|

| 0.4 | M₁O₂ + M₂ | 0.8 / 12.5 | M₁O₂, M₂ metallic | Partially Stable (M₂ leaches) |

| 0.9 | M₁M₂O₄ (spinel) | 1.2 / 1.5 | M₁M₂O₄ dominant | Stable |

| 1.4 | M₁O₃ + M₂O₃ | 45.0 / 8.7 | M₁O₃, amorphous M₂-oxyhydroxide | Unstable (High dissolution) |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Experimental Pourbaix Validation

| Item | Function/Brief Explanation |

|---|---|

| High-Purity Acid Electrolytes (e.g., H₂SO₄, HClO₄) | Provide the acidic medium (pH 0-3). High purity minimizes contaminant interference. |

| Reversible Hydrogen Electrode (RHE) | The essential reference electrode for acidic work, as its potential scales with pH. |

| Rotating Disk Electrode (RDE) Setup | Enables controlled mass transport, isolating intrinsic material stability from diffusion limits. |

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) | Detects trace-level dissolution of catalyst components into the electrolyte (ppt-ppb sensitivity). |

| In-situ/Operando Raman or FTIR Spectroelectrochemistry Cell | Probes molecular structure and adsorbates on the catalyst surface during potential hold. |

| Projector Augmented-Wave (PAW) Pseudopotential Library | The foundational set of atomic potentials for accurate DFT calculations in VASP, ABINIT, etc. |

| Materials Project/ OQMD Database API | Allows retrieval of computed DFT energies for known phases, serving as benchmarks or inputs. |

| Implicit Solvation Software (VASPsol, SIESTA sol) | Computes solvation free energies for aqueous ions, critical for accurate Pourbaix boundaries. |

Advanced Application: Multi-Element Systems and Kinetic Extensions

For complex catalysts (e.g., high-entropy alloys, doped perovskites), the diagram becomes multi-dimensional. The stable phase is determined by minimizing the total free energy subject to element conservation.

Diagram for Multi-Element Stability Analysis:

Diagram 2: Multi-Element Phase Fraction Analysis

Kinetic limitations (e.g., slow dissolution, oxide formation barriers) can cause materials to remain in metastable states. Ab initio molecular dynamics (AIMD) or nudged elastic band (NEB) calculations can provide activation energies for phase transitions, adding a kinetic overlay to the thermodynamic Pourbaix map.

DFT-calculated Pourbaix diagrams are a cornerstone computational tool for predicting the thermodynamic stability of novel materials in acidic electrolytes. When integrated with targeted experimental validation protocols, they form a rapid feedback loop for designing durable electrocatalysts. This approach directly addresses the core challenge of the overarching thesis: moving beyond trial-and-error to rationally engineer catalysts that persist under the harsh, oxidizing conditions of acidic electrochemistry.

The stability of electrocatalysts in acidic electrolytes, such as those in proton exchange membrane fuel cells (PEMFCs) and electrolyzers, is a fundamental limitation to their long-term performance and commercial viability. Research framed within the context of Pourbaix (potential-pH) diagram analysis provides a thermodynamic roadmap for predicting material stability under operational electrochemical conditions. This whitepaper synthesizes current understanding of the primary atomistic degradation pathways—dissolution, oxidation, and phase transformation—and provides a technical guide for their experimental prediction and quantification. The integration of in situ and operando characterization with computational Pourbaix analysis is critical for advancing durable catalyst design.

Core Degradation Pathways: Mechanisms and Predictors

Dissolution

Dissolution involves the loss of metal atoms from the catalyst surface into the electrolyte. It is driven by electrochemical potential and pH, perfectly contextualized by Pourbaix diagrams which map stable soluble ion species.

Key Mechanisms:

- Direct Cationic Dissolution: M → Mn+ + ne-

- Transient Oxide-Mediated Dissolution: Formation of a surface oxide (MxOy) followed by its chemical dissolution.

- Place-Exchange and Underpotential Deposition (UPD) facilitated dissolution, relevant for Pt and its alloys.

Oxidation and Surface Oxide Formation

Beyond monolayer surface oxide, bulk oxidation can lead to passivating layers or non-conductive species that degrade catalytic activity. Pourbaix diagrams delineate the potential-pH conditions for the stability of metallic vs. oxide phases.

Phase Transformation

This includes changes in crystal structure, composition, or morphology.

- Demetallation/Dealloying: Selective leaching of one component from a bimetallic catalyst (e.g., Co from PtCo).

- Agglomeration/Ostwald Ripening: Migration and coalescence of nanoparticles, driven by surface energy minimization.

- Support Corrosion: Degradation of carbon or oxide supports, leading to catalyst detachment.

Table 1: Experimentally Measured Dissolution Rates of Key Catalysts in 0.1 M HClO4 at 80°C

| Catalyst | Potential (V vs. RHE) | Dissolution Rate (ng cm-2 s-1) | Primary Dissolution Mechanism | Key Reference (Year) |

|---|---|---|---|---|

| Polycrystalline Pt | 1.0 - 1.2 | 0.05 - 0.5 | Transient Oxide Formation | L. Geiger et al. (2022) |

| Pt3Ni nanoparticle | 1.0 - 1.2 | 1.2 - 5.0 | Dealloying (Ni loss) | S. K. Kulkarni et al. (2023) |

| Ru@Pt core-shell | 1.0 - 1.4 | 15.0 - 50.0 | Core Corrosion & Shell Detachment | T. Fuchs et al. (2023) |

| Iridium Oxide (IrO2) | 1.4 - 1.6 | 0.01 - 0.1 | Cationic (Ir3+/4+) | M. P. Yadav et al. (2024) |

Table 2: Thermodynamic Predictors from Calculated Pourbaix Diagrams

| Material | Critical pH at 0.9V RHE | Stable Phase at OCV (pH 1) | Potential for Oxide Formation (V vs. RHE, pH 1) | Soluble Species Threshold Potential (V vs. RHE, pH 1) |

|---|---|---|---|---|

| Platinum (Pt) | < 0 | Pt(0) | >0.8 | >1.2 (Pt2+) |

| Palladium (Pd) | ~2.5 | Pd(0) | >0.9 | >1.4 (Pd2+) |

| Cobalt (Co) | >7.0 | Co2+(aq) | N/A | < 0.0 (Co2+) |

| Iridium (Ir) | < 0 | Ir(0) | >0.7 (IrO2) | >1.35 (IrO42-) |

Experimental Protocols for Degradation Prediction

Protocol 1:In SituInductively Coupled Plasma-Mass Spectrometry (ICP-MS)

Objective: Quantify real-time dissolution rates of catalyst materials. Methodology:

- Setup: Integrate an electrochemical flow cell directly to the ICP-MS nebulizer. Use a peristaltic pump for continuous electrolyte flow (~0.2 mL/min).

- Electrode: Prepare a thin-film rotating disk electrode (RDE) with a known catalyst loading (e.g., 20 µgmetal/cm2 on glassy carbon).

- Electrolyte: Use high-purity acidic electrolyte (e.g., 0.1 M HClO4).

- Procedure: Apply a potential hold or cycling protocol (e.g., 0.6 - 1.0 V RHE, 500 mV/s). The ICP-MS monitors selected ion isotopes (e.g., 195Pt, 60Ni) continuously.

- Calibration: Perform post-experiment standard addition calibration for quantitative concentration conversion.

- Data Analysis: Correlate ion concentration spikes with specific potential holds or cycle numbers to identify potential-dependent dissolution.

Protocol 2:OperandoX-ray Absorption Spectroscopy (XAS)

Objective: Probe oxidation state and local coordination changes during operation. Methodology:

- Cell: Use a custom-designed electrochemical XAS cell with X-ray transparent windows (e.g., Kapton).

- Electrode: Prepare a catalyst-coated gas diffusion layer or a high-surface-area carbon cloth to ensure sufficient signal.

- Measurement: Conduct experiments at a synchrotron beamline. Collect X-ray Absorption Near Edge Structure (XANES) and Extended X-ray Absorption Fine Structure (EXAFS) spectra while applying a controlled potential.

- Analysis: Fit XANES spectra using linear combination analysis with metal foil and oxide standards. Fit EXAFS spectra to determine coordination numbers and bond distances, identifying oxide formation or amorphization.

Protocol 3: Identical Location Transmission Electron Microscopy (IL-TEM)

Objective: Track nanoscale morphological and compositional changes of the same particles over time. Methodology:

- Sample Prep: Deposit a dilute catalyst ink onto a TEM finder grid with coordinate markers.

- Initial Characterization: Acquire high-resolution TEM (HRTEM), scanning TEM (STEM), and energy-dispersive X-ray spectroscopy (EDS) maps of specific grid squares.

- Electrochemical Aging: Carefully transfer the grid to a custom electrochemical cell, subject it to degradation protocols (e.g., potential cycling), then rinse and dry.

- Relocation & Re-imaging: Relocate the exact same particles using the grid coordinates. Re-acquire images and spectra.

- Analysis: Quantify changes in particle size, shape, crystallinity, and composition for direct correlation with electrochemical history.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Degradation Studies

| Item | Function/Brief Explanation | Example Specification |

|---|---|---|

| Perchloric Acid (HClO4) | High-purity electrolyte; minimal anion adsorption avoids complex interference. | TraceSELECT Ultra, ≥70% |

| Nafion Dispersion | Proton-conducting binder for preparing catalyst inks for thin-film electrodes. | 5 wt% in lower aliphatic alcohols |

| Isotopically Enriched Tracers | For ultra-sensitive dissolution tracking via ICP-MS without background interference. | e.g., 196Pt-enriched Pt/C catalyst |

| Single-Element Standards for ICP-MS | For quantitative calibration of dissolved ion concentrations. | 1000 µg/mL in 2% HNO3 |

| High-Surface-Area Carbon Support | Model support for catalyst nanoparticles in fundamental studies. | Vulcan XC-72R or Ketjenblack EC-300J |

| Reference Electrodes | Stable potential reference in acidic media. | Reversible Hydrogen Electrode (RHE) in the same electrolyte. |

Visualization Diagrams

Title: Electrochemical Dissolution Pathway of Metal Catalysts

Title: Multi-Method Workflow for Degradation Prediction

Proton Exchange Membrane (PEM) water electrolysis is a critical technology for green hydrogen production, requiring highly stable and active electrocatalysts for the acidic oxygen evolution reaction (OER) and hydrogen evolution reaction (HER). The selection of catalyst materials is fundamentally governed by their thermodynamic and electrochemical stability under operating conditions (pH ~0, potentials >1.4 V vs. RHE). Pourbaix diagrams (potential-pH diagrams) provide the essential framework for predicting the stable phases of an element in aqueous electrolytes. This guide frames catalyst selection—precious metals Iridium and Platinum, and their non-precious alternatives—within this context of Pourbaix-derived stability in acidic media.

Catalyst Selection & Stability: A Pourbaix Perspective

The operational window of PEM electrolysis (high anodic potential, low pH) is highly corrosive. Pourbaix diagrams predict that most non-noble metals form soluble ions or oxides that dissolve, leaving only a small group of elements with stable oxide phases. Iridium forms a stable IrO₂ phase, while platinum is stable as Pt metal but forms a thin, passivating oxide layer. Non-precious candidates must be screened for a similar stable solid oxide phase within the operational "PEM window."

Table 1: Key Catalyst Materials & Pourbaix-Predicted Stability in Acidic OER Conditions

| Material | Stable Phase (at 1.8 V, pH 0) | Theoretical Dissolution Potential (V vs. RHE) | Key Stability Challenge per Pourbaix |

|---|---|---|---|

| Iridium (Ir) | IrO₂ (solid) | >2.0 V | Over-oxidation to soluble IrO₄²⁻ at >~2.05 V |

| Iridium Oxide (IrO₂) | IrO₂ (solid) | >2.0 V | Same as above; surface defects can lower actual stability |

| Platinum (Pt) | Pt / PtO₂ (thin layer) | ~1.8 V (for PtO₂) | Pt dissolution via place-exchange mechanism at high potential |

| Ruthenium (Ru) | RuO₂ (solid) | ~1.4 V | Over-oxidation to soluble RuO₄ at low overpotential |

| Cobalt Spinel (Co₃O₄) | Soluble Co²⁺, Co³⁺ | <1.0 V | No stable solid oxide phase at low pH/high potential |

| Manganese Oxide (MnOx) | Soluble Mn²⁺ | <1.2 V | Dissolves unless stabilized in a perovskite matrix |

Experimental Protocols for Stability Assessment

Protocol 1: Inductive Coupled Plasma Mass Spectrometry (ICP-MS) for Dissolution Measurement.

- Objective: Quantify catalyst dissolution rates under operating conditions.

- Method:

- Prepare an electrochemical cell with the catalyst coated on a substrate as working electrode.

- Use a high-purity acidic electrolyte (e.g., 0.1 M HClO₄). Employ a membrane-separated compartment for the counter electrode.

- Apply a constant anodic potential (e.g., 1.8 V vs. RHE) or use accelerated stress tests (potential cycling, e.g., 1.2-1.8 V vs. RHE at 500 mV/s).

- Periodically extract small aliquots (e.g., 500 µL) of the electrolyte.

- Dilute samples with 2% ultrapure HNO₃ and analyze via ICP-MS.

- Calculate dissolution rates in ng·cm⁻²·h⁻¹ or atoms released per site per second.

Protocol 2: In-situ Electrochemical Quartz Crystal Microbalance (EQCM).

- Objective: Monitor mass changes of the catalyst layer in real-time.

- Method:

- Coat a gold-sputtered quartz crystal resonator with the catalyst ink.

- Calibrate frequency shift (Δf) to mass change (Δm) using Sauerbrey equation.

- Immerse the crystal in acidic electrolyte and apply potential protocols.

- A mass decrease indicates dissolution or oxide reduction; a mass increase indicates oxide formation. Correlate with simultaneous voltammetry.

Protocol 3: Rotating Ring-Disk Electrode (RRDE) for Detection of Soluble Species.

- Objective: Detect soluble intermediates or corrosion products.

- Method:

- Deposit catalyst on the disk electrode.

- Apply OER potentials to the disk.

- Hold the Pt ring at a potential suitable for reducing specific soluble species (e.g., 0.4 V vs. RHE to reduce O₂ from dissolved IrO₄²⁻ or RuO₄).

- The ring current provides a direct measure of soluble species generation from the disk.

Catalyst Pathways and Research Workflow

Title: Catalyst R&D Workflow for Acidic Electrolysis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials & Reagents for Catalyst Research

| Reagent / Material | Function & Purpose | Key Considerations |

|---|---|---|

| Nafion Dispersion (e.g., D521) | Binder for catalyst inks; provides proton conductivity in catalyst layer. | Use high purity, dilute appropriately in low-water alcohols to ensure uniform coating. |

| High-Surface Area Carbon (e.g., Vulcan XC-72) | Support material for dispersed precious metal nanoparticles; enhances electronic conductivity. | Can corrode at high OER potentials; use with caution for anodes. |

| Iridium Chloride (IrCl₃·xH₂O) / Iridium Acetylacetonate (Ir(acac)₃) | Precursors for synthesizing IrO₂ nanoparticles or organometallic deposition. | Purity defines final catalyst impurity levels. Handling in glovebox may be required. |

| Chloroplatinic Acid (H₂PtCl₆) | Common precursor for Pt nanoparticle synthesis (e.g., Adams' method, impregnation). | Source of Pt(IV) for reduction to metallic Pt. |

| Non-Precious Precursors (e.g., Co(NO₃)₂, Mn(Ac)₂, NiSO₄) | For synthesis of transition metal oxides, perovskites, or nitrides. | Often require high-temperature calcination or hydrothermal synthesis. |

| 0.1 M Perchloric Acid (HClO₄) Electrolyte | Standard acidic electrolyte for fundamental half-cell studies (e.g., in RRDE). | High purity (Merck Suprapur or equivalent) to avoid trace ion contamination. Requires extreme safety handling. |

| Nafion 115/117 Membranes | PEM for Membrane Electrode Assembly (MEA) testing. | Requires standard boiling pretreatment in H₂O₂ and H₂SO₄ for proton activation and cleaning. |

| Toray or Sigracet Carbon Paper | Gas Diffusion Layer (GDL) in MEA, provides electrical contact and gas transport. | May require hydrophobic PTFE coating to manage water flooding. |

| SGL Carbon Cloth | Alternative to carbon paper, often used for better mechanical conformity. |

Table 3: Comparative Performance Metrics for Selected Catalysts (Representative Data)

| Catalyst | OER Overpotential @ 10 mA/cm² (mV) | Mass Activity @ 1.5 V (A/g) | Dissolution Rate @ 1.8 V, 80°C (ng·cm⁻²·h⁻¹) | Estimated Cost per kg (USD, approx.) |

|---|---|---|---|---|

| IrO₂ (nanoparticle) | 270 - 320 | 20 - 50 | 5 - 20 | ~160,000 |

| IrO₂ (nanowire) | 250 - 290 | 60 - 120 | 2 - 10 | >200,000 |

| Pt (HER cathode) | N/A (HER: 30-70 mV) | High (HER) | 10 - 100 (at cathode) | ~90,000 |

| RuO₂ | 220 - 280 | 100 - 200 | 500 - 5000 (very high) | ~20,000 |

| Iridium Ruthenium Oxide (Ir₀.₇Ru₀.₃O₂) | 240 - 300 | 40 - 80 | 50 - 200 | ~120,000 |

| SrTiO₃ (SrIrO₃ perovskite) | 300 - 350 | 80 - 150 | 1 - 5 (enhanced) | Variable |

| Acid-Stable Spinel (e.g., (Mn,Co)₃O₄) | >400 | < 0.1 | Still high under OER | < 1,000 |

| Transition Metal Nitride/Carbide (e.g., Mo₂C for HER) | N/A (HER: 90-150 mV) | Moderate (HER) | Lower than pure metal | < 500 |

The rigorous application of Pourbaix stability principles is paramount for rational catalyst design in PEM electrolysis. While Iridium-based materials remain the state-of-the-art OER catalyst due to their favorable Pourbaix-predicted stability, their cost drives research into two main avenues: 1) Ultra-low-loading Ir nanostructures that maximize utilization, and 2) Non-precious metal alternatives that must be engineered—often as mixed oxides, perovskites, or nitrides—to create a kinetically stabilized surface that mimics the Pourbaix stability of IrO₂. Future experimental protocols will increasingly rely on in-situ and operando characterization coupled with high-throughput screening to map the complex interplay between activity, stability, and structure under realistic acidic conditions.

Pourbaix diagrams are foundational to electrocatalyst design, mapping thermodynamic stability of materials as a function of potential and pH. For acidic electrolytes (e.g., proton exchange membrane water electrolyzers), the diagram predicts that only a handful of noble metals like Ir, Pt, and Ru oxides are stable. However, real-world operation reveals catastrophic failure modes—dissolution, corrosion, amorphization—in materials deemed "stable" by thermodynamics. This discrepancy arises from kinetic overpotentials. High anodic potentials (e.g., >1.6 V vs. RHE for oxygen evolution) and transient conditions (start-up/shutdown, load cycling) impose kinetic drivers that Pourbaix diagrams do not capture. This whitepaper details the experimental and theoretical framework for integrating kinetic overpotentials into stability assessments, a critical advancement for durable catalyst design.

The Kinetic Overpotential Framework

Kinetic overpotentials ((\etak)) accelerate degradation by providing the driving force for non-equilibrium dissolution pathways. The total applied potential ((E{applied})) is the sum of the thermodynamic potential ((E{therm})), the kinetic overpotential for the reaction ((\eta{rxn})), and the kinetic overpotential for degradation ((\eta_{deg})):

[ E{applied} = E{therm} + \eta{rxn} + \eta{deg} ]

While (\eta{rxn}) is often studied (e.g., OER activity), (\eta{deg}) is the critical, often-neglected component that dictates catalyst lifetime. It manifests through:

- Place Exchange: Cation migration and place-exchange with oxygen at high potentials, leading to amorphous oxide formation.

- Transient Dissolution: Sub-second dissolution spikes during potential cycling, not predicted at equilibrium.

- Local Acidification: Proton generation during OER creates a localized pH at the catalyst surface far more acidic than the bulk.

Quantitative Data: Thermodynamic vs. Kinetic Stability

The following table compiles recent experimental data highlighting the divergence between thermodynamic predictions and kinetic stability for selected catalysts in 0.5 M H₂SO₄ (pH ~0.3).

Table 1: Stability Metrics for OER Catalysts in Acidic Electrolyte

| Catalyst Material | Thermodynamic Stability (Pourbaix Prediction, 1.8 V vs. RHE) | Dissolution Rate at 1.8 V, 80°C (ng cm⁻² s⁻¹) | Onset Potential for Kinetic Degradation (V vs. RHE) | Key Degradation Mechanism |

|---|---|---|---|---|

| IrO₂ (rutile) | Stable (Passive) | 0.05 - 0.15 | ~2.0 V | Transient Ir³⁺/Ir⁴⁺ oxidation to soluble Ir⁵⁺/Ir⁶⁺ |

| RuO₂ | Stable (Passive) | 5.0 - 15.0 | ~1.4 V | Oxidation to soluble RuO₄ |

| Pt (anode) | Stable (Passive) | 0.01 - 0.05 | ~1.8 V | Pt oxide place-exchange & Pt²⁺ dissolution |

| La₀.₅Sr₀.₅CoO₃₋δ | Unstable (Soluble) | 1200 - 2500 | ~1.5 V | Cation leaching, perovskite lattice collapse |

| IrNiOx core-shell | Stable (Passive) | 0.02 - 0.08 | ~2.1 V | Shell pinhole corrosion, Ni²⁺ leaching |

Experimental Protocols for Probing Kinetic Stability

Protocol 4.1: Online Inductively Coupled Plasma-Mass Spectrometry (ICP-MS)

- Objective: Quantify time- and potential-resolved dissolution of catalyst elements.

- Setup: The electrochemical flow cell effluent is directly coupled to the ICP-MS nebulizer via PTFE tubing.

- Procedure:

- A thin-film catalyst on a rotating disk electrode (RDE) or a gas diffusion electrode (GDE) is mounted in a custom flow cell.

- Electrolyte (0.5 M H₂SO₄, ultrapure) is pumped through the cell at 0.2 mL/min.

- Apply a potential program (e.g., potentiostatic hold, cyclic voltammetry).

- ICP-MS data is acquired in time-resolved analysis (TRA) mode. Data is synchronized with electrochemical data using a trigger signal.

- Quantify dissolution rates using external calibration standards. Normalize to electrochemical surface area (ECSA).

Protocol 4.2: Coupled Electrochemical Quartz Crystal Microbalance (EQCM) with X-ray Photoelectron Spectroscopy (XPS)

- Objective: Correlate in-situ mass changes with chemical state evolution under potential control.

- Procedure:

- Deposit catalyst onto the Au-coated quartz crystal of the EQCM.

- Perform electrochemical aging protocol (e.g., 1000 cycles, 0.05-1.8 V vs. RHE, 1 V/s) in N₂-purged 0.1 M HClO₄.

- Monitor resonant frequency shift ((\Delta f)) and dissipation for mass ((\Delta m)) and viscoelastic changes.

- Transfer the crystal in-situ (using an anaerobic transfer vessel) to the XPS chamber.

- Acquire high-resolution spectra (Ir 4f, O 1s, C 1s) at different take-off angles to probe near-surface composition vs. bulk-like composition.

Diagram: The Kinetic Degradation Pathways in Acidic OER

Diagram Title: Kinetic Overpotential-Driven Degradation Pathways

Diagram: Integrated Stability Assessment Workflow

Diagram Title: Integrated Stability Assessment Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents & Materials for Kinetic Stability Studies

| Item | Function & Rationale | Critical Specification/Note |

|---|---|---|

| Ultrapure H₂SO₄ or HClO₄ | Provides the acidic electrolyte (pH <1). Minimizes impurity-driven degradation. | Trace metal grade (<1 ppb of Fe, Cu, Ni). Use with PFA or fluorinated bottles. |

| Isotopically Enriched Tracers (e.g., ¹⁹³Ir, ¹⁰¹Ru) | Allows for ultra-sensitive, interference-free dissolution tracking in ICP-MS, especially in complex matrices. | >95% isotopic enrichment. Dilute to ppm stock in 2% ultrapure HNO₃. |

| Single-Crystal Terraced Electrodes (e.g., Pt(111), Au(111)) | Model surfaces to study fundamental place-exchange and dissolution kinetics without porosity/complexity effects. | Meticulous flame-annealing and transfer in iodine vapor required. |

| Scanning Electrochemical Flow Cell (SEFC) | Enables mapping of dissolution heterogeneity across an electrode surface when coupled to ICP-MS. | No commercially available standard; requires custom fabrication (PEEK, Kalrez seals). |

| Anaerobic Electrode Transfer Vessel | Maintains potentiostatic control or a fixed potential during transfer from electrochemical cell to surface analysis tool (XPS, TEM). | Must maintain UHV-compatible seal and be magnetically coupled for manipulation. |

| Nafion XL or Sustainion Membranes | For realistic testing in zero-gap MEA configuration, where local acidification/water transport differs from RDE. | Pre-treatment (boiling in H₂O₂, H₂SO₄, DI water) is critical for reproducibility. |

Beyond the Diagram: Troubleshooting Stability Failures and Optimizing Catalyst Durability

Within the broader thesis on Pourbaix diagram catalyst stability in acidic electrolytes, a persistent and critical challenge is the systematic observation of experimental metal dissolution rates that exceed the stability regions predicted by thermodynamic Pourbaix diagrams. This whitepaper provides an in-depth technical analysis of the root causes for these discrepancies, emphasizing kinetic and non-equilibrium factors dominant in operational electrochemical environments.

Core Theoretical Limitations of Pourbaix Diagrams

Pourbaix diagrams are thermodynamic tools, mapping equilibrium phases as a function of potential (Eh) and pH. Their predictions assume:

- Bulk equilibrium between solid and dissolved species.

- A closed, homogeneous system.

- Pure metal or simple, well-defined compounds.

- The absence of complexing agents beyond H+ and OH–.

- Negligible influence of time-dependent factors.

Operational electrochemical catalysts violate these assumptions, leading to the observed dissolution discrepancies.

Quantitative Analysis of Discrepancy Drivers

The following table summarizes key factors, their quantitative impact, and thermodynamic vs. experimental comparison.

Table 1: Primary Factors Causing Excess Experimental Dissolution

| Factor Category | Specific Mechanism | Typical Quantitative Impact on Dissolution Rate | Pourbaix Assumption Violated |

|---|---|---|---|

| Kinetic Overpotential | Applied anodic potential driving dissolution beyond equilibrium. | Can increase rate by 101–103× at 0.1–0.3 V overpotential. | Equilibrium potential (Eh). |

| Surface State Complexity | Amorphous surface oxides, defects, step edges, nanoparticulation. | Nanoparticles (3-5 nm) dissolve 10-100× faster than bulk. | Well-defined crystalline bulk phase. |

| Local Chemical Environment | Transient local pH shifts at anode (H+ depletion) or cathode (OH– generation). | Anode surface pH can be 2-5 units higher than bulk in mild buffer. | Bulk pH uniform and static. |

| Complexing Ligands | Presence of Cl–, CN–, NH3, or organic species in electrolyte. | 10 mM Cl– can increase Pt dissolution by 50-200%. | Only H2O, H+, OH– as ligands. |

| Transient Passivation | Formation and subsequent chemical/electrochemical dissolution of surface oxides. | Oxide growth/reduction cycles can release ions at rates 100× steady-state. | Stable, protective passivation layer. |

Detailed Experimental Protocols for Dissolution Analysis

Protocol 1: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) Coupled with Electrochemical Flow Cell

Objective: Quantify dissolved metal concentrations in operando with high sensitivity. Methodology:

- Setup: Integrate a miniature electrochemical flow cell (e.g., thin-layer channel) with the ICP-MS sample introduction system via PTFE tubing.

- Electrode: Working electrode is the catalyst of interest (e.g., Pt/C, IrOx nanoparticles) deposited on a rotating disk electrode (RDE) or as a thin film on a flow-through substrate.

- Electrolyte: Acidic electrolyte (e.g., 0.1 M HClO4, 0.5 M H2SO4) continuously pumped at 0.2-0.5 mL/min.

- Procedure:

- Apply a controlled potentiostatic or potentiodynamic waveform (e.g., cyclic voltammetry from 0.05 to 1.4 VRHE, 50 mV/s).

- The effluent from the cell is directly introduced into the ICP-MS nebulizer.

- The ICP-MS monitors selected isotope signals (e.g., 195Pt, 193Ir, 58Ni) in time-resolved mode (integration time ~100 ms).

- Calibrate using standard metal solutions introduced via the identical flow path.

- Data Analysis: Synchronize chronoamperometric current data with ICP-MS temporal dissolution profile to correlate charge passed with ions released.

Protocol 2: On-Line Electrochemical Mass Spectrometry (OEMS) for Detected Dissolved Species

Objective: Identify volatile or gaseous products from dissolution (e.g., O2, Cl2, CO2) that may correlate with catalyst degradation. Methodology:

- Setup: Use a dual-compartment electrochemical cell separated by a Teflon membrane. The working electrode compartment is sealed and connected to a quadrupole mass spectrometer (QMS) via a capillary inlet.

- Electrode: Same as Protocol 1, under a controlled atmosphere (Ar, N2).

- Procedure:

- Purge the system with inert gas.

- Apply potential steps or cycles while monitoring relevant mass-to-charge (m/z) ratios (e.g., m/z=32 for O2 from oxide formation/reduction, m/z=36 for 36Cl+ from Cl2 evolution in HCl).

- Correlate MS ion current peaks with electrochemical features.