Mastering Probe Molecule IR Spectroscopy: A Complete Protocol for Advanced Surface Analysis in Drug Development

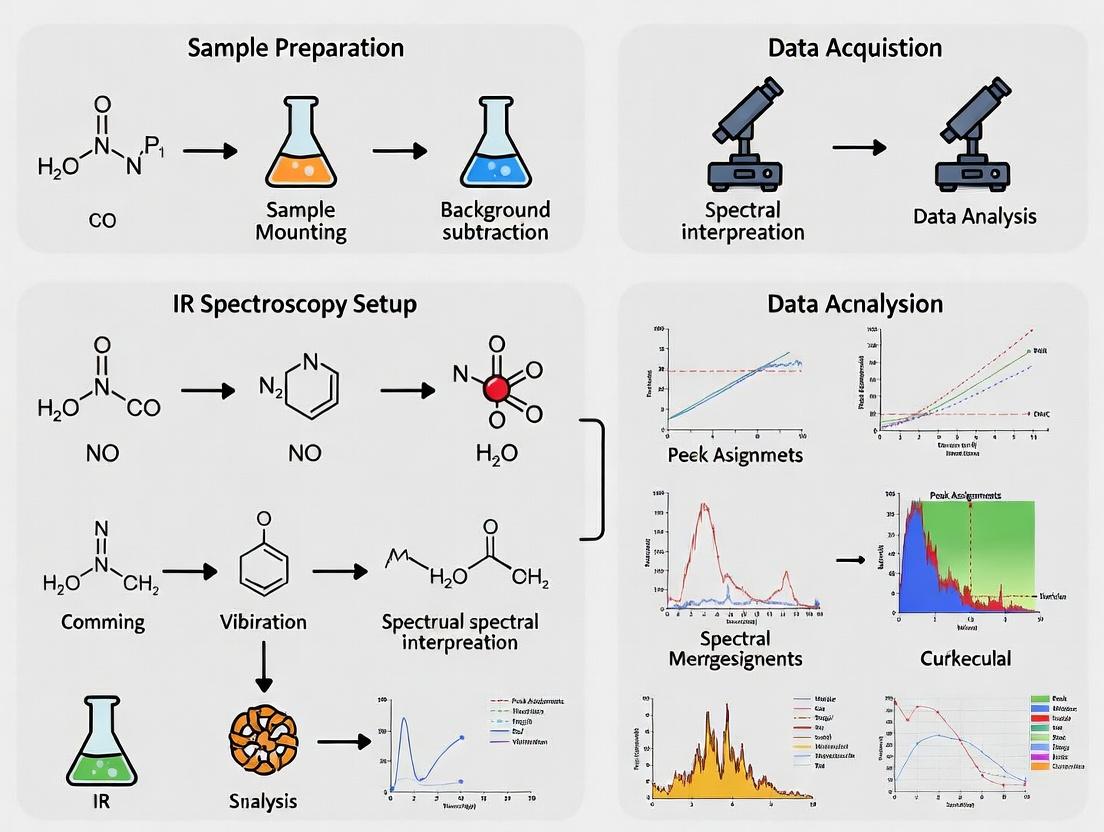

This comprehensive guide details the established protocols and modern advancements in probe molecule infrared (IR) spectroscopy for surface characterization, a critical technique for researchers and drug development professionals.

Mastering Probe Molecule IR Spectroscopy: A Complete Protocol for Advanced Surface Analysis in Drug Development

Abstract

This comprehensive guide details the established protocols and modern advancements in probe molecule infrared (IR) spectroscopy for surface characterization, a critical technique for researchers and drug development professionals. The article systematically explores the fundamental principles of how specific probe molecules (e.g., CO, NH3, pyridine) interact with surface sites to reveal acidity, basicity, and metal coordination. It provides a step-by-step methodological framework for experimental setup, probe selection, and data acquisition tailored to biomedical materials like catalysts, adsorbents, and drug delivery systems. Practical sections address common troubleshooting scenarios, spectral interpretation challenges, and optimization strategies for signal-to-noise ratio and sensitivity. Finally, the article validates the technique by comparing it with complementary methods like NMR, XPS, and TPD, establishing its unique role in quantifying active sites. This resource empowers scientists to reliably deploy probe molecule IR to unlock surface-activity relationships critical for designing next-generation therapeutics and biomaterials.

Probe Molecule IR Spectroscopy Explained: Unlocking Surface Chemistry for Biomedical Research

Within the context of developing a robust protocol for using infrared (IR) spectroscopy with probe molecules for surface analysis research, this article elucidates the core principle of probe molecules as "molecular spies." These specially designed molecules are deployed onto material surfaces to adsorb at specific sites, where their vibrational modes, sensitively detected by IR spectroscopy, report back critical information about the surface's chemical composition, acidity/basicity, porosity, and active site distribution. This non-destructive espionage technique is fundamental in catalysis, drug development (e.g., characterizing drug delivery carriers), and materials science.

Application Notes

Characterizing Surface Acidity and Basicity

Probe molecules like carbon monoxide (CO), ammonia (NH₃), and pyridine are used to quantify the type, strength, and concentration of acid sites on catalytic surfaces (e.g., zeolites, aluminosilicates).

Table 1: IR Spectral Signatures of Common Acidity Probe Molecules

| Probe Molecule | Target Site | IR Vibration Mode | Typical Wavenumber Range (cm⁻¹) | Information Conveyed |

|---|---|---|---|---|

| Carbon Monoxide (CO) | Lewis Acid Sites | C≡O Stretch | 2150-2250 | Strength of Lewis acidity (higher shift = stronger site) |

| Ammonia (NH₃) | Brønsted & Lewis Acids | N-H Deformation | ~1450 (Lewis), ~1620 (Brønsted) | Distinguishes acid site type |

| Pyridine | Brønsted & Lewis Acids | Ring Vibrations | ~1545 (B), ~1450 (L) | Quantifies concentration of each acid type |

| Deuterated Acetonitrile (CD₃CN) | Lewis Acid Sites | C≡N Stretch | 2250-2350 | Particularly sensitive to very strong Lewis sites |

Probing Surface Porosity and Accessibility

Nitrogen (N₂) and carbon dioxide (CO₂) are used as probe molecules for physisorption studies, but smaller molecules like CO can assess pore accessibility in microporous materials used in drug delivery systems.

Table 2: Probe Molecules for Porosity and Accessibility Assessment

| Probe Molecule | Kinetic Diameter (Å) | Primary IR Vibration (cm⁻¹) | Application in Surface Analysis |

|---|---|---|---|

| Carbon Monoxide (CO) | 3.76 | 2143 (gas phase) | Accessibility of metal sites in pores |

| Nitrogen (N₂) | 3.64 | ~2331 (N≡N stretch) | Standard for surface area & pore size distribution |

| Carbon Dioxide (CO₂) | 3.30 | Asymmetric stretch ~2350 | Analysis of ultramicropores & basic sites |

Detailed Experimental Protocols

Protocol 1: Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) of CO on Catalytic Surfaces

Objective: To identify and quantify Lewis acid sites on a gamma-alumina catalyst.

Materials & Reagents:

- High-temperature DRIFTS cell with KBr windows.

- FTIR spectrometer with MCT detector.

- Gamma-alumina sample (powder).

- Ultra-high purity (UHP) CO gas (10% in He, balance).

- UHP Helium for purge and pretreatment.

Procedure:

- Sample Pretreatment: Place ~50 mg of sample in the DRIFTS cup. Activate the surface by heating to 400°C under a 30 mL/min He flow for 60 minutes to remove adsorbed contaminants. Cool to analysis temperature (e.g., -196°C using liquid N₂ for CO, or 25°C).

- Background Collection: At the analysis temperature, collect a background single-beam spectrum under He flow.

- Probe Adsorption: Switch the gas flow to 10% CO/He for 15 minutes, allowing saturation adsorption.

- Purge: Switch back to pure He flow for 10 minutes to remove physisorbed and gas-phase CO.

- Sample Spectrum Collection: Collect the single-beam spectrum of the adsorbed species.

- Data Processing: Convert the sample spectrum to absorbance units using the background. Identify the positions and integrate the areas of the adsorbed CO bands (~2200-2250 cm⁻¹).

Protocol 2: Transmission IR of Pyridine on Solid Acids for Drug Carrier Analysis

Objective: To distinguish Brønsted and Lewis acid sites on a mesoporous silica drug carrier functionalized with aluminum.

Materials & Reagents:

- Transmission IR cell with NaCl windows.

- Self-supporting sample wafer press.

- Mesoporous silica-alumina sample.

- Liquid pyridine, spectroscopic grade.

- Vacuum line system (<10⁻³ mbar capability).

Procedure:

- Wafer Preparation: Press ~15 mg of sample powder into a thin, self-supporting wafer (~1 cm diameter).

- In-situ Activation: Mount the wafer in the IR cell. Connect to the vacuum line. Evacuate and heat to 350°C for 2 hours to clean the surface. Cool to 150°C under vacuum.

- Background Spectrum: Collect the background spectrum of the activated wafer.

- Probe Dosing: Expose the wafer to saturated pyridine vapor (from a reservoir held at room temperature) for 5 minutes. Evacuate the cell at 150°C for 30 minutes to remove physisorbed pyridine.

- Sample Spectrum Collection: Collect the spectrum of the chemisorbed pyridine.

- Analysis: Identify bands at ~1545 cm⁻¹ (Brønsted-bound pyridinium ion) and ~1450 cm⁻¹ (Lewis-coordinated pyridine). Use published molar extinction coefficients to estimate site concentrations.

Visualizations

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for IR Probe Molecule Experiments

| Item | Function in Experiment | Key Consideration |

|---|---|---|

| Probe Gases (CO, NH₃, NO, CO₂) | Serve as the molecular spies; their purity is critical to avoid false signals. | Use UHP grade (≥99.999%) with calibrated mixtures. Store in appropriate gas cylinders. |

| Liquid Probes (Pyridine, Acetonitrile-d₃) | Volatile liquid spies for acid/base characterization. | Must be spectroscopic grade, dried over molecular sieves, and stored under inert atmosphere. |

| IR-Transparent Windows (KBr, CaF₂, ZnSe) | Allow IR beam to pass into the sample cell and interact with the adsorbed probe. | Selection depends on spectral range, hardness, and hygroscopicity (e.g., KBr avoids <400 cm⁻¹, is hygroscopic). |

| High-Temperature/Vacuum IR Cell | Enables in-situ sample pretreatment and controlled probe molecule exposure. | Must have heating/cooling capability, gas/vapor dosing lines, and vacuum compatibility. |

| Reference Catalyst (e.g., H-ZSM-5, γ-Al₂O₃) | Standard materials with well-characterized acid sites to validate the protocol. | Used for method calibration and benchmarking new probe molecules. |

| MCT or InGaAs Detector | Provides high sensitivity in the mid-IR region essential for detecting low coverages of adsorbed probes. | Requires liquid N₂ cooling (MCT) for optimal performance. |

1. Introduction Within the broader thesis on developing standardized protocols for surface analysis research using infrared (IR) spectroscopy of probe molecules, this document details the essential toolkit of four classical probes. These small, basic molecules are selectively chemisorbed onto catalytic or material surfaces, and their resulting vibrational fingerprints provide diagnostic information on surface acidity, basicity, oxidation state, and coordination geometry. This note provides current application data, detailed experimental protocols, and material requirements for their effective use.

2. Diagnostic Vibrations and Quantitative Data

Table 1: Key Probe Molecules and Their Diagnostic IR Vibrations

| Probe Molecule | Primary Diagnostic Stretch (cm⁻¹) | Surface Property Probed | Spectral Shift Indication (Higher Frequency →) |

|---|---|---|---|

| Carbon Monoxide (CO) | ν(CO): 2000-2200 | Lewis acid sites (metal cations), oxidation state, coordination. | Stronger Lewis acidity, higher oxidation state of adsorption site. |

| Pyridine (C5H5N) | ν(19b) & ν(8a): ~1440-1460 & ~1580-1620 | Lewis acidity (coord. to cations). | Presence of Lewis acid sites. |

| ν(19b): ~1485-1500 | Both Lewis & Brønsted acidity. | Co-presence of acid site types. | |

| ν(8a): ~1530-1550 | Brønsted acidity (protonation). | Presence of Brønsted acid sites. | |

| Ammonia (NH3) | δas(NH3+): ~1400-1450 | Brønsted acidity. | Ammonium ion formation on Brønsted sites. |

| δs(NH3): ~1100-1150 | Coordinated to Lewis acid sites. | Coordination to Lewis sites. | |

| Acetonitrile-d3 (CD3CN) | ν(C≡N): 2250-2320 | Lewis acidity, cation charge/radius. | Increased Lewis acid strength. |

| ν(C≡N): ~2290-2320 | Coordinated to Lewis sites. | Baseline for weakly interacting CD3CN. | |

| ν(C≡N): 2275-2300 | Hydrogen-bonding to Brønsted sites. | Interaction with Brønsted sites. |

Table 2: Characteristic CO Stretch Frequencies on Different Metal Sites

| Adsorption Site Type | Typical ν(CO) Range (cm⁻¹) | Common Example |

|---|---|---|

| Metallic (low oxidation state) | 2000-2070 | CO on Pd⁰, Pt⁰ |

| Linear on cation (Lewis acid) | 2070-2200 | CO on Al³⁺, Zn²⁺, Mg²⁺ |

| Bridging/bound to multiple sites | 1800-1950 | CO bridging two metal atoms |

| Carbonyl complexes | 2200-2230 | CO on isolated Cu⁺ ions |

3. Experimental Protocols

Protocol 3.1: General Workflow for In Situ/Operando DRIFTS Probe Molecule Experiment

Title: In Situ DRIFTS Probe Molecule Analysis Workflow

Protocol 3.2: Specific Procedure for CO Probe IR Spectroscopy

- Material: Place 20-50 mg of finely ground sample into the DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy) or transmission IR cell.

- Activation: Activate the sample in situ under a flow of dry air/O₂ (20 mL/min) at 400-500°C for 1 hour, followed by purging with inert gas (He, Ar) at the same temperature for 30 minutes. Cool to desired adsorption temperature (typically 30-100°C) under inert flow.

- Background: Collect a high-resolution (4 cm⁻¹) background spectrum of the activated sample under inert flow.

- Adsorption: Switch to a gas stream of 1-5% CO in an inert balance (He, Ar) at a total flow of 20 mL/min for 20-30 minutes.

- Desorption/Purging: Switch back to pure inert gas flow for 30-60 minutes to remove all physisorbed and weakly bound CO.

- Measurement: Collect the sample spectrum. Subtract the background spectrum to obtain the final spectrum of chemisorbed CO.

- Analysis: Identify the number, position, and intensity of ν(CO) bands in the 2000-2200 cm⁻¹ region (Table 1 & 2).

Protocol 3.3: Specific Procedure for Pyridine Probe IR Spectroscopy

- Material & Activation: As per Protocol 3.2, Steps 1-3.

- Saturation: At analysis temperature (typically 150°C to distinguish acid strength), saturate the sample by exposing it to pyridine vapor. This is done by flowing inert gas through a pyridine saturator held at 0°C or by injecting small, repeated doses of liquid pyridine into the gas stream.

- Purging: Purge with inert gas at the same temperature (150°C) for 30-60 minutes to remove all physisorbed pyridine.

- Measurement & Analysis: Collect spectrum. The region 1400-1650 cm⁻¹ is analyzed. The band at ~1545 cm⁻¹ indicates Brønsted acid sites, the band at ~1455 cm⁻¹ indicates Lewis acid sites, and the band at ~1490 cm⁻¹ confirms the presence of both (Table 1).

4. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for Probe Molecule IR Experiments

| Item | Function/Explanation |

|---|---|

| In Situ DRIFTS or Transmission IR Cell | High-temperature, gas-tight reaction chamber with IR-transparent windows (e.g., CaF₂, ZnSe) allowing sample treatment and spectral collection in controlled environments. |

| Probe Gases (1-5% CO/He, pure NH3) | Certified calibration gas mixtures for precise, reproducible dosing of CO and NH3 probe molecules. |

| Liquid Probe Molecules (Pyridine, CD3CN) | HPLC or spectroscopic grade, stored over molecular sieves to ensure dryness and purity. |

| High-Purity Inert Gases (He, Ar) | Purified (with O₂ and H₂O traps) for sample activation and as carrier/diluent gas. |

| Mass Flow Controllers (MFCs) | For precise and automated control of gas mixture composition and flow rates during dosing and purging steps. |

| Pyridine Saturator/Vapor Dosing System | A temperature-controlled bubbler or injection loop system to generate a consistent partial pressure of pyridine vapor. |

| Reference Catalyst Samples | Well-characterized materials (e.g., Al₂O₃ for Lewis sites, H-ZSM-5 for Brønsted sites) to validate experimental setup and spectral assignments. |

5. Data Interpretation Workflow

Title: Probe Molecule IR Data Interpretation Logic

Infrared spectroscopy of adsorbed probe molecules is a cornerstone technique for characterizing the type, strength, and concentration of acid and base sites on solid surfaces. This Application Note details the protocols for differentiating between Brønsted (proton-donating) and Lewis (electron-pair accepting) sites using specific probe molecules, providing researchers with a standardized methodology for surface analysis in catalysis and materials science.

Within the broader thesis on IR probe molecule protocols for surface analysis, the precise discrimination of acid site nature is critical. Brønsted acidity originates from proton donors (e.g., surface hydroxyls), while Lewis acidity arises from coordinatively unsaturated sites (e.g., Al³⁺). Probe molecule IR exploits the distinct perturbations in the vibrational spectra of molecules upon interaction with these sites.

Core Principles & Probe Molecule Selection

Different probe molecules form characteristic adducts with Brønsted and Lewis sites, leading to diagnostic IR bands.

Table 1: Common Probe Molecules and Their Diagnostic IR Bands

| Probe Molecule | Target Site | Key Diagnostic Vibration (cm⁻¹) | Spectral Signature for Brønsted Acid | Spectral Signature for Lewis Acid |

|---|---|---|---|---|

| Ammonia (NH₃) | Acid Sites | N-H stretching (~3400-3100), deformation (~1450-1600) | NH₄⁺ formation: deformation band ~1430-1480 | Coordinated NH₃: deformation band ~1620-1670 |

| Pyridine (C5H5N) | Acid Sites | Ring breathing modes (~1400-1700) | Band at ~1540 cm⁻¹ (pyridinium ion) | Band at ~1450 cm⁻¹ (coordinated pyridine) |

| Carbon Monoxide (CO) | Lewis Acid Sites | C-O stretching | Weak interaction (hydrogen bonding) ~2150-2170 | Strong shift: 2180-2250+ cm⁻¹ (lower frequency for weaker sites) |

| Deuterated Acetonitrile (CD3CN) | Acid Sites | C≡N stretching | Very weak perturbation: ~2295-2305 cm⁻¹ | Strong shift: 2270-2350 cm⁻¹ (correlates with strength) |

Detailed Experimental Protocols

Protocol A: Sample Preparation and In-Situ Cell Setup

Objective: Prepare a self-supporting wafer and activate the sample surface under vacuum/controlled atmosphere. Materials: High-purity probe molecules, IR-transparent salt windows (KBr, CaF₂), in-situ IR cell, furnace, vacuum system. Procedure:

- Wafer Formation: Press 10-20 mg of finely ground sample into a thin, self-supporting wafer (~1-2 cm²).

- Cell Loading: Mount the wafer in the holder of a dedicated in-situ IR cell equipped with heaters and gas/vacuum ports.

- Activation: Heat the sample to the desired activation temperature (typically 300-500°C) under high vacuum (<10⁻⁵ mbar) or dry inert gas flow for 1-2 hours to clean the surface.

- Background Scan: Cool to analysis temperature (often 25-150°C) and collect a background single-beam spectrum of the activated sample.

Protocol B: Pyridine Adsorption for Acid Site Discrimination

Objective: Quantify Brønsted and Lewis acid site concentrations. Procedure:

- Dosing: Expose the activated wafer to pyridine vapor (saturated at room temperature or via a calibrated dose) for 5-10 minutes.

- Equilibration & Removal: Isolate the cell and allow system to equilibrate. Subsequently, evacuate at the analysis temperature (e.g., 150°C) for 30-60 minutes to remove physisorbed and weakly bound pyridine.

- Spectrum Acquisition: Collect the IR spectrum in transmission or DRIFTS mode.

- Data Analysis: Integrate the areas of the bands at ~1540 cm⁻¹ (B) and ~1450 cm⁻¹ (L). Use published molar extinction coefficients (e.g., εB ≈ 1.13 cm/μmol, εL ≈ 1.28 cm/μmol for some zeolites) to calculate site concentrations.

Protocol C: Low-Temperature CO Probing for Lewis Acidity

Objective: Assess Lewis acid site strength and heterogeneity. Procedure:

- Cooling: Cool the activated sample in the IR cell to cryogenic temperature (e.g., -196°C using liquid N₂ or -140°C).

- Incremental Dosing: Introduce small, calibrated doses of CO (e.g., 0.05-0.1 mmol/g) sequentially onto the sample.

- Spectral Monitoring: After each dose, collect a spectrum until saturation is approached.

- Analysis: Monitor the C-O stretching region (2250-2100 cm⁻¹). The wavenumber of the adsorbed CO band is inversely correlated with Lewis acid strength (higher ν(CO) indicates stronger Lewis acidity). Analyze peak positions and intensities as a function of coverage.

The Scientist's Toolkit: Essential Materials

Table 2: Key Research Reagent Solutions & Materials

| Item | Function & Importance |

|---|---|

| In-Situ IR Cell | Allows sample thermal treatment, evacuation, and gas dosing while measuring spectra. Core component for reliable data. |

| Self-Supporting Wafer Die | Forms powdered sample into a thin disk for transmission IR, optimizing signal-to-noise. |

| High-Purity Pyridine (dried over molecular sieves) | Primary probe for B/L discrimination. Must be anhydrous to avoid water interference. |

| Carbon Monoxide (CO), 99.997% | Sensitive probe for weak Lewis sites and cations. High purity avoids carbonyl contaminants. |

| Deuterated Acetonitrile (CD3CN) | Minimizes spectral interference in the C≡N region; useful for strong Lewis acids. |

| IR-Transparent Windows (KBr, CaF₂, ZnSe) | Material choice depends on spectral range and experimental conditions (hygroscopic, temperature). |

| Calibrated Gas Dosing System | For quantitative adsorption of probe molecules (e.g., known volumes, pressure transducers). |

| Molar Extinction Coefficients (Literature Data) | Essential for converting integrated IR band areas to quantitative site densities (μmol/g). |

Data Interpretation & Visualization

Diagram Title: IR Probe Molecule Analysis Workflow

Diagram Title: Key Probe IR Band Signatures for Acid Sites

The systematic application of these protocols enables the definitive characterization of surface acidity. Combining complementary probes like pyridine (for B/L ratio) and CO (for Lewis strength) provides a comprehensive picture essential for rational catalyst and material design in pharmaceutical synthesis and beyond.

Application Notes

This document details the application of Fourier-Transform Infrared (FTIR) spectroscopy with molecular probes for characterizing metal centers and defect sites on solid surfaces, a cornerstone of catalyst design and material science. The technique leverages the selective adsorption of small probe molecules, which alters their vibrational modes, providing a fingerprint of surface site chemistry, coordination environment, and electronic state.

Table 1: Common Probe Molecules and Their Diagnostic Information

| Probe Molecule | Target Surface Sites | Diagnostic IR Region (cm⁻¹) | Information Gained |

|---|---|---|---|

| Carbon Monoxide (CO) | Metal cations (Lewis acids), Reduced metal clusters, Defects | 2200-1700 (ν(CO)) | Site-specific adsorption strength, oxidation state, coordination unsaturation (e.g., atop vs. bridged bonding). |

| Nitric Oxide (NO) | Metal cations, Oxygen vacancies, Radical sites | 1900-1600 (ν(NO)) | Oxidation state, spin state, and electron density at metal centers; probes redox-active sites. |

| Pyridine (C₅H₅N) | Lewis Acid Sites (metal cations), Brønsted Acid Sites (surface -OH) | ~1450 (Lewis), ~1540 (Brønsted) (19b mode) | Quantifies and distinguishes between Lewis and Brønsted acid site concentrations. |

| Carbon Dioxide (CO₂) | Basic sites (O²⁻, OH⁻), Lewis acid-base pairs | 2400-2300 (asym. stretch), 1700-1200 (carbonates) | Identifies basic oxide ions and hydroxyl groups; forms carbonate species revealing site geometry. |

| Deuterated Methane (CD₄) | Cationic sites, Defect sites (low-coordination) | 2300-2100 (ν(CD)) | Probes very strong Lewis acid sites and defect sites via C-D bond perturbation. |

Table 2: Quantitative Data from a Representative CO Probe Experiment on a Model Catalyst

| Catalyst Sample | ν(CO) Peak Position (cm⁻¹) | Peak Assignment | Estimated Coverage (μmol/g) | Relative Site Abundance (%) |

|---|---|---|---|---|

| Pt/SiO₂ (Fully Reduced) | 2070 | Linear CO on Pt⁰ | 85.2 | 78 |

| Pt/SiO₂ (Fully Reduced) | 1850 | Bridged CO on Pt⁰ | 24.1 | 22 |

| Pt/Al₂O₃ (Oxidized) | 2115, 2140 | CO on Ptδ⁺ | 45.5 | 100 |

| Defective TiO₂ | 2180, 2110 | CO on Ti⁴⁺ (5c, 4c) | 12.3 | N/A |

| Defective TiO₂ | 2155 | CO on OH groups | 8.7 | N/A |

Experimental Protocols

Protocol 1: In Situ DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy) with CO Probe for Acid Site Characterization

Objective: To identify and quantify the types of metal centers and defect sites on a metal oxide catalyst surface.

Materials:

- High-temperature/vacuum DRIFTS cell with ZnSe windows.

- FTIR spectrometer with MCT detector.

- Mass flow controllers and gas manifold (He, O₂, H₂, 1% CO/He).

- Sample holder with coarse quartz wool.

- Catalyst powder (~20-50 mg, sieved to 100-200 μm).

Procedure:

- Sample Preparation: Load the catalyst powder into the DRIFTS cell sample cup. Place quartz wool on top to prevent powder displacement.

- Pretreatment: Seal the cell. Purge with inert gas (He, 30 mL/min) at room temperature for 15 min. Heat to 500°C (10°C/min) under He flow and hold for 1 hour to remove physisorbed contaminants.

- Reduction/Oxidation (Conditional): For reduced metal sites, switch to 5% H₂/He at 500°C for 1 hour. For clean oxidized surfaces, use 5% O₂/He. Cool to analysis temperature (e.g., 30°C) in He flow.

- Background Collection: At the analysis temperature, under flowing He, collect a high-resolution (4 cm⁻¹) background spectrum (128 scans).

- CO Adsorption: Introduce 1% CO/He mixture at a constant flow (30 mL/min). Monitor the IR spectra in real-time (collect scans every 30-60 seconds) until no further increase in peak intensities is observed (saturation).

- Desorption Study: Switch back to pure He flow. Monitor spectra over time as temperature is ramped (e.g., 10°C/min to 400°C) to assess adsorption strength via the temperature-dependent disappearance of CO bands.

Protocol 2: Transmission FTIR of Pressed Wafers with Pyridine Probe for Acidity Measurement

Objective: To distinguish and quantify Lewis and Brønsted acid sites.

Materials:

- Vacuum IR cell with KBr windows.

- Hydraulic press and die (13 mm).

- Pyridine vapor source (liquid pyridine in a bubbler kept at 0°C).

- High-vacuum system (capable of <10⁻⁵ mbar).

Procedure:

- Wafer Preparation: Press ~15 mg of catalyst powder at 5 tons for 1 minute to form a thin, self-supporting wafer (~10-15 mm diameter).

- Cell Loading & Pretreatment: Mount the wafer in the vacuum IR cell. Evacuate the cell and heat the sample to 400°C under dynamic vacuum for 2 hours.

- Background Collection: Cool to 150°C, record the background spectrum.

- Pyridine Adsorption: Expose the wafer to pyridine vapor (equilibrium pressure ~5 mbar) for 5 minutes.

- Evacuation: Evacuate the cell at 150°C for 30 minutes to remove physisorbed pyridine.

- Spectrum Acquisition: Record the spectrum at 150°C. The bands at ~1450 cm⁻¹ (19b mode) and ~1540 cm⁻¹ are integrated and compared to previously determined molar extinction coefficients to quantify Lewis and Brønsted acid sites, respectively.

Visualizations

Workflow for Probe Molecule IR Spectroscopy

Probe-Site Interaction & IR Response Map

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

| Item | Function & Rationale |

|---|---|

| Carbon Monoxide (CO), 1% in He/Ar | Primary probe for metal centers. The ν(CO) stretch is highly sensitive to the electron density and geometry of the adsorption site, shifting predictably with oxidation state. |

| Deuterated Pyridine (C₅D₅N) | Probes acid sites without spectral interference in the critical 1400-1600 cm⁻¹ region where catalyst support (e.g., alumina, silica) often has vibrations. |

| Nitric Oxide (NO), 1% in He | Probe for redox-active and paramagnetic centers. Forms distinct nitrosyl complexes, informing on electron density and spin state. |

| Carbon Dioxide (CO₂), Ultra-high Purity | Probe for surface basicity. Reacts with O²⁻ and OH⁻ groups to form carbonate/bicarbonate/carboxylate species with characteristic IR patterns. |

| High-Temperature/Vacuum IR Cell | Allows in situ sample pretreatment (oxidation, reduction, annealing) and probe dosing under controlled atmosphere, essential for studying clean, well-defined surfaces. |

| Mercury Cadmium Telluride (MCT) Detector | A cryogenically cooled detector essential for high-sensitivity measurement in the mid-IR range (4000-900 cm⁻¹), especially for weakly absorbing probe molecules. |

| KBr or ZnSe IR Windows | Chemically inert, transparent in the mid-IR region. ZnSe is preferred for high-pressure/temperature or aqueous studies due to lower solubility. |

| Molar Extinction Coefficients (ε) Library | Pre-calibrated ε values for probes like pyridine on different materials are crucial for converting IR band intensities into quantitative site densities (μmol/g). |

Within the broader thesis on using infrared (IR) spectroscopy with probe molecules for surface analysis, the pretreatment and activation of samples are critical, non-negotiable steps. These protocols directly determine the accessibility, cleanliness, and reactivity of the surface sites to be probed, thereby dictating the validity of the spectroscopic data. This document details standardized methodologies and considerations for preparing materials commonly analyzed in catalysis and drug development, such as metal oxides, zeolites, and porous carbons.

Core Pretreatment Protocols

Thermal Activation (Calcination/Dehydration)

Objective: To remove physisorbed water, contaminants, and volatile adsorbates, and to generate clean, coordinatively unsaturated surface sites.

Detailed Protocol for Metal Oxide Pellets (e.g., γ-Al₂O₃, SiO₂):

- Loading: Place the sample (typically 20-50 mg) into a specialized IR spectroscopy cell (e.g., a quartz or CaF₂ cell with KBr windows) equipped for in situ heating, evacuation, and gas dosing.

- Initial Purge: Flow dry, oxygen-containing gas (e.g., synthetic air, O₂) at 50 mL/min for 30 minutes at room temperature to displace atmospheric moisture.

- Programmed Heating: Increase the temperature to the target activation temperature (e.g., 450°C for γ-Al₂O₃, 500°C for zeolites) at a controlled ramp rate of 5-10°C/min under continuous gas flow.

- Dwell Time: Maintain the sample at the target temperature for a minimum of 2 hours.

- Evacuation: Switch off the furnace, evacuate the cell to a high vacuum (<10⁻⁵ mbar) using a turbomolecular pump, and allow the sample to cool to the desired analysis temperature (often 25-150°C) under dynamic vacuum.

- Verification: Acquire a background IR spectrum of the activated surface. A clean spectrum with minimal residual hydroxyl band interference indicates successful pretreatment.

Key Parameters Table:

| Material Type | Typical Activation Temperature (°C) | Atmosphere | Dwell Time (hr) | Target Surface State |

|---|---|---|---|---|

| γ-Alumina | 400 - 500 | O₂ or Vacuum | 2-4 | Dehydroxylated, Lewis acid sites |

| Silica (SiO₂) | 450 - 500 | Vacuum | 3-5 | Isolated silanols |

| H-ZSM-5 Zeolite | 500 - 550 | Vacuum | 2-3 | Brønsted acid sites (cleaned) |

| Titania (TiO₂) | 300 - 400 | O₂ then Vacuum | 1-2 | Clean, reduced surface (after O₂ treatment) |

| Porous Carbon | 300 - 350 | Vacuum | 4-6 | Removal of H₂O and organics |

Reduction/Oxidation Cycles

Objective: To generate specific surface oxidation states or metallic sites, particularly for supported metal catalysts.

Detailed Protocol for Supported Metal Catalysts (e.g., 1% Pt/Al₂O₃):

- Initial Oxidation: Follow Steps 1-4 of the thermal activation protocol in a flow of pure O₂ (50 mL/min) at 400°C for 1 hour to oxidize any carbonaceous residues and ensure a uniform oxidized metal precursor state.

- Purging: Evacuate the cell and flush with an inert gas (Ar, He) at the oxidation temperature for 30 minutes.

- Reduction: Introduce a flow of 5% H₂/Ar (50 mL/min). Maintain at the reduction temperature (e.g., 350°C for Pt, 500°C for Cu) for 1-2 hours.

- Cooling & Cleaning: Evacuate the cell at the reduction temperature for 30 minutes to remove hydrogen, then cool to analysis temperature under high vacuum. This step is critical before introducing probe molecules.

Quantitative Analysis of Surface Sites via Probe Molecules

Objective: To titrate and characterize the concentration and strength of acid/base/redox sites.

Protocol for Pyridine Adsorption for Acid Site Quantification:

- Baseline: Obtain a high-resolution spectrum of the fully activated sample at the analysis temperature (e.g., 150°C) as the background.

- Dosing: Introduce a saturation dose of pyridine vapor (typically by exposing the sample to ~1 mbar of pyridine) into the IR cell for 5-10 minutes.

- Equilibration & Evacuation: Isolate the cell and allow equilibrium for 15 minutes. Subsequently, evacuate the cell at the same temperature for 30 minutes to remove all physisorbed pyridine.

- Measurement: Acquire the IR spectrum. The bands at ~1545 cm⁻¹ (pyridinium ion, Brønsted sites) and ~1455 cm⁻¹ (coordinated pyridine, Lewis sites) are measured.

- Quantification: Using the Lambert-Beer law and published molar extinction coefficients (ε), calculate site density. A commonly used coefficient for the 1545 cm⁻¹ band is ε ≈ 0.73 cm/μmol. The formula is: Site Density (μmol/g) = (Integrated Absorbance * S) / (ε * m), where S is the sample area (cm²), and m is the mass (g).

Quantitative Data for Common Probe Molecules:

| Probe Molecule | Target Site | Characteristic IR Band (cm⁻¹) | Typical Extinction Coefficient (ε, cm/μmol) | Notes |

|---|---|---|---|---|

| Pyridine | Brønsted Acid | ~1545 | 0.73 ± 0.10 | Temperature-dependent, requires evacuation. |

| Pyridine | Lewis Acid | ~1455 | 1.11 ± 0.20 | Specific coefficient depends on cation. |

| CO | Lewis Acid Sites | 2200-2250 | Variable | Used for strong Lewis sites (e.g., Al³⁺). |

| CO | Metal Sites (e.g., Pt⁰) | ~2050-2070 | Variable | Shift indicates electron density. |

| NH₃ | Brønsted/Lewis Acid | ~1450 / ~1620 | Requires calibration | Broader bands, more complex quantification. |

| CD₃CN | Lewis Acidity | 2250-2350 | Variable | Lower-frequency shift correlates with strength. |

Visualized Workflows

Title: Sample Pretreatment & IR Analysis Workflow

Title: Pretreatment Variables Impact on IR Results

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item Name | Function & Rationale | Critical Specification |

|---|---|---|

| In-Situ IR Cell | Allows thermal treatment, gas dosing, and spectral acquisition without air exposure. Maintains sample integrity. | High-vacuum seal (<10⁻⁶ mbar), heating capability (>500°C), IR-transparent windows (KBr, CaF₂, ZnSe). |

| High-Purity Gases (O₂, H₂/Ar, He) | Used for oxidation, reduction, and purge steps. Impurities (H₂O, CO) can poison surfaces. | 99.999% purity, equipped with moisture/oxygen traps (e.g., Molsieves, Cu catalyst). |

| Probe Molecules (Pyridine-d₅, CO, NH₃) | Selective adsorption onto specific surface sites (acid, metal, etc.) generates diagnostic IR bands. | High chemical purity, subjected to freeze-pump-thaw cycles to remove dissolved gases. |

| Calibrated Micropipette/Syringe | For precise liquid-phase introduction of probes (e.g., pyridine) into a vacuum manifold for vapor dosing. | Gas-tight, volume accuracy ±1%. |

| Turbomolecular Pumping Station | Achieves high vacuum necessary to remove physisorbed species and create a clean surface. | Ultimate vacuum <10⁻⁷ mbar, compatible with probe molecule vapors. |

| Temperature Controller | Precisely controls heating ramp and dwell during activation. Critical for reproducibility. | Programmable, with accurate thermocouple (K-type) reading from sample position. |

| Molar Extinction Coefficients (ε) | Published values converting IR band intensity to quantitative site density (μmol/g). | Must be selected for the specific probe, band, and material type. Major source of uncertainty. |

Step-by-Step Protocol: Performing Probe Molecule IR Experiments for Drug Development Materials

This application note details the protocol for designing and utilizing an in situ/operando Infrared (IR) spectroscopy cell, framed within a broader thesis on using IR with probe molecules for surface analysis. The setup is critical for studying surface chemistry, adsorption mechanisms, and reaction intermediates under controlled, realistic conditions, directly relevant to catalyst development and drug formulation research.

Key Design Considerations & Quantitative Specifications

The cell must maintain controlled environmental conditions while allowing precise IR beam transmission. Key parameters are summarized below.

Table 1: Critical Design Parameters for an In Situ/Operando IR Cell

| Parameter | Target Specification | Rationale |

|---|---|---|

| Temperature Range | 25°C to 600°C (± 1°C) | Covers most catalytic and sorption studies. |

| Pressure Range | High Vacuum (10⁻⁷ mbar) to 5 bar | Enables UHV surface studies to pressurized reactions. |

| Window Material | CaF₂, ZnSe, or Diamond | IR-transparent; choice depends on spectral range and chemical resistance. |

| Gas Flow Rate Control | 0.1 to 100 sccm (± 0.05 sccm) | Precise dosing of probe molecules (e.g., CO, NO, pyridine). |

| Heating/Cooling Rate | 0.1 to 50 °C/min | Controlled thermal ramps for activation/desorption studies. |

| Sample Area | ~1 cm² | Optimizes signal for pressed pellets or coated wafers. |

| Path Length | 2-5 mm (adjustable) | Balances gas phase signal interference and sensitivity. |

Detailed Experimental Protocols

Protocol 3.1: Cell Assembly and Leak Testing

Objective: To assemble the IR cell and ensure integrity under operational vacuum/temperature. Materials: Cell body, IR windows (CaF₂), gold gaskets, torque wrench, vacuum pump, helium leak detector.

- Window Sealing: Place a fresh gold gasket on the polished window seat. Carefully position the IR window.

- Torque Application: Using a calibrated torque wrench, tighten window holder nuts in a cross-pattern to 10 Nm to ensure a uniform, cold-weld seal.

- Initial Pump-Down: Connect the cell to a vacuum station. Rough pump to <10⁻³ mbar.

- Leak Check: Use a helium mass spectrometer leak detector. Spray helium around all seals. A leak rate < 1 x 10⁻⁹ mbar L/s is acceptable for high-vacuum studies.

- Pressure Test: Isolate the cell and monitor pressure rise over 30 minutes. A rise of < 0.1 mbar/min confirms integrity.

Protocol 3.2: In Situ DRIFTS with CO Probe Molecule

Objective: To characterize metal surface sites using CO as a probe molecule. Materials: Catalyst pellet, CO (5% in He), high-purity He, mass flow controllers, temperature programmer.

- Sample Activation: Place a catalyst wafer (~50 mg) in the cell holder. Heat to 300°C at 5°C/min under 20 sccm He flow for 1 hour. Cool to 30°C.

- Background Collection: Under He flow, collect a background IR spectrum (64 scans, 4 cm⁻¹ resolution).

- CO Adsorption: Switch flow to 5% CO/He at 10 sccm for 30 minutes.

- Spectral Acquisition: Collect spectra (every 2 min) during adsorption. Key bands: Gaseous CO (~2143 cm⁻¹), Linearly adsorbed CO on metals (~2000-2080 cm⁻¹), Bridged CO (~1800-1900 cm⁻¹).

- Desorption Study: Switch back to pure He. Perform a temperature-programmed desorption (TPD) while collecting spectra, heating to 400°C at 5°C/min. Monitor the decrease in adsorbed CO band intensity.

Protocol 3.3: Operando Reaction Study (CO Oxidation)

Objective: To monitor surface intermediates during a catalytic reaction. Materials: Pt/Al₂O₃ catalyst, 2% CO/He, 20% O₂/He, online mass spectrometer or gas chromatograph.

- Conditioning: Activate catalyst under O₂ at 300°C, then reduce under H₂ at 250°C.

- Set Reaction Conditions: Set cell to 150°C. Establish a flow of 2% CO and 20% O₂ in He balance (total flow 50 sccm, GHSV ~10,000 h⁻¹).

- Operando Data Collection: Simultaneously:

- Collect IR spectra every 30 seconds (8 scans each).

- Monitor effluent gas composition via MS/GC (e.g., CO₂ production every 2 min).

- Data Correlation: Correlate the appearance/disappearance of IR bands (e.g., adsorbed CO, carbonates) with changes in catalytic activity (CO₂ yield).

Visualization of Workflows

Diagram Title: In Situ/Operando IR Experiment Workflow

Diagram Title: Schematic of Operando IR Cell Components

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Probe Molecule IR Studies

| Item | Function & Specification |

|---|---|

| Probe Gases (CO, NO, CO₂) | Function: Map surface sites via their specific adsorption bands. Spec: High purity (≥99.999%) with calibrated mixtures (e.g., 1-5% in inert balance). |

| Basic Probe Vapors (Pyridine, NH₃) | Function: Differentiate Brønsted vs. Lewis acid sites. Spec: Analytical grade, dehydrated over molecular sieves. Delivered via saturation/He carrier stream. |

| IR Window Materials (CaF₂, ZnSe, Diamond) | Function: Transmit IR beam while containing the environment. Spec: CaF₂ (1200-4000 cm⁻¹, avoids aqueous studies); ZnSe (500-4000 cm⁻¹, avoids strong acids); Diamond (far-IR to 4000 cm⁻¹, chemically inert). |

| High-Purity Inert Gas (He, Ar) | Function: Purge, diluent, and carrier gas. Spec: ≥99.9999%, with integrated oxygen/moisture traps (<1 ppmv). |

| Calibration Gas Mixtures | Function: Quantify gas phase concentrations and calibrate online analyzers. Spec: NIST-traceable mixtures of reactants/products (e.g., CO/O₂/CO₂ in He). |

| Gold Gaskets (Foil, 0.5 mm thick) | Function: Provide a vacuum-tight, malleable seal for IR windows. Spec: High-purity gold (99.99%), annealed, single-use per experiment. |

| Catalyst/Wafer Holder (Stainless Steel or Ceramic) | Function: Holds sample in the precise IR beam path. Spec: Chemically inert, with integrated heating cartridge and thermocouple well. |

Within the broader thesis on protocols for using infrared (IR) spectroscopy with probe molecules for surface analysis, this document details the systematic workflow for in-situ and operando studies. This methodology is critical for researchers in catalysis, material science, and drug development investigating surface sites, acidity, basicity, and reactivity.

Key Research Reagent Solutions & Materials

| Item | Function & Specification |

|---|---|

| Self-Supporting Wafer | A thin, pure pellet of the catalyst/sample material, typically 5-20 mg/cm², allowing for transmission IR analysis without spectral interference. |

| Probe Molecules | Small, IR-active molecules (e.g., CO, NO, NH₃, Pyridine, CO₂) chosen for their specific interaction with surface sites (Lewis/Brønsted acid sites, metals). Must be of high purity (≥99.9%). |

| In-Situ IR Cell | A sealed, temperature-controlled (RT to 800°C) reactor with IR-transparent windows (e.g., CaF₂, ZnSe) for sample treatment and probe dosing under controlled atmosphere/vacuum. |

| High-Precision Manifold | A gas dosing system with calibrated volumes and pressure transducers (0-1000 Torr range) for precise, quantitative introduction of probe gases. |

| Reference Spectra Library | A digital database of spectra for pure probe molecules and common surface species, essential for accurate spectral subtraction and peak assignment. |

Detailed Experimental Protocol

Sample Preparation & Loading

- Wafer Preparation: Weigh 10-30 mg of finely powdered sample. Press into a self-supporting wafer (typically 13-20 mm diameter) using a hydraulic press at 2-5 tons for 1-2 minutes.

- Cell Assembly: Mount the wafer securely in the sample holder of the in-situ IR cell. Ensure it is perpendicular to the IR beam path.

- Initial Decontamination: Place the cell in the spectrometer. Purge with inert gas (e.g., Ar, 30 mL/min) and heat to 150°C for 1 hour to remove physisorbed water and contaminants.

Sample Pre-Treatment (Activation)

- Thermal/Oxidative Treatment: Switch gas flow to 20% O₂/He (or pure O₂). Ramp temperature to 400-500°C (5°C/min) and hold for 1-2 hours.

- Evacuation/Reductive Treatment (if needed): Evacuate cell to <10⁻³ Torr, or switch to a reducing flow (e.g., 5% H₂/Ar) at specified temperature for reduction of metal centers.

- Background Collection: Cool sample to the desired analysis temperature (e.g., 30°C). Under inert flow or vacuum, collect a high-resolution (4 cm⁻¹) background spectrum of the clean, activated sample.

Quantitative Probe Dosing

- Manifold Calibration: The dosing manifold volume (V_dose) is pre-calibrated. The pressure (P) of the probe gas in this volume is measured with a transducer.

- Dosing Calculation: The number of moles (n) dosed is calculated using the Ideal Gas Law: n = (P * V_dose) / (R * T), where R is the gas constant and T is manifold temperature.

- Incremental Dosing: Introduce small, sequential doses of the probe molecule (e.g., 0.05 µmol per dose for CO on metals) to the sample cell. Allow equilibrium (2-5 min) after each dose.

- Spectral Collection: After each equilibrium period, collect a single-beam spectrum. Convert it to absorbance using the stored background spectrum.

Spectral Processing & Analysis

- Spectrum Subtraction: Subtract the spectrum of the gas-phase probe molecule using a reference spectrum.

- Peak Deconvolution: Fit overlapping bands (e.g., in the OH region 3800-3400 cm⁻¹ or CO region 2200-1800 cm⁻¹) using Gaussian/Lorentzian functions.

- Quantification: For quantitative analysis, use the integrated area of a specific absorbance band and its known extinction coefficient (ε) to calculate site density via the Beer-Lambert law.

Table 1: Common IR Probe Molecules for Surface Analysis

| Probe Molecule | Target Surface Sites | Characteristic IR Bands (cm⁻¹) | Typical Dosing Amount |

|---|---|---|---|

| Carbon Monoxide (CO) | Metal sites (Pt, Pd, Rh), Lewis acid sites | 2250-2000 (M⁰-CO), 2200-2100 (Mⁿ⁺-CO) | 0.05-0.5 µmol doses |

| Ammonia (NH₃) | Brønsted & Lewis acid sites | 1450-1410 (Lewis-bound), 1485-1440 (Brønsted-bound) | Saturation dosing (10-100 Torr) |

| Pyridine (C₅H₅N) | Lewis & Brønsted acid sites | ~1450 (Lewis), ~1545 (Brønsted), ~1490 (both) | Vapor exposure at 150°C |

| Nitrogen (N₂) | Weak Lewis acid sites, cations | ~2330-2250 | High-pressure dosing (100-500 Torr) |

| Carbon Dioxide (CO₂) | Basic sites (O²⁻), amphoteric sites | 1650-1200 (carbonate/bicarbonate species) | 0.1-1 µmol doses |

Table 2: Typical Workflow Parameters for an In-Situ IR Experiment

| Process Step | Key Parameter | Typical Value / Range |

|---|---|---|

| Background Collection | Resolution | 4 cm⁻¹ |

| Scans | 64-128 | |

| Temperature | Analysis Temp (e.g., 30°C) | |

| Probe Dosing | Equilibrium Time | 2-5 minutes per dose |

| Dosing Precision | ±0.01 µmol | |

| Pressure Range | 0.1 - 100 Torr (per dose) | |

| Spectral Analysis | Extinction Coefficient (ε) for CO on metals | ~2-5 cm/µmol (site-dependent) |

| Detection Limit (site density) | ~0.5 µmol/g |

Workflow & Data Interpretation Diagrams

Systematic IR Workflow from Sample to Data

IR Spectral Data Interpretation Pathway

This application note, framed within a broader thesis on protocols for using infrared (IR) spectroscopy with probe molecules for surface analysis, provides a detailed guide for researchers in catalysis, materials science, and drug development. The strategic selection of probe molecules based on their molecular properties is critical for characterizing surface acidity, basicity, and porosity. The interaction between the probe and the active site produces distinct IR spectral shifts, enabling quantitative and qualitative surface analysis.

Core Principles of Probe Molecule Selection

The fundamental principle is to match the chemical property of the probe molecule with the target surface property.

- Acidity Measurement: Use basic probe molecules (e.g., pyridine, ammonia, CO) which donate electron density to Lewis acid sites or protonate on Brønsted acid sites.

- Basicity Measurement: Use acidic probe molecules (e.g., CO₂, chloroform, pyrrole) which donate protons or accept electron density from basic sites.

- Porosity & Accessibility: Use probe molecules of varying kinetic diameter (e.g., CO, N₂, alkanes) to assess pore size, volume, and diffusion limitations.

Quantitative Probe Molecule Properties & Selection Table

The following table summarizes key probe molecules, their target properties, and characteristic IR bands.

Table 1: Probe Molecules for Surface Characterization via IR Spectroscopy

| Probe Molecule | Target Surface Property | Molecular Characteristic | Characteristic IR Bands (v, cm⁻¹) | Key Information Derived |

|---|---|---|---|---|

| Carbon Monoxide (CO) | Lewis Acidity, Weak Sites | Weak σ-base, Strong π-acceptor | 2250-2150 (v(CO)) | Strength & concentration of Lewis acid sites (blue shift). Low-temp use. |

| Pyridine (C₅H₅N) | Lewis & Brønsted Acidity | Strong base (lone pair on N) | ~1450 (Lewis bound), ~1540 (Brønsted bound) | Distinguishes L vs. B acid sites & their relative concentration. |

| Ammonia (NH₃) | Total Acidity (Strong) | Strong base, small size | ~1450-1250 (δas/s(NH₄⁺)), ~3330-3100 (v(N-H)) | Quantifies strong acid sites; can be non-discriminatory. |

| Deuterated Acetonitrile (CD₃CN) | Lewis Acidity, Porosity | Weak base, nitrile stretch | ~2330-2275 (v(C≡N)) | Probes very strong Lewis sites (large blue shift). Polarity probe. |

| Carbon Dioxide (CO₂) | Basicity | Acidic, linear molecule | 1750-1200 (carbonate/bicarbonate species) | Identifies O²⁻ (basic), OH (weak basic) sites. |

| Deuterated Chloroform (CDCl₃) | Basicity | Weak C-H acid | ~2260 (v(C-D)) shift to lower frequency | Measures base strength via H-bonding (red shift of C-D stretch). |

| Pyrrole (C₄H₅N) | Basicity | Weak N-H acid | ~3490-3300 (v(N-H)) shift to lower frequency | Probes Lewis basicity via N-H bond weakening. |

| Nitrogen (N₂) | Porosity, Surface Area | Inert, small kinetic diameter | ~2331 (v(N≡N)) | Physisorption for pore volume/size (often paired with 77K). |

Detailed Experimental Protocols

Protocol 3.1: Characterizing Solid Acidity using Pyridine Adsorption FTIR

Objective: To distinguish and quantify Brønsted and Lewis acid sites on a solid catalyst (e.g., zeolite, alumina).

Materials:

- FTIR spectrometer with high-temperature/vacuum cell with KBr windows.

- Sample holder (wafer press).

- High-vacuum system (<10⁻⁵ mbar).

- Probe: Pyridine, purified and stored over molecular sieves.

Procedure:

- Sample Preparation: Press 10-20 mg of sample into a self-supporting wafer (~13 mm diameter). Place wafer in the IR cell holder.

- Pre-treatment: Activate the sample in situ by heating under vacuum (e.g., 400°C for 2 hours) to remove adsorbed water and contaminants. Cool to analysis temperature (typically 150°C).

- Background Scan: Acquire a background IR spectrum of the activated sample.

- Probe Dosing: Expose the sample to pyridine vapor (5-10 mbar) for 5-10 minutes to ensure saturation.

- Equilibration & Evacuation: Isolate the cell and evacuate at the analysis temperature (150°C) for 30 minutes to remove all physisorbed pyridine.

- Spectrum Acquisition: Collect the IR spectrum in transmission mode (e.g., 4000-1000 cm⁻¹, 64 scans, 4 cm⁻¹ resolution).

- Data Analysis: Identify bands at ~1540 cm⁻¹ (Brønsted-bound pyridinium ion) and ~1450 cm⁻¹ (Lewis-coordinated pyridine). Use molar extinction coefficients (e.g., εB ≈ 0.73 cm/μmol, εL ≈ 1.11 cm/μmol for some zeolites) to calculate site concentrations: C (μmol/g) = (A * S) / (ε * m), where A=integrated absorbance, S=wafer area (cm²), m=sample mass (g).

Protocol 3.2: Probing Porosity and Site Accessibility using Low-Temperature CO Adsorption

Objective: To assess pore confinement effects and characterize weak acid sites.

Materials:

- FTIR with liquid N₂-coolable in situ cell.

- High-vacuum manifold.

- Probe: High-purity CO gas.

Procedure:

- Follow steps 1-3 from Protocol 3.1 for sample activation and background scan.

- Cooling: Cool the sample to -196°C (77 K) using liquid nitrogen.

- Incremental Dosing: Introduce small, controlled doses of CO (0.1-1 mbar increments) onto the cooled sample.

- Spectrum Acquisition: After each dose, allow equilibrium and collect an IR spectrum in the v(CO) region (2250-2150 cm⁻¹).

- Analysis: Observe the position of the carbonyl stretch. A shift to higher wavenumbers (>2170 cm⁻¹) indicates interaction with Lewis acid sites. The appearance of multiple peaks can indicate sites in different pore environments (e.g., in zeolites). The integrated peak area vs. pressure can be used for semi-quantitative analysis.

Visualization of Method Selection & Workflow

Title: Probe Selection Logic for Surface IR Analysis

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Probe Molecule IR Experiments

| Item | Function & Critical Specification |

|---|---|

| High-Vacuum In Situ IR Cell | Allows thermal activation and controlled gas dosing on the sample wafer. Must have heating (>500°C), cooling (LN₂), vacuum ports, and IR-transparent windows (KBr, ZnSe, CaF₂). |

| Self-Supporting Wafer Die | Press for creating uniform, crack-free sample wafers for transmission IR. Typical diameter: 13 mm. |

| Pyridine, Anhydrous (≥99.5%) | Primary probe for acid site discrimination. Must be purified (freeze-pump-thaw) and stored over 3Å molecular sieves to remove water. |

| Carbon Monoxide, ⁵⁹CO (≥99%) | Probe for weak/strong Lewis acidity. Isotopically labeled ¹³CO (≥99% atom) is essential to avoid gas-phase interference in the 2150 cm⁻¹ region. |

| Deuterated Acetonitrile (CD₃CN, ≥99.8% D) | Probe for strong Lewis acidity and polarity. High deuteration level minimizes interfering C-H stretch bands. |

| High-Purity Carrier/Activation Gases | Oxygen (for oxidative pretreatment), Helium/Argon (for inert atmosphere, purge). Must be ultra-dry (<5 ppm H₂O) and use appropriate gas purifiers. |

| 3Å Molecular Sieves | For on-line or offline drying of probe vapors and inert gases to prevent water contamination of active surfaces. |

| Reference Zeolite (e.g., H-ZSM-5, H-Y) | Standard material with well-known acidity for method validation and calibration of extinction coefficients. |

| FTIR Spectrometer with MCT Detector | Must have high sensitivity in the mid-IR region. Mercury Cadmium Telluride (MCT) detector is preferred for its high signal-to-noise ratio, especially for low-temperature experiments. |

Within the thesis on Protocol for using infrared spectroscopy (IR) with probe molecules for surface analysis research, meticulous data acquisition is paramount. This document outlines best practices for key acquisition parameters—spectral resolution, number of scans, and background subtraction—to ensure high-quality, reproducible data for probing surface sites, acidity, and reaction mechanisms.

Core Acquisition Parameters: Quantitative Guidelines

Optimizing these parameters balances signal-to-noise ratio (SNR), spectral detail, and acquisition time.

Table 1: Recommended FTIR Acquisition Parameters for Probe Molecule Studies

| Parameter | Typical Range for Surface Analysis | Rationale & Impact | Practical Consideration |

|---|---|---|---|

| Spectral Resolution | 2 - 4 cm⁻¹ | Determines ability to resolve closely spaced adsorbate bands. Higher resolution reveals fine structure but increases scan time and file size. | Use 4 cm⁻¹ for routine surveys of strongly absorbing probes (e.g., CO). Use 2 cm⁻¹ for detailed analysis of weakly absorbing or complex probes (e.g., pyridine, NO). |

| Number of Scans | 64 - 512 scans | Improves SNR by a factor of √N. More scans reduce noise but increase acquisition time and risk of sample drift. | 64-128 scans often sufficient for strong signals. Use 256-512 for weak signals or difference spectroscopy. Always match scan count for sample and background. |

| Apodization Function | Happ-Genzel or Blackman-Harris | Reduces spectral artifacts from the interferogram's finite length. Choice affects line shape and resolution. | Happ-Genzel offers a good general compromise between resolution and side-lobe suppression. |

| Phase Correction | Mertz or Power Spectrum | Corrects for asymmetrical interferograms. Essential for quantitative accuracy. | Modern FTIRs perform this automatically. Mertz is standard for high-resolution work. |

| Background Spectrum | Clean, probe-free surface under identical conditions | Removes contributions from the spectrometer, atmosphere (H₂O, CO₂), and the sample substrate. | Acquire immediately before sample exposure. Re-acquire frequently for long experiments. Store in a library for consistent processing. |

Detailed Experimental Protocols

Protocol 3.1: Optimized Data Acquisition for CO Probe Molecule IR

Objective: To acquire high-quality IR spectra of CO adsorbed on a metal catalyst surface to determine adsorption sites and metal dispersion.

Materials:

- In-situ IR cell with temperature-controlled environment.

- Catalyst wafer (self-supporting or on IR-transparent window).

- High-purity CO and inert gas (e.g., He, Ar).

- FTIR spectrometer with MCT/A detector cooled with liquid N₂.

Procedure:

- Sample Pretreatment: Activate the catalyst in the IR cell under flowing inert gas at required temperature (e.g., 400°C, 1h), followed by cooling to analysis temperature (e.g., -196°C to 30°C).

- Background Acquisition: At the analysis temperature, under inert flow, acquire a background single-beam spectrum.

- Parameters: Resolution = 4 cm⁻¹, Scans = 128, Apodization = Happ-Genzel.

- Probe Exposure: Introduce a calibrated dose of CO (e.g., 1% CO in He) onto the catalyst. Maintain flow until saturation is observed.

- Sample Spectrum Acquisition: Acquire the single-beam spectrum of the adsorbed species using the exact same acquisition parameters as the background.

- Spectrum Generation: Compute the absorbance spectrum (

A = -log10(Sample_Spectrum / Background_Spectrum)). - Repeat: For titration studies, repeat steps 3-5 with increasing CO doses.

Protocol 3.2: Background Subtraction and Difference Spectroscopy Protocol

Objective: To isolate the spectrum of a surface-bound species by subtracting contributions from gas-phase or undesired surface species.

Materials:

- Set of single-beam spectra from a time/dose series.

- Spectral processing software (e.g., OPUS, GRAMS, MATLAB).

Procedure:

- Collect a Reference Background Library: Acquire high-SNR background spectra under all relevant conditions (e.g., empty cell, clean catalyst at various temperatures).

- Acquire Data Series: For a reaction or adsorption experiment, collect sequential single-beam spectra (

S_i) at defined time intervals using fixed acquisition parameters. - Initial Absorbance Calculation: Convert each to absorbance (

A_i) using the most appropriate static background (e.g., clean catalyst before probe exposure). - Sequential Difference Spectroscopy: To highlight changes, compute difference spectra:

ΔA = A_i - A_ref, whereA_refis an absorbance spectrum from a key reference state (e.g., before reaction). - Gas-Phase Subtraction: If gas-phase peaks interfere, scale and subtract a prerecorded spectrum of the pure gas-phase probe using least-squares fitting routines on specific gas-phase rotational bands.

- Validation: Ensure subtracted spectra have flat baselines in regions where no adsorbate signals are expected (e.g., 2400-2300 cm⁻¹ for CO₂-free air).

Visualizing Workflows and Relationships

Diagram 1: FTIR Data Acquisition & Processing Workflow

Diagram 2: Parameter Interdependence on Spectrum Quality

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Probe Molecule IR Spectroscopy

| Item | Function & Relevance in Surface Analysis |

|---|---|

| Carbon Monoxide (CO), 99.97%+ | Primary probe for metal sites. Stretching frequency (2000-2200 cm⁻¹) indicates oxidation state, coordination, and back-donation. |

| Deuterated Acetonitrile (CD₃CN) | Probe for Lewis acidity. C≡N shift correlates with acid strength. Deuterated form avoids overlap with CH stretches. |

| Pyridine, 99.9%+ | Classical probe to distinguish Brønsted (1540 cm⁻¹) and Lewis (1450 cm⁻¹) acid sites. Must be thoroughly dried. |

| Nitric Oxide (NO), 99.5%+ | Probe for redox and coordination sites on metals and cations. Useful for paramagnetic centers. |

| Potassium Bromide (KBr), IR Grade | For preparing transmission pellets of powdered samples when self-supporting wafers are not feasible. |

| MCT/A Detector | Mercury Cadmium Telluride detector cooled by liquid N₂. Provides high sensitivity in the mid-IR, essential for weak signals. |

| In-Situ IR Cell with ZnSe/ CaF₂ Windows | Allows controlled sample environment (temperature, pressure, gas flow) for in-situ or operando studies. |

| Self-Supporting Catalyst Wafer Die | For pressing powdered catalysts into thin wafers (~5-20 mg/cm²) for transmission measurements without a substrate. |

Application Notes

This application note details the use of in situ and operando Infrared (IR) spectroscopy with probe molecules as a core technique within a comprehensive thesis on surface analysis protocols. This approach provides unparalleled insights into surface acidity/basicity, active site identification, adsorption mechanisms, and host-guest interactions in diverse nanomaterials.

Key Quantitative Insights: The following tables summarize critical data derived from IR probe molecule studies across the three material classes.

Table 1: Characterization of Surface Acidity/Basicity Using Probe Molecules

| Probe Molecule | Target Site | IR Spectral Region (cm⁻¹) | Information Gained | Typical Material |

|---|---|---|---|---|

| CO | Lewis acid sites (e.g., Al³⁺, Zn²⁺) | 2250-2150 (stretching) | Strength & concentration of Lewis sites. Shift ↑ = stronger site. | Zeolites, γ-Al₂O₃, MOFs |

| Pyridine (Py) | Brønsted (B) & Lewis (L) acid sites | ~1540 (B), ~1450 (L) | Quantitative B/L ratio and acid type distribution. | Solid acid catalysts, MOFs |

| NH₃ | Brønsted & Lewis acid sites | ~1450 & ~1620 (deformation) | Total acid site strength and thermal stability of adducts. | Zeolites, Sulfated ZrO₂ |

| CDCl₃ | Basic sites (e.g., O²⁻) | ~2260 (C-D stretch) | Strength of basic sites. Shift ↓ = stronger interaction. | MgO, CaO, basic MOFs |

| CO₂ | Basic O²⁻ sites | 1650-1300 (carbonate bands) | Formation of mono-/bi-dentate carbonates maps basicity. | Mixed metal oxides |

Table 2: IR Probe Data for MOF & Drug Carrier Host-Guest Analysis

| Probe / Load | Material Class | Key IR Spectral Changes | Inferred Interaction Mechanism |

|---|---|---|---|

| N₂ (77K) | MOFs (e.g., Cu-BTC, ZIF-8) | Shift in -OH stretch of framework (~3600 cm⁻¹) | Probing open metal sites & framework flexibility. |

| H₂O/D₂O | Mesoporous Silica (SBA-15, MCM-41) | Intensity of isolated vs. H-bonded -OH (~3740 vs. ~3550 cm⁻¹) | Surface hydrophilicity/hydrophobicity, silanol density. |

| Doxorubicin | Polymeric NPs (PLGA), Mesoporous SiO₂ | Shift in C=O stretch (~1720 cm⁻¹) of drug & carrier | Hydrogen bonding or electrostatic drug-carrier interaction. |

| CO (as a drug analogue) | Porous Carbon Carriers | Shift of CO peak relative to gas phase (>2143 cm⁻¹) | π-back donation to graphitic surfaces, indicating adsorption sites. |

Experimental Protocols

Protocol 1: In Situ DRIFTS (Diffuse Reflectance IR Fourier Transform Spectroscopy) for Catalyst Acidity Measurement Objective: To quantify Brønsted and Lewis acid sites on a solid catalyst using pyridine adsorption.

- Sample Preparation: Place ~20 mg of finely ground, dehydrated catalyst sample into the DRIFTS cell’s sample cup.

- Pre-treatment: Activate the sample in situ under a flow of dry He or N₂ (30 mL/min) at 400°C for 2 hours to remove physisorbed water and contaminants. Cool to 150°C under flow.

- Background Scan: Collect a background single-beam spectrum at the analysis temperature (e.g., 150°C).

- Probe Adsorption: Expose the sample to a vapor-saturated stream of pyridine (e.g., by bubbling He through liquid pyridine at 0°C) for 30 minutes.

- Desorption/Purging: Switch to pure He flow at the same temperature for 60 minutes to remove physisorbed pyridine.

- Spectrum Acquisition: Collect the IR spectrum (typically 64-128 scans at 4 cm⁻¹ resolution).

- Quantification: Use the molar extinction coefficients for the bands at ~1545 cm⁻¹ (Brønsted) and ~1454 cm⁻¹ (Lewis) to calculate site densities (e.g., using the formula: Site density = (A * S) / (ε * m), where A=integrated absorbance, S=scattering coefficient, ε=extinction coefficient, m=sample mass).

Protocol 2: Probing MOF Open Metal Sites with Low-Temperature CO Adsorption Objective: To characterize coordinatively unsaturated metal sites (CUS) in a Metal-Organic Framework.

- Sample Activation: Load 30-50 mg of MOF into a high-vacuum IR cell with KBr windows. Dehydrate and degas under dynamic vacuum (<10⁻⁵ mbar) at 150-200°C for 12-24 hours.

- Cooling: Cool the activated sample to 100 K using a liquid nitrogen cryostat.

- Background: Acquire a background spectrum at 100 K.

- Dosing: Introduce small, incremental doses of high-purity CO gas (e.g., 0.1 mbar steps) onto the sample.

- Equilibrium & Measurement: Allow equilibrium after each dose and collect a transmission IR spectrum.

- Analysis: Monitor the ν(CO) region (2250-2100 cm⁻¹). The appearance, shift, and saturation of bands indicate the strength and population of CUS. Bands above 2170 cm⁻¹ typically indicate σ-bonding to strong Lewis acid sites.

Protocol 3: Analyzing Drug-Polymer Interactions in Nano-Carriers via ATR-FTIR Objective: To elucidate the interaction mechanism between a loaded drug (e.g., Doxorubicin) and a polymeric carrier (e.g., PLGA).

- Sample Group Preparation: Prepare three samples: i) Pure drug, ii) Empty polymer nanoparticles, iii) Drug-loaded nanoparticles. Ensure they are lyophilized.

- ATR Setup: Use a diamond or ZnSe ATR crystal. Clean with suitable solvent and acquire background.

- Measurement: Place a small amount (~1 mg) of each powdered sample directly on the ATR crystal. Apply consistent pressure via the anvil. Collect spectra (e.g., 32 scans, 4 cm⁻¹ resolution) for each sample.

- Spectral Deconvolution: Focus on the fingerprint region (1800-1500 cm⁻¹). Compare the exact peak positions and shapes of key functional groups (e.g., drug's C=O, C-O, N-H; polymer's ester C=O).

- Interaction Identification: A shift (>5 cm⁻¹) or broadening of the drug's characteristic peaks upon loading indicates specific interactions like H-bonding (shift) or π-π stacking (broadening/shoulder).

Visualizations

Workflow for In Situ IR Probe Molecule Experiment

IR Probe Applications within Thesis Framework

The Scientist's Toolkit: Essential Research Reagent Solutions

| Reagent / Material | Function in IR Probe Experiments |

|---|---|

| Carbon Monoxide (CO), 99.99% | Primary probe for Lewis acid site strength and metal oxidation state via ν(CO) frequency shift. |

| Deuterated Chloroform (CDCl₃) | Probe for surface basicity; the C-D stretching frequency is sensitive to H-bonding with surface O sites. |

| Anhydrous Pyridine | Standard probe for discriminating and quantifying Brønsted vs. Lewis acid sites. |

| Ammonia (NH₃) Gas | Strong base probe for assessing total acid site strength and distribution. |

| Deuterated Water (D₂O) | Probe for surface hydroxyl groups and hydrophilicity; avoids strong H₂O IR interference. |

| Nitrogen (N₂) Gas, High Purity | Used for purging and as a weak probe at cryogenic temperatures to assess very weak sites. |

| KBr or CaF₂ Windows | Material for transmission IR cells; transparent in mid-IR range, inert for most samples. |

| High-Surface-Area Silica (e.g., Aerosil) | Common reference and dilution material for preparing DRIFTS samples. |

| Zeolite H-ZSM-5 (Reference Catalyst) | Well-characterized acidic material used as a benchmark for validating probe molecule protocols. |

| IR-grade Potassium Bromide (KBr) | For preparing pellets for transmission IR measurements of powders. |

Solving Common Challenges: Troubleshooting and Optimizing Your Probe IR Spectra

Within a research thesis focused on using infrared (IR) spectroscopy with probe molecules for surface analysis, obtaining high-quality spectra is paramount. Weak intensity or excessive noise in diagnostic bands can severely compromise data interpretation, leading to incorrect conclusions about surface sites, adsorbate conformation, or reaction mechanisms. This application note systematically outlines the primary causes of poor signal-to-noise (S/N) ratio in probe molecule IR experiments and provides detailed protocols for diagnosis and resolution.

Common Causes and Quantitative Impact

The following table summarizes major factors degrading S/N, their typical impact on band intensity or noise level, and the primary spectral symptom.

Table 1: Primary Causes of Poor S/N in Probe Molecule IR Spectroscopy

| Cause Category | Specific Factor | Typical Impact on Band Intensity (I) or Noise (N) | Key Spectral Symptom |

|---|---|---|---|

| Sample Preparation | Inadequate surface coverage of probe molecule | I: Severe decrease (>80%) | Weak or absent bands |

| Incorrect pellet density (transmission) | I: Decrease up to 70% | Bands appear weak/diffuse | |

| Contaminated surface (e.g., hydrocarbons) | N: Increase, I: Decrease for target bands | High background, masked bands | |

| Instrument & Setup | Deteriorated IR source | I: Gradual decrease (up to 60%) | Overall low signal |

| Misaligned optics | I: Severe decrease (>90%) | Very weak signal | |

| Moisture/CO₂ in optical path | N: Major increase | Sharp spurious bands (e.g., ~2350 cm⁻¹) | |

| Inadequate aperture setting | I: Decrease, N: Potential decrease | Weak signal, possible improved resolution | |

| Data Collection | Insufficient number of scans | N: High (inversely proportional to √scans) | High baseline noise |

| Improper detector selection | I/N: Suboptimal gain/response | Poor sensitivity in specific spectral regions | |

| Incorrect resolution setting | I: Decrease if set too high | Broadened, weak bands | |

| Probe Molecule | Unsuitable probe (weak dipole change) | I: Inherently low | Weak bands despite optimization |

| Probe decomposition on surface | I: Decrease over time | Bands change/disappear during experiment |

Diagnostic Protocol

Follow this workflow to systematically identify the source of poor S/N.

Protocol 1: Stepwise Diagnosis of S/N Issues

Objective: To isolate the component responsible for weak or noisy infrared bands. Materials: High-purity KBr (for transmission), known stable sample (e.g., polystyrene film), dry nitrogen or purge gas supply, alignment tools per spectrometer manufacturer. Procedure:

- Initial Spectrum Assessment:

- Collect a fresh single-beam background spectrum under standard experimental conditions (e.g., 4 cm⁻¹ resolution, 256 scans).

- Collect a single-beam spectrum of your sample.

- Examine the raw single-beam sample spectrum (not absorbance). The signal height in a clean region (e.g., 2000 cm⁻¹) should be at least 10-20% of the detector's saturation limit. If not, proceed to Step 2.

- Instrument Baseline Check:

- Without any sample in the beam path, collect a background and immediately collect a "sample" spectrum with an empty chamber or clean holder.

- Transform to absorbance. A flat, featureless line near 0 ± 0.01 AU indicates a clean optical path. Large, sharp bands indicate contamination (H₂O, CO₂). A sloping or noisy baseline suggests source or detector issues.

- Standard Sample Test:

- Place a stable reference standard (e.g., polystyrene film) in the beam.

- Collect a spectrum at standard parameters.

- Compare the intensity and noise of key bands (e.g., 1601 cm⁻¹) to historical data or known benchmarks. If noise is high or intensity is low, the issue is instrumental. If the standard appears normal, the issue lies with your specific sample preparation.

- Optical Path Purge Verification:

- Ensure the spectrometer purge is active and stable for >30 minutes.

- Monitor the atmospheric bands in a single-beam background. The intensity of the water rotation band near 1800 cm⁻¹ should be minimal and stable. High or fluctuating levels indicate a poor purge.

- Sample-Specific Verification (for surface studies):

- Confirm probe molecule dosing procedure. Ensure the surface was properly activated/cleaned prior to dosing.

- For transmission cells, verify pellet uniformity and that it is mounted squarely in the beam.

Figure 1: Diagnostic workflow for poor S/N in IR spectra.

Optimization Protocols

Protocol 2: Optimizing Sample Preparation for Transmission IR

Objective: Prepare a high-quality, self-supporting catalyst wafer for probe molecule IR studies with maximum transmission and minimal scattering. Materials: Fine-powdered catalyst sample, die set and press, KBr (optional, for dilution), hydraulic press. Procedure:

- Pellet Preparation: For strongly absorbing materials, dilute 1-5 mg of sample with 100-200 mg of pre-dried KBr. For pure samples, use 5-20 mg. Grind thoroughly in an agate mortar.

- Pressing: Transfer powder to a 13 mm or 20 mm die set. Apply pressure gradually to 5-8 tons (for KBr mixtures) or 0.5-2 tons (for pure self-supporting wafers). Hold for 1-2 minutes.

- Activation: Mount the pellet in a high-temperature transmission cell. Activate under vacuum or flowing dry gas (e.g., 10% O₂/He) by ramping to the desired temperature (e.g., 400°C) for 1-2 hours to clean the surface.

- Probe Dosing: Cool to analysis temperature (often 25-100°C). Admit a calibrated, small dose of probe molecule (e.g., 0.1-5 mbar of CO, NH₃, pyridine). Let it equilibrate, then evacuate for 5-15 minutes to remove physisorbed species.

- Spectrum Acquisition: Collect background on the activated sample. After dosing, collect sample spectrum immediately.

Protocol 3: Optimizing Data Acquisition Parameters

Objective: Acquire spectra with an optimal balance of S/N, resolution, and time. Materials: FT-IR spectrometer with appropriate detector. Procedure:

- Detector Selection: For mid-IR (4000-400 cm⁻¹) with liquid N₂, use a Mercury Cadmium Telluride (MCT) detector for highest sensitivity. For room-temperature operation, use a DTGS detector for broader linear range.

- Resolution Setting: Set resolution to 4 cm⁻¹ for most surface studies. Lower (e.g., 8 cm⁻¹) increases S/N but loses fine structure. Higher (e.g., 2 cm⁻¹) decreases S/N; only use if necessary to resolve sharp gas-phase bands.

- Scan Number Optimization: Acquire successive spectra of your sample, doubling the number of scans (e.g., 32, 64, 128, 256). Plot the noise (e.g., peak-to-peak in a flat region like 2200-2000 cm⁻¹) versus √(scans). Choose a scan number where the noise improvement plateaus. For most quantitative work, 128-512 scans are typical.

- Aperture Selection: Use the largest aperture that does not cause vignetting or reduce spectral resolution for your sample size. A smaller aperture reduces energy but can improve beam definition.

Table 2: Data Acquisition Optimization Guide

| Parameter | Standard Value for Surface IR | Effect on S/N | When to Adjust |

|---|---|---|---|

| Spectral Resolution | 4 cm⁻¹ | Lower res. → Higher S/N | Increase to 2 cm⁻¹ for gas-phase analysis. Decrease to 8 cm⁻¹ for very weak signals. |

| Number of Scans | 128 - 512 | N ∝ 1/√(scans) | Increase until noise level is acceptable for quantitative analysis. |

| Aperture Size | Manufacturer default for sample area | Larger → More signal, potential for spillover | Reduce if sample is small or to improve definition in micro-sampling. |

| Detector Gain | Auto or Standard | Higher gain amplifies signal AND noise | Manually increase for extremely weak signals from highly diluted samples. |

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Probe Molecule IR

| Item | Function in Surface Analysis | Key Consideration |

|---|---|---|

| Carbon Monoxide (CO), ⁵⁵CO | Probe for metal sites (M⁰, M⁺). Band position (∼2200-2000 cm⁻¹) indicates oxidation state and coordination. | Use high purity (>99.99%). ⁵⁵CO isotope helps confirm assignments by predictable shift (∼30-50 cm⁻¹ lower). |

| Deuterated Acetonitrile (CD₃CN) | Probe for Lewis acid sites via CN stretch. Less prone to H-bonding network than other nitriles. | Hygroscopic. Must be thoroughly dried over molecular sieves and distilled under inert atmosphere before use. |

| Deuterated Pyridine (C₅D₅N) | Distinguishes Lewis (∼1450 cm⁻¹) vs. Brønsted (∼1540 cm⁻¹) acid sites. Deuterium minimizes interference in C-H region. | Purify by freeze-pump-thaw cycles to remove dissolved gases and light impurities. |

| Ammonia (NH₃) / Deuterated Ammonia (ND₃) | Probe for acid site strength and coordination. Symmetric deformation modes are diagnostic. | ND₃ is used to shift bands away from framework vibrational regions of zeolites. Highly basic, can induce surface reactions. |

| Potassium Bromide (KBr), Optical Grade | Matrix for diluting strongly absorbing samples to prepare transmission pellets. | Must be dried at ∼400°C for 24 hours and stored in a desiccator to avoid IR-absorbing water. |

| High-Temperature In-Situ Cell | Allows sample activation (heating under vacuum/gas) and controlled probe molecule dosing at defined temperatures. | Ensure IR-transparent windows (e.g., KBr, ZnSe, CaF₂) are compatible with temperature and chemical environment. |

Figure 2: Core workflow for probe molecule IR surface analysis.

Within the broader thesis on Protocol for using infrared spectroscopy (IR) with probe molecules for surface analysis research, a critical operational challenge is the accurate isolation of surface-adsorbate signals from gas-phase spectral artifacts. These artifacts, primarily from residual probe molecules and environmental moisture, can obscure or mimic genuine surface species, leading to misinterpretation of active sites, bonding configurations, and reaction mechanisms. This application note details systematic protocols for identifying, quantifying, and correcting for these interferences to ensure data fidelity in catalytic, material science, and drug development research.

Table 1: Common Gas-Phase Interferences in Probe-Molecule IR Spectroscopy

| Interference Source | Characteristic IR Bands (cm⁻¹) | Potential Overlap With Surface Species | Typical Origin |

|---|---|---|---|

| Gas-Phase CO | ~2143 (stretch) | Metal-carbonyls (2100-1800 cm⁻¹) | Incomplete purging, CO probe molecule. |

| Atmospheric CO₂ | 2360, 2340 (asymmetric stretch) | Can create ill-defined baseline features. | Ambient air leakage, outgassing. |

| Water Vapor (H₂O) | 3900-3500 (ν, δ comb. bands), ~1600 (δ bend) | O-H stretches of surface hydroxyls, adsorbed water. | Residual moisture in cell/purge gas. |