Navigating Catalyst Characterization: A Practical Guide to Interpreting XRD, BET, XPS, and TEM Data

This article provides a comprehensive guide for researchers, scientists, and drug development professionals facing challenges in interpreting heterogeneous catalyst characterization data.

Navigating Catalyst Characterization: A Practical Guide to Interpreting XRD, BET, XPS, and TEM Data

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals facing challenges in interpreting heterogeneous catalyst characterization data. It addresses four core needs: establishing foundational knowledge of common techniques and their expected outcomes, applying methodologies for specific catalyst systems, troubleshooting common artifacts and misinterpretations, and validating findings through complementary data correlation. The guide aims to bridge the gap between raw data acquisition and robust, publication-ready conclusions, with a focus on applications in catalytic processes relevant to pharmaceutical synthesis and green chemistry.

Decoding the Basics: Core Principles of XRD, BET, XPS, and TEM for Catalyst Analysis

Technical Support Center: Troubleshooting & FAQs

FAQ 1: Why is my BET surface area measurement significantly lower than expected for my mesoporous catalyst?

- Answer: This is a common issue often related to incomplete sample preparation or instrument parameters.

- Primary Cause: Inadequate outgassing. Residual moisture or volatile contaminants block the micropores and mesopores, preventing nitrogen access.

- Troubleshooting Guide:

- Verify Outgassing Protocol: Ensure the sample was heated under vacuum (typically 150-300°C, depending on material stability) for a sufficient time (often 6-12 hours). For some materials, a flowing inert gas purge is acceptable.

- Check for "Soft" Degassing: Some catalysts, especially organic-inorganic hybrids, can collapse under standard outgassing temperatures. Reduce the outgassing temperature and time incrementally to find a stable condition.

- Analyte Choice: For very low surface area materials (<10 m²/g), consider using krypton adsorption instead of nitrogen for improved accuracy.

FAQ 2: My XRD pattern shows broad, poorly defined peaks. Is my catalyst amorphous or are there instrument issues?

- Answer: Broad peaks indicate small crystallite size (< 5 nm) or microstrain, not necessarily an amorphous material.

- Troubleshooting Steps:

- Confirm Instrument Alignment: Run a standard reference material (e.g., NIST Si 640c) to verify the diffractometer's alignment and resolution.

- Optimize Scan Parameters: Increase the counting time per step and use a slower scan speed to improve the signal-to-noise ratio.

- Analyze Crystallite Size: Apply the Scherrer equation to the peak broadening (FWHM) to estimate crystallite size. Remember to subtract instrumental broadening.

- Complement with TEM: Use Transmission Electron Microscopy to visually confirm nanocrystalline domains versus amorphous regions.

- Troubleshooting Steps:

FAQ 3: During XPS analysis, I observe an unexpected shift in my binding energy peaks. How do I determine if it's a chemical state change or a charging effect?

- Answer: Distinguishing chemical shift from charging is critical.

- Protocol for Diagnosis:

- Use a Charge Reference: Always reference your spectra to a known internal standard. For supported catalysts, use the adventitious carbon C 1s peak at 284.8 eV, or the support's main element (e.g., Al 2p for Al₂O₃ at 74.5 eV).

- Check All Peaks: Sample charging shifts all peaks in the spectrum by the same amount. A chemical shift affects only the peaks of the element in that specific chemical state.

- Use a Flood Gun: Ensure the charge neutralizer (flood gun) is correctly optimized for your insulating sample. Adjust electron flux and energy.

- Data Correction: If charging is uniform, apply a simple linear shift correction based on your reference peak.

- Protocol for Diagnosis:

FAQ 4: In my H₂-TPR profile, I get multiple, overlapping reduction peaks. How do I deconvolute them to assign them to specific catalyst components?

- Answer: Overlap indicates multiple reducible species with similar reduction temperatures.

- Deconvolution Methodology:

- Run Reference Materials: Perform TPR on pure, individual components of your catalyst (e.g., the bare support, a bulk model of the active phase) to identify their characteristic reduction temperatures.

- Vary Experimental Conditions: Perform TPR with different heating rates. The position of true reduction peaks will shift with heating rate, while artifacts may not.

- Use Quantitative Analysis: Integrate the total H₂ consumption and compare it with the theoretical consumption based on the complete reduction of suspected species (e.g., CuO → Cu, Fe₂O₃ → Fe).

- Mathematical Deconvolution: Use fitting software (e.g., Gaussian, Lorentzian functions) to mathematically separate overlapping peaks. Always support this with the chemical evidence from steps 1-3.

- Deconvolution Methodology:

Key Characterization Techniques: What They Measure

| Technique (Acronym) | Primary Physical Property Measured | Typical Output | Key Information Provided |

|---|---|---|---|

| Nitrogen Physisorption (BET) | Gas adsorption/desorption isotherm | Surface area (m²/g), pore volume (cm³/g), pore size distribution | Total specific surface area, meso/microporosity |

| X-ray Diffraction (XRD) | Coherent scattering of X-rays by crystalline planes | Diffraction pattern (Intensity vs. 2θ) | Crystalline phase identification, crystallite size, unit cell parameters |

| X-ray Photoelectron Spectroscopy (XPS) | Kinetic energy of ejected core-level electrons | Spectrum (Counts vs. Binding Energy) | Elemental surface composition (top 5-10 nm), chemical oxidation states |

| Temperature-Programmed Reduction (TPR) | Consumption of reducing gas (H₂) vs. temperature | Profile (Signal vs. Temperature) | Reducibility of metal species, metal-support interaction strength |

| Transmission Electron Microscopy (TEM) | Interaction of transmitted electrons with a thin sample | High-resolution images, diffraction patterns | Particle size/distribution, morphology, lattice fringes (crystallinity) |

| NH₃/CO₂-Temperature Programmed Desorption (TPD) | Desorption of probe molecules vs. temperature | Profile (Signal vs. Temperature) | Acidic (NH₃) or basic (CO₂) site strength and quantity |

Experimental Protocol: Standard 5-Point BET Surface Area Analysis

- Sample Preparation: Weigh 50-200 mg of catalyst into a pre-weighed, clean analysis tube. The optimal mass provides a total surface area between 20-100 m² for the measurement.

- Degassing: Attach tube to the degas port. Heat sample to 300°C (or material-specific temperature) under vacuum (<10⁻³ mbar) or flowing inert gas for a minimum of 6 hours to remove adsorbed contaminants.

- Cooling & Taring: Cool to ambient temperature under inert atmosphere/ vacuum. Precisely weigh the tube containing the degassed sample.

- Analysis Setup: Mount tube on the analysis port. Immerse the sample bulb in a liquid nitrogen bath (-196°C).

- Data Acquisition: The instrument exposes the sample to incremental partial pressures of N₂ (P/P₀ typically 0.05, 0.10, 0.15, 0.20, 0.25). The quantity of gas adsorbed at each point is measured volumetrically or gravimetrically.

- Data Processing: The linear form of the BET equation is applied to the 5 data points. The slope and intercept of the plot of

1/[Q(P₀/P - 1)]vs.P/P₀are used to calculate the monolayer capacity (Qm) and the C constant. Surface area is then derived from Qm.

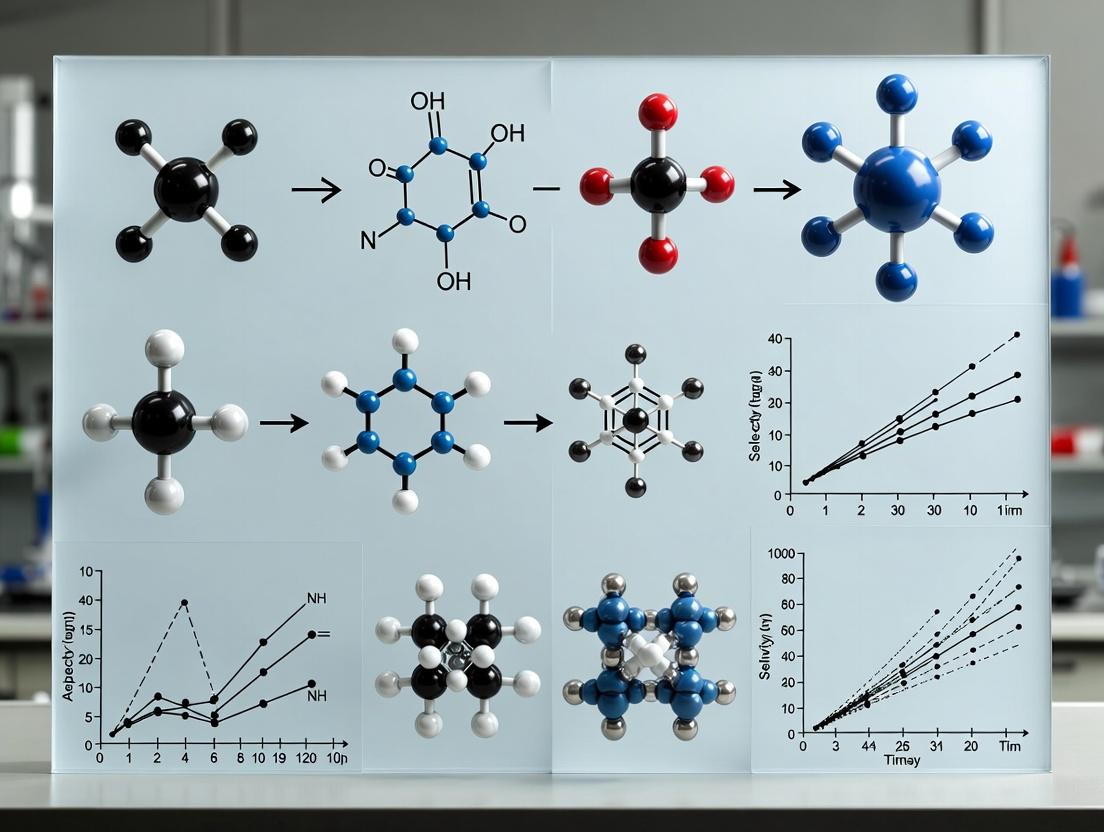

Visualizing the Catalyst Characterization Workflow

Diagram Title: Interrelated Catalyst Characterization Workflow

The Scientist's Toolkit: Essential Reagent Solutions

| Reagent / Material | Primary Function in Catalyst Characterization |

|---|---|

| Liquid Nitrogen (LN₂) | Cryogen for BET (adsorbate bath), cool traps for vacuum systems, and cooling detectors in XRD/TEM. |

| High-Purity Gases (N₂, He, H₂, Ar, 10% H₂/Ar) | N₂: BET adsorbate. He: Carrier gas in TPR/TPD, pycnometry. H₂/Ar: Reducing mixture for TPR. Ar: Inert atmosphere for sample transfer/storage. |

| Silicon XRD Standard (e.g., NIST 640c) | Calibration reference for correcting instrumental broadening and peak position in X-ray diffraction. |

| Adventitious Carbon | In-situ charge reference for XPS on insulating samples (C 1s peak at 284.8 eV). |

| Ammonia (NH₃) & Carbon Dioxide (CO₂) | Probe molecules for Temperature-Programmed Desorption (TPD) to quantify acid and base sites, respectively. |

| Ultrathin Carbon TEM Grids | Sample support film for Transmission Electron Microscopy, providing minimal background interference. |

| Precision Alumina Crucibles | Inert, high-temperature resistant containers for thermal analysis (TPR/TPD/TGA). |

| Micromeritics Sample Tubes | Specialized glassware designed for specific physisorption analyzers to ensure accurate volume calibration. |

Troubleshooting Guides & FAQs

Q1: My calculated crystallite size from the Scherrer equation is significantly smaller than my BET surface area-derived particle size. What is the issue?

A: This is a common discrepancy. The Scherrer equation measures the coherent diffraction domain size, which can be smaller than the physical particle if the particle is polycrystalline (composed of multiple smaller crystallites). BET measures the physical particle size contributing to surface area. Verify by TEM. Also, ensure you have correctly separated size broadening from instrumental and strain broadening. Using the Scherrer equation without this deconvolution leads to underestimation.

Q2: After refining my XRD pattern for microstrain analysis, I get a negative strain value. Is this possible, and what does it mean?

A: While unusual, a negative microstrain value is theoretically possible and indicates compressive lattice strain within the crystallites. However, first troubleshoot your analysis:

- Check Peak Fit: Re-examine your peak fitting. Overlapping peaks or poor background subtraction can cause erroneous peak width measurements.

- Verify Reference: Ensure your chosen standard for instrumental broadening correction is appropriate and free of size/strain effects itself.

- Model Limit: The simple Williamson-Hall plot assumes strain is isotropic. Anisotropic strain (varying with crystallographic direction) can produce anomalous results. Consider using the Halder-Wagner or Warren-Averbach methods for a more robust analysis.

Q3: The peaks in my nanocatalyst's XRD pattern are very broad and noisy. How can I improve data quality for reliable size/strain analysis?

A: For nanomaterials, data quality is paramount.

- Increase Counting Time: Significantly increase the scan time per step to improve signal-to-noise ratio.

- Use a Monochromator: If available, use a high-resolution diffractometer with a monochromator to reduce fluorescent background.

- Sample Preparation: Ensure a flat, uniform sample surface. Avoid preferred orientation by using a back-loading sample holder or side-drift mounting.

- Synchrotron Source: For extremely small crystallites (< 3 nm), consider using a synchrotron XRD source for its high-intensity, parallel beam.

Q4: When performing a Williamson-Hall plot, my data points are highly scattered and do not form a clear line. What went wrong?

A: Scatter indicates the assumptions of the model are not fully met.

- Anisotropic Effects: Your crystallites may exhibit anisotropic size or strain (e.g., plate- or rod-like shapes). Perform individual analysis on multiple (hkl) reflections to check for trends.

- Poor Peak Deconvolution: The integral breadth (β) must be accurately measured for each peak. Use a proper peak fitting function (e.g., Voigt, Pseudo-Voigt) and ensure Kα₂ stripping is performed.

- Incorrect Instrumental Correction: The instrumental broadening function must be accurately determined from the standard measured under identical conditions.

Table 1: Common XRD Methods for Crystallite Size & Strain Analysis

| Method | Formula/Plot | Measures | Key Assumptions | Typical Range | Limitations |

|---|---|---|---|---|---|

| Scherrer Equation | D = Kλ / (β cosθ) | Crystallite Size (D) | Size broadening only; spherical crystallites; no strain. | 1-100 nm | Does not separate strain. Requires shape factor (K~0.9). |

| Williamson-Hall (W-H) Plot | β cosθ = (Kλ / D) + 4ε sinθ | Size (from y-intercept) & Strain (ε, from slope) | Strain is isotropic; size and strain broadening are additive. | 5-150 nm | Assumes isotropic nature; fails for anisotropic systems. |

| Halder-Wagner Method | (β/d)² = 1/L (β/d) + (ε/2)² | Size (L) & Strain (ε) | Refined from W-H; better for larger β. | 2-50 nm | More complex fitting required. |

| Warren-Averbach Method | Fourier analysis of peak profiles | Size Distribution & Strain | Separates size & strain coefficients via Fourier series. | < 50 nm | Requires multiple orders of a reflection; complex computation. |

Table 2: Essential Parameters for the Scherrer Equation

| Parameter | Symbol | Typical Value/Note | Common Error |

|---|---|---|---|

| Wavelength | λ | Cu Kα1 = 1.5406 Å | Using incorrect Kα wavelength. |

| Scherrer Constant | K | ~0.94 for spherical cubic crystals | Using K=0.89 for all shapes. Varies with (hkl) & shape. |

| Full Width at Half Maximum | β | In radians, after instrumental correction. | Using observed FWHM without correction. |

| Bragg Angle | θ | In radians. | Using degrees in the cosine term. |

Experimental Protocols

Protocol 1: Sample Preparation for Accurate XRD Size/Strain Analysis

Objective: To prepare a flat, randomly-oriented powder sample to minimize instrumental aberrations and preferred orientation.

Materials: Fine powder sample, back-loading or side-drift XRD sample holder, glass slide, razor blade.

Procedure:

- Place the empty sample holder on a flat surface.

- For a back-loading holder, fill the cavity from the rear by pressing the powder against a glass slide to create a flat surface. Secure the rear plate.

- For a side-drift holder, place the holder on its side and gently press the powder into the cavity using a glass slide or razor blade to create a flat, level surface.

- Carefully remove excess powder from the edges without disturbing the packed surface.

- Mount the holder in the diffractometer, ensuring the sample surface is aligned with the goniometer focus.

Protocol 2: Instrumental Broadening Calibration Using a Standard Reference Material (SRM)

Objective: To obtain the instrumental broadening function for subsequent deconvolution.

Materials: NIST SRM 660c (LaB₆) or 640d (Si), prepared using Protocol 1.

Procedure:

- Prepare the SRM sample identically to your unknown samples (same holder, same packing method).

- Run the XRD scan over the exact same angular range and under the exact same instrumental conditions (slits, voltage, current) as used for your samples.

- Measure the FWHM (β_inst) of several sharp peaks across the 2θ range.

- Fit the measured β_inst values versus 2θ to a polynomial function (e.g., Cagliotti function). This function represents your instrumental profile.

Protocol 3: Williamson-Hall Plot Analysis

Objective: To separate size and microstrain contributions to peak broadening.

Materials: XRD pattern of sample, instrumental broadening function, peak fitting software.

Procedure:

- Collect XRD data for your sample and the SRM under identical conditions.

- Fit all well-resolved peaks in your sample pattern using a Pseudo-Voigt function. Extract the Integral Breadth (β_sample) for each peak.

- For each corresponding 2θ angle, determine β_inst from your calibration function.

- Calculate the Total Broadening (βtotal) using the deconvolution approximation: βtotal = √(βsample² - βinst²).

- Calculate β* = β_total cosθ / λ and d* = 2 sinθ / λ for each peak.

- Plot β* vs. d* (Williamson-Hall plot).

- Perform a linear fit: y = A + Bx.

- Crystallite Size (D) = K / A (where K~0.9-1.0).

- Microstrain (ε) = B / 4.

Visualizations

Title: XRD Crystallite Size and Strain Analysis Workflow

Title: Deconvolution of XRD Peak Broadening Components

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for XRD Sample Preparation & Analysis

| Item | Function/Description | Example Product/Brand |

|---|---|---|

| Standard Reference Material (SRM) | Calibrates the instrument's inherent broadening function for accurate deconvolution. | NIST SRM 660c (LaB₆), NIST SRM 640d (Si) |

| Zero-Background Holder | Provides a low-noise, flat substrate for mounting limited or difficult samples. | Silicon single crystal wafer holder. |

| Back-Loading Sample Holder | Allows preparation of a flat sample surface with minimal preferred orientation. | Bruker A100B27, PANalytical cavity holder. |

| Side-Loading Sample Holder | Alternative method for creating a flat, random-orientation sample surface. | Generic aluminum or stainless-steel holder. |

| Micro-Mortar & Pestle | For gentle grinding of powder to ensure homogeneity without inducing strain. | Agate mortar and pestle (avoids contamination). |

| High-Resolution XRD System | Diffractometer with a monochromator to reduce background and improve peak resolution. | Malvern Panalytical Empyrean, Bruker D8 Advance. |

| Peak Fitting Software | Essential for accurate extraction of FWHM and integral breadth from overlapping peaks. | HighScore Plus, Jade, Fityk, OriginPro. |

Troubleshooting Guides & FAQs

Isotherm Analysis Issues

Q1: Our adsorption isotherm does not show a clear linear region in the BET transform plot (P/P₀ between 0.05 and 0.35). How should we proceed? A: A non-linear BET transform indicates potential issues with the material or measurement. First, verify the sample was properly degassed (see Protocol 1). If the isotherm is Type II or IV with a clear knee but no linear region, the material may have high micropore content, making the standard BET model inappropriate. Use a t-plot or DFT method for microporous materials. If the isotherm is non-porous (Type II) and still non-linear, check for chemical interaction between adsorbate and sample; consider using a different adsorbate (e.g., Ar at 87 K).

Q2: The BET plot has a high positive intercept, yielding a negative C constant. What does this mean and how can we report the surface area? A: A negative C value is physically meaningless and invalidates the BET surface area calculation. This commonly occurs with microporous materials where the BET assumptions break down. Do not report the surface area. Instead, characterize the sample using:

- t-plot or αₛ-plot to separate microporous and external surface area.

- DFT/NLDFT methods using a kernel appropriate for your material type.

- Langmuir model only if the isotherm is truly Type I (strictly microporous).

Q3: Our measured surface area is significantly lower than expected for a known catalyst. What are the most likely causes? A: This is often a sample preparation issue. Follow the systematic checklist below.

| Probable Cause | Diagnostic Check | Corrective Action |

|---|---|---|

| Incomplete Degassing | Check isotherm for drift or poor closure at P/P₀ ~0. | Increase degas temperature/time (ensure thermal stability). See Protocol 1. |

| Pore Blockage | Compare adsorption/desorption branches for hysteresis loop distortion. | Use a gentler activation method; avoid sintering or condensate formation. |

| Sample Mass Too High | Low pressure points show high uptake (>30% of total). | Reduce sample mass to ensure monolayer coverage is in the valid BET range. |

| Non-accessible pores | Analyze with a larger probe molecule (e.g., N₂ vs. CO₂). | Use appropriate probe molecule size for the expected pore diameter. |

Instrumentation & Data Quality

Q4: The hysteresis loop of our mesoporous material shows abrupt, vertical closure at P/P₀ ~0.42 (Type H2 or H3). Is this real or an artifact? A: This is often the "tensile strength effect" (TSE) artifact or "cavitation," where liquid nitrogen becomes metastable in narrow necks. It indicates pore network effects. To distinguish real porosity from artifact:

- Use a different adsorbate: Argon at 87 K often provides a more realistic desorption branch without cavitation.

- Perform a DFT analysis: Use a kernel for cylindrical/slit pores with connectivity.

- Note: The adsorption branch is considered the thermodynamically stable path; use it for pore size distribution (PSD) calculations via BJH or DFT.

Q5: How do we ensure accurate quantification for very low surface area materials (<5 m²/g)? A: Low-area materials require special care. Use Krypton adsorption at 77 K, as its lower saturation pressure (P₀) allows for more precise measurement in the BET relative pressure range. Ensure the analysis tube and dead volume are calibrated with high precision. Increase sample mass to the instrument's limit, provided it doesn't create excessive pressure errors.

Experimental Protocols

Protocol 1: Standard Sample Degassing for BET Analysis

Purpose: To remove physisorbed contaminants (H₂O, CO₂) from the sample surface without altering its structure. Materials: BET analyzer with degas port, sample tube, heating mantle, high vacuum system (<10⁻² Torr), analytical balance.

- Weigh: Accurately weigh a clean, dry sample tube. Add sample (mass dependent on expected surface area: 50-200 mg for ~10-100 m²/g). Reweigh.

- Mount: Attach tube to degas port with minimal handling. Ensure all connections are tight.

- Heat & Evacuate: Apply heat (typically 150-300°C for inorganic catalysts; verify thermal stability via TGA first) under dynamic vacuum (<10⁻² Torr) for a minimum of 3 hours. For microporous materials, extend to 6-12 hours.

- Cool & Isolate: After degassing, isolate the sample under vacuum and allow it to cool to room temperature. Cooling under vacuum is critical to prevent re-adsorption.

- Transfer: Immediately transfer the sample tube to the analysis port per the instrument manual.

Protocol 2: Valid BET Range Selection (Rouquerol Criteria)

Purpose: To objectively identify the linear region of the BET transform for a valid surface area calculation.

- Calculate n(1-P/P₀): For each data point in the isotherm, calculate the transform term.

- Plot vs. P/P₀: Create the BET transform plot.

- Identify Linear Region: The valid region must satisfy both:

- The quantity

n(1-P/P₀)continuously increases withP/P₀. - The calculated monolayer capacity (

n_m) from the linear fit yields aP/P₀value at which the monolayer is completed (P_m) that lies within the selected pressure range.

- The quantity

- Iterate: If criteria fail, restrict the pressure range and re-calculate until they are met. Automated software often includes this check.

Visualizations

Diagram 1: BET Analysis Decision Workflow

Diagram 2: Common Isotherm Types & Features

The Scientist's Toolkit: BET Analysis Essentials

| Item | Function & Rationale |

|---|---|

| High-Purity Gases (N₂, Ar, Kr) | Adsorbates must be >99.999% pure to prevent contamination of the sample surface and ensure accurate pressure measurements. |

| Liquid N₂ Dewar (77 K) / Liquid Ar Dewar (87 K) | Provides a constant-temperature bath for adsorption. Argon at 87 K is preferred for microporous analysis to avoid quadrupole moment effects of N₂. |

| Calibrated Analysis Tubes | Precisely known free space (dead volume) is critical for accurate uptake calculation. Tubes must be matched to sample mass/porosity. |

| Micromeritics ASAP 2460 or equiv. | Automated physisorption analyzer with precise pressure transducers (0.1-1000 Torr range) and dual-station degas ports for high-throughput. |

| Reference Material (e.g., Alumina, Carbon Black) | Certified surface area standard used to validate instrument performance and operator technique periodically. |

| Thermogravimetric Analyzer (TGA) | Used prior to BET to determine safe, non-destructive degassing temperature for the sample material. |

| DFT/NLDFT Software Kernel | Model-specific (e.g., carbon slit, silica cylindrical) software for advanced pore size analysis, especially for micro/mesoporous materials. |

| Ultra-high Vacuum System | Degassing station capable of achieving <10⁻² Torr to thoroughly clean the sample surface without thermal degradation. |

Technical Support Center: Troubleshooting XPS Analysis for Catalyst Characterization

Frequently Asked Questions (FAQs)

Q1: Why do my catalyst's XPS peaks shift significantly between different measurements on the same sample? A: Binding energy shifts can arise from sample charging, differential charging in insulating catalyst supports, or a change in the Fermi level due to doping. For catalysts, ensure consistent and adequate charge neutralization (flood gun settings). For supported metal catalysts on oxides, consider a thin, uniform conductive coating (e.g., Au sputtering at low levels) if charging is severe and irreproducible. Always reference to a known internal standard (e.g., adventitious C 1s at 284.8 eV or a support element like Al 2p in Al₂O₃).

Q2: How do I distinguish between metallic, oxide, and sulfide states of a transition metal (e.g., Mo or Ni) in my catalyst? A: Identify chemical states by analyzing both the binding energy (BE) shift and the spectral shape (peak asymmetry, presence of shake-up satellites). For example:

- Metallic States: Typically have symmetric peaks and lower BE.

- Oxide States: Have higher BE shifts (1-4 eV) and often show characteristic satellite features on the high BE side of the main peak.

- Sulfide States: Exhibit BE values between metal and oxide. Always compare with reliable reference spectra from databases or pure standard samples measured on your instrument.

Q3: What are the practical quantification limits for detecting dopants or surface species on my catalyst? A: XPS is a surface-sensitive technique with a practical detection limit of approximately 0.1 - 1.0 atomic % of the sampled volume. This limit depends on the element's cross-section, the signal-to-noise ratio, and overlap with other peaks. For trace dopants (<0.1%), consider more sensitive techniques like SIMS or ICP-MS.

Q4: My peak fitting results seem arbitrary. What is a robust protocol for deconvoluting overlapping peaks? A: Adhere to a constrained fitting protocol:

- Use a Shirley or Tougaard background.

- Fix the spin-orbit doublet separation and area ratio based on known values (e.g., 2p₃/₂ and 2p₁/₂ for transition metals).

- Use consistent full width at half maximum (FWHM) for peaks belonging to the same chemical species.

- Validate fits by comparing with known reference spectra and by using the minimum number of components justified by the chemistry.

Q5: How does the choice of background subtraction affect my quantitative results? A: The background model significantly impacts calculated peak areas. A Shirley background is most common for polymers and organics, while a linear background may suffice for metals. For quantitative accuracy, especially in catalysis where support effects matter, use the same background subtraction method for all comparative samples.

Quantitative Data Reference Tables

Table 1: Characteristic Binding Energy Shifts for Common Catalyst Elements

| Element & Transition | Metallic State (eV) | Oxide State (eV) | Sulfide State (eV) | Key Identifier |

|---|---|---|---|---|

| Ni 2p₃/₂ | 852.6 - 853.1 | 853.5 - 855.5 (NiO) | 853.0 - 854.5 | Strong satellite ~6 eV above main peak for Ni²⁺. |

| Mo 3d₅/₂ | 227.7 - 228.0 | 232.3 - 232.8 (MoO₃) | 228.6 - 229.2 (MoS₂) | Well-separated doublet (Δ~3.1 eV). |

| C 1s (Reference) | C-C/C-H: 284.8 | C-O: 286.2-286.5 | O-C=O: 288.8-289.0 | Adventitious carbon standard. |

| Al 2p (Support) | Al⁰: 72.7 | Al₂O₃: 74.0 - 75.5 | - | Sharp peak for oxide. |

Table 2: Practical Limits of XPS Quantification

| Parameter | Typical Range/Value | Impact on Quantification |

|---|---|---|

| Detection Limit | 0.1 - 1.0 at% | Limits detection of low-concentration dopants. |

| Sampling Depth (λ) | 5 - 10 nm (for organics) 1.5 - 4 nm (for metals) | Probes only the outermost surface layers. |

| Absolute Accuracy | ±10 - 20% | Requires sensitivity factors (relative sensitivity factors, RSFs). |

| Relative Accuracy | ±5 - 10% | Good for comparing same element across samples. |

Experimental Protocols

Protocol 1: Reliable XPS Sample Preparation for Powdered Catalysts

- Material: Powdered catalyst.

- Substrate Preparation: Use double-sided conductive carbon tape on a standard sample stub.

- Loading: Gently tap a small amount of powder onto the tape. Use a gentle stream of dry air or duster gas to remove loose particles, leaving a thin, uniform layer.

- Pre-Measurement Treatment: If the sample is air-sensitive, use an inert atmosphere transfer vessel. For hydrated samples, consider mild drying in the introduction chamber (e.g., 80°C, 30 min) to minimize outgassing, unless hydration state is of interest.

- Mounting: Ensure good electrical contact between the stub and the sample holder.

Protocol 2: Peak Fitting and Deconvolution for Transition Metal Spectra (e.g., Ni 2p)

- Data Acquisition: Collect high-resolution spectrum with sufficient counts (e.g., >10,000 counts in main peak) and a small step size (e.g., 0.1 eV).

- Background Subtraction: Apply a Shirley background to the region of interest.

- Define Constraints:

- Set the spin-orbit splitting (Δ) for Ni 2p to ~17.3 eV.

- Fix the area ratio of 2p₃/₂ : 2p₁/₂ to 2:1.

- Constrain the FWHM of doublet components for the same species to be equal (±0.1 eV).

- Add Components: Introduce doublets for each expected chemical state (e.g., metallic, oxide, satellite). Initial positions should be based on reference data (Table 1).

- Iterative Fitting: Use a non-linear least squares algorithm to fit. Adjust peak positions, heights, and widths only within chemically reasonable limits.

- Validation: The fit should align with visual inspection of the raw data, and the residual (difference between fit and data) should be minimal and random.

Visualization: XPS Data Analysis Workflow

Title: XPS Peak Analysis and Fitting Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in Catalyst XPS Analysis |

|---|---|

| Indium Foil | A soft, conductive substrate for pressing powder samples to improve electrical contact and reduce charging. |

| Double-Sided Conductive Carbon Tape | Standard adhesive for mounting powder samples to stubs; provides moderate conductivity. |

| Argon Gas (High Purity) | Used in ion gun for sample cleaning (sputtering) to remove surface contaminants before analysis. |

| Gold (Au) Sputtering Target | Source for depositing an ultra-thin conductive layer on insulating samples to mitigate charging. |

| Calibration Standards (Au, Ag, Cu Foils) | Clean metal foils for performing instrumental energy scale calibration and verifying resolution. |

| Inert Atmosphere Transfer Vessel | Allows safe transfer of air-sensitive catalysts (e.g., reduced samples) from glovebox to XPS without air exposure. |

| Reference Powder Samples (e.g., MoS₂, NiO) | Well-characterized materials for verifying chemical state binding energies and training purposes. |

Technical Support Center: Troubleshooting Guides & FAQs

FAQ 1: How do I differentiate between the catalyst support material and the deposited active phase nanoparticles when their contrast is very similar?

Answer: Similar contrast often arises when the atomic numbers (Z) of the support and active phase are close, reducing Z-contrast. To resolve this:

- Use Scanning TEM (STEM) with High-Angle Annular Dark-Field (HAADF): This technique provides Z-contrast imaging, where intensity scales approximately with Z². Heavier elements appear brighter.

- Employ Electron Energy Loss Spectroscopy (EELS) or Energy-Dispersive X-Ray Spectroscopy (EDS): Acquire spectrum images or point spectra to map elemental distribution. Co-location of specific elements confirms the active phase.

- Adjust Imaging Parameters: Slightly under-focus the objective lens to enhance phase contrast at particle edges. Use a smaller objective aperture to increase contrast, but be aware it may reduce resolution.

Experimental Protocol for Elemental Mapping:

- Switch to STEM mode on your TEM/STEM microscope.

- Align the microscope and set the camera length to achieve a suitable HAADF collection angle (typically 50-200 mrad).

- Acquire a reference HAADF image.

- Set up the EDS or EELS system for simultaneous acquisition.

- Define the scan area and dwell time (e.g., 10-50 µs/pixel to avoid drift and damage).

- Acquire the spectrum image dataset.

- Use software (e.g., Velox, DigitalMicrograph, ESPRIT) to extract elemental maps by integrating counts under characteristic peaks (e.g., Pt Lα for Pt, Al Kα for Al₂O₃ support). Overlay these maps on the HAADF image.

FAQ 2: I see unusual, non-crystalline features. Are they amorphous phases, damage, or preparation artifacts?

Answer: This is a common interpretation challenge. Follow this diagnostic flowchart:

Title: Diagnostic Flowchart for Unusual TEM Features

Experimental Protocol for Beam Damage Assessment:

- Low-Dose Imaging: Use the microscope's "low-dose" or "min-dose" mode. Focus on an adjacent area before moving to the region of interest (ROI) to expose it only for the final image capture.

- Dose Series Experiment: Acquire sequential images of the same area at constant illumination. Monitor the appearance or growth of features over time. Use a calibrated dose meter.

- kV Dependency Test: Image similar sample areas at different accelerating voltages (e.g., 80kV, 120kV, 200kV). If features change or vanish at lower kV, it suggests beam damage.

FAQ 3: How can I quantify the size distribution of active nanoparticles when they are sitting on a thick, textured support?

Answer: Thick or rough supports complicate thresholding. Use a multi-step protocol:

Experimental Protocol for Nanoparticle Sizing on Textured Supports:

- Image Acquisition: Acquire high-resolution HAADF-STEM images. Ensure optimal signal-to-noise ratio without saturating the detector.

- Background Subtraction: Apply a rolling-ball or top-hat filter (radius larger than largest nanoparticle) to subtract the slowly varying background from the support texture.

- Particle Identification: Use automated particle analysis software (e.g., ImageJ/Fiji with "Find Maxima" or machine learning tools like Ilastik) on the background-subtracted image.

- Manual Verification and Refinement: Manually add missed particles and remove false positives from support features. Use the EDS overlay from FAQ 1 as a verification mask.

- Measurement: Set a consistent intensity threshold (e.g., 50% of peak height) to define particle boundaries. Measure Feret's diameter or equivalent circular diameter for >200 particles for statistical significance.

- Statistical Reporting: Report mean size, standard deviation, and histogram.

Table 1: Quantitative Comparison of Common Artifacts vs. Real Features

| Feature Characteristic | Contamination Artifact | Beam Damage | Real Amorphous Phase | Crystalline Active Phase |

|---|---|---|---|---|

| Typical Location | Near grid bars, holes, edges | Whole scan area, specific crystals | Random, within catalyst | Random, on support |

| Response to Beam | May grow or move | Grows rapidly with dose | Stable at low dose | Stable or sinter at high dose |

| SAED/FFT Pattern | None | Becomes diffuse/vanishes | Diffuse halo(s) | Sharp diffraction spots/rings |

| EDS/EELS Signal | C, Cu (grid), Cl (solvent) | May show elemental loss | Unique chemical signature | Unique chemical signature |

| Mitigation Action | Plasma clean, better prep | Lower dose, lower kV, cool | N/A | Lower dose for imaging |

Table 2: Key Research Reagent & Materials Toolkit

| Item | Function in TEM Sample Prep for Catalysts |

|---|---|

| Ultrasonic Dispersion Bath | Gently breaks up catalyst powder aggregates in suspension without fracturing particles. |

| High-Purity Ethanol or Isopropanol | Volatile solvent for creating catalyst suspension; leaves minimal residue upon drying. |

| Lacey Carbon or Holey Carbon TEM Grids | Provides thin support film with holes, allowing particles to be imaged suspended over vacuum, minimizing background. |

| Glow Discharge System | Renders carbon grids hydrophilic, ensuring even suspension spreading and reducing agglomeration. |

| Micro-pipettes (<10 µL) | Allows precise transfer of small volumes of catalyst suspension onto the TEM grid. |

| Plasma Cleaner | Removes hydrocarbon contamination from grids before and after sample deposition. |

| Cryo Transfer Holder | Maintains sample at liquid N₂ temperature, mitigating beam damage for sensitive materials (e.g., MOFs, certain oxides). |

| Focused Ion Beam (FIB) System | For site-specific preparation of cross-sectional lamellae from real catalyst pellets or monoliths. |

Title: Optimal TEM Workflow for Catalyst Analysis

From Theory to Practice: Applying Characterization Techniques to Real Catalytic Systems

Technical Support Center: Troubleshooting Catalyst Characterization

Frequently Asked Questions (FAQs)

Q1: For a supported Pt/Al₂O₃ catalyst, my H₂ chemisorption data suggests a high dispersion, but TEM shows large particles. What could cause this discrepancy?

A: This common issue often stems from spillover or incomplete reduction. H₂ can dissociate on Pt and spill over onto the Al₂O₃ support, leading to an overestimation of active metal surface area. Conversely, if the pre-reduction step is incomplete, the measured H₂ uptake will be low relative to the actual metal surface.

- Troubleshooting Protocol:

- Verify Reduction: Conduct Temperature-Programmed Reduction (TPR) prior to chemisorption to confirm complete reduction of PtOx species. A standard protocol is to heat at 10°C/min to 500°C under 5% H₂/Ar.

- Use Back Titration: Perform a pulsed CO chemisorption followed by O₂ titration and then a second CO chemisorption. This isolates the signal from metal sites only.

- Cross-validate: Use a surface-sensitive technique like X-ray Photoelectron Spectroscopy (XPS) to check the oxidation state and approximate surface composition.

Q2: When characterizing acid sites in a zeolite (e.g., H-ZSM-5) using ammonia-TPD, I get a broad, overlapping desorption peak. How can I deconvolute Brønsted and Lewis acid sites?

A: Broad, overlapping peaks indicate a distribution of acid strengths and/or site types.

- Troubleshooting Protocol:

- Use Probe Molecules with Different Basicity: Perform TPD using pyridine (stronger base) and then trimethylphosphine (TMP) or CO. Pyridine adsorbs on both Brønsted (B) and Lewis (L) sites, while CO is selective for strong Lewis sites.

- Couple with FTIR: Perform in situ Fourier-Transform Infrared Spectroscopy (FTIR) of adsorbed pyridine. The distinct bands (e.g., ~1545 cm⁻¹ for B-acid sites, ~1455 cm⁻¹ for L-acid sites) allow direct quantification. Protocol: Dehydrate zeolite at 450°C, adsorb pyridine at 150°C, evacuate, and collect spectra.

- Vary Probe Amount: Conduct a series of TPD runs with increasing ammonia doses. Weak sites will only populate at high doses, helping to identify their contribution.

Q3: My N₂ physisorption isotherm for a MOF (e.g., MOF-5) shows a low BET surface area and poor porosity compared to literature. What are the likely causes?

A: This almost always points to incomplete activation or framework collapse.

- Troubleshooting Protocol:

- Optimize Activation: Solvent molecules trapped in the pores block N₂ access. Implement a supercritical CO₂ drying protocol or use a gentle thermal activation under dynamic vacuum with a slow temperature ramp (0.5-1°C/min) to the optimal temperature (e.g., 150°C for MOF-5).

- Check for Hydrostability: Many MOFs are sensitive to moisture. Perform all sample handling in an inert atmosphere glovebox. Characterize immediately after activation.

- Verify Crystallinity: Collect a Powder X-ray Diffraction (PXRD) pattern post-activation. Loss of crystallinity confirms framework degradation.

Table 1: Primary Characterization Techniques by Catalyst Type

| Catalyst Type | Primary Structure/ Morphology | Surface Composition/ Oxidation State | Acidity/Basicity | Porosity | Active Site Density |

|---|---|---|---|---|---|

| Supported Metals | XRD, TEM | XPS, H₂/CO Chemisorption | CO₂-TPD (for basic supports) | N₂ Physisorption | H₂/CO Chemisorption |

| Zeolites | XRD, SEM | XPS, Al NMR | NH₃-TPD, Pyridine-FTIR | Ar Physisorption | NH₃-TPD, Stoichiometric probes |

| MOFs | PXRD, SEM | XPS | Probe-IR (e.g., CO, NH₃) | N₂/Ar Physisorption | Not typically applicable |

Table 2: Common Artifacts and Corrective Actions

| Symptom | Possible Artifact | Corrective Action / Cross-Check Technique |

|---|---|---|

| Low metal dispersion by chemisorption | Incomplete reduction | Perform TPR first; use XPS to check oxidation state. |

| Overestimated acidity by NH₃-TPD | Ammonia adsorption on non-acidic sites | Use IR with pyridine; use basicity-graded probes. |

| Hysteresis in MOF N₂ isotherm | Pore collapse/defects | Check PXRD pre/post adsorption; optimize activation. |

| Weak/No signal in XPS | Charging (insulators) | Use flood gun; mix with conducting substrate (Au grid). |

Experimental Protocols

Protocol 1: Temperature-Programmed Reduction (TPR) for Supported Metals

- Pretreatment: Load 50-100 mg catalyst in a U-shaped quartz reactor. Purge with inert gas (Ar) at 150°C for 1 hour to remove physisorbed water.

- Reduction: Cool to 50°C. Switch to 5% H₂/Ar (30 mL/min flow). Record baseline.

- Ramp: Heat the reactor at 10°C/min to a final temperature (e.g., 800°C for most oxides).

- Detection: Monitor H₂ consumption using a Thermal Conductivity Detector (TCD). Calibrate the TCD signal with a known amount of CuO standard.

Protocol 2: In Situ Pyridine FTIR for Acid Site Characterization

- Pellet Preparation: Press the catalyst powder into a self-supporting wafer (~10 mg/cm²).

- Dehydration: Place wafer in a high-temperature IR cell with CaF₂ windows. Heat under vacuum (10⁻⁵ mbar) to 450°C for 2 hours. Collect background spectrum.

- Adsorption: Cool to 150°C. Expose wafer to pyridine vapor (equilibrated at room temperature) for 15 minutes.

- Desorption: Evacuate at 150°C for 30 minutes to remove physisorbed pyridine.

- Measurement: Collect IR spectrum. Quantify Brønsted (1545 cm⁻¹) and Lewis (1455 cm⁻¹) sites using published molar extinction coefficients.

Visualization of Characterization Strategy

Diagram Title: Catalyst Characterization Decision Workflow

Diagram Title: Data Interpretation Troubleshooting Logic

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Example Use Case |

|---|---|---|

| 5% H₂/Ar Gas Cylinder | Reducing agent for TPR and pre-treatment of metal catalysts. | Activating a Pt/Al₂O₃ catalyst before chemisorption. |

| Ultra-high Purity (UHP) N₂ & Ar | Inert carrier and analysis gas for physisorption and TPD. | Performing BET surface area analysis on a zeolite. |

| Anhydrous Pyridine | Specific probe molecule for IR spectroscopy to differentiate Brønsted/Lewis acid sites. | Characterizing acid sites in H-ZSM-5. |

| Calibrated CuO Standard | Quantitative reference material for calibrating TCD response in TPR/TPD. | Quantifying H₂ consumption in a TPR experiment. |

| Micromeritics ASAP 2020 | Automated instrument for physisorption and chemisorption analysis. | Measuring pore size distribution of a MOF. |

| In Situ IR Cell | High-temperature, vacuum-capable cell for monitoring surface species. | Tracking adsorbed intermediates during a reaction on a catalyst surface. |

| Alumina Crucibles | Inert, high-temperature containers for thermal analysis (TGA/DSC). | Studying the thermal stability of a catalyst precursor. |

Technical Support Center: Troubleshooting & FAQs

Q1: Our Pt/Al2O3 catalyst shows low activity for nitrobenzene hydrogenation. XRD confirms Pt is present, but CO chemisorption suggests very low metal dispersion. What could be the issue?

A: Low dispersion often indicates Pt sintering or poor reduction. First, check your calcination and reduction protocols.

- Excessive Calcination Temperature: Temperatures >500°C can cause Pt species to migrate and agglomerate.

- Inadequate Reduction: Ensure your reduction temperature (typically 300-400°C in H₂ flow) is held for sufficient time (1-2 hours). Use Temperature-Programmed Reduction (TPR) to verify the complete reduction of PtOx species.

- Protocol - TPR: Load 50-100 mg catalyst in a quartz reactor. Flush with inert gas (Ar, 30 mL/min). Cool to 50°C. Switch to 5% H₂/Ar (30 mL/min) and heat to 600°C at 10°C/min while monitoring H₂ consumption.

Q2: H₂-TPR of our fresh Pt/Al2O3 shows two distinct reduction peaks. Does this indicate multiple Pt species or a problem?

A: Multiple peaks are common and not necessarily a problem. They often represent the stepwise reduction of different Pt oxide species interacting with the Al₂O₃ support. A low-temperature peak (<200°C) typically corresponds to easily reduced surface PtOx. A higher-temperature peak (200-400°C) may indicate Pt species in stronger interaction with the support (e.g., in alumina pores). Compare with known literature TPR profiles for Pt/Al₂O₃.

Q3: XPS analysis reveals a shift in the Pt 4f binding energy (BE) to a higher value than expected for Pt⁰. Is the metal not fully reduced?

A: Not always. A positive BE shift (e.g., 71.8 eV vs. the standard 71.2 eV for Pt⁰) can also indicate:

- Charge Transfer from Pt to Support: Due to strong metal-support interaction (SMSI) with Al₂O₃.

- Small Pt Particle Size: Quantum size effects in nanoparticles <2 nm can increase BE.

- Troubleshooting Step: Perform a CO-DRIFTS experiment. The frequency of the linear CO band (~2080-2050 cm⁻¹ for Pt⁰) is more sensitive to the electronic state than XPS BE. Compare with reference spectra.

Q4: During accelerated aging tests, activity drops sharply. N₂ physisorption shows a significant decrease in surface area and pore volume. What happened?

A: This points to thermal sintering of the Al₂O₃ support and concurrent Pt aggregation. High temperatures and steam (a byproduct of hydrogenation) can cause alumina pore collapse.

- Mitigation Protocol - Support Stabilization:

- Doping: Dope Al₂O₃ with 1-3 wt% La or Si prior to Pt impregnation.

- Procedure: Prepare a solution of La(NO₃)₃, pore-fill the Al₂O₃, dry at 120°C, and calcine at 700°C. This creates a barrier to phase transformation and pore collapse.

Table 1: Diagnostic Data for Common Pt/Al2O3 Issues

| Observed Problem | Primary Characterization Technique | Typical Result Indicating Problem | Reference Normal Value |

|---|---|---|---|

| Low Metal Dispersion | CO Pulse Chemisorption | Dispersion < 20% | >40% for fresh 1-2 nm Pt |

| Pt Sintering | TEM / H₂ Chemisorption | Avg. Particle Size > 3 nm | < 2 nm for high dispersion |

| Incomplete Reduction | H₂-TPR | Reduction peak > 400°C | Main peak < 250°C |

| Support Degradation | N₂ Physisorption | BET SA loss > 30% | < 10% loss after mild aging |

| Carbon Deposition (Coking) | TPO (O₂) | Broad CO₂ peak > 300°C | No significant peak |

Table 2: Key Pt Spectral Signatures

| Technique | Spectral Feature | Typical Value for Pt⁰ | Shift Indication |

|---|---|---|---|

| XPS | Pt 4f₇/₂ BE | 71.0 - 71.2 eV | Higher BE → Oxidation or SMSI |

| CO-DRIFTS | Linear CO Stretch (v_CO) | 2060 - 2075 cm⁻¹ | Higher v_CO → Electron-deficient Pt |

| XAS | Pt L₃-edge White Line | Moderate intensity | Increased intensity → Unfilled d-states |

Experimental Protocols

Protocol 1: CO Chemisorption for Pt Dispersion

- Pre-treatment: Reduce 100 mg catalyst in flowing H₂ (50 mL/min) at 350°C for 2 hrs. Cool to 35°C in He.

- Adsorption: Inject pulses of 10% CO/He (0.5 mL pulse volume) into a He carrier stream over the catalyst until effluent peaks are constant (saturation).

- Calculation: Assume a stoichiometry of CO:Ptₛᵤᵣfₐcₑ = 1:1. Dispersion = (Moles CO adsorbed / Total moles Pt) * 100%.

Protocol 2: CO-DRIFTS for Pt Surface State

- Background: Place catalyst in DRIFTS cell, reduce in-situ with H₂ at 300°C, purge with Ar at 300°C, cool to 30°C in Ar, and collect background spectrum.

- Adsorption: Expose to 1% CO/He for 15 mins.

- Measurement: Purge with Ar for 10 mins to remove physisorbed CO. Collect spectrum (typically 64 scans at 4 cm⁻¹ resolution).

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Pt/Al2O3 Characterization

| Item | Function / Purpose |

|---|---|

| 5% H₂/Ar Gas Cylinder | Safe reducing mixture for TPR and pre-treatment. |

| 1% CO/He Gas Cylinder | Titrant for chemisorption (pulse) and probe for DRIFTS. |

| High-Purity γ-Al2O3 Support | High-surface-area (150-200 m²/g) support for Pt impregnation. |

| Chloroplatinic Acid (H2PtCl6) | Common Pt precursor for aqueous impregnation. |

| Tetramminoplatinum(II) Nitrate | Chlorine-free Pt precursor to avoid acid site formation. |

| Lanthanum(III) Nitrate | Dopant precursor for stabilizing Al2O3 against sintering. |

| Certified Reference Material (e.g., 5% Pt/SiO2) | Benchmark for validating chemisorption and TPR measurements. |

| Porous Quartz Wool | For catalyst bed packing in tubular microreactors. |

Visualization: Data Interpretation Workflow

Title: Pt/Al2O3 Problem Diagnosis Decision Tree

Title: Pt/Al2O3 Synthesis & Characterization Protocol Flow

Technical Support Center

Troubleshooting Guides & FAQs

FAQ 1: Temperature-Programmed Desorption of Ammonia (NH3-TPD) Q: My NH3-TPD profile shows broad, overlapping desorption peaks. How can I better distinguish between weak, medium, and strong acid sites? A: Broad peaks often indicate a heterogeneous distribution of acid strengths or diffusion limitations. Follow this protocol:

- Pre-treatment: Ensure uniform activation. Heat sample (0.1 g) to 500°C (5°C/min) under He flow (30 mL/min) for 2 hours.

- Ammonia Saturation: Cool to 100°C in He. Expose to a 5% NH3/He mixture for 60 minutes.

- Physisorbed NH3 Removal: Flush with He at 150°C for 120 minutes to remove loosely bound ammonia.

- Desorption Run: Heat from 150°C to 700°C at a slower ramp rate (e.g., 5°C/min vs. standard 10°C/min). Monitor with a TCD.

- Data Deconvolution: Use software (e.g., Origin, PeakFit) to mathematically deconvolute the broad peak into Gaussian components representing distinct acid site populations.

Table 1: Typical NH3-TPD Peak Assignments for Zeolites

| Peak Temperature Range (°C) | Relative Acid Strength | Commonly Attributed Site Type |

|---|---|---|

| 150 - 250 | Weak | Lewis sites, silanols |

| 250 - 400 | Medium | Weak Brønsted sites |

| 400 - 600 | Strong | Strong Brønsted sites |

FAQ 2: Nitrogen Physisorption for Porosity Q: My N2 physisorption isotherm shows a low BET surface area and an underdeveloped micropore volume. What could be wrong? A: This suggests incomplete activation or pore blockage.

- Sample Mass: Use 50-100 mg of finely powdered catalyst.

- Degas Protocol: Degas at 300°C under vacuum for a minimum of 12 hours. For robust zeolites, 350°C for 15 hours is recommended to fully remove adsorbed water and organics.

- Isotherm Analysis: Ensure you are using the correct relative pressure (P/P0) range for BET calculation (typically 0.05-0.25). Use t-Plot or NL-DFT methods for micropore volume.

- Check for Issues: A hysteresis loop at low P/P0 may indicate swelling or chemisorption artifacts.

Table 2: Expected N2 Physisorption Data for Common Zeolites

| Zeolite Type | Typical BET Surface Area (m²/g) | Typical Micropore Volume (cm³/g) | Isotherm Type (IUPAC) |

|---|---|---|---|

| ZSM-5 (MFI) | 300 - 450 | 0.15 - 0.18 | Type I |

| Y (FAU) | 600 - 900 | 0.30 - 0.35 | Type I |

| Beta (BEA) | 500 - 750 | 0.20 - 0.25 | Type I |

FAQ 3: Pyridine FTIR Spectroscopy Q: The bands for Lewis and Brønsted acid sites in my Pyridine FTIR spectra are weak and noisy. How can I improve signal quality? A: Weak signals can result from low acid site density or suboptimal experimental conditions.

- Pellet Preparation: Create a thin, self-supporting wafer (5-15 mg/cm²). Apply gentle pressure (2-3 tons) to ensure transparency.

- In-situ Cell: Use a dedicated in-situ IR cell with KBr windows. Pre-treat the wafer under vacuum (10⁻³ Pa) at 400°C for 2 hours.

- Pyridine Dosing: Expose to saturated pyridine vapor at 150°C for 15 minutes, then evacuate at the same temperature for 30 minutes to remove physisorbed pyridine.

- Spectrum Acquisition: Collect spectra at 150°C (not room temperature) at 4 cm⁻¹ resolution. Accumulate at least 64 scans.

The Scientist's Toolkit: Key Reagent Solutions

Table 3: Essential Research Reagents for Zeolite Acidity/Porosity Characterization

| Item/Reagent | Function & Specification |

|---|---|

| 5% NH3/He Gas Mixture | Probe molecule for Temperature-Programmed Desorption (TPD) to quantify acid site concentration and strength. |

| High-Purity He (99.999%) | Carrier gas for TPD; also used for sample pre-treatment and purging. |

| Ultra-high Purity N2 (99.999%) | Adsorptive gas for surface area and pore size distribution measurements. |

| Liquid Pyridine (anhydrous, 99.8%) | Probe molecule for FTIR spectroscopy to discriminate between Lewis and Brønsted acid sites. |

| KBr (FTIR Grade) | Material for making infrared-transparent windows for in-situ cells or preparing pellets for DRIFTS. |

Experimental Workflow for Integrated Characterization

Acid & Porosity Characterization Workflow

Pyridine FTIR Spectral Band Assignment Logic

Pyridine FTIR Band Assignment Logic

Technical Support Center: Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: During in situ XPS, my catalyst surface shows a rapid reduction in the oxide signal upon heating in H₂, but the activity doesn't change. What could be happening?

A: This is a classic "spectator species" issue. The oxide being reduced is likely a surface species not involved in the rate-limiting step. Perform a complementary technique like in situ Raman to check for bulk oxide states. Quantify the percentage of surface reduced versus total catalyst mass. If less than 5% of the total mass is changing, it is likely not relevant to bulk activity. Confirm by correlating data points in a table:

| Time (min) | Surface Oxide % (XPS) | Bulk Oxide % (Raman) | Reaction Rate (mol/g·s) |

|---|---|---|---|

| 0 | 100 | 100 | 0.01 |

| 5 | 30 | 98 | 0.01 |

| 10 | 10 | 97 | 0.009 |

Q2: My operando IR spectra become featureless and the baseline shifts drastically at high temperature and pressure. How do I resolve this?

A: This is typically caused by blackbody radiation (glow) and scattering. Implement the following protocol:

- Experimental Protocol for High-Temp IR:

- Use a liquid-N₂-cooled MCT detector.

- Place a cold gas cell (e.g., with KBr windows cooled by circulating chilled ethanol) between the reactor and detector to absorb IR emission from the hot sample.

- Perform a background scan at the exact reaction temperature with an inert gas flowing.

- Use a low scan velocity and more scans to improve S/N ratio.

- For data processing, apply a concave rubber-band baseline correction (5-10 points) or a polynomial fit.

Q3: How do I distinguish between an active intermediate and a deactivation byproduct in operando spectroscopy?

A: This requires a dose-response analysis. Follow this methodology:

- Introduce an isotopically labeled reactant (e.g., switch from ¹²CO to ¹³CO) while monitoring spectra and product formation rate via MS.

- The true active intermediate will show a kinetic isotope effect (KIE) and its spectral feature will shift according to the isotope's mass.

- A deactivation species (e.g., coke) will accumulate and not be affected by the isotopic switch.

Q4: In operando XRD, I observe peak broadening under reaction conditions. Is it due to particle size change or amorphization?

A: Perform a Williamson-Hall analysis in situ.

- Experimental Protocol:

- Collect full XRD patterns (e.g., 20-80° 2θ) at regular time intervals under reaction flow.

- For each phase, measure the integral breadth (β) of at least 5 diffraction peaks.

- Plot β·cosθ vs. 4·sinθ (Williamson-Hall plot). The slope gives strain (η) and the y-intercept is related to crystallite size (Kλ/L).

- A constant y-intercept with increasing slope indicates strain (lattice distortion). An increasing y-intercept indicates size reduction or amorphization.

| Condition | Crystallite Size (nm) from WH Plot | Microstrain (η) | Phase Assignment |

|---|---|---|---|

| Before reaction | 12.4 ± 0.8 | 0.0012 | Co₃O₄ |

| Under O₂, 300°C | 11.9 ± 1.1 | 0.0015 | Co₃O₄ |

| Under H₂, 300°C | 8.2 ± 1.5 | 0.0038 | CoO |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Critical Notes |

|---|---|

| SiC Diluent | Chemically inert, high thermal conductivity. Mix with catalyst to prevent hotspots and improve gas flow in operando cells. Pre-treat at 900°C in air to remove surface contaminants. |

| Porous Carbon Tape | For mounting powder samples in in situ XPS/UPS. Conductive, UHV-compatible, and minimizes charging. Must be pre-baked in vacuum (150°C) to outgas. |

| KBr (Optical Grade) | For making pellets for transmission IR. Must be dried at 200°C for 24h and handled in a dry-air glovebox to avoid adsorbed water IR bands. |

| Isotopic Gases (¹³CO, D₂, ¹⁸O₂) | For tracing reaction pathways and identifying active intermediates. Use with a calibrated mass spectrometer for quantitative analysis of switching experiments. |

| Quartz Wool | Used as a support or plug in tubular microreactors. Must be acid-washed (10% HNO₃) and calcined (800°C, 4h) to remove organics and sodium. |

| Au Paste | For creating seals or conductive bridges in electrochemical operando setups. Stable under oxidizing conditions up to ~500°C. Avoid use under H₂ above 300°C. |

| Alumina Crucibles (Open) | For in situ TGA/DSC measurements. Ensure they are identical in weight (±0.1 mg) to the reference crucible. Pre-calcine to stabilize mass. |

Experimental Workflow for Correlation

Diagram Title: Operando Data Correlation Workflow

Pathway for Signal Artifact Diagnosis

Diagram Title: Signal Artifact Diagnosis Pathway

Correlating Physicochemical Properties with Catalytic Performance Metrics

Technical Support Center: Troubleshooting Catalyst Characterization Data Interpretation

This support center is designed within the thesis context of Solving common problems in catalyst characterization data interpretation research. It provides targeted FAQs and guides for researchers, scientists, and drug development professionals facing challenges in linking physicochemical properties to catalytic metrics like activity, selectivity, and stability.

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: My BET surface area measurement is high, but the catalyst shows unexpectedly low activity. What could be the issue? A: High BET surface area does not guarantee high activity. The problem may be that the measured surface area is not accessible or active. Consider these points:

- Pore Blocking: Micropores (<2 nm) may contribute significantly to surface area but reactants cannot access them. Correlate N₂ physisorption data with pore size distribution (PSD) plots.

- Inactive Support Surface: The surface area is dominated by the support material, not the active phase. Use techniques like XPS or TEM-EDS to confirm dispersion of the active metal/sites.

- Mass Transfer Limitations: High surface area materials often have small pores, leading to diffusion limitations that mask intrinsic kinetics. Perform a Weisz-Prater criterion calculation for internal diffusion or vary particle size to test.

Q2: My X-ray Diffraction (XRD) pattern shows no peaks for the expected active metal oxide phase. How should I interpret this? A: The absence of distinct crystalline peaks can indicate two primary scenarios:

- High Dispersion: The active phase is highly dispersed, forming particles smaller than ~4-5 nm, which are XRD-amorphous. This is often desirable. Confirm using: High-resolution TEM or CO chemisorption to measure particle size/dispersion.

- Formation of an Amorphous Phase: The synthesis method led to a non-crystalline structure. Confirm using: X-ray Absorption Spectroscopy (XAS, e.g., EXAFS) to probe the local atomic structure even without long-range order.

Q3: How do I distinguish between metal sintering and carbon deposition (coking) as causes of catalyst deactivation from stability test data? A: Both cause activity decline but have different physicochemical roots. Implement a diagnostic protocol:

- Post-reaction Characterization Triad:

- TEM: Directly image particle size increase (sintering) vs. carbon layers/filaments (coking).

- Temperature-Programmed Oxidation (TPO): Measure CO₂ evolution peak ~300-600°C to quantify combustible carbon deposits.

- XRD: Check for sharpening of metal peaks (sintering).

- In-situ/Operando Observation: If possible, use environmental TEM or coupled TGA-MS to observe deactivation in real time.

Q4: The Turnover Frequency (TOF) I calculated varies widely with the characterization method used for active site counting (e.g., H₂ chemisorption vs. STEM particle sizing). Which one is correct? A: This is a common data interpretation challenge. TOF is only as accurate as the active site count.

- H₂ Chemisorption: Assumes a specific stoichiometry (e.g., H:Pt = 1:1). It may underestimate sites if some are blocked or overestimate if hydrogen spills over to the support.

- STEM Particle Sizing: Assumes all particles are visible, spherical, and have a known geometric model (e.g., cuboctahedron) to convert size to site count. It misses subsurface or support-incorporated sites.

- Actionable Solution: Report TOF with a clear subscript (e.g., TOFH2, TOFSTEM). Use a complementary kinetic probe reaction with known structure sensitivity to infer the effective active site count. Consistency across methods validates your count.

Q5: In Temperature-Programmed Reduction (TPR) profiles, how do I assign overlapping reduction peaks to specific metal species? A: Overlapping peaks indicate multiple reducible species with similar reduction temperatures.

- Deconvolution Protocol:

- Perform TPR on pure, reference materials (e.g., isolated metal oxide, bulk support) individually.

- Physically mix these reference materials and run TPR to see if peak positions shift due to proximity effects.

- Use a deconvolution software (e.g., with Gaussian/Lorentzian fits), but anchor the initial peak positions and widths using reference data. Do not rely on mathematical fitting alone.

- Correlate with XPS data in the same sample to identify oxidation states pre- and post-reduction.

Table 1: Common Characterization Techniques for Key Physicochemical Properties

| Target Property | Primary Technique(s) | Key Output Metrics | Common Pitfalls & Data Validation Cues |

|---|---|---|---|

| Surface Area & Porosity | N₂ Physisorption (BET, BJH, DFT) | BET SA (m²/g), Pore Volume (cc/g), PSD | Micropore overestimation with BET; Validate with t-plot or DFT model for micro/mesopores. |

| Crystallite Phase & Size | X-ray Diffraction (XRD) | Phase ID, Crystallite Size (Scherrer), Lattice Strain | Amorphous phases invisible; Use Rietveld refinement for quantitative phase analysis. |

| Active Site Dispersion | H₂/CO Chemisorption, STEM | Dispersion (%), Particle Size (nm) | Stoichiometry assumption error; Cross-check chemisorption with STEM on same sample batch. |

| Oxidation State & Environment | XPS, XAS (XANES/EXAFS) | Binding Energy (eV), Oxidation State, Coordination # | Surface sensitivity (XPS); Require reliable charge reference (e.g., adventitious C 1s at 284.8 eV). |

| Acidity/Basicity | NH₃/CO₂-TPD, Pyridine-IR | Acid/Base Site Density (μmol/g), Strength Distribution | Desorption may be diffusion-limited; Use multiple heating rates to check. |

Table 2: Correlation Guide: Property vs. Performance Anomaly

| Observed Performance Issue | Primary Physicochemical Property to Investigate | Recommended Characterization Suite | Expected Data Shift if Issue is Confirmed |

|---|---|---|---|

| Activity Decline Over Time (Stability) | 1. Active Site Loss2. Pore Blockage | Post-reaction TEM, TPO, N₂ Physisorption | TEM: Particle size ↑ (sintering) or Carbon layers.TPO: CO₂ evolution peak.BET: Surface Area/Pore Volume ↓. |

| High Activity but Low Selectivity | Presence of Multiple Active Site Types | Probe Reactions, Selective Chemisorption, IR Spectroscopy | Different site densities from selective titrations; IR shows distinct surface intermediates. |

| Poor Activity Despite High Metal Loading | Low Accessibility or Poor Dispersion | XRD, STEM, Chemisorption | XRD: Large crystalline peaks.STEM/ Chemisorption: Low dispersion number. |

| Activity Inconsistent with Theory/Prediction | Electronic State Modification (Strong Metal-Support Interaction) | XPS, XAS, In-situ Raman | XPS: Binding energy shift of metal.XANES: Change in white line intensity. |

Experimental Protocols

Protocol 1: Standardized BET Surface Area & Pore Size Analysis with Data Validation Objective: To accurately determine the specific surface area and pore size distribution of a heterogeneous catalyst.

- Sample Preparation (~0.1-0.3 g): Degas sample at 150-300°C under vacuum for 6-12 hours to remove adsorbed contaminants.

- Physisorption Measurement: Using a volumetric analyzer (e.g., Micromeritics, Quantachrome), measure N₂ adsorption-desorption isotherms at 77 K across a relative pressure (P/P₀) range of 0.01 to 0.99.

- BET Surface Area Calculation:

- Use the adsorption data in the relative pressure range of 0.05-0.30 P/P₀.

- Apply the BET equation:

1/[W((P₀/P)-1)] = (C-1)/(Wₘ*C) * (P/P₀) + 1/(Wₘ*C) - Plot

1/[W((P₀/P)-1)]vs.P/P₀. The linear region should have a correlation coefficient R² > 0.9995. - Calculate the monolayer volume

Wₘfrom slope/intercept, then Surface Area:SA = (Wₘ * N * σ) / m, where N is Avogadro's number, σ is cross-sectional area of N₂ (0.162 nm²), m is sample mass.

- Pore Size Distribution (PSD): Apply the Barrett-Joyner-Halenda (BJH) method to the desorption branch for mesopores (2-50 nm). For microporous materials (<2 nm), use Non-Local Density Functional Theory (NLDFT) models with the appropriate adsorbate kernel.

- Validation: The BET C constant should be positive. Check for Type I (microporous), IV (mesoporous), or II (non-porous) isotherm shapes to confirm material type matches PSD.

Protocol 2: Temperature-Programmed Reduction (TPR) for Reducibility Assessment Objective: To determine the reducibility, reduction temperature, and quantify the hydrogen consumption of catalyst species.

- Setup: Place ~50 mg of catalyst in a U-shaped quartz reactor. Use a thermal conductivity detector (TCD).

- Pre-treatment: Purge with inert gas (Ar, 20 ml/min) at 150°C for 1 hour to dry the sample.

- Baseline Stabilization: Cool to 50°C under inert flow. Switch gas to 5% H₂/Ar (reducing mix), flow 20 ml/min, until stable TCD signal.

- Reduction Ramp: Initiate a linear temperature ramp (e.g., 5-10°C/min) from 50°C to a final temperature (e.g., 800-900°C). Continuously monitor TCD signal.

- Calibration: After the run, inject known volumes of pure H₂ or a reducing mix pulse via a calibration loop to determine the TCD response factor (μV per μmol H₂).

- Data Analysis: Integrate the area under each reduction peak. Convert peak area to moles of H₂ consumed using the calibration factor. Report reduction temperatures (T_max) and total H₂ uptake (μmol/g).

Mandatory Visualizations

Diagnostic Workflow for Catalyst Deactivation

Property-Performance Correlation Network

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Catalyst Characterization Experiments

| Item/Category | Example Product/Specification | Primary Function in Characterization |

|---|---|---|

| High-Purity Gases | 5% H₂/Ar (TPR), 5% O₂/He (TPO), 99.999% N₂ (BET), 10% CO/He (Chemisorption) | Reductant, oxidant, adsorbate, and carrier gases for in-situ treatments and physisorption/chemisorption measurements. |

| Standard Reference Materials | NIST-certified Al₂O₃ (BET standard), LaB₆ (XRD line broadening standard), Pure metal foils (XPS/XAS calibration). | Calibrating instrument response, verifying accuracy of surface area, crystallite size, and energy scale measurements. |

| Quantitative Calibration Mixtures | Certified CO in N₂, CH₄ in He, etc., for GC-TCD/FID calibration. | Converting detector signal (μV) from TPR/TPO/TGA-MS into absolute molar quantities of gas consumed/evolved. |

| Microporous/Mesoporous Reference Catalysts | Zeolite Y (micro), SBA-15 (meso), provided by groups like ICPC or commercial suppliers. | Benchmarking pore size distribution analysis methods (BJH, DFT) and validating experimental protocols. |

| In-situ Cell Windows | CVD Diamond, Boron Nitride, or high-grade Quartz windows for IR/Raman/XAS. | Enabling operando characterization by withstanding reaction conditions (high T/P) while transparent to probe beam. |

| Conductive Adhesives/Tapes | Carbon tape, Silver paste, Copper tape for SEM/ TEM/ XPS mounting. | Providing stable, non-contaminating electrical and physical bonding of catalyst powder to sample holders. |

Solving the Puzzle: Troubleshooting Artifacts, Ambiguities, and Data Misinterpretations

Troubleshooting Guides & FAQs

Q1: What causes a broad amorphous hump in my XRD pattern, and how can I mitigate it? A: A broad hump (typically 15-35° 2θ) indicates the presence of amorphous material. In catalyst research, this often comes from the support (e.g., amorphous silica or alumina) or an un-calcined precursor. To mitigate:

- Increase Crystallinity: Optimize calcination temperature and time. Use a slow ramp rate (e.g., 1-2°C/min) to allow gradual crystal formation.

- Background Subtraction: Use software (e.g., HighScore, Jade) to subtract a measured background from an amorphous standard or to fit and subtract a polynomial background.

- Chemical Treatment: For supported catalysts, selective leaching of the amorphous phase (if chemically distinct) can sometimes clarify the pattern of the crystalline phase.

Q2: My sample shows extreme variation in peak intensities compared to the reference pattern. What is happening? A: This is typically Preferred Orientation (Texture). Plate- or needle-shaped crystals align preferentially on the sample holder, enhancing intensity from certain lattice planes. Solutions:

- Sample Preparation: Avoid pressing or grinding. Use a back-loading sample holder. For powders, gently side-drift the sample into a cavity holder.

- Rotational Spinning: Use a sample spinner during data collection to average out orientation effects.

- Data Analysis: Apply a March-Dollase or Rietveld texture model during refinement to correct intensities.

Q3: A minor phase in my catalyst is completely obscured by a major phase's peaks. How can I detect it? A: This is Phase Masking. The major phase's strong, sharp peaks overwhelm the weak signals of the minor phase.

- Increase Data Quality: Collect data with long count times (e.g., 5-10 sec/step) over the key angular range to improve signal-to-noise for minor peaks.

- Use Reference Intensity Ratio (RIR): Calculate the theoretical detection limit. If the minor phase concentration is below ~1-2 wt%, consider alternative techniques (e.g., Raman spectroscopy, TEM).

- Selective Chemical or Physical Removal: If possible, selectively dissolve the major phase to concentrate the minor phase for analysis.

- Synchrotron XRD: Use the high intensity and resolution of a synchrotron source to separate closely spaced peaks.

Q4: My quantitative phase analysis (QPA) results are inconsistent. What are the main error sources? A: Common sources and their mitigation strategies are summarized in the table below.

| Error Source | Impact on QPA | Mitigation Strategy |

|---|---|---|

| Preferred Orientation | High error for anisotropic crystals. | Use a spinner, careful prep, texture model in refinement. |

| Microabsorption | Overestimation of low-absorbing phases. | Use fine grinding (<10 µm) or apply a microabsorption correction (e.g., Brindley). |

| Amorphous Content | Overestimation of crystalline phases. | Use an internal standard (e.g., 10-20 wt% NIST corundum) to quantify amorphous fraction. |

| Poor Crystallinity | Peak broadening, poor pattern fit. | Optimize synthesis/calcination; use whole-pattern (Rietveld) methods. |

| Inaccurate Background | Incorrect scaling of weak peaks. | Manually set background points in key regions. |

Experimental Protocols

Protocol 1: Sample Preparation to Minimize Preferred Orientation

- Equipment: Back-loading flat plate sample holder, glass slide, blade.

- Procedure: Fill the sample cavity by gently drifting the powder from the side with a glass slide. Do not press or compact. Level the surface with a clean blade using a single, gentle scraping motion. Do not overfill.

- Verification: Run a preliminary scan on a standard known for orientation (e.g., mica). If (00l) peaks are suppressed relative to a pressed sample, preparation is successful.

Protocol 2: Internal Standard Method for Amorphous Content Quantification

- Materials: High-purity crystalline standard (e.g., NIST 676a corundum, α-Al₂O₃), your sample containing amorphous material.

- Weighing: Accurately weigh a mixture of ~80% unknown sample and ~20% corundum standard. Mix thoroughly in an agate mortar or via ball milling (dry, short time).

- Data Collection: Run a standard XRD scan with sufficient counting statistics.

- Rietveld Refinement: Refine the pattern, modeling all identifiable crystalline phases including the corundum standard.

- Calculation: The refined weight fraction of corundum ((W{cor,ref})) will differ from the known added weight fraction ((W{cor,added})). The amorphous fraction ((W{amorph})) is calculated as: (W{amorph} = 1 - \frac{W{cor,added}}{W{cor,ref}})

Diagrams

Title: Logical Flow for XRD Problem Diagnosis

Title: Quantitative Phase Analysis (QPA) Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in XRD Troubleshooting |

|---|---|

| NIST Standard Reference Material 676a (Corundum) | Certified internal standard for quantitative amorphous content and lattice parameter calibration. |

| Zero-Diffraction (Quartz) Plate | Sample holder for minimizing background noise during sensitive measurements. |

| Back-Loading Sample Holder | Holder designed to prepare samples with minimal pressure, reducing preferred orientation. |

| Sample Spinner | Motorized stage that rotates the sample during measurement to average out orientation effects. |

| LaB₆ (NIST SRM 660c) | Certified line profile standard for instrumental broadening correction and peak shape calibration. |

| Si (NIST SRM 640e) | Certified silicon powder standard for precise instrument alignment and 2θ calibration. |

| Micro-Agate Mortar & Pestle | For gentle, contamination-free grinding to reduce particle size and microabsorption effects. |

| Rietveld Refinement Software (e.g., HighScore, GSAS-II, TOPAS) | Essential for advanced analysis including QPA, texture correction, and lattice parameter determination. |

Troubleshooting Guides & FAQs

Q1: Our BET surface area results for a microporous catalyst are abnormally high and the linear region in the BET plot is poorly defined. What is the issue and how can we confirm it?

A: This is a classic sign of misapplying the BET theory to microporous (pores < 2 nm) materials. The BET model assumes multilayer adsorption on open surfaces, which breaks down in micropores where pore filling occurs instead. The "high" surface area is an artifact.

Confirmatory Protocol:

- t-Plot or αₛ-Plot Analysis:

- Method: Re-plot the adsorption data as volume adsorbed vs. thickness of an adsorbed film (t-plot using standard isotherm data) or vs. normalized adsorption (αₛ-plot).

- Interpretation: A plot passing through the origin suggests no micropores. A positive intercept indicates micropore filling, allowing you to calculate the micropore volume and external surface area separately.

- NLDFT/QSDFT Analysis:

- Method: Fit the entire adsorption isotherm (preferably at 77 K with N₂ or Ar) to a Non-Local Density Functional Theory (NLDFT) or Quenched Solid DFT kernel appropriate for your assumed pore geometry (slit, cylindrical).

- Output: This provides a pore size distribution plot, quantitatively identifying microporosity.

Q2: The C constant from our BET plot is negative. Is this possible, and what does it indicate?