Operando Spectroscopy: Decoding Catalytic Mechanisms in Real Time

This article provides a comprehensive overview of operando spectroscopy, an analytical methodology that simultaneously couples spectroscopic characterization of materials with activity and selectivity measurements under working catalytic conditions.

Operando Spectroscopy: Decoding Catalytic Mechanisms in Real Time

Abstract

This article provides a comprehensive overview of operando spectroscopy, an analytical methodology that simultaneously couples spectroscopic characterization of materials with activity and selectivity measurements under working catalytic conditions. Tailored for researchers and scientists, the content explores the foundational principles of operando spectroscopy, detailing its critical role in establishing structure-activity-selectivity relationships. It further examines a suite of methodological approaches—including X-ray, vibrational, and UV-Vis spectroscopies—and their specific applications in heterogeneous and electrocatalysis. The discussion extends to best practices in reactor design, strategies to overcome common experimental pitfalls, and the integration of transient analysis and computational modeling for data validation and mechanistic insight. By synthesizing knowledge across these domains, this article serves as a guide for leveraging operando spectroscopy to drive innovation in catalyst design and development.

What is Operando Spectroscopy? Principles and Evolution of a Transformative Methodology

The pursuit of sustainable chemistry and clean energy technologies hinges on the development of next-generation catalysts, a process fundamentally underpinned by a thorough mechanistic understanding of how these catalysts function under realistic working conditions [1]. Within this context, operando spectroscopy has emerged as a powerful and transformative methodology that transcends the capabilities of traditional in-situ characterization. While in-situ techniques are performed on a catalytic system under simulated reaction conditions—such as elevated temperature, applied voltage, or the presence of reactants—operando techniques represent a significant advancement by probing the catalyst under conditions as close as possible to reality while simultaneously measuring its catalytic activity [1]. This critical link between spectroscopic data and simultaneous activity measurement is the defining characteristic of operando analysis, enabling researchers to construct direct, concrete links between a catalyst's dynamic physical/electronic structure and its macroscopic performance [1]. This Application Note delineates the core principles of operando spectroscopy, provides structured protocols for its implementation, and highlights its pivotal role in accelerating catalyst development for applications from renewable energy to pharmaceutical synthesis.

Core Principles and Key Techniques

The fundamental objective of operando spectroscopy is to deconvolute the complex interplay of a catalyst's structure, its environment, and its resulting performance. This often requires sophisticated reactor designs that incorporate optical windows or other modifications to allow for spectroscopic measurement while maintaining authentic reaction conditions, including considerations of mass transport and gas/liquid/solid interfaces [1]. A common challenge in the field is the mismatch between characterization conditions and real-world operating environments; for instance, many operando reactors are batch systems with planar electrodes, which can lead to poor reactant transport and pH gradients not present in flow-based industrial reactors [1]. Co-designing reactors with integrated spectroscopic probes is therefore essential to bridge this gap and collect mechanistically relevant data.

Table 1: Comparison of Key Operando Spectroscopy Techniques

| Technique | Key Measured Parameters | Spatial/Temporal Resolution | Primary Applications in Catalysis |

|---|---|---|---|

| X-ray Absorption Spectroscopy (XAS) | Local electronic & geometric structure, oxidation state [1] | -- | Elucidating active sites in electrocatalysts (e.g., OER, CO2R) [1] [2] |

| Vibrational Spectroscopy (IR, Raman) | Reaction intermediates, surface species, product formation [1] | ~300-500 nm spatial (SRS) [3] | Tracking intermediates in CO2 reduction [1]; mapping ion concentrations [3] |

| Electrochemical Mass Spectrometry (EC-MS) | Gaseous or volatile products, reaction intermediates [1] | Sub-second temporal (with optimized design) [1] | Quantifying Faradaic efficiency, detecting transient species [1] |

| Operando UV-Vis Spectroelectrochemistry | Redox states, reaction kinetics, coverage of surface species [4] | -- | Probing charge transfer in water oxidation catalysts [4] |

| Stimulated Raman Scattering (SRS) | 3D chemical mapping, ion concentrations [3] | 10 mM sensitivity, ~2 μs/pixel [3] | Visualizing ion transport and dendrite growth in batteries [3] |

Detailed Experimental Protocols

Protocol 1: Operando X-Ray Absorption Spectroscopy (XAS) for Electrocatalyst Evolution

This protocol outlines the procedure for tracking the dynamic evolution of an electrocatalyst's structure under operating conditions, as applied in the study of defect generation in silver nanocrystals for CO2 reduction [2].

- Objective: To monitor the time-dependent changes in the electronic structure and local coordination environment of a catalyst during an electrochemical reaction.

- Materials and Equipment:

- Electchemical Cell: A specialized 3-electrode electrochemical cell with X-ray transparent windows (e.g., Kapton film) [1].

- Catalyst: Catalyst ink (e.g., Ag₂O precursor mixed with conductive carbon and binder) deposited on a working electrode [2].

- Synchrotron Beamline: A beamline capable of fast XAS measurements (XANES/EXAFS) with time resolution on the order of minutes or seconds [2].

- Potentiostat: For applying controlled electrochemical potentials.

- Step-by-Step Procedure:

- Cell Assembly: Load the working electrode into the operando XAS cell with counter and reference electrodes and the requisite electrolyte.

- Baseline Measurement: Collect a reference XAS spectrum of the precursor catalyst (e.g., Ag₂O) at open-circuit potential.

- Reaction Initiation & Data Acquisition: Apply the target reduction potential (e.g., -0.7 V vs. RHE for CO2R) to initiate the electrochemical reaction. Simultaneously, begin collecting a time-series of fast XAS spectra.

- Activity Correlation: Simultaneously record the electrochemical current to correlate structural changes with catalytic activity.

- Data Analysis: Fit the EXAFS spectra to extract coordination numbers and bond distances. Track the decay of the Ag-O scattering path and the emergence of the Ag-Ag path to quantify the reduction of the oxide precursor and the formation of metallic Ag with defects [2].

Protocol 2: Operando Stimulated Raman Scattering (SRS) for Ion Transport Visualization

This protocol describes the application of SRS microscopy for the 3D visualization of ion concentration gradients in functional electrochemical devices, such as batteries [3].

- Objective: To quantitatively map the evolution of local ionic concentrations and correlate them with morphological changes (e.g., dendrite growth) during operation.

- Materials and Equipment:

- SRS Microscope: Equipped with two synchronized picosecond lasers (pump and Stokes).

- Electrochemical Cell: A custom cell (e.g., Li/gel electrolyte/Li symmetric cell) compatible with high-numerical-aperture objectives [3].

- Tuned System: The laser difference frequency tuned to the Raman shift of the target anion (e.g., ~1100 cm⁻¹ for BOB⁻) or Li⁺-solvent interaction [3].

- Step-by-Step Procedure:

- Calibration: Establish a linear calibration curve by measuring the SRS signal intensity from electrolytes with known concentrations.

- Operando Imaging: Apply a current density to drive the electrochemical reaction (e.g., Li deposition). Simultaneously acquire SRS image stacks in 3D over time.

- Concentration Mapping: Convert the SRS signal intensity at each pixel into ionic concentration using the calibration curve. The anion concentration can represent the cation concentration (e.g., [BOB⁻] for [Li⁺]) due to the electroneutrality principle [3].

- Morphological Correlation: Use the same microscope in reflectance mode to record the corresponding electrode morphology.

- Data Interpretation: Identify regions of ion depletion (low SRS signal) and correlate them with the onset and growth of dendritic structures. This can reveal a multi-stage deposition process from no depletion to partial and full depletion [3].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Research Reagents and Materials for Operando Studies

| Item/Category | Function & Importance | Example Specifics |

|---|---|---|

| X-ray Transparent Windows | Allows probe beam to enter/exit the reactor while maintaining internal conditions [1]. | Kapton film, silicon nitride windows. |

| Gas Diffusion Electrodes (GDE) | Enables high current density operation by improving mass transport of gaseous reactants (e.g., CO₂) [2]. | Carbon-based GDE for flow-cell reactors. |

| Isotope-Labeled Reactants | Validates reaction intermediates and pathways by creating a unique spectroscopic signature [1]. | ¹³CO₂ for tracing carbon pathways in CO2 reduction. |

| Solid Electroly Interphase (SEI) | An artificial coating to homogenize ion flux and suppress detrimental side reactions [3]. | Li₃PO₄ layer on a Li metal anode. |

| Pervaporation Membrane | Enables rapid transport of volatile products from the electrolyte to the mass spectrometer [1]. | PTFE or Gore-Tex membranes in EC-MS. |

Data Processing and Workflow Visualization

Modern operando spectroscopy generates complex, multi-dimensional datasets where measurement noise can be a significant challenge [5]. To extract quantitative insights, advanced data processing is often required. Deep learning-based denoising, for example, has been successfully applied to operando microscopy data from techniques like scanning transmission X-ray microscopy (STXM) and optical microscopy, revealing nanoscale chemical heterogeneity that was previously obscured [5]. This denoising preserves physical fidelity and reduces uncertainty in subsequent quantitative analysis, such as model learning with partial differential equation-constrained optimization [5]. Furthermore, for spectral data, techniques like adaptive penalized least squares (asPLS) are critical for correcting baseline drift in Fourier Transform Infrared (FTIR) spectra, ensuring accurate quantitative analysis of gas concentrations [6].

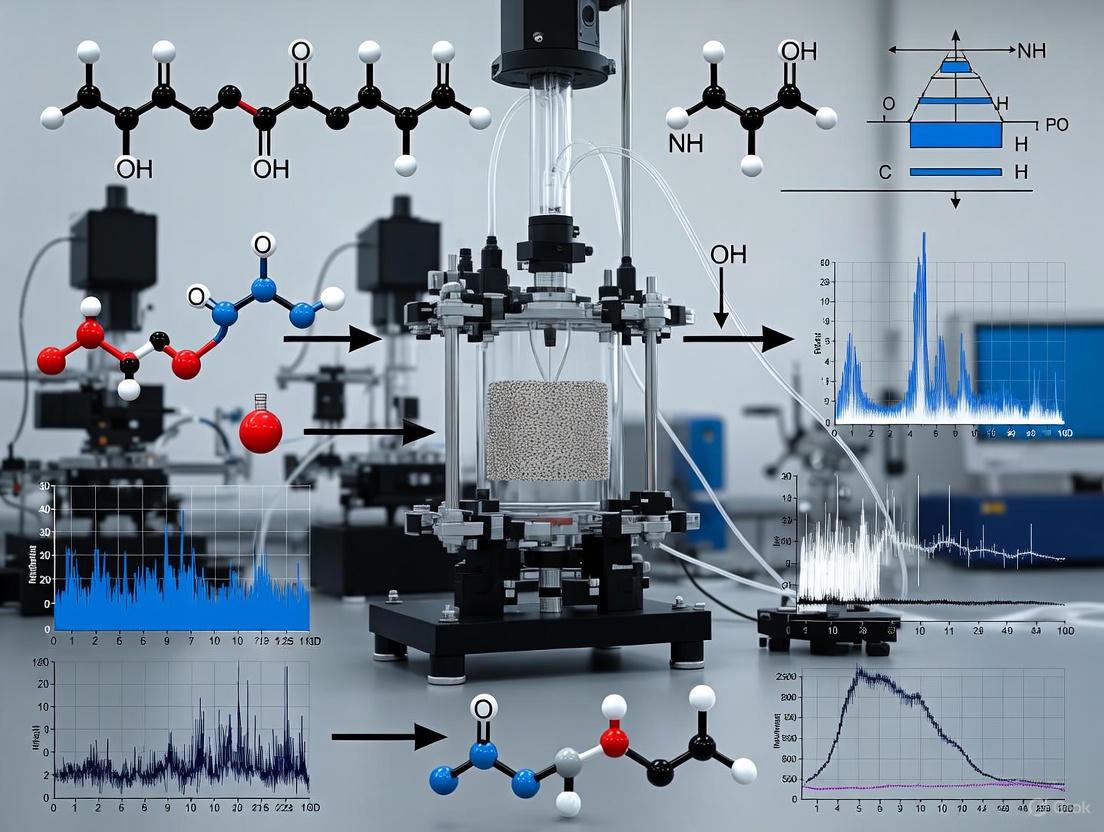

The following workflow diagram summarizes the integrated logical process of designing and executing an operando spectroscopy study.

Operando Spectroscopy Workflow

Operando spectroscopy represents a paradigm shift in catalytic analysis, moving beyond static observation or studies under simulated conditions to provide a dynamic, holistic view of catalysts at work. By integrating sophisticated reactor design, multi-modal spectroscopic probes, simultaneous activity measurement, and advanced data analysis, this approach allows researchers to deconvolute complex reaction mechanisms and establish definitive structure-activity relationships. As the field advances, innovations in reactor design to better mimic industrial conditions, the integration of machine learning for data analysis, and the development of faster, more sensitive spectroscopic techniques will further solidify operando spectroscopy as an indispensable tool in the quest for more efficient, selective, and stable catalysts for a sustainable future.

Operando spectroscopy represents a significant advancement in analytical methodology for catalysis research and drug development. It is defined by its core principle: the simultaneous combination of spectroscopic characterization of a material during a reaction with the direct measurement of its catalytic activity and selectivity [7] [8]. This approach moves beyond traditional in situ methods by insisting that spectroscopic data is collected under realistic, working conditions while quantitative performance data (e.g., conversion rates, product yield) is gathered from the very same sample and at the same time [7] [1]. The power of this methodology lies in its ability to directly link the molecular structure of a catalyst to its function, thereby establishing fundamental structure-activity relationships that are critical for the rational design of more efficient and selective catalysts and therapeutic agents [7] [8]. For researchers in drug development, this translates to a powerful tool for elucidating reaction mechanisms and optimizing synthetic pathways for active pharmaceutical ingredients (APIs).

Key Operando Techniques and Their Applications

The following table summarizes the primary operando techniques, their structural probes, and representative applications in catalysis and related fields.

Table 1: Key Operando Spectroscopy Techniques and Applications

| Technique | Structural Information Probed | Simultaneous Activity Measurement | Example Applications |

|---|---|---|---|

| Operando Raman Spectroscopy [8] [1] | Molecular vibrations, surface species, reaction intermediates. | Gas chromatography (GC) for product identification and quantification [7]. | Study of fuel cell catalytic layers; investigation of catalyst active sites under reaction conditions [8]. |

| Operando X-Ray Absorption Spectroscopy (XAS) [8] [1] | Local electronic structure, oxidation state, coordination geometry. | Current density, product formation rates (e.g., via electrochemical mass spectrometry) [1]. | Redox dynamics in solid oxide fuel cell (SOFC) anodes; oxidation state changes in electrocatalysts [8]. |

| Operando Vibrational Spectroscopy (IR) [8] [1] | Chemical bonds, functional groups, adsorbed intermediates. | Gas chromatography or mass spectrometry for activity/selectivity [8]. | Mechanism of CCl₄ decomposition over La₂O₃; identification of intermediates in heterogeneous catalysis [8]. |

| Operando Electrochemical Mass Spectrometry (EC-MS) [1] | Identity and quantity of gaseous or volatile reactants, intermediates, and products. | Electrochemical current, potential, and charge. | Detection of acetaldehyde and propionaldehyde intermediates during CO₂ electroreduction [1]. |

| Operando Transmission Electron Microscopy (TEM) [9] | Atomic-scale structure, morphology, and dynamics. | Gas environment control, with activity data often correlated from separate experiments. | Atomic-level observation of catalyst behavior during industrially relevant reactions [9]. |

Detailed Experimental Protocols

Protocol: Operando Raman-GC for Heterogeneous Catalysis

This protocol outlines a methodology for studying a catalytic reaction using simultaneous Raman spectroscopy and gas chromatography, based on a case study presented in the literature [7].

1. Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Operando Raman-GC Experiments

| Item | Function/Description |

|---|---|

| Catalytic Material | The solid catalyst under investigation, often in powder form. |

| Operando Reactor Cell | A specialized cell that holds the catalyst, allows reactant flow, controls temperature, and provides optical access for the Raman laser [8]. |

| Raman Spectrometer | Equipped with a probe containing optical fibers for excitation and detection. A laser source (e.g., 532 nm) is typical [8]. |

| Gas Chromatograph (GC) | Equipped with appropriate detectors (e.g., FID, TCD) for separating and quantifying reaction products [7]. |

| Mass Flow Controllers | Precisely regulate the flow rates of gaseous reactants into the reactor cell. |

| Heating System | Oven or cartridge heater to maintain the catalyst at the desired reaction temperature. |

2. Experimental Workflow

The diagram below illustrates the integrated workflow of an operando Raman-GC experiment.

3. Step-by-Step Procedure

- Catalyst Loading and Reactor Setup: Pack the catalyst sample into the operando reactor cell. Ensure the catalyst bed is stable and the cell is sealed properly. Connect the gas feed lines from the mass flow controllers and the outlet to the GC sampling loop.

- System Conditioning and Activation: Purge the system with an inert gas (e.g., N₂ or He). Raise the temperature to the desired reaction level under the inert flow. This step may involve activating the catalyst, for example, by reducing it in a H₂ stream if required.

- Baseline Data Collection: With the catalyst under inert atmosphere at reaction temperature, collect a background Raman spectrum. Also, run the GC to establish a baseline for product analysis.

- Initiation of Reaction and Simultaneous Measurement: Switch the gas flow from inert to the reactant mixture (e.g., propane in air for dehydrogenation). Immediately begin the operando measurement cycle:

- Start continuous or frequent time-resolved Raman spectral acquisition, focusing on the catalyst bed.

- Simultaneously, initiate automated, periodic sampling from the reactor effluent into the GC for analysis.

- Data Acquisition and Monitoring: Continue the simultaneous Raman and GC measurements over the desired time course of the reaction. Monitor for changes in Raman bands (indicating formation or consumption of surface species) and the appearance/disappearance of products in the GC chromatograms.

- Data Correlation and Analysis: Correlate the temporal evolution of the spectroscopic features (Raman bands) with the catalytic performance data (product concentrations, conversion, selectivity) obtained from GC. This direct correlation is the foundation for proposing reaction mechanisms and active site involvement [7].

Protocol: Operando XAS for Electrocatalysis

This protocol is adapted from recent best practices in electrocatalysis research [1], which highlights its relevance for sustainable energy applications linked to drug development.

1. Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for Operando XAS Experiments in Electrocatalysis

| Item | Function/Description |

|---|---|

| Working Electrode | The electrocatalyst material, typically coated as a thin film on a conductive substrate like carbon paper or a glassy carbon disk. |

| Operando Electrochemical Cell | A cell with X-ray transparent windows (e.g., Kapton, polyimide) and a designed flow path for electrolytes [1]. |

| Synchrotron Beamline | Provides the high-flux, tunable X-ray source required for XAS measurements. |

| Potentiostat/Galvanostat | Applies and controls the electrochemical potential or current during the experiment. |

| Product Detection System | May be coupled online, such as a gas chromatograph for liquid products or a mass spectrometer for gaseous products. |

2. Experimental Workflow

The diagram below outlines the critical steps for a successful operando XAS experiment.

3. Step-by-Step Procedure

Cell Design and Validation (Critical Step):

- Use or fabricate an electrochemical cell that minimizes the X-ray path length through the electrolyte to reduce signal absorption, while ensuring the working electrode is properly aligned in the X-ray beam [1].

- Best Practice: Prior to operando measurements, validate that the cell's electrochemical performance (e.g., achievable current densities, mass transport) is comparable to a standard laboratory reactor to ensure relevance of the mechanistic insights [1].

Catalyst Electrode Preparation: Deposit a homogeneous layer of the catalyst ink onto the conductive substrate. Accurately determine the catalyst loading.

System Alignment and Baseline Collection: Assemble the cell with the catalyst as the working electrode, along with the counter and reference electrodes. Fill with electrolyte. Align the X-ray beam to focus on the catalyst layer. Collect a XANES and/or EXAFS spectrum of the catalyst at open circuit potential or a known reference state.

Simultaneous Operando Measurement:

- Apply a series of electrochemical potentials (or use a controlled current) relevant to the catalytic reaction of interest (e.g., oxygen evolution, CO₂ reduction).

- At each applied potential, collect the XAS spectrum (both XANES and EXAFS regions if possible).

- Crucially, record the electrochemical current in real time. If possible, use coupled techniques like electrochemical mass spectrometry (EC-MS) to quantitatively track product formation simultaneously [1].

Data Processing and Analysis:

- Process the XAS data (background subtraction, normalization, etc.) to extract quantitative parameters such as edge energy shifts (oxidation state) and Fourier transforms (local coordination).

- Plot these structural parameters directly against the applied potential and the measured catalytic current/product formation rates.

Interpretation and Modeling: Correlate changes in the catalyst's electronic and geometric structure (from XAS) with its activity and selectivity. Use theoretical modeling (e.g., DFT calculations) to assign spectral features and validate the proposed active site structure under working conditions [1].

The Scientist's Toolkit: Critical Reagents and Materials

The following table consolidates essential tools and reagents for designing operando studies.

Table 4: The Scientist's Toolkit for Operando Studies

| Category / Item | Specific Examples | Function in Operando Studies |

|---|---|---|

| Spectroscopic Systems | Raman Spectrometer with fiber-optic probe; XAS beamline setup; FTIR Spectrometer. | Provides the fundamental probe for molecular, electronic, or geometric structure of the catalyst under reaction conditions [8]. |

| Activity Measurement | Micro-Gas Chromatograph (GC); Mass Spectrometer (MS); Potentiostat. | Quantifies the catalytic performance (conversion, selectivity, reaction rate) simultaneously with spectral acquisition [7] [8] [1]. |

| Reactor Core | In situ Raman cell; Spectro-electrochemical flow cell; High-temperature/pressure reactor. | The central platform that hosts the catalyst, maintains reaction conditions, and integrates spectroscopic and activity measurement ports [8] [1]. |

| Data Analysis Software | Multivariate analysis packages; DFT calculation software; Custom scripts for data synchronization. | Enables the correlation of large spectroscopic and catalytic datasets to extract meaningful structure-activity relationships [1]. |

| Probes & Calibrants | Isotope-labeled reactants (e.g., ¹⁸O₂, D₂); Internal standards for GC/MS; Reference materials for XAS calibration. | Used for advanced control experiments to validate reaction mechanisms and ensure measurement accuracy [1]. |

The evolution of characterization techniques from in-situ to operando represents a paradigm shift in catalytic science. This transition marks a move from observing catalysts under simulated reaction conditions to analyzing them under real working environments with simultaneous activity measurement. The genesis of this field has fundamentally altered our ability to establish structure-property relationships by providing direct evidence of catalytic mechanisms and active site behavior under realistic conditions [1]. This methodological revolution has been particularly transformative for complex processes such as electrocatalytic water splitting and CO₂ reduction, where catalyst structures dynamically evolve during operation [10] [11].

The critical distinction between these approaches lies in their experimental philosophy. In-situ techniques are performed on catalytic systems under simulated reaction conditions, while operando techniques combine these measurements with simultaneous activity monitoring, creating a direct correlation between catalyst structure and function [1]. This evolution has addressed fundamental challenges in catalysis research, where pre- and post-reaction characterization often failed to capture transient intermediates and dynamic surface reconstructions that define catalytic performance [10].

Conceptual Framework and Definitions

Terminology and Distinctions

The conceptual framework distinguishing in-situ from operando characterization has been crystallized through community consensus. In-situ techniques probe catalytic systems under simulated reaction conditions, applying relevant stimuli such as elevated temperature, applied voltage, solvent immersion, or reactant presence. In contrast, operando techniques incorporate the additional crucial dimension of simultaneous activity measurement under conditions that closely mirror actual catalytic operation [1].

This distinction is not merely semantic but reflects a fundamental advancement in experimental methodology. Operando approaches explicitly address the reaction environment complexity, including mass transport phenomena, gas/liquid/solid interfaces, and quantitative product formation analysis [1]. The power of operando methodology is exemplified in studies of transition metal chalcogenides (TMCs), where what was initially perceived as the catalyst (e.g., CoSₓ) was revealed through operando analysis to be merely a pre-catalyst that reconstructs into the true active species (e.g., CoOOH) under operational conditions [10].

Historical Development Trajectory

The historical development from in-situ to operando characterization follows a logical progression driven by the recognition of dynamic catalyst behavior. Traditional ex-situ approaches provided limited insights because catalysts undergo significant structural transformations during operation that are not reversible upon removal from reaction environments [11].

This evolution has been accelerated by parallel advancements in multiple domains. Detector technology has enabled higher temporal resolution, while reactor design innovations have allowed for more realistic reaction conditions within characterization instruments [9] [1]. The field has progressively shifted from studying model systems under idealized conditions to investigating industrially relevant catalysts under realistic operating environments, bridging the materials gap that long plagued catalysis research [9].

Table: Historical Evolution of Characterization Approaches in Catalysis

| Era | Primary Approach | Key Characteristics | Technical Limitations |

|---|---|---|---|

| Pre-1990s | Ex-situ characterization | Post-reaction analysis; Static snapshots; Vacuum conditions | Irreversible surface changes; Missing intermediates; No performance correlation |

| 1990s-2000s | In-situ emergence | Simulated reaction conditions; Controlled environments; Real-time observation | Limited spatial/temporal resolution; Pressure and temperature gaps; No simultaneous activity measurement |

| 2000s-2010s | Operando conceptualization | Simultaneous structure and activity monitoring; Closing the pressure gap; Correlation with function | Reactor design challenges; Complex data interpretation; Limited multimodal approaches |

| 2010s-Present | Advanced operando | Atomic-scale resolution under working conditions; Multimodal integration; High-throughput capabilities | Data management; Artifact identification; Bridging time and length scales |

The Operando Technique Toolkit

Technique Classification Framework

Operando characterization techniques can be systematically categorized based on their fundamental detection principles and the specific insights they provide into catalytic systems. This classification framework helps researchers select complementary techniques that collectively provide a comprehensive understanding of catalytic mechanisms [12].

Table: Classification of Operando Techniques by Detection Principle and Application

| Technique Category | Example Techniques | Primary Information Obtained | Spatial Resolution | Temporal Resolution |

|---|---|---|---|---|

| Photonic Techniques | XAS, Raman, IR, GIXRD, UV-Vis | Surface chemical information; Bonding; Intermediate identification | ~nm-μm | ms-s |

| Electronic Methods | TEM, SEM, EELS, EC-STM | Structural and morphological data; Atomic arrangement | Atomic-scale | ms-s |

| Electrochemical Current Mapping | SECM, SECCM | Spatial heterogeneity of reactivity; Active site distribution | ~20 nm | ~3 ms |

| Fluorescence Microscopy | Super-resolution fluorescence | Catalytic activity distribution; Nanobubble mapping | nm-scale | Varies |

| Mass Spectrometry | DEMS, ICP-MS | Reactant, intermediate, and product monitoring | N/A | ms-s |

Key Technique Capabilities and Applications

Each operando technique provides unique insights into catalytic mechanisms. X-ray absorption spectroscopy (XAS) probes the local electronic and geometric structure of catalysts under working conditions, making it invaluable for tracking oxidation state changes and coordination environment evolution during reaction [1] [13]. Vibrational spectroscopies, including IR and Raman, provide molecular-level information about reaction intermediates and surface species through their characteristic bond vibrations [1] [13].

Electrochemical mass spectrometry (ECMS), particularly differential electrochemical mass spectrometry (DEMS), enables direct detection and quantification of reactants, intermediates, and products during catalytic reactions [1]. Advanced implementations have addressed response time limitations by depositing catalysts directly onto pervaporation membranes, bringing the detection point closer to the active sites [1].

Scanning electrochemical microscopy (SECM) and its variant scanning electrochemical cell microscopy (SECCM) directly map electrochemical activity with nanoscale spatial resolution, enabling the identification and quantification of active sites [12]. These techniques have revealed significant heterogeneity in catalytic activity across different surface sites, challenging homogeneous catalyst models [12].

Experimental Protocols and Best Practices

Reactor Design Considerations

Reactor design represents a critical component of successful operando studies, as it must satisfy dual requirements of enabling characterization while maintaining relevant reaction conditions. A fundamental challenge lies in the frequent mismatch between characterization requirements and realistic catalytic environments [1].

Conventional operando reactors often employ batch operation with planar electrodes, which differs significantly from the continuous flow reactors and gas diffusion electrodes used in industrial applications. This discrepancy leads to altered mass transport characteristics, potentially creating misleading concentration gradients and pH variations at catalyst surfaces [1]. These microenvironmental changes can obscure intrinsic reaction kinetics and lead to erroneous mechanistic interpretations.

Best practices in reactor design advocate for closing the transport gap through innovative approaches. For DEMS measurements, depositing catalysts directly onto pervaporation membranes significantly reduces response times by minimizing the path length between reaction events and detection [1]. Similarly, in grazing incidence X-ray diffraction (GIXRD), careful optimization of X-ray path length through electrolytes balances signal attenuation with sufficient interaction volume at catalyst surfaces [1]. Emerging strategies include modifying zero-gap reactors with beam-transparent windows, enabling operando characterization under industrially relevant conditions [1].

Standardized Protocol for Operando Electrochemical TEM

The development of polymer electrochemical liquid cells has enabled breakthrough capabilities in operando transmission electron microscopy (TEM), allowing direct observation of catalyst restructuring at atomic resolution during operation [11]. The following protocol outlines a standardized approach for studying Cu-based nanocatalysts in CO₂ electroreduction reactions (CO₂RR), adaptable to other catalytic systems.

Materials and Equipment

- Polymer electrochemical liquid cell with appropriate membrane thickness

- Aberration-corrected transmission electron microscope with fast imaging capabilities

- Nanopipette probe for precise electrolyte confinement (for SECCM variants)

- Potentiostat/Galvanostat for electrochemical control

- Direct electron detector (DED) capable of high frame rates (up to 200 fps)

- Cryo-transfer holder for intermediate analysis

- Cu or CuAg nanowire catalysts as model systems

Experimental Procedure

Cell Assembly and Leak Testing

- Assemble polymer electrochemical liquid cell according to manufacturer specifications

- Perform leak testing prior to insertion into TEM column

- Verify electrical connectivity for all electrodes

Electrochemical Conditions Setup

- Implement two-electrode or three-electrode system based on experimental requirements

- For CO₂RR studies, apply potentials ranging from -0.5 V to -1.2 V vs. RHE

- Record current-time transients simultaneously with image acquisition

Imaging Parameters Optimization

- Set electron dose to balance signal-to-noise ratio with beam sensitivity

- Configure fast camera for high temporal resolution (up to 200 fps)

- For atomic-resolution imaging, employ dose-efficient acquisition modes

Multimodal Data Acquisition

- Acquire high-resolution TEM movies of dynamic restructuring processes

- Perform simultaneous energy-dispersive X-ray spectroscopy (EDS) for elemental mapping

- Collect electron energy loss spectroscopy (EELS) data for chemical state analysis

- Implement four-dimensional scanning TEM (4D-STEM) for strain mapping

Post-reaction Analysis

- Rapidly freeze sample using cryo-transfer capabilities

- Analyze intermediates and transient structures while preserving reaction state

- Correlate TEM findings with complementary operando XAS and Raman data

Data Analysis and Interpretation

- Process large datasets using advanced computer-assisted analysis algorithms

- Reconstruct 3D morphological evolution from 2D image series

- Correlate structural changes with electrochemical performance metrics

- Identify and quantify active site density and distribution

- Differentiate beam-induced artifacts from genuine electrochemical phenomena through control experiments

Complementary Technique Integration

A robust operando study integrates multiple complementary techniques to overcome individual limitations. The multimodal characterization toolbox approach combines operando TEM with XAS, Raman spectroscopy, and mass spectrometry to provide comprehensive insights [11]. This strategy leverages the high spatial and temporal resolution of TEM with the chemical sensitivity of spectroscopic methods, enabling direct correlation between structural dynamics and reaction mechanisms [11].

Critical to this integrated approach is the implementation of systematic control experiments to identify and mitigate potential artifacts. For operando TEM, this includes demonstrating that observed structural changes occur specifically in response to electrochemical stimuli rather than electron beam effects [11]. Similarly, in vibrational spectroscopy, isotope labeling experiments strengthen intermediate identification by producing predictable spectral shifts [1].

Visualization Framework

Conceptual Relationship Diagram

The following diagram illustrates the conceptual relationships and workflow in operando characterization, showing how different techniques contribute to comprehensive catalytic mechanism analysis:

Experimental Workflow for Catalyst Analysis

This diagram outlines a standardized experimental workflow for operando catalyst analysis, integrating multiple techniques to establish comprehensive structure-activity relationships:

Research Toolkit and Essential Materials

Table: Essential Research Reagent Solutions and Materials for Operando Studies

| Reagent/Material | Function/Application | Technical Considerations |

|---|---|---|

| Polymer Electrochemical Cells | Enables atomic-resolution TEM in liquid environments | Membrane thickness critical for resolution; Compatible with cryo-freezing |

| Transition Metal Chalcogenides | Model pre-catalyst systems for OER studies | Undergo surface reconstruction to form active oxyhydroxides |

| Cu and CuAg Nanowires | Model catalysts for CO₂RR studies | Experience segregation, leaching, and alloying during operation |

| Isotope-labeled Reactants (e.g., ¹⁸O, D, ¹³C) | Mechanism verification through predictable spectral shifts | Essential for validating intermediate identification in spectroscopy |

| Nanopipette Probes | Confined electrochemical cells for SECCM | Enable ~20 nm spatial resolution and ~3 ms temporal resolution |

| Beam-transparent Windows | Enable operando characterization in zero-gap reactors | Must maintain reactor integrity while allowing probe transmission |

| Fast Electron Detectors | High-temporal resolution imaging in TEM | Capable of 200 fps acquisition; 11 μs readout times with DED |

| Pervaporation Membranes | Product detection in DEMS | Catalyst deposition directly on membrane reduces response time |

The historical evolution from in-situ to operando characterization has fundamentally transformed catalytic science by enabling direct observation of catalysts under working conditions. This paradigm shift has revealed the dynamic nature of catalytic systems, where surface reconstruction, intermediate formation, and active site evolution collectively determine performance [10] [11]. The operando approach has successfully addressed the materials gap by demonstrating that working catalyst structures often differ dramatically from their pre- or post-reaction states [11].

Future advancements in operando methodology will likely focus on closing remaining gaps in temporal and spatial resolution while improving the multimodal integration of complementary techniques [9] [1]. The handling and interpretation of increasingly large and complex datasets will require advanced computational approaches, including machine learning and artificial intelligence [1] [12]. As these capabilities mature, operando characterization will continue to accelerate the development of more efficient, selective, and stable catalysts for sustainable energy technologies [9] [12].

Establishing Structure-Activity-Selectivity Relationships

Structure-Activity-Selectivity Relationships (SASR) represent a fundamental framework in chemical and pharmaceutical research, enabling the systematic understanding of how a molecule's structure influences its biological activity and binding specificity toward particular targets. Establishing robust SASRs is paramount for rational design of catalysts and therapeutics, allowing researchers to optimize for efficacy while minimizing off-target effects and toxicity [14] [15]. Within modern drug discovery and catalyst development, SASR studies guide the critical path from initial hit identification to optimized lead compounds, providing a roadmap for navigating vast chemical spaces [14] [16].

The integration of operando spectroscopy has revolutionized this field by allowing researchers to characterize catalytic materials and molecular interactions under actual working conditions, simultaneously correlating structural features with activity and selectivity measurements in real-time [9] [8]. This powerful combination enables the direct establishment of structure-property relationships, moving beyond static characterization to capture dynamic reaction intermediates and catalyst evolution that often dictate selectivity patterns [9] [1].

Fundamental Concepts of Structure-Activity-Selectivity Relationships

From SAR to SASR: An Evolving Paradigm

The foundation of SASR lies in Structure-Activity Relationship (SAR) studies, which systematically explore how modifications to a molecule's structure affect its biological activity or catalytic function [15]. The evolution to include selectivity as a core component reflects the growing emphasis in chemical and pharmaceutical research on developing targeted therapies and specific catalysts that minimize side effects and unwanted byproducts [17]. For example, in cyclin-dependent kinase (CDK) inhibitor research, achieving selectivity for specific CDK subtypes (e.g., CDK4/6 versus CDK2) is crucial for developing cancer therapeutics with reduced side effects [17].

Key Structural Determinants of Activity and Selectivity

Multiple structural features collectively determine a compound's biological activity and selectivity profile, with even subtle modifications potentially causing significant changes in performance [16] [15].

Table 1: Key Structural Features Governing Activity and Selectivity

| Structural Feature | Impact on Activity | Influence on Selectivity |

|---|---|---|

| Functional Groups | Directly participate in target binding; affect solubility and stability [16] | Determine interaction specificity with target vs. off-target sites |

| Stereochemistry | Enantiomers may exhibit different therapeutic effects [16] | Chirality can create preferential binding to specific target conformations |

| Molecular Size/Shape | Determines ability to fit into target binding site [16] | Steric hindrance can prevent binding to off-targets with smaller active sites |

| Lipophilicity | Affects membrane permeability and absorption [16] | Differential distribution across tissue types can create functional selectivity |

| Electronic Effects | Influence reactivity and binding affinity through charge distribution [16] | Can preferentially stabilize interactions with specific target residues |

The pharmacophore—the essential molecular framework responsible for biological activity—serves as the structural blueprint for SASR studies [16] [15]. Identifying and characterizing the pharmacophore allows researchers to distinguish features critical for primary activity from those that modulate selectivity [15].

Operando Spectroscopy for SASR Analysis

Principles and Methodologies

Operando spectroscopy has emerged as a transformative methodology for elucidating SASRs by providing real-time characterization of working catalysts and molecular interactions. The term "operando" (Latin for "working") specifically denotes methodologies that combine simultaneous spectroscopic characterization with measurement of catalytic activity and selectivity under realistic reaction conditions [8]. This approach stands in contrast to traditional in situ techniques, which may not maintain authentic reaction environments during characterization [8].

The core principle of operando spectroscopy involves integrating spectroscopic measurement directly into reaction systems, enabling researchers to capture transient intermediates, catalyst restructuring, and reaction dynamics that directly influence selectivity patterns [9] [8]. This capability is particularly valuable for establishing conclusive structure-activity-selectivity relationships that remain relevant under practical operating conditions [1].

Key Operando Techniques for SASR Studies

Multiple spectroscopic techniques have been adapted for operando SASR investigations, each providing unique insights into different aspects of structure-function relationships.

Table 2: Essential Operando Spectroscopy Techniques for SASR Studies

| Technique | Structural Information | Activity/Selectivity Correlation | Applications in SASR |

|---|---|---|---|

| Operando TEM | Morphology, crystal structure, chemical composition at atomic scale [9] | Direct visualization of structural changes during reaction [9] | Catalyst degradation studies; nanoparticle restructuring [9] |

| Operando NMR | Molecular structure, intermediate identification, atomic environment [18] | Real-time monitoring of reaction species and pathways [18] | Electrocatalysis reaction mechanisms [18] |

| Operando XAS | Local electronic structure, oxidation states, coordination geometry [1] | Correlation of electronic structure with product selectivity [1] | Active site characterization during catalytic cycles [1] |

| Operando Vibrational Spectroscopy | Chemical bonding, molecular identity through vibrational fingerprints [1] | Identification of reaction intermediates and surface species [1] | Monitoring reactive intermediates in heterogeneous catalysis [1] |

Experimental Protocols for Establishing SASR

Protocol 1: Integrated Operando TEM for Catalyst SASR

Objective: Characterize structural dynamics of catalytic nanomaterials under working conditions to correlate atomic-scale structural features with activity and selectivity metrics.

Materials and Reagents:

- In Situ TEM Holder: Specialist holder with gas/liquid cell capabilities (e.g., Protochips Atmosphere, DENSsolutions Wildfire) [9]

- Microelectromechanical System (MEMS) Reactor: Chip-based reactor with integrated heating elements and electron-transparent windows [9]

- Mass Spectrometer: For real-time gas analysis and product quantification [9]

- Catalyst Material: Nanoparticle suspensions or pre-fabricated thin-film catalysts [9]

- Reaction Gases/Liquids: High-purity reactants representative of operational conditions [9]

Procedure:

- Catalyst Preparation: Deposit catalyst material onto MEMS reactor, ensuring uniform coverage of heating/imaging area [9].

- Reactor Assembly: Load MEMS reactor into specialized TEM holder following manufacturer protocols for gas/liquid connections [9].

- System Integration: Connect gas/liquid delivery systems and mass spectrometer for simultaneous activity measurement [9].

- Condition Establishment: Introduce reaction media while gradually heating to target temperature, monitoring structural stability [9].

- Data Acquisition: Collect high-resolution TEM images and spectroscopic data (EELS/EDS) simultaneously with mass spectrometry activity data [1].

- Correlation Analysis: Align temporal structural changes with activity/selectivity profiles to identify active sites and deactivation mechanisms [9].

Critical Considerations:

- Beam Effects: Minimize electron dose to reduce beam-induced artifacts that may alter catalyst behavior [9].

- Pressure Gap: Acknowledge limitations in achieving full industrial pressure conditions within TEM vacuum constraints [9].

- Data Correlation: Ensure precise synchronization of spectroscopic and activity data streams for meaningful SASR establishment [1].

Protocol 2: Machine Learning-Driven SASR for Kinase Inhibitors

Objective: Derive quantitative SASR models for cyclin-dependent kinase inhibitors using supervised machine learning approaches to predict selectivity profiles.

Materials and Reagents:

- Chemical Dataset: Curated set of kinase inhibitors with known activity/selectivity profiles (e.g., BindingDB) [17]

- Molecular Descriptor Software: DRAGON, OpenBabel, or equivalent for calculating molecular descriptors [17]

- Machine Learning Platform: KNIME, Python/R with scikit-learn, or specialized tools like MOE [17] [15]

- Model Validation Tools: External test sets, cross-validation frameworks [17]

Procedure:

- Data Curation: Collect and curate molecular structures with associated activity data from public databases (e.g., BindingDB) [17].

- Structure Optimization: Generate 3D molecular structures using Merck Molecular Force Field (MMFF94) with optimization convergence threshold of 10⁻⁶ kcal mol⁻¹ [17].

- Descriptor Calculation: Compute comprehensive molecular descriptor sets (450+ descriptors) including hydrophilicity, total polar surface area, Moriguchi octanol-water partition coefficient [17].

- Feature Selection: Apply Pearson correlation filtering (90% similarity cutoff) to eliminate multicollinear descriptors [17].

- Model Training: Implement Supervised Kohonen Network (SKN) and Counter Propagation Artificial Neural Network (CPANN) models using tenfold cross-validation [17].

- Model Validation: Evaluate prediction accuracy (target: 0.75-0.94 for external test sets) and generate selectivity maps from descriptor space [17].

- Virtual Screening: Apply validated models to screen large compound libraries (e.g., 2 million compounds from PubChem) for novel selective inhibitors [17].

Critical Considerations:

- Data Quality: Rigorously remove duplicates and standardize activity measurements across datasets [17].

- Domain Applicability: Define model applicability domains to identify when predictions remain reliable [14] [17].

- Interpretability: Prioritize models that allow extraction of interpretable structural rules governing selectivity [17].

The Scientist's Toolkit: Essential Research Reagents and Solutions

Table 3: Key Research Reagents and Materials for SASR Studies

| Reagent/Material | Function | Application Examples |

|---|---|---|

| MEMS Reactor Chips | Enable high-resolution imaging under controlled reaction environments [9] | Gas-solid catalysis studies; nanoparticle sintering analysis [9] |

| Specialized TEM Holders | Provide interface between reactor chips and microscope [9] | Operando TEM of catalyst dynamics [9] |

| Molecular Descriptor Packages | Quantify structural and physicochemical properties [17] | QSAR model development; chemical space mapping [17] |

| In Situ Spectroscopy Cells | Allow spectroscopic measurement under reaction conditions [8] [1] | Reaction intermediate identification; active site characterization [8] |

| Mass Spectrometry Interfaces | Enable real-time product analysis during spectroscopic measurement [9] [1] | Product distribution quantification; reaction pathway elucidation [9] |

Case Studies and Applications

Case Study: Selective CDK Inhibitor Development

A comprehensive SASR study analyzed 8,592 small molecules with binding affinities to CDK1, CDK2, CDK4, CDK5, and CDK9 to derive general patterns governing inhibitor selectivity [17]. Using supervised Kohonen networks and molecular descriptors including hydrophilicity and total polar surface area, researchers developed predictive models with accuracies of 0.75-0.94 for external test sets [17]. The resulting selectivity maps identified specific regions in chemical space associated with activity against particular CDK subtypes, enabling rational design of inhibitors with enhanced selectivity profiles [17]. This approach successfully addressed the persistent challenge of achieving CDK selectivity, crucial for developing targeted therapies with minimized side effects [17].

Case Study: Single-Atom Catalyst SASR via Operando Spectroscopy

In heterogeneous catalysis, operando XAS and TEM have been instrumental in establishing SASRs for single-atom catalysts (SACs) in reactions such as CO₂ reduction [19] [1]. These studies revealed how the local coordination environment and electronic structure of metal centers (e.g., Ni, Fe, Co single atoms on carbon supports) dictate product selectivity between CO, formate, and hydrocarbons [19]. By correlating operando XAS measurements of oxidation states with product distribution analysis, researchers identified specific M-Nₓ coordination motifs that favor multi-carbon products through enhanced C-C coupling [19]. These insights guide the rational design of SACs with precisely tuned coordination environments to achieve desired selectivity patterns [19].

Visualization of SASR Workflows

Diagram 1: Integrated SASR Establishment Workflow. This workflow illustrates the iterative process of combining experimental testing with operando spectroscopy to develop predictive SASR models.

Diagram 2: Operando Spectroscopy Experimental Setup. This diagram shows the key components and data flows in a typical operando spectroscopy experiment for SASR studies.

The establishment of robust Structure-Activity-Selectivity Relationships represents a critical advancement in rational design strategies for both pharmaceuticals and catalytic materials. By integrating advanced computational approaches with operando spectroscopic techniques, researchers can now move beyond simple activity optimization to precisely control molecular specificity and reaction pathways. The protocols and methodologies outlined in this application note provide a framework for systematically correlating structural features with functional outcomes under relevant working conditions. As operando techniques continue to evolve with improved temporal and spatial resolution, and machine learning approaches incorporate increasingly sophisticated descriptor sets, the precision and predictive power of SASR models will further accelerate the development of highly selective catalysts and therapeutics. The iterative cycle of computational prediction, synthetic implementation, and operando validation represents a powerful paradigm for navigating complex chemical spaces toward optimized functional molecules.

The rational design of high-performance catalysts is a cornerstone of the modern energy transition and sustainable chemical production. For decades, catalyst development often relied on trial and error or the discovery of fortuitous "lucky catalysts," leaving a critical knowledge gap in our understanding of their actual functioning mechanisms [20]. Traditional characterization methods, which analyze catalysts under static, ex-situ conditions, provide limited insight because catalyst structure is dynamic; it can transform dramatically when exposed to reaction temperatures, pressures, and chemical environments [8] [21]. This discrepancy between a catalyst's rest state and its working state creates a fundamental barrier to progress.

Operando spectroscopy bridges this gap. The term "operando," derived from Latin for "working," defines an analytical methodology that combines the simultaneous measurement of spectroscopic data from a catalyst under realistic working conditions with real-time monitoring of its catalytic activity and selectivity [8]. This powerful approach allows researchers to construct precise structure-activity relationships, moving beyond static snapshots to observe the dynamic behavior of active sites, identify reaction intermediates, and unravel complex reaction pathways as they occur [22] [21]. Ultimately, this detailed mechanistic understanding is the key to engineering a new generation of catalysts with optimized efficiency, selectivity, and stability for applications from renewable energy to pharmaceutical synthesis [23].

The Operando Methodology

Defining the Approach

Operando spectroscopy is more than a single technique; it is a class of methodology that integrates multiple analytical approaches. Its core principle is the simultaneous correlation of catalyst structure with function. As defined by the scientific community, an operando experiment must meet two key criteria: first, the spectroscopic characterization of the catalyst must be performed under conditions that closely mimic the true industrial or operational environment (e.g., high temperature, pressure, in the presence of reactants). Second, the catalytic activity and selectivity must be measured online and at the same time [8] [21].

This differentiates operando from simpler in situ studies. While in situ (Latin for "in position") techniques also analyze a catalyst under simulated reaction conditions, they often lack the simultaneous activity measurement or are conducted in reactor cells that cannot maintain the necessary kinetic conditions for a realistic assessment [8]. The operando methodology was formally coined in the catalytic literature in 2002 and has since become the gold standard for mechanistic investigation, with dedicated international conferences cementing its importance in the field [8].

The Critical Need: From Static Snapshots to Dynamic Motion Pictures

Catalyst scientists have long desired a "motion picture" of each catalytic cycle, revealing the precise bond-making and bond-breaking events at the active site [8]. Operando spectroscopy makes this goal attainable. The critical need for this approach arises from several key limitations of conventional methods:

Dynamic Nature of Active Sites: The active phase of a catalyst is frequently not the one observed at room temperature before the reaction starts. It can undergo chemical and structural transformations—such as changes in oxidation state, coordination environment, or crystallographic phase—under the influence of the reaction medium [21]. Operando methods are designed to detect these transient states.

Identification of True Intermediates: Many proposed reaction mechanisms are based on theoretical intermediates that may not be stable or abundant under real conditions. Operando spectroscopy, particularly time-resolved techniques, can monitor the formation and disappearance of intermediate species on the catalyst surface in real-time, providing direct evidence for or against a proposed pathway [8].

Bridging the "Materials Gap": There is often a significant disparity between laboratory test conditions and industrial reactor environments. Operando methodology aims to minimize this compromise, allowing for spectroscopic investigation under conditions that are physically and chemically relevant to industrial application [8] [21]. Without this, insights gained may be academically interesting but lack practical utility for catalyst design.

Key Operando Techniques and Experimental Protocols

The choice of operando technique depends on the specific catalytic system and the information required. The most common and informative techniques are summarized below, with detailed protocols for implementation.

Table 1: Key Operando Spectroscopy Techniques and Their Primary Applications

| Technique | Acronym | Primary Information Obtained | Ideal For |

|---|---|---|---|

| X-Ray Absorption Spectroscopy | XAS | Local electronic structure, oxidation state, coordination geometry | Probing active metal centers in heterogeneous catalysts |

| Vibrational Spectroscopy (IR & Raman) | IR, Raman | Molecular fingerprints, identity of surface species and intermediates | Tracking reaction pathways and adsorbed species |

| Electrochemical Mass Spectrometry | EC-MS | Real-time product evolution and quantification | Coupling electrochemical reactions with product analysis |

| X-Ray Diffraction | XRD | Crystalline phase, long-range order, structural evolution | Monitoring phase changes under reaction conditions |

Protocol: Operando X-Ray Absorption Spectroscopy (XAS)

Objective: To determine the changes in the oxidation state and local coordination environment of a metal active site during catalytic operation.

Materials and Reactor Design:

- Reactor Cell: A dedicated in situ/operando cell capable of withstanding reaction temperatures and pressures, equipped with X-ray transparent windows (e.g., Kapton, Be).

- Catalyst: A thin, uniform wafer of the powdered catalyst to ensure proper X-ray transmission.

- Gas Delivery System: For controlled introduction of reactants and inert gases.

- Online Analyzer: A mass spectrometer (MS) or gas chromatograph (GC) connected to the reactor effluent stream to measure activity/selectivity simultaneously [8] [21].

Procedure:

- Calibration: Record a reference XAS spectrum of the catalyst in a known state (e.g., fully oxidized) at room temperature.

- Conditioning: Activate the catalyst inside the operando cell under a specified gas flow and temperature.

- Data Acquisition: Initiate the catalytic reaction by introducing the reactant feed.

- Simultaneous Measurement:

- Continuously collect XAS spectra (XANES and EXAFS regions) at the absorption edge of the metal of interest.

- Simultaneously, use the online MS/GC to quantify reactants and products in the effluent gas stream.

- Data Correlation: Align the spectroscopic data (e.g., edge energy shift in XANES for oxidation state, Fourier transform of EXAFS for coordination) with the catalytic activity data on a common time axis [8] [21].

Pitfalls to Avoid:

- Self-Absorption: Using too thick a catalyst sample can distort the XAS signal.

- Mass Transport Limitations: The cell design must allow for efficient reactant flow to avoid concentration gradients that distort activity measurements [21].

Protocol: Operando Vibrational Spectroscopy (Raman/IR)

Objective: To identify molecular species and intermediates adsorbed on the catalyst surface during the reaction.

Materials and Reactor Design:

- Reactor Cell: A cell with optical windows transparent to the relevant light source (quartz for UV-Vis/Raman, IR-transparent salt crystals like CaF2 for IR).

- Probe Integration: For Raman, a fiber-optic probe can be inserted directly into the reactor. For IR, the beam must pass through the catalyst bed and windows.

- Online Analyzer: MS or GC for activity correlation.

Procedure:

- Background Collection: Acquire a background spectrum of the catalyst under inert atmosphere at reaction temperature.

- Reaction Initiation: Introduce the reactant stream to start the catalytic reaction.

- Simultaneous Measurement:

- Collect sequential Raman or IR spectra with a high signal-to-noise ratio.

- Record the corresponding product composition data from the online analyzer.

- Spectral Analysis: Identify new absorption/emission bands, track their intensity over time, and assign them to specific molecular vibrations of surface species [8].

- Isotope Labeling (Advanced Validation): Repeat the experiment with isotopically labeled reactants (e.g., ¹⁸O₂, ¹³CO). A shift in the vibrational frequency of the observed intermediates confirms their assignment and involvement in the reaction pathway [21].

Pitfalls to Avoid:

- Laser-Induced Heating: In Raman spectroscopy, high-power lasers can locally overheat the catalyst sample. Power must be carefully controlled and its effect quantified [8].

- Gas Phase Interference: In IR spectroscopy, signals from the gas phase can obscure surface signals. Use of diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) can mitigate this [8].

Experimental Design and Workflow

A successful operando study requires meticulous planning and an integrated workflow that connects reactor design, multi-modal characterization, and data interpretation. The following diagram illustrates the core logical workflow for designing and executing an operando spectroscopy study.

The Quintessence of Reactor Design

The operando reactor is not merely a container; it is the central instrument that must satisfy often conflicting requirements. Its design is paramount to obtaining accurate and realistic data [22] [21].

Key Design Considerations:

- Optimal Environment: The cell must maintain the precise temperature, pressure, and flow conditions of a real catalytic process while providing access for a spectroscopic beam or probe [8].

- Mass Transport: A common pitfall is poor mass transport in operando cells compared to industrial reactors. This can create concentration and pH gradients at the catalyst surface, leading to misinterpretation of intrinsic reaction kinetics. Designs that enable convective flow, such as those mimicking gas diffusion electrodes, are superior to simple batch cells [21].

- Minimized Dead Volume: To capture short-lived intermediates, the path between the reaction event and the analytical detector (e.g., the mass spectrometer) must be as short as possible. Advanced designs deposit the catalyst directly onto the detection membrane to achieve millisecond response times [21].

- Probe Compatibility: Windows must be transparent to the specific probe (X-ray, IR, visible light), and the cell geometry must allow for an adequate signal-to-noise ratio. For example, in grazing-incidence X-ray diffraction, the incident beam's path through the electrolyte must be minimized to prevent signal attenuation [21].

The Scientist's Toolkit: Essential Research Reagent Solutions

Implementing operando spectroscopy requires specialized instruments and materials. The following table details key components and their functions in a typical operando experiment.

Table 2: Essential Research Reagent Solutions for Operando Studies

| Item Category | Specific Examples | Function in Operando Experiment |

|---|---|---|

| Spectroscopic Systems | XAS Beamline Setup; Confocal Raman Micro-spectrometer; FTIR Spectrometer | Provides the primary probe for analyzing catalyst structure and surface species under reaction conditions. |

| Online Activity Monitors | Mass Spectrometer (MS); Gas Chromatograph (GC) | Quantifies reaction products and conversion in real-time, enabling direct correlation with spectroscopic data. |

| Operando Reactor Cells | High-Temperature/Pressure In-Situ Cells; Electrochemical Flow Cells | The core platform that houses the catalyst, maintains reaction conditions, and interfaces with spectroscopic probes and analyzers. |

| Catalyst Samples | Metal Hydrides; Oxide-derived Nanocatalysts; Zeolites | The functional material under investigation, often prepared as thin wafers or coated onto specialized substrates. |

| Reactive Gases & Isotopes | CO₂, H₂, O₂; ¹³CO, ¹⁸O₂ | Serve as reactants. Isotopically labeled compounds are used to validate the identity and role of reaction intermediates. |

Operando spectroscopy has fundamentally transformed our approach to understanding and designing catalysts. By moving beyond static characterization to observe dynamic catalyst behavior under working conditions, this methodology provides the critical insights needed to establish robust structure-activity relationships. The future of operando lies in the development of more sophisticated multi-modal instruments that combine multiple spectroscopic techniques simultaneously, the integration of advanced data analysis and machine learning to handle complex datasets, and the continued innovation in reactor design to further close the gap between laboratory analysis and real-world industrial conditions [22] [21]. As these tools and protocols become more accessible, they will undoubtedly accelerate the development of the high-efficiency, selective, and sustainable catalysts required for the global energy transition and a greener chemical industry因地制宜.

A Practical Guide to Operando Techniques: From Reactor Design to Real-World Applications

Operando spectroscopy represents a paradigm shift in catalytic science, referring to a class of analytical techniques that monitor catalysts under actual working conditions while simultaneously measuring their activity and selectivity [24]. This approach provides direct correlation between a catalyst's physicochemical state and its performance, enabling researchers to move beyond static ex-situ characterizations that often fail to capture dynamic structural changes occurring during catalytic processes [21]. The fundamental principle of operando methodology bridges the gap between fundamental characterization and practical performance, allowing researchers to identify true active sites, detect transient reaction intermediates, and understand deactivation mechanisms [13] [24]. For researchers investigating catalytic mechanisms—particularly in energy conversion systems like fuel cells, electrolyzers, and synthetic fuel production—mastering this toolkit is essential for rational catalyst design.

The distinction between in-situ and operando techniques is crucial for proper experimental design. In-situ techniques are performed on a catalytic system under simulated reaction conditions (elevated temperature, applied voltage, solvent presence), while operando techniques require both simulated conditions and simultaneous measurement of catalytic activity [21]. This simultaneous correlation provides the critical link between molecular-level structural information and macroscopic catalytic performance metrics.

Comparative Analysis of Spectroscopic Techniques

Table 1: Key Operando Spectroscopic Techniques for Catalytic Research

| Technique | Key Applications in Catalysis | Spatial Resolution | Time Resolution | Key Measurable Parameters | Key Limitations |

|---|---|---|---|---|---|

| XAS | Electronic structure, oxidation state, local coordination [24] | Bulk-sensitive | Seconds to milliseconds [25] | Oxidation state, coordination geometry, interatomic distances | Requires synchrotron source; complex data analysis |

| XPS | Surface composition, chemical states, elemental composition [24] | Surface (0-10 nm) [24] | Minutes | Elemental composition, chemical state, oxidation state | Requires UHV; complex cell design for electrochemical studies |

| Raman | Molecular vibrations, adsorbate identification, phase transitions [26] [27] | ~1 μm | Sub-second [27] | Adsorbate identity (CO, OH), surface oxidation states, coke formation | Fluorescence interference; weak signal intensity |

| IR | Molecular vibrations, surface intermediates, reaction mechanisms [13] | ~10-100 μm | Milliseconds to seconds | Reaction intermediates, surface species, functional groups | Strong solvent absorption; limited surface sensitivity |

| UV-Vis | Electronic transitions, redox states, reaction kinetics [4] [28] | Bulk-sensitive | Milliseconds [4] | Redox states, electronic structure, reaction kinetics | Primarily bulk information; overlapping features |

Table 2: Optimal Application Domains for Operando Techniques

| Technique | Electrocatalysis | Thermocatalysis | Photocatalysis | Battery Research |

|---|---|---|---|---|

| XAS | Excellent (Oxidation state changes under potential control) [25] | Excellent (High-temperature cells available) | Good | Excellent (Charge compensation mechanisms) |

| XPS | Challenging (Requires special electrochemical cells) [24] | Good (AP-XPS available) | Limited | Limited |

| Raman | Excellent (Surface adsorbate tracking) [27] | Excellent (Coke formation studies) [26] | Excellent | Good (Phase transformation studies) |

| IR | Excellent (Aqueous-compatible setups) | Excellent (Probe molecules) | Good | Limited |

| UV-Vis | Excellent (Redox process kinetics) [4] [28] | Good | Excellent (Charge carrier dynamics) | Good (State-of-charge monitoring) |

Experimental Protocols & Methodologies

Protocol 1: Operando X-ray Absorption Spectroscopy (XAS)

Principle: XAS measures element-specific absorption coefficients as a function of incident X-ray energy, providing information about oxidation states and local coordination environments [24]. The technique is particularly valuable for tracking changes in the electronic and geometric structure of catalytic active sites under working conditions [25].

Experimental Setup:

- Cell Design: Utilize a custom-designed electrochemical cell with X-ray transparent windows (e.g., Kapton film). For fuel cell studies, employ specialized membrane electrode assembly (MEA) cells with X-ray transparent current collectors [25].

- Detection Mode: For concentrated samples (>1-5% target element), transmission mode is preferred. For dilute systems or thin films, fluorescence detection mode provides better signal-to-noise [24] [25].

- Synchronization: Implement potential/current control synchronized with XAS data acquisition to correlate structural changes with electrochemical states [25].

- Reference Standards: Collect spectra of well-characterized reference compounds with known oxidation states and coordination geometries for energy calibration and linear combination analysis.

Data Analysis Workflow:

- Energy Alignment: Align spectra using a reference foil (e.g., Mn foil for Mn K-edge) collected simultaneously.

- Background Subtraction: Remove pre-edge background using a linear or polynomial function.

- Normalization: Normalize the post-edge region to unity absorption.

- EXAFS Fourier Transform: Convert k-space data to R-space to obtain pair distribution functions.

- Fitting: Fit the EXAFS region using theoretical standards to extract coordination numbers, interatomic distances, and disorder parameters.

Key Applications in Catalysis:

- Tracking potential-dependent oxidation state changes in Mn spinel oxides during oxygen reduction reaction (ORR) [25]

- Identifying the active state of Co and Mn oxides in anion exchange membrane fuel cells [25]

- Monitoring structural transformations in Cu-based catalysts during CO2 electroreduction [27]

Protocol 2: Operando Raman Spectroscopy

Principle: Raman spectroscopy measures inelastic scattering of monochromatic light, providing information about molecular vibrations that can identify chemical species, including surface adsorbates and catalyst phases [26] [27].

Experimental Setup:

- Excitation Source: Select appropriate laser wavelength (e.g., 532 nm, 785 nm) to balance signal intensity and fluorescence minimization. UV lasers (e.g., 325 nm) can avoid fluorescence in carbonaceous materials [26].

- Electrochemical Cell: Utilize a three-electrode configuration with a Raman-transparent window (e.g., CaF2, quartz). Ensure working electrode is positioned close to the window for optimal signal collection [27].

- Time-Gating Implementation: For fluorescent samples, employ time-gated detection with pulsed lasers and CMOS-SPAD detectors to suppress fluorescence based on its slower time dynamics compared to Raman scattering [26].

- Synchronization: Synchronize potential control with spectral acquisition for time-resolved studies during pulsed electrolysis [27].

Data Collection Parameters:

- Spectral Range: Typically 200-2000 cm⁻¹ for catalyst and adsorbate studies

- Integration Time: 0.1-2 seconds for time-resolved studies [27]

- Laser Power: 1-10 mW at sample to minimize laser-induced degradation

- Spectral Resolution: 4-8 cm⁻¹ for most catalytic applications

Key Applications in Catalysis:

- Tracking OH and CO adsorbates on Cu surfaces during pulsed CO2 electroreduction [27]

- Monitoring coke formation on Pt-Sn catalysts during propane dehydrogenation [26]

- Identifying surface oxidation states of Cu catalysts through Cu-O vibration modes [27]

Protocol 3: Operando UV-Vis Spectroelectrochemistry

Principle: UV-Vis spectroelectrochemistry measures electronic transitions in materials under potential control, providing information about redox states, reaction intermediates, and kinetics [4] [28].

Experimental Setup:

- Cell Configuration: Use a thin-layer spectroelectrochemical cell with optically transparent electrodes (e.g., FTO, ITO, or mesostructured semiconductor films) [4] [28].

- Optical Path: Implement short path lengths (<1 mm) for transmission measurements to minimize solvent absorption [28].

- Synchronization: Employ high-speed potentiostat-software communication for simultaneous spectral and electrochemical data acquisition [4].

- Detection System: Utilize high-sensitivity CCD or CMOS detectors with high dynamic range for capturing subtle spectral changes [4].

Quantitative Analysis Methods:

- Differential Coulometric Attenuation: Formalize spectral changes relative to charge passed to extract redox stoichiometries [4].

- Kinetic Modeling: Apply population models to time-resolved spectral data to extract rate constants for catalytic steps [28].

- Multivariate Analysis: Use principal component analysis or multivariate curve resolution to deconvolute overlapping spectral features from multiple species.

Key Applications in Catalysis:

- Quantifying accumulation of reactive species at catalyst-electrolyte interfaces [28]

- Characterizing kinetics of rate-determining steps in (photo)electrocatalysis [28]

- Tracking charge carrier dynamics in semiconductor photocatalysts [4]

Experimental Workflow Integration

Diagram 1: Integrated workflow for operando spectroscopic investigation of catalytic mechanisms

Research Reagent Solutions & Essential Materials

Table 3: Essential Research Reagents and Materials for Operando Spectroscopy

| Material/Reagent | Function/Application | Key Considerations |

|---|---|---|

| X-ray Transparent Windows (Kapton, SiNx) | Allows X-ray transmission in XAS and XPS cells [25] | Thickness optimization for signal transmission vs. pressure resistance |

| Optically Transparent Electrodes (FTO, ITO) | Working electrodes for UV-Vis and Raman spectroelectrochemistry [28] | Surface roughness affects signal quality; conductivity vs. transparency trade-offs |

| Ion-Exchange Membranes (Nafion, AEM) | Separator in electrochemical cells mimicking device conditions [25] | Chemical compatibility with electrolyte and operating conditions |

| Potentiostat/Galvanostat | Applied potential/current control with spectroscopic synchronization [4] | Fast response time for pulsed experiments; software synchronization capabilities |

| Synchrotron Radiation Source | High-brightness X-rays for XAS and XPS [24] | Limited access through proposal systems; energy tunability requirements |

| Time-Gated Detectors (CMOS-SPAD) | Fluorescence rejection in Raman spectroscopy [26] | Time resolution (<1 ns) critical for effective fluorescence suppression |

| Reference Compounds (Metal Foils, Oxides) | Energy calibration and reference spectra for XAS [25] | High purity essential for accurate calibration |

| Isotope-Labeled Reactants (13CO, D2O) | Mechanism elucidation through vibrational frequency shifts [27] | Cost considerations; isotopic purity effects on interpretation |

Advanced Technical Considerations

Reactor Design Best Practices

Proper reactor design is paramount for meaningful operando studies, as poorly designed cells can lead to erroneous conclusions. Key considerations include: