Optimizing Biocatalysis: A CFD Modeling Guide for Mass Transfer in Enzymatic Bioreactors

This article provides a comprehensive guide to Computational Fluid Dynamics (CFD) modeling of mass transfer in enzymatic bioreactors, tailored for researchers and process engineers.

Optimizing Biocatalysis: A CFD Modeling Guide for Mass Transfer in Enzymatic Bioreactors

Abstract

This article provides a comprehensive guide to Computational Fluid Dynamics (CFD) modeling of mass transfer in enzymatic bioreactors, tailored for researchers and process engineers. We explore the fundamental coupling of fluid dynamics, reaction kinetics, and enzyme deactivation. A detailed methodology for implementing Eulerian-Lagrangian and porous media approaches is presented, followed by strategies for diagnosing and mitigating common mass transfer limitations. The guide concludes with validation techniques and a comparative analysis of reactor configurations (e.g., stirred-tank, packed-bed, membrane reactors), highlighting how validated CFD models serve as powerful tools for scaling up enzymatic processes in pharmaceutical and biochemical manufacturing.

The Core Physics of Enzymatic Bioreactors: Why Mass Transfer is the Critical Bottleneck

Within the context of advancing CFD modeling of mass transfer in enzymatic bioreactors, this application note details the critical interplay between hydrodynamics, reaction kinetics, and interphase mass transfer. Optimizing this triad is essential for scaling up enzymatic processes for pharmaceutical synthesis, where precise control over product yield and purity is paramount.

Core Principles & Quantitative Data

The performance of an enzymatic stirred-tank bioreactor (STR) is governed by the interdependence of three factors. The table below summarizes key parameters and their typical ranges for a model cellulase-based hydrolysis system.

Table 1: Key Parameters Governing Bioreactor Performance Triad

| Domain | Parameter | Symbol | Typical Range (Example: Cellulase System) | Impact on Performance |

|---|---|---|---|---|

| Hydrodynamics | Impeller Reynolds Number | Re | 10⁴ - 10⁵ (Turbulent) | Determines mixing quality & shear environment. |

| Hydrodynamics | Power Input per Unit Volume | P/V | 0.5 - 2.0 kW/m³ | Affects bubble dispersion & particle suspension. |

| Kinetics | Michaelis Constant | Kₘ | 1 - 10 g/L (for substrate) | Enzyme-substrate affinity. Lower = higher affinity. |

| Kinetics | Turnover Number | kₐₜ | 10 - 100 s⁻¹ | Maximum catalytic rate per enzyme molecule. |

| Mass Transfer | Volumetric Mass Transfer Coefficient | kₗa (O₂) | 10 - 200 h⁻¹ | Capacity for oxygen supply (critical for oxidative enzymes). |

| Mass Transfer | Liquid-Solid Mass Transfer Coefficient | kₛ | 1x10⁻⁵ - 1x10⁻⁴ m/s | Rate of substrate transport to immobilized enzyme. |

| Integrated | Damköhler Number (Type II) | Da | Ratio of reaction rate to mass transfer rate | Da >> 1: Mass transfer limited; Da << 1: Kinetically limited. |

Experimental Protocols

Protocol 1: Determination of Volumetric Mass Transfer Coefficient (kₗa) via Dynamic Gassing-Out Method

Application: Quantifying oxygen transfer capability in aerated enzymatic bioreactors.

Materials:

- Bioreactor system with dissolved oxygen (DO) probe, air sparger, and nitrogen supply.

- Data acquisition system.

- Buffer solution (e.g., 0.1 M phosphate buffer, pH as per enzyme optimum).

Procedure:

- Calibration: Calibrate the DO probe at 0% (sparge with N₂) and 100% saturation (sparge with air at operating conditions).

- Deoxygenation: Sparge the vessel filled with buffer at the working volume with pure nitrogen. Monitor DO until it reaches a steady state near 0%.

- Re-aeration: Switch the gas supply from N₂ to air at the desired flow rate (Q₉) while maintaining constant agitation speed (N). Record the increase in DO (% saturation) over time until a new steady state (C*) is reached.

- Data Analysis: Plot ln[(C* - C)/(C* - C₀)] versus time (t), where C is DO at time t and C₀ is DO at t=0. The slope of the linear region is equal to kₗa.

Protocol 2: Characterizing Enzyme Kinetics under Bioreactor Shear Conditions

Application: Measuring intrinsic kinetic parameters (Vₘₐₓ, Kₘ) in a simulated hydrodynamic environment.

Materials:

- Enzyme of interest (e.g., free or immobilized lipase).

- Substrate solution at varying concentrations.

- Bioreactor or well-controlled stirred vessel.

- Offline analytical method (e.g., HPLC, spectrophotometer).

Procedure:

- Reactor Setup: Fill the bioreactor with buffer at controlled temperature and pH.

- Shear Pre-exposure: Add the enzyme preparation. Subject it to the target agitation speed (N) for a defined pre-exposure period (e.g., 30 min) without substrate to simulate shear history.

- Kinetic Assay: Initiate the reaction by adding a concentrated substrate stock to achieve the desired initial concentration ([S]₀). Sample the reaction mixture at frequent intervals.

- Analysis: For each [S]₀, determine the initial reaction velocity (v₀). Fit the resulting v₀ vs. [S]₀ data to the Michaelis-Menten model (e.g., using Lineweaver-Burk or nonlinear regression) to extract Vₘₐₓ and Kₘ.

- Comparison: Repeat at different agitation speeds to assess the impact of hydrodynamics (shear) on apparent kinetic constants.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Triad Analysis

| Item | Function & Relevance |

|---|---|

| Dissolved Oxygen Probe (Clark-type) | Critical for direct in-situ measurement of oxygen levels, essential for determining kₗa and monitoring aerobic enzymatic processes. |

| Computational Fluid Dynamics (CFD) Software (e.g., ANSYS Fluent, COMSOL) | Enables virtual modeling of hydrodynamic flow fields, shear stress distribution, and species concentration gradients to predict kₗa and mixing times. |

| Immobilized Enzyme Carriers (e.g., ECR8305 Epoxy-Activated Resin) | Provides a solid support for enzyme immobilization, facilitating catalyst reuse and altering liquid-solid mass transfer dynamics. |

| Particle Image Velocimetry (PIV) System | Allows non-invasive, experimental measurement of velocity fields within transparent bioreactor models to validate CFD simulations. |

| Tracer Dyes (e.g., Fluorescein, Rhodamine) | Used in residence time distribution (RTD) studies to characterize macro-mixing and flow patterns in bioreactors. |

Visualizations

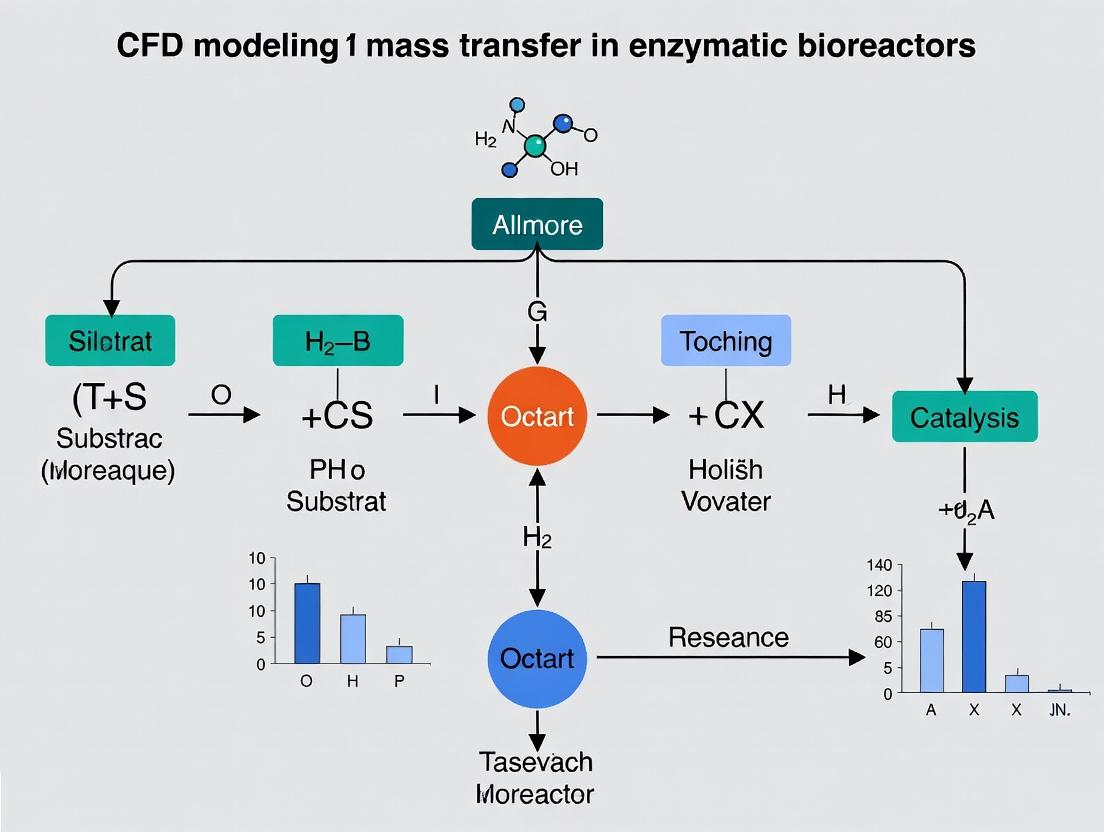

Diagram Title: Interdependence of the Bioreactor Performance Triad

Diagram Title: Dynamic Method for kLa Measurement Workflow

In Computational Fluid Dynamics (CFD) modeling of enzymatic bioreactors, the accurate prediction of mass transfer from bulk fluid to immobilized enzyme surfaces is critical for predicting reaction rates and scaling up processes. This performance is characterized by dimensionless numbers: the Sherwood (Sh), Schmidt (Sc), and Reynolds (Re) numbers. These parameters link hydrodynamic conditions, fluid properties, and mass transfer coefficients, forming the cornerstone of reactor design and optimization in drug development, such as in the production of monoclonal antibodies or enzyme-catalyzed pharmaceutical intermediates.

Theoretical Framework & Quantitative Data

The relationship between these numbers is often expressed through correlations of the form: Sh = f(Re, Sc).

Table 1: Key Dimensionless Numbers in Mass Transfer

| Parameter | Symbol | Formula | Physical Interpretation | Typical Range in Stirred Enzymatic Bioreactors |

|---|---|---|---|---|

| Reynolds Number | Re | Re = (ρ u L) / μ | Ratio of inertial to viscous forces. Characterizes flow regime. | 1,000 - 100,000 (Turbulent) |

| Schmidt Number | Sc | Sc = μ / (ρ D_AB) | Ratio of momentum diffusivity to mass diffusivity. Compares fluid and species transport properties. | 100 - 100,000 (Liquids) |

| Sherwood Number | Sh | Sh = (k_L L) / D_AB | Ratio of convective to diffusive mass transfer. Represents the normalized mass transfer coefficient. | 1 - 10,000+ |

Table 2: Common Empirical Correlations for Particle-Liquid Systems

| Correlation | Formula | Applicability | Key Variables |

|---|---|---|---|

| Ranz-Marshall (Sphere) | Sh = 2 + 0.6 Re^(1/2) Sc^(1/3) | Flow past a single spherical particle (e.g., immobilized enzyme bead). | Re based on particle diameter. |

| Frössling Correlation | Sh = 2 + 0.552 Re^(0.5) Sc^(0.33) | Similar application, widely used for gas/liquid or solid/liquid systems. | - |

| Correlation for Packed Beds | Sh = (0.35 + 0.34 Re^(0.5) + 0.15 Re^(0.58)) Sc^(0.33) | Fixed-bed enzymatic reactors. | Re based on particle diameter and superficial velocity. |

Experimental Protocols for Parameter Determination

Protocol 3.1: Determining the Mass Transfer Coefficient (k_L) and Sherwood Number via Dissolution of a Benzoic Acid Coated Particle

Objective: To experimentally determine the liquid-side mass transfer coefficient (k_L) and calculate the Sherwood number for a model particle in a stirred tank, simulating an immobilized enzyme carrier.

Materials: See The Scientist's Toolkit below. Procedure:

- Particle Preparation: Coat a non-porous, spherical particle (e.g., alumina sphere of known diameter, d_p) with a thin, uniform layer of benzoic acid. Measure and record the exact initial mass (m_0).

- Reactor Setup: Fill a calibrated stirred-tank bioreactor with a known volume (V) of distilled water. Control temperature at 25°C ± 0.5°C using a circulating water jacket.

- Hydrodynamic Calibration: Set the impeller speed (N) to a desired value. Calculate the impeller Reynolds number: Re = (ρ N d_i^2) / μ, where d_i is impeller diameter.

- Dissolution Experiment: a. Submerge the coated particle in the reactor, ensuring it is fixed in a location representative of bulk flow (e.g., suspended via a thin wire in the impeller stream). b. Initiate dissolution by starting the impeller. Record the start time (t=0). c. At regular time intervals (e.g., every 30 seconds for 10 minutes), take a 5 mL sample and analyze it for benzoate concentration via UV spectrophotometry at 274 nm. d. Construct a calibration curve of absorbance vs. concentration using benzoic acid standards.

- Data Analysis: a. Plot concentration vs. time. The initial slope (dC/dt) is used, as mass transfer is limiting. b. Calculate k_L from the mass balance: dC/dt = (k_L A (C_s - C_b)) / V, where A is particle surface area, C_s is surface saturation concentration (from literature), and C_b is bulk concentration (approximated as zero initially). c. Calculate Sh using the particle diameter as the characteristic length (L): Sh = (k_L d_p) / D_AB. The diffusivity (D_AB) of benzoic acid in water at 25°C is 1.21 x 10⁻⁹ m²/s.

- Replication: Repeat at different impeller speeds (Reynolds numbers) to generate data for a Sh vs. Re correlation.

Protocol 3.2: Validating CFD Model Predictions Against ExperimentalSh

Objective: To use experimentally derived Sh numbers to validate a multiphase CFD model of the bioreactor. Procedure:

- CFD Model Setup: Create a 3D geometry of the experimental bioreactor. Use an Eulerian-Lagrangian framework to model fluid flow and particle tracking.

- Simulation: Run transient simulations at the same Re values as the experiment. Use a species transport model to simulate benzoic acid dissolution.

- Extraction of Simulated k_L: From the simulation, extract the flux of benzoic acid from the particle surface and the average bulk concentration. Calculate the simulated k_L.

- Validation: Calculate simulated Sh numbers. Plot experimental vs. simulated Sh as a function of Re. Statistical analysis (e.g., MAPE < 15%) validates the model's mass transfer prediction capability.

Visualization: Workflow for CFD-Driven Mass Transfer Analysis

Diagram Title: Workflow for CFD Mass Transfer Model Validation

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Mass Transfer Experiments

| Item | Function/Brief Explanation |

|---|---|

| Benzoic Acid (ACS Grade) | Model solute for dissolution studies. High purity ensures accurate concentration measurements. |

| Non-porous Alumina Spheres (Precise diameter) | Inert, model particles for coating. Provide consistent, known surface area. |

| UV-Vis Spectrophotometer & Cuvettes | For quantitative analysis of benzoic acid concentration in solution via absorbance at 274 nm. |

| Temperature-Controlled Stirred-Tank Bioreactor (Baffled) | Provides a well-mixed, controlled hydrodynamic environment for experiments. Baffles prevent vortex formation. |

| Precision Impeller Speed Controller | Accurately sets and maintains the impeller rotational speed (RPM), defining the system's Reynolds number. |

| Computational Fluid Dynamics (CFD) Software (e.g., ANSYS Fluent, COMSOL) | Platform for creating and solving the numerical model of fluid flow and mass transfer. |

| Species Diffusivity Database (e.g., NIST) | Source for accurate diffusion coefficient (D_AB) values needed for calculating Sc and Sh. |

| Digital pH/Conductivity Meter | May be used as an alternative or supplementary method to track dissolution progress. |

Coupling Reaction Kinetics (Michaelis-Menten) with Transport Phenomena

This protocol details the integration of Michaelis-Menten enzyme kinetics with mass transport fundamentals, essential for developing accurate computational fluid dynamics (CFD) models of enzymatic bioreactors. In drug development, such as for monoclonal antibody production or enzymatic synthesis of active pharmaceutical ingredients (APIs), the local substrate concentration at the enzyme's active site is governed not just by bulk fluid concentration but by convective and diffusive transport. A purely kinetic model fails to predict performance at scale. These application notes provide the experimental framework to quantify the coupled kinetics-transport phenomena, generating critical input parameters for multiphysics CFD simulations.

Core Quantitative Data: Kinetic & Transport Parameters

The following tables summarize key parameters required to couple kinetics with transport models. Representative values from recent literature are provided.

Table 1: Representative Michaelis-Menten Parameters for Enzymes in Bioprocessing

| Enzyme (Example) | Substrate | kcat (s⁻¹) | Km (mM) | Optimal pH | Optimal Temp (°C) | Reference Year |

|---|---|---|---|---|---|---|

| Glucose Oxidase | D-Glucose | 800 - 1200 | 20 - 35 | 5.5 | 30-35 | 2023 |

| Lipase (Candida rugosa) | p-NPP | 4500 | 0.15 | 7.5 | 37 | 2022 |

| L-Asparaginase (Therapeutic) | L-Asparagine | 350 | 0.015 | 7.4 | 37 | 2023 |

| β-Galactosidase | ONPG | 400 | 0.11 | 7.3 | 37 | 2024 |

| Transglutaminase | CBZ-Gln-Gly | 95 | 1.8 | 6.0 | 50 | 2022 |

Table 2: Key Transport & System Parameters for Immobilized Enzyme Bioreactors

| Parameter | Symbol | Typical Range | Unit | Measurement Method |

|---|---|---|---|---|

| Effective Diffusivity in Carrier | D_e | 1x10⁻¹¹ – 1x10⁻⁹ | m²/s | Uptake/Pulsed Field Gradient NMR |

| Film Mass Transfer Coefficient | k_L | 1x10⁻⁵ – 1x10⁻³ | m/s | Limiting Current Technique |

| Catalyst Particle Radius | R_p | 50 – 500 | μm | Laser Diffraction (PSD) |

| Bed Porosity (Packed Bed) | ε_b | 0.3 – 0.5 | - | Pycnometry |

| Tortuosity | τ | 1.5 – 4.0 | - | Calculated from De / DAB |

Experimental Protocols

Protocol 3.1: Determining Intrinsic Kinetics & Effectiveness Factor

Objective: To measure the true Michaelis-Menten parameters (kcat, Km) free from mass transfer limitations and subsequently determine the effectiveness factor (η) for immobilized enzyme systems.

Materials: See Scientist's Toolkit.

Procedure:

- Homogeneous Kinetics:

- Prepare 10 substrate solutions (S) in assay buffer, spanning 0.2Km to 5Km.

- In a microplate or cuvette, add 980 µL of substrate solution and initiate reaction with 20 µL of free enzyme solution (low concentration to avoid product inhibition).

- Monitor product formation spectrophotometrically/fluorometrically for 60-120s. Record initial velocity (v).

- Fit v vs. [S] data to the Michaelis-Menten equation (non-linear regression) to obtain intrinsic kcat and Km.

Immobilized Enzyme Kinetics:

- Use the same substrate concentration range as in Step 1.

- In a stirred well-mixed batch reactor, add 10 mL of substrate solution and a known mass of immobilized enzyme beads.

- Maintain vigorous agitation (≥ 500 rpm) to eliminate external film resistance.

- Sample supernatant at regular intervals (e.g., every 30s) and assay for product.

- Calculate the observed reaction rate per mass of catalyst (v_obs).

Effectiveness Factor Calculation:

- For a first-order approximation at low [S] (<< Km), η ≈ vobs / (vintrinsic * enzyme mass ratio).

- For full range analysis, use the Thiele modulus (φ) calculation. For spherical particles: φ = Rp * sqrt( (Vmax/De*Km) ) where Vmax is per particle volume. Use η vs. φ correlation curves to determine η.

Protocol 3.2: Quantifying External Film Mass Transfer Coefficient (k_L)

Objective: To experimentally determine k_L under simulated bioreactor flow conditions.

Procedure (Dissolution Method using Non-Porous Analog):

- Fabricate or obtain non-porous particles of the same size and shape as your immobilized enzyme carrier.

- Coat these particles with a sparingly soluble compound (e.g., benzoic acid).

- Pack a small-scale column reactor with these particles.

- Perfuse with a buffer (at known temperature and viscosity) at a controlled flow rate (Q) corresponding to your target reactor's superficial velocity.

- Measure the concentration of the dissolved coating in the effluent over time using UV spectrometry until saturation.

- Apply a mass balance: kL * a * (Csat - Cbulk) = Q * (Cout - Cin) / Vbed.

ais the specific surface area of the particles.C_satis the saturation concentration.- Solve for kL. Repeat for different flow rates to establish kL vs. Re relationship.

Protocol 3.3: CFD-Ready Parameter Extraction from a Stirred-Tank Batch Run

Objective: To conduct an integrated experiment that yields data for validating a coupled kinetics-CFD model.

Procedure:

- Setup: Fit a lab-scale stirred tank reactor with a Rushton turbine. Use standard geometry (Dtank/Dimpeller = 3, H/D_tank = 1). Immobilize enzyme on 200µm spherical beads.

- Instrumentation: Equip with online pH and dissolved O₂/CO₂ probes (as relevant). Use Particle Image Velocimetry (PIV) or Laser Doppler Anemometry (LDA) to map the fluid velocity field at your standard agitation speed (e.g., 300 rpm).

- Reaction Run: Charge reactor with substrate solution at S_0 ≈ 2*Km. Initiate reaction by adding immobilized enzyme. Sample from a fixed, representative port at defined time intervals.

- Data Output for CFD: Record:

- Time-series of bulk substrate and product concentration.

- Fluid velocity field from PIV/LDA (used to validate CFD hydrodynamics).

- Power input (from torque sensor) to calculate energy dissipation rate.

- CFD Model Input: Use intrinsic kinetics from Protocol 3.1, measured kL from 3.2, particle properties, and reactor geometry. Simulate the batch run, comparing model-predicted bulk concentration decay with experimental data from Step 4. Adjust De within plausible bounds for calibration.

Visualizing the Coupling: Diagrams

Title: Mass Transfer Steps Coupled with Enzyme Kinetics

Title: CFD Model Coupling Workflow for Bioreactor

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function/Application in Kinetics-Transport Studies |

|---|---|

| p-Nitrophenyl Phosphate (pNPP) / p-Nitrophenyl Palmitate (pNPP) | Chromogenic substrate for hydrolytic enzymes (phosphatases, lipases). Release of p-nitrophenol allows easy UV-Vis monitoring of initial rates. |

| Sepharose/ Agarose Beads (e.g., CNBr-activated) | Common macroporous carrier for enzyme immobilization via covalent binding. Enables study of internal diffusion effects. |

| Dextran Tracer Molecules (of varying MW) | Used in inverse size-exclusion chromatography (iSEC) to characterize pore size distribution and tortuosity of immobilization supports. |

| Sodium Alginate & Calcium Chloride | For entrapment immobilization via ionotropic gelation. Allows creation of uniform, size-controlled beads for diffusion studies. |

| Ru(bpy)₃²⁺ Fluorescent Tracer | An oxygen-sensitive fluorophore used in micro-PIV/LIF experiments to simultaneously map fluid velocity and dissolved oxygen concentration fields. |

| Computational Tools:- COMSOL Multiphysics- ANSYS Fluent with UDFs- Python (SciPy, FEniCS) | Software platforms for implementing coupled CFD-reaction engineering simulations. Enable solving Navier-Stokes equations with user-defined kinetic source terms. |

Application Notes

This document provides application notes and protocols for the study of enzyme deactivation within the context of Computational Fluid Dynamics (CFD) modeling of mass transfer in enzymatic bioreactors. The concurrent effects of shear stress (from fluid flow), pH, and temperature are critical for predicting enzyme longevity and activity in industrial bioprocesses, including drug substance development. Understanding these deactivation kinetics enables the optimization of bioreactor design and operation to maximize yield and cost-efficiency.

Key Parameters and Quantitative Data

The following tables summarize key quantitative relationships and data from recent literature relevant to modeling combined deactivation effects.

Table 1: Typical Deactivation Rate Constants (k_d) for Representative Enzymes Under Isolated Stresses

| Enzyme (Example) | Shear Rate (1/s) | pH | Temperature (°C) | k_d (min⁻¹) | Half-life (min) | Primary Deactivation Mechanism |

|---|---|---|---|---|---|---|

| Lipase (C. rugosa) | 500 | 7.0 | 40 | 0.0021 | 330 | Unfolding/Aggregation |

| L-Asparaginase | 100 | 7.4 | 37 | 0.00095 | 730 | Subunit Dissociation |

| Catalase | 10,000 | 7.0 | 25 | 0.012 | 58 | Shear-induced Fragmentation |

| Glucose Isomerase | 50 | 8.0 | 60 | 0.0047 | 147 | Chemical Denaturation |

Table 2: Synergistic Effect Model Coefficients for Combined Stress Deactivation (Generalized Model: kd,combined = kd,T * f(pH) * g(τ) + Interaction Terms)

| Interaction Factor | Description | Typical Range of Impact on k_d (Fold Increase) | Reference Model Form | ||

|---|---|---|---|---|---|

| Temperature-pH | Low pH amplifies heat sensitivity. | 1.5 - 5.0 | exp(α₁ΔT * | ΔpH | ) |

| Shear-Temperature | High shear lowers thermal transition threshold. | 1.2 - 3.0 | (1 + β₁ * τ) * k_d,T | ||

| Shear-pH | Extreme pH enhances shear susceptibility. | 1.1 - 2.5 | 1 + γ₁ * τ * | ΔpH |

Table 3: CFD-Relevant Parameters for Bioreactor Shear Field Mapping

| Parameter | Symbol | Typical Range in Stirred Tank | Relevance to Enzyme Deactivation |

|---|---|---|---|

| Turbulent Dissipation Rate | ε (W/kg) | 0.1 - 10 | Determines local shear stress intensity. |

| Kolmogorov Length Scale | η (μm) | 10 - 100 | Indicates smallest eddy size; can match enzyme aggregate dimensions. |

| Wall Shear Stress | τ_w (Pa) | 0.01 - 1.0 | Critical for immobilized enzyme systems near surfaces. |

| Impeller Tip Speed | V_tip (m/s) | 1 - 5 | Correlates with maximum shear rate in tank. |

Experimental Protocols

Protocol: Quantifying Combined Shear, pH, and Temperature Effects on Soluble Enzyme Activity

Objective: To determine the deactivation rate constant (k_d) of a soluble enzyme under simultaneous, controlled shear, pH, and temperature conditions, generating data for CFD model validation.

Materials: See "The Scientist's Toolkit" below.

Method:

- Enzyme Solution Preparation: Prepare a concentrated stock solution of the target enzyme in a suitable buffer (e.g., 50 mM phosphate). Determine initial specific activity via a standard assay.

- Couette Shear Device Setup: Calibrate a concentric cylinder (Couette) shear device. Fill the annular gap with the enzyme solution. Set the temperature control of the device outer jacket to the target value (e.g., 30, 40, 50°C).

- Experimental Run: For each combination of pH (e.g., 6, 7, 8) and temperature: a. Adjust the pH of the enzyme solution using dilute HCl or NaOH. b. Load the solution into the pre-heated/cooled shear device. c. Apply a constant, uniform shear stress (τ) by setting the rotation speed of the inner cylinder. Calculate τ using device geometry and viscosity. d. Immediately begin sampling (t=0).

- Sampling and Activity Assay: a. Withdraw small aliquots (e.g., 100 µL) from the sampling port at regular time intervals (e.g., 0, 10, 20, 40, 60, 90, 120 min). b. Immediately dilute each sample 10-fold in ice-cold assay buffer to quench shear and thermal effects. c. Measure the residual enzyme activity for each sample using the standard assay (e.g., spectrophotometric product formation).

- Data Analysis: a. Plot residual activity (A/A₀) versus time for each condition. b. Fit the data to a first-order deactivation model: A/A₀ = exp(-kd * t). c. Extract the deactivation rate constant (kd) for each shear-pH-temperature combination. d. Perform multi-factor regression analysis to develop an empirical correlation: k_d = f(T, pH, τ).

Protocol: Local Activity Measurement for Immobilized Enzyme Systems in a Mimic Flow Cell

Objective: To correlate local hydrodynamic conditions (simulated by CFD) with local enzyme deactivation in an immobilized bed or on a surface.

Method:

- Surface Functionalization: Immobilize the enzyme onto a defined surface (e.g., epoxy-activated glass slide, microfluidic channel wall) using a standard covalent coupling protocol.

- Flow Cell Assembly: Integrate the enzyme-functionalized surface into a transparent flow cell with defined geometry (e.g., rectangular channel).

- CFD Flow Field Characterization: Perform a CFD simulation of the flow cell at the target flow rates to map the local wall shear stress (τ_w) and mass transfer coefficients.

- Operational Deactivation: Perfuse the flow cell with substrate-containing buffer at the desired pH and temperature. Apply a constant flow rate for a set duration (e.g., 24-72 hours) to induce deactivation.

- Spatially-Resolved Activity Staining: Stop flow. Introduce a chromogenic or fluorogenic substrate solution that yields an insoluble, colored/precipitated product at sites of enzyme activity.

- Image Analysis & Correlation: a. Capture high-resolution images of the stained surface. b. Quantify local color intensity/product density as a proxy for local residual activity. c. Map this activity data onto the CFD-generated shear stress map to establish a spatial correlation between τ_w and deactivation.

Diagrams

Title: Enzyme Deactivation Pathways Under Stress

Title: CFD Workflow for Deactivation Modeling

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Protocols | Key Considerations |

|---|---|---|

| Couette Shear Device | Generates a uniform, quantifiable laminar shear field for controlled stress studies. | Requires precise temperature control jacket. Calibrate gap width and viscosity for accurate τ. |

| Epoxy-Activated Glass Slides | Provide a stable surface for covalent enzyme immobilization for flow cell studies. | Ensure consistent surface chemistry across batches. |

| Chromogenic/ Fluorogenic Substrate | Enables visual detection and quantification of localized enzyme activity after stress. | Product must be insoluble for spatial mapping. Must be specific to the target enzyme. |

| Multi-Parameter Bioreactor Probes (pH, DO, T) | Monitors and controls critical environmental parameters in real-time during scale-down studies. | Require regular calibration. Must be non-invasive to flow. |

| Standard Activity Assay Kit | Provides a reliable, repeatable method to quantify residual enzyme activity in sampled aliquots. | Must have a linear range covering expected activity loss. Quenching step is critical. |

| Tris/HCl & Phosphate Buffer Systems | Maintain precise pH during experiments across a physiological range (6-9). | Choose buffer with minimal temperature coefficient and no metal chelation if needed. |

| Computational Fluid Dynamics (CFD) Software | Simulates the complex hydrodynamic environment (shear, mixing) in production-scale bioreactors. | Requires user expertise in multiphase flow and species transport modeling. |

Application Notes: Challenges in Bioreactor CFD

Computational Fluid Dynamics (CFD) modeling of enzymatic bioreactors is fundamental for optimizing mass transfer, reaction kinetics, and ultimately, product yield. The core challenges are intrinsically multi-phase and multi-scale.

Multi-Phase Nature: Bioreactors typically involve gas-liquid (e.g., oxygen sparging), liquid-solid (enzymes immobilized on carriers), and sometimes liquid-liquid (in multiphasic reaction systems) interactions. Accurate modeling must account for interphase momentum, heat, and mass transfer.

Multi-Scale Complexity: The system spans vastly different scales:

- Macro-scale (1e-1 to 1 m): Overall reactor hydrodynamics, mixing patterns, and global circulation.

- Meso-scale (1e-3 to 1e-1 m): Bubble/droplet dynamics, impeller boundary layers, and local shear regions.

- Micro-scale (1e-6 to 1e-3 m): Diffusion boundary layers around catalyst particles or cells, and intrinsic reaction kinetics at the enzyme active site.

The primary challenge is to develop models that bridge these scales efficiently, capturing micro-scale phenomena critical for mass transfer without making macro-scale simulations computationally prohibitive.

Table 1: Characteristic Scales and Parameters in a Stirred-Tank Enzymatic Bioreactor

| Parameter | Typical Range / Value | Description & Relevance to CFD |

|---|---|---|

| Reactor Volume | 1 L – 20,000 L | Macro-scale, defines computational domain and Reynolds number. |

| Impeller Tip Speed | 1 – 6 m/s | Determines turbulent kinetic energy dissipation rate (ε), crucial for shear and micro-mixing. |

| Energy Dissipation Rate (ε) | 0.1 – 10 W/kg (avg.)Up to 100 W/kg (local) | Key for determining Kolmogorov length scale and sub-grid scale models. |

| Kolmogorov Length Scale (η) | 10 – 100 μm | Smallest turbulent eddy size. Mesh must resolve or model features below this. |

| Sauter Mean Diameter (d₃₂) | 1 – 5 mm (gas bubbles) | Critical parameter for interfacial area in gas-liquid mass transfer. |

| Oxygen Mass Transfer Coefficient (kₗa) | 10 – 500 h⁻¹ | Target output of mass transfer models. Depends on hydrodynamics and bubble size. |

| Enzyme Particle/Carrier Size | 50 – 500 μm | Micro-scale. Determines internal and external mass transfer resistance (Thiele modulus). |

| Diffusivity (O₂ in water) | ~2.1e-9 m²/s | Micro-scale property. Essential for calculating mass transfer rates and boundary layers. |

Table 2: Common CFD Modeling Approaches for Multi-Scale Challenges

| Modeling Approach | Scale Addressed | Methodology | Key Limitation |

|---|---|---|---|

| Eulerian-Eulerian (Two-Fluid) | Macro/Meso (Multiphase) | Treats phases as interpenetrating continua. Solves Navier-Stokes for each phase. | Requires closure models for interphase forces (drag, lift). Less accurate for discrete particle tracking. |

| Eulerian-Lagrangian (DPM) | Meso/Micro (Particles/Bubbles) | Treats fluid as continuum (Eulerian) and tracks discrete particles/bubbles (Lagrangian). | Computationally expensive for high holdup (>10%). |

| Population Balance Model (PBM) | Meso (Bubble/Droplet Size) | Coupled with Eulerian methods to predict size distribution due to coalescence & breakup. | Requires kernel models; increases computational cost. |

| Porous Media Model | Micro (Particle Bed) | Models packed-bed or immobilized enzyme zones as porous regions with momentum sink. | Requires empirical permeability data. Does not resolve individual particles. |

| Coupling with Kinetics | All Scales | Integrates reaction rate equations (e.g., Michaelis-Menten) as source/sink terms in species transport equations. | Assumes homogeneous distribution at sub-grid scale; may need closure for segregation. |

Experimental Protocols for Model Validation

Accurate CFD models require validation against controlled experimental data. Below are protocols for key measurements.

Protocol 1: Measurement of Local Gas Holdup and Bubble Size Distribution

Objective: To obtain validation data for Eulerian-Eulerian or PBM-coupled CFD simulations of gas-liquid mixing.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Setup: Operate the bioreactor under standard conditions (set agitation speed, aeration rate, temperature).

- Optical Probe Insertion: Calibrate the optical fiber probe. Insert it into the reactor at predetermined coordinates (e.g., near impeller, in bulk region, near wall) using a traversing system.

- Data Acquisition: Record the probe signal at a high sampling frequency (≥1 kHz) for a minimum of 60 seconds per location. The signal voltage shifts when the probe tip encounters a gas bubble.

- Signal Processing: Analyze the time-series signal using dedicated software.

- Gas Holdup (α): Calculate as the fraction of total time the signal indicates "gas phase."

- Bubble Size (d₃₂): Determine from the duration of each gas signal pulse, using the known local bubble velocity (from a paired double-tip probe or PIV correlation).

- Spatial Mapping: Repeat steps 2-4 at multiple locations to build a spatial map of holdup and bubble size.

Protocol 2: Determination of Volumetric Mass Transfer Coefficient (kₗa)

Objective: To validate the integrated mass transfer prediction of a multiphase CFD model.

Methodology (Dynamic Gassing-Out Method):

- Decxygenation: Sparge the liquid medium (without cells/enzymes) with nitrogen to remove dissolved oxygen. Monitor until DO reaches ~0-5% saturation.

- Initiation of Oxygenation: Switch the gas supply to air or oxygen at the desired flow rate. Ensure agitation is at the target RPM.

- Data Logging: Record the dissolved oxygen (DO) concentration from a calibrated probe over time until saturation (100%) is reached.

- Analysis: Plot ln(1 – (C/C)) versus time (t), where C is DO concentration and C is saturation concentration. The slope of the linear region of this plot is the kₗa value.

Protocol 3: µPIV for Micro-Scale Hydrodynamics Around Immobilized Enzymes

Objective: To characterize the flow field and shear at the particle scale for validating micro-scale boundary conditions in CFD.

Methodology:

- Micro-Reactor Setup: Construct or use a transparent flow cell containing a representative sample of immobilized enzyme carriers.

- Seeding & Imaging: Seed the fluid with fluorescent tracer particles (e.g., 1 µm diameter). Illuminate a thin laser sheet (~100 µm thick) across the region of interest (e.g., near a single carrier).

- Image Capture: Use a high-speed, high-sensitivity CCD camera mounted on a microscope to capture double-frame images of the particle field.

- Vector Calculation: Process the image pairs using cross-correlation algorithms (e.g., in commercial PIV software) to compute the velocity vector field around the carrier.

- Shear Rate Calculation: Post-process the velocity field to determine the spatial gradient of velocity, from which the local shear rate tensor is derived.

Visualization of Multi-Scale CFD Workflow

Diagram Title: Multi-Scale CFD Coupling and Validation Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Bioreactor CFD Validation Experiments

| Item / Reagent | Function & Relevance |

|---|---|

| Optical Fiber Probe (Single/Double Tip) | Measures local gas holdup and bubble velocity/size in opaque or transparent fluids. Critical for validating multiphase flow fields. |

| Micro-PIV System (Laser, Camera, Tracers) | Measures velocity fields at micron resolution. Essential for characterizing micro-scale hydrodynamics near particles or membranes. |

| Fluorescent Tracer Particles (1-10 µm) | Seed fluid for PIV measurements. Must be inert, neutrally buoyant, and sufficiently reflective/excitable. |

| Dissolved Oxygen (DO) Probe (Polarographic) | Measures oxygen concentration dynamics for determining the volumetric mass transfer coefficient (kLa), a key model output. |

| Inert Tracer Dyes (e.g., Rhodamine WT) | Used in Residence Time Distribution (RTD) studies to validate macro-mixing and flow patterns predicted by CFD. |

| Calibrated Enzyme Carriers/ Beads | Well-characterized particles (size, porosity, activity) used as a model solid phase to study liquid-solid mass transfer and reaction coupling. |

| High-Fidelity CFD Software (ANSYS Fluent, OpenFOAM, COMSOL) | Platforms for implementing multi-phase (Eulerian, VOF, DPM), turbulence (RANS, LES), and reaction models. |

| Non-Newtonian Fluid Simulants (e.g., CMC, Xanthan Gum solutions) | Used to model the complex rheology of fermentation broths or cell cultures, affecting shear and mixing. |

Building Your CFD Model: From Geometry to Solution for Enzymatic Systems

Within the broader thesis research on Computational Fluid Dynamics (CFD) modeling of mass transfer in enzymatic bioreactors, a rigorous and reproducible workflow is essential. This application note details the protocol for a step-by-step CFD workflow, from pre-processing to post-processing, tailored for the analysis of mass transfer phenomena critical to bioreactor efficiency, enzyme-substrate interaction, and ultimately, biopharmaceutical production.

Pre-processing Protocol

Pre-processing involves the creation of the computational model, including geometry definition, meshing, and setting physical properties and boundary conditions.

Geometry Acquisition and Cleanup

- Protocol: Import the 3D CAD model of the enzymatic bioreactor (e.g., stirred tank, packed bed, membrane reactor) in a neutral format (STEP, IGES). Using the CFD software's geometry tools, repair any gaps, misalignments, or non-manifold edges. Simplify the geometry by removing unnecessary features (small bolts, labels) that do not significantly impact bulk fluid flow but increase mesh complexity. For internal flows, define fluid volume regions explicitly.

- Application to Thesis: For a stirred-tank enzymatic bioreactor, ensure the impeller blades, baffles, and sparger geometry are accurately represented, as these directly dictate the turbulence and mixing governing mass transfer.

Meshing Strategy and Generation

- Protocol: A hybrid meshing approach is recommended. Use a structured hexahedral mesh in regions of high shear and expected gradients (near the impeller, substrate injection port) and unstructured tetrahedral cells elsewhere. Implement boundary layer inflation (prism layers) on all wetted walls to resolve viscous sub-layers, critical for accurate shear stress and mass transfer coefficient predictions. The protocol must include a mesh independence study.

- Mesh Independence Study Protocol:

- Generate a coarse base mesh.

- Solve the flow field to steady-state.

- Refine the mesh globally by ~30% cell increase.

- Re-solve and compare key outputs (e.g., velocity at a monitor point, overall shear rate).

- Repeat steps 3-4 until the change in key outputs is <2%. The penultimate mesh is deemed independent.

Physics and Boundary Condition Setup

- Protocol: Select the appropriate multiphase and species transport models. For enzymatic bioreactors, this typically involves:

- Fluid: Incompressible Newtonian fluid (aqueous media).

- Turbulence Model: Realizable k-ε or SST k-ω model, given their robustness for internal flows with rotation and separation.

- Species Transport: Enable species transport without reactions. The enzymatic reaction kinetics will be applied via User-Defined Functions (UDFs) or post-processing.

- Boundary Conditions: Define inlet (substrate feed), outlet (pressure-outlet), walls (no-slip for tank, moving wall for impeller), and symmetry/periodic boundaries if applicable. Initialize the domain with the continuous phase.

Diagram Title: CFD Pre-processing Workflow Logic

Solving & Simulation Protocol

This phase involves the numerical solution of the discretized governing equations (Navier-Stokes, continuity, species transport).

Solver Configuration

- Protocol: Use a pressure-based coupled solver for improved convergence. Set second-order upwind discretization schemes for momentum, turbulence, and species to minimize numerical diffusion. For transient simulations of unsteady mixing (essential for most bioreactors), use a bounded second-order implicit transient formulation.

Solution Monitoring and Convergence

- Protocol: Define residuals for continuity, velocity components, k, ε, and species with a convergence criterion of at least 1e-4. Additionally, set up point, surface, or volume monitors for key quantities (e.g., average velocity in a zone, mass flow rate at outlet, shear rate at enzyme immobilization surface). A solution is considered converged when residuals plateau below the criterion and monitor values stabilize.

UDF Implementation for Enzymatic Kinetics

- Protocol: To model Michaelis-Menten kinetics locally within the CFD domain, compile a UDF. This UDF defines the substrate consumption rate source term (

S_s) in the species transport equation as:S_s = - (V_max * C_s) / (K_m + C_s), whereV_maxis the maximum reaction rate andK_mis the Michaelis constant. The UDF is hooked to the species source term in the appropriate fluid cell zone.

Diagram Title: CFD Solving Control Loop

Post-processing & Analysis Protocol

Post-processing transforms raw simulation data into actionable insights on mass transfer and reactor performance.

Qualitative Flow Field Visualization

- Protocol: Generate contour plots on relevant planes or surfaces for velocity magnitude, turbulent kinetic energy, substrate concentration, and shear stress. Create vector plots to visualize flow direction and recirculation zones. Generate streamlines or pathlines from key inlets to assess mixing patterns and dead zones.

Quantitative Data Extraction

- Protocol: Create iso-surfaces for specific concentration values (e.g., 90% of inlet concentration) to visualize reaction fronts. Use surface integrals to calculate average shear stress on enzyme-bound surfaces. Use volume integrals to calculate total substrate consumption rate. Extract discrete data along user-defined lines (e.g., from impeller to tank wall) for detailed profiles.

Key Performance Indicator (KPI) Calculation for Bioreactors

- Protocol: Calculate mass transfer coefficients (

k_L) using the correlation between local substrate flux and concentration gradient at catalytic surfaces. Determine mixing time via transient tracer simulations. Calculate the spatial uniformity index of substrate concentration at a given time.

Table 1: Quantitative Outputs from CFD Simulation of a Stirred-Tank Enzymatic Bioreactor

| Parameter | Symbol | Extraction Method | Typical Value Range (Example) | Significance for Thesis |

|---|---|---|---|---|

| Volumetric Mass Transfer Coefficient | k_L a |

Surface integral of flux / volume avg. driving force | 0.01 - 0.05 s⁻¹ | Governs overall substrate availability to enzyme. |

| Wall Shear Stress | τ_w |

Surface average on immobilization surface | 0.1 - 5 Pa | Impacts enzyme activity/deactivation; biofilm formation. |

| Mixing Time | θ_m |

Time for tracer concentration to reach 95% homogeneity | 10 - 100 s | Determines feed distribution and concentration gradients. |

| Substrate Conversion Efficiency | X_s |

(1 - Outlet Mass Flow/Inlet Mass Flow) * 100% |

60 - 95% | Direct measure of bioreactor performance. |

| Velocity Gradient (Shear Rate) | G |

Volume average of velocity gradient magnitude | 10 - 200 s⁻¹ | Influences micromixing and mass transfer rate. |

Diagram Title: Post-processing to Thesis Input Pathway

The Scientist's Toolkit: CFD for Enzymatic Bioreactors

Table 2: Essential Research Reagent Solutions & Computational Materials

| Item | Function/Description | Application in Protocol |

|---|---|---|

| Commercial CFD Software (ANSYS Fluent, STAR-CCM+) | Platform for executing the entire workflow. Provides solvers, meshers, and post-processors. | Used in all stages (Pre, Solve, Post). Essential for implementing the protocols. |

| High-Performance Computing (HPC) Cluster | Computational resource for handling large mesh counts and transient simulations. | Critical for solving complex multiphase/species models and mesh independence studies. |

| User-Defined Function (UDF) Code (C/Python) | Custom script to implement enzymatic reaction kinetics into the CFD solver. | Protocol 2.3: Defines the Michaelis-Menten source term for substrate consumption. |

| CAD Software (SolidWorks, AutoCAD) | Tool for creating and modifying the precise 3D geometry of the bioreactor. | Protocol 1.1: Geometry acquisition, cleanup, and simplification before meshing. |

| Data Analysis & Plotting Tool (Python, MATLAB) | Environment for processing numerical outputs, calculating KPIs, and generating publication-quality charts. | Protocol 3.2 & 3.3: Analysis of extracted quantitative data and KPI generation. |

Within the broader thesis on Computational Fluid Dynamics (CFD) modeling of mass transfer in enzymatic bioreactors, selecting the appropriate multiphase modeling approach is critical. Enzymatic bioreactors, central to modern bioprocessing for drug development, involve complex interactions between fluid phases, solid catalysts (e.g., immobilized enzymes), and dissolved substrates/products. Accurate simulation of hydrodynamics, turbulence, and interfacial mass transfer is essential for scaling up from laboratory to industrial production. This document provides application notes and protocols to guide researchers in choosing between the Eulerian-Lagrangian (EL) and Eulerian-Eulerian (EE) frameworks.

Theoretical Framework & Model Comparison

Core Conceptual Differences

- Eulerian-Eulerian (EE) Model: Treats all phases as interpenetrating continua. Fields for volume fractions, velocities, and pressures are defined for each phase and solved over the entire domain. Suitable for high dispersed-phase volume fractions (>10%).

- Eulerian-Lagrangian (EL) Model: Treats the continuous phase as a continuum (Eulerian) and tracks individual particles/droplets/bubbles of the dispersed phase (Lagrangian). Suitable for low volume fractions and where particle history (e.g., residence time, individual mass transfer) is critical.

Quantitative Model Comparison & Selection Criteria

Table 1: Comparative Analysis of EL vs. EE Models for Enzymatic Bioreactors

| Criterion | Eulerian-Eulerian Model | Eulerian-Lagrangian Model |

|---|---|---|

| Dispersed Phase Fraction | High (>10% typical). Dense slurries, fluidized beds. | Low to moderate (<10-12%). Sparged reactors, spray systems. |

| Computational Cost | Moderate to High (solves Navier-Stokes for each phase). Scales with mesh size. | Very High (scales with number of particles tracked). Requires significant RAM/CPU for large particle counts. |

| Particle Resolution | Averaged. No individual particle information. | Resolves individual particle trajectories, history, and forces. |

| Mass Transfer Coupling | Coupled via interphase transfer terms in continuum equations. | Can be coupled per particle; allows for stochastic and dynamic variations. |

| Ideal Bioreactor Type | Stirred tank with high solid catalyst load, Slurry bubble columns. | Packed beds, Low-solid-fraction immobilized enzyme reactors, Air-lift bioreactors with sparse bubbles. |

| Key Challenge | Accurate closure models for interphase drag, turbulence dispersion. | Managing computational load for realistic particle numbers; two-way coupling. |

Table 2: Common Closure Models & Parameters

| Model Component | Typical Models/Values (Enzymatic Bioreactor Context) | Application Note |

|---|---|---|

| Interphase Drag (EE & EL) | Schiller-Naumann, Gidaspow, Grace. Drag coefficient (Cd) depends on particle Reynolds number. | For immobilized enzyme particles (50-500 µm), Schiller-Naumann often sufficient. |

| Turbulence (EE) | k-ε (Standard, RNG), k-ω SST. Dispersed phase turbulence via Tchen's theory or per-phase models. | RNG k-ε handles low Reynolds numbers and swirling flows common in stirred tanks. |

| Mass Transfer Coefficient | Higbie's Penetration Theory, Frössling Correlation. Sherwood number (Sh) function of Re and Sc. | Sh = 2 + 0.6Re^(1/2)Sc^(1/3) for spherical particles. Critical for substrate uptake rate. |

| Particle Forces (EL) | Drag, Pressure Gradient, Virtual Mass, Basset History, Brownian (for <1µm). | For enzyme carrier particles >10µm, drag dominates; Brownian motion negligible. |

Application Protocols

Protocol: Implementing an Eulerian-Eulerian Simulation for a Stirred Enzymatic Slurry Reactor

Objective: Model hydrodynamics and substrate concentration field in a tank with a high loading of immobilized enzyme particles.

Workflow:

- Pre-processing & Meshing:

- Geometry: Create a 3D CAD of the bioreactor including impeller(s), baffles, sparger.

- Meshing: Use a hybrid mesh. Employ a rotating/sliding mesh or MRF approach for impeller motion. Ensure mesh refinement in high-shear regions (impeller tip, sparger outlet).

- Mesh Independence: Conduct a study with 3 progressively finer meshes. Monitor volume-averaged turbulent dissipation rate and particle volume fraction in a key region. Proceed when variation <2%.

Solver Setup (ANSYS Fluent/OpenFOAM Example):

- Model: Enable Eulerian multiphase model with 2 phases: liquid (continuous, e.g., aqueous buffer) and solid (dispersed, enzyme carriers).

- Turbulence: Select RNG k-ε model with Eulerian multiphase treatment.

- Drag: Select Gidaspow model (combines Wen-Yu for dilute regions and Ergun for dense regions).

- Mass Transfer: Enable Species Transport. Define substrate species. Set interphase mass transfer using User-Defined Function (UDF) based on kinetic rate law (e.g., Michaelis-Menten) and diffusion.

- Boundary Conditions: Inlet (substrate feed flow rate, turbulent intensity 5%), Outlet (pressure-outlet), Walls (no-slip for liquid, specularity coefficient for solids).

Solution & Monitoring:

- Use the Phase Coupled SIMPLE algorithm.

- Initialize flow field, then run calculation until scaled residuals plateau below 1e-4 for continuity and 1e-6 for energy/species.

- Monitor integral quantities (total substrate consumption rate, torque on impeller) for steady-state.

Post-processing:

- Quantify: Volume-averaged substrate concentration, spatial distribution of solid holdup, mass transfer coefficient distribution.

- Validate: Compare predicted substrate conversion % against experimental bench-scale data.

Diagram Title: EE Model Protocol for Enzymatic Slurry Reactor

Protocol: Implementing an Eulerian-Lagrangian Simulation for a Packed Bed Enzyme Reactor

Objective: Track individual substrate-laden fluid parcels through a porous bed of immobilized enzyme particles to assess residence time distribution and conversion.

Workflow:

- Pre-processing & Meshing:

- Geometry: Model the packed bed as a porous zone or explicitly model particle arrangement if feasible.

- Meshing: Generate a conformal mesh. For explicit geometry, ensure at least 10 cells per particle diameter.

- Particle Definition: In the DPM (Discrete Phase Model) setup, define inert particles representing fluid parcels/substrate packets. Set diameter (e.g., 100 µm) and density equal to the continuous fluid.

Solver Setup:

- Continuous Phase: Solve Navier-Stokes for single-phase flow (buffer fluid). Use laminar or low-Re turbulence model.

- Dispersed Phase: Enable Discrete Phase Model (DPM) with Inert particle type. Activate Interaction with Continuous Phase (two-way coupling).

- Injections: Define a surface injection at the reactor inlet. Specify particle flow rate (to represent substrate flux) and initial velocity.

- Mass Transfer: Use User-Defined Scalars or a UDF to attach a scalar (substrate concentration) to each particle. Decrease this scalar along the trajectory based on a reaction rate law dependent on local enzyme loading and residence time.

Tracking & Solution:

- Set DPM tracking parameters (max steps, length scale).

- Run continuous phase iteration, then inject and track particles. Iterate until coupled solution is stable.

- Sample particle trajectories and record scalar history.

Data Analysis:

- Calculate distribution of residence times (RTD) from particle escape times.

- Corfinal substrate concentration with residence time to map conversion efficiency.

- Identify channeling or stagnant zones from particle pathlines.

Diagram Title: EL/DPM Protocol for Packed Bed Reactor Analysis

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for CFD-Supported Enzymatic Bioreactor Research

| Item | Function/Description | Example/Notes |

|---|---|---|

| Immobilized Enzyme Carrier | Solid support (particle) to which enzyme is covalently or adsorptively bound, providing reusability and stability. | Eupergit C (Oxirane acrylic beads, 100-250 µm), Agarose-based resins, Magnetic nanoparticles (for easy separation). |

| Substrate Analogues (Fluorogenic/Chromogenic) | Provide measurable signal (fluorescence/color) upon enzymatic conversion, used for in vitro kinetic assays to determine Vmax, Km. | 4-Methylumbelliferyl (4-MU) conjugated substrates, p-Nitrophenyl (pNP) esters. Critical for validating kinetic parameters used in UDFs. |

| Computational Fluid Dynamics (CFD) Software | Platform for implementing EE or EL simulations, solving governing equations, and post-processing results. | ANSYS Fluent (Commercial, extensive models), OpenFOAM (Open-source, high flexibility), COMSOL Multiphysics (Strong coupled physics). |

| High-Performance Computing (HPC) Cluster | Essential for running complex, transient, coupled multiphase simulations with fine meshes and many particles. | Local Linux clusters or cloud-based HPC (AWS, Azure). EL simulations particularly GPU-accelerated. |

| Reaction Kinetics Data | Experimentally derived parameters defining the enzyme's catalytic rate as a function of substrate concentration. | Michaelis Constant (Km), Turnover Number (kcat), Inhibition Constants (Ki). Input for mass transfer UDFs. |

| Particle Image Velocimetry (PIV) / Laser Doppler Anemometry (LDA) | Experimental techniques to measure velocity fields in laboratory-scale bioreactors for CFD model validation. | 2D/3D PIV Systems (Dantec Dynamics, LaVision). Provides spatial velocity data to compare against simulated flow fields. |

Implementing Porous Media Models for Immobilized Enzyme Reactors

This work forms a critical component of a doctoral thesis focused on Computational Fluid Dynamics (CFD) modeling of mass transfer phenomena in enzymatic bioreactors. The primary objective is to develop and validate high-fidelity porous media models that accurately predict coupled hydrodynamics, substrate diffusion, and reaction kinetics within packed-bed immobilized enzyme reactors (IMERs). Such models are essential for the rational design and scale-up of bioreactors used in biopharmaceutical synthesis and continuous-flow biocatalysis.

Core Principles & Current Research Synthesis

Immobilized enzyme reactors leverage porous solid supports (e.g., silica, polymer beads, monoliths) to enhance enzyme stability, enable reuse, and facilitate continuous processing. The central challenge lies in the multiphysics interaction between fluid flow, mass transfer, and Michaelis-Menten kinetics within the complex pore network. Recent research, gathered via live search, emphasizes the integration of microscale characterization (e.g., µCT scanning) with CFD to define realistic porous domain geometries and effective transport parameters.

Table 1: Key Parameters for Porous Media Modeling in IMERs

| Parameter | Symbol | Typical Range/Value | Determination Method | Impact on Model |

|---|---|---|---|---|

| Porosity | ε | 0.3 - 0.8 | Mercury porosimetry, µCT analysis | Volumetric fluid domain |

| Tortuosity | τ | 1.5 - 10 | Electrochemical/ diffusion cell, estimation from ε | Effective diffusivity |

| Permeability | k (m²) | 1e-12 - 1e-8 | Darcy's law experiment, Carman-Kozeny equation | Pressure drop, velocity field |

| Effective Diffusivity | D_eff (m²/s) | 0.1 - 0.5 * D_ab | Tracer pulse experiment, correlation (Deff = (ε/τ)*Dab) | Substrate mass transfer rate |

| Enzyme Loading | [E]_immob (mg/mL bed) | 10 - 100 | Bradford assay on digested support | Maximum reaction rate (V_max) |

| Apparent Kinetics | Kmapp, Vmaxapp | > Kmsoluble | Lineweaver-Burk plot from packed-bed experiments | Source term in species transport |

Research Toolkit: Essential Reagents & Materials

Table 2: Research Reagent Solutions for IMER Characterization

| Item | Function & Brief Explanation |

|---|---|

| Porous Support Material (e.g., Glyoxyl-agarose, EziG silica, epoxy methacrylate) | Provides high-surface-area, functionalized solid phase for covalent enzyme immobilization. |

| Target Enzyme Solution (e.g., Lipase B, Penicillin G Acylase) | The biocatalyst to be immobilized. Purity is critical for determining accurate loading and activity. |

| Non-reactive Tracer (e.g., Acetone, Blue Dextran) | Used in Residence Time Distribution (RTD) studies to characterize hydrodynamic dispersion without reaction. |

| Substrate Solution (e.g., p-Nitrophenyl butyrate for lipase) | Used in activity assays. Hydrolysis product (p-nitrophenol) is easily quantified via UV-Vis. |

| Bradford Reagent | Colorimetric assay to quantify protein (enzyme) loading on the support after immobilization. |

| Buffer Solutions (e.g., Phosphate, Tris-HCl) | Maintain optimal pH for enzyme activity and stability during immobilization and operation. |

| Stopping Agent (e.g., Na₂CO₃ for p-nitrophenol assays) | Rapidly shifts pH to stop reaction and develop full color for product quantification. |

Experimental Protocols for Model Parameterization

Protocol 4.1: Determination of Apparent Kinetic Parameters in a Packed-Bed

Objective: To obtain Vmaxapp and Kmapp for use as source terms in the CFD reaction model.

- Reactor Preparation: Pack a jacketed glass column (e.g., 0.5 cm D, 5 cm L) with precisely weighed immobilized enzyme beads. Maintain constant temperature via circulator.

- Substrate Feed: Prepare substrate solutions in buffer across a concentration range (e.g., 0.2Km to 5Km, estimated from soluble kinetics).

- Continuous-Flow Operation: Pump each substrate concentration through the bed at a very low flow rate (e.g., 0.1 mL/min) to ensure near-complete conversion (<5%). Collect effluent.

- Product Quantification: Analyze effluent for product concentration ([P]) using appropriate method (e.g., UV-Vis, HPLC).

- Calculation: Reaction rate, r = ([P] * Volumetric Flow Rate) / Bed Volume. Fit r vs. [S]in data to Michaelis-Menten model (non-linear regression) to extract Vmaxapp (mol/m³s) and Kmapp (mol/m³).

Protocol 4.2: Residence Time Distribution (RTD) for Hydrodynamic Dispersion

Objective: To estimate axial dispersion coefficient (D_ax), required for some porous media models.

- Pulse Input: Under operational flow conditions, inject a sharp pulse of non-reactive tracer (e.g., 50 µL of 1M acetone) at the column inlet.

- Effluent Monitoring: Continuously measure tracer concentration at outlet via conductivity or UV detector.

- Data Analysis: Plot normalized C(t) vs. t curve. Calculate variance (σ²t) of the distribution. Use closed-closed vessel dispersion model: Dax / uL = (σθ²) / 2, where σθ² = σ²t / tmean², u is superficial velocity, L is bed length.

CFD Modeling Workflow & Pathway

The logical workflow for implementing the porous media model within a commercial CFD solver (e.g., ANSYS Fluent, COMSOL) is described below.

Diagram 1: CFD Porous Media Model Implementation Workflow

Data Integration & Model Validation Table

Table 3: Example Validation Data Set for a Lipase-Based IMER

| Experimental Measurement | Value | Simulated CFD Output | % Error | Notes |

|---|---|---|---|---|

| Pressure Drop (∆P) at 1 mL/min | 4.2 kPa | 3.9 kPa | -7.1% | Depends on fitted permeability. |

| Conversion at [S]_in = 10 mM, 0.5 mL/min | 68% | 71% | +4.4% | Sensitive to Kmapp & D_eff. |

| Conversion at [S]_in = 10 mM, 2.0 mL/min | 24% | 22% | -8.3% | Sensitive to dispersion/D_ax. |

| Apparent V_max (from bed activity) | 1.8e-3 mol/m³·s | Input parameter | N/A | Used as constant in UDF. |

| Apparent K_m | 45 mol/m³ | Input parameter | N/A | Used as constant in UDF. |

Defining User-Defined Functions (UDFs) for Complex Enzyme Kinetics

Application Notes

Within the broader thesis on Computational Fluid Dynamics (CFD) modeling of mass transfer in enzymatic bioreactors, the accurate representation of enzyme kinetics is paramount. The inherent limitations of standard CFD solvers in modeling complex, non-standard kinetic expressions necessitate the use of User-Defined Functions (UDFs). This protocol details the development and implementation of UDFs for advanced kinetic models, bridging the gap between biochemical reality and computational simulation for researchers and drug development professionals.

Complex kinetics, such as substrate inhibition, multi-substrate ping-pong mechanisms, or allosteric cooperative behavior, are often described by rate equations that cannot be implemented via standard dropdown menus in CFD software (e.g., ANSYS Fluent, COMSOL). UDFs allow the direct coding of these equations, enabling spatially resolved simulations where local reaction rates depend on computed concentration and flow fields.

Key Considerations:

- Coupling: The UDF must correctly couple the kinetic rate (source/sink term) with the solved species transport equations.

- Numerical Stability: Poorly coded rate equations can lead to negative concentrations or solver divergence. Implementation must include robustness checks (e.g., clamping concentrations to non-negative values).

- Performance: UDFs are called repeatedly. Efficient, vectorizable code is essential for feasible simulation times.

Quantitative Data for Common Complex Kinetic Models

The following table summarizes rate equations and parameters for non-Michaelis-Menten kinetics frequently requiring UDF implementation.

Table 1: Complex Enzyme Kinetic Models for UDF Development

| Kinetic Model | Rate Equation (v) | Key Parameters | Typical Application in Bioreactors |

|---|---|---|---|

| Substrate Inhibition | v = (V_max * [S]) / (K_m + [S] + ([S]^2 / K_i)) |

V_max: Max. velocity, K_m: Michaelis const., K_i: Inhibition const. |

High-substrate concentration processes (e.g., ethanol fermentation). |

| Allosteric (Hill Equation) | v = (V_max * [S]^n) / (K_0.5^n + [S]^n) |

V_max: Max. velocity, K_0.5: Substrate conc. at half V_max, n: Hill coeff. (cooperativity). |

Multi-subunit enzymes (e.g., dehydrogenases). |

| Ping-Pong Bi-Bi | v = (V_max * [A] * [B]) / (K_mB * [A] + K_mA * [B] + [A][B]) |

V_max: Max. velocity, K_mA, K_mB: Michaelis const. for substrates A & B. |

Transaminase, peroxidase reactions. |

| Competitive Inhibition | v = (V_max * [S]) / (K_m * (1 + [I]/K_i) + [S]) |

V_max: Max. velocity, K_m: Michaelis const., K_i: Inhibition const., [I]: Inhibitor conc. |

Product or by-product inhibition scenarios. |

| Non-Competitive Inhibition | v = (V_max * [S]) / ((K_m + [S]) * (1 + [I]/K_i)) |

V_max: Max. velocity, K_m: Michaelis const., K_i: Inhibition const., [I]: Inhibitor conc. |

Toxin or heavy metal inhibition. |

Protocols

Protocol 1: Development and Compilation of a UDF for Substrate Inhibition Kinetics in ANSYS Fluent

This protocol details the steps to create, compile, and hook a UDF to model substrate inhibition kinetics within a CFD bioreactor simulation.

I. UDF Script Creation (C Language)

- Create a new text file named

udf_kinetic_sub_inh.c. - Implement the following code, which defines the reaction rate source term for a species named

"substrate".

- Save the file in your Fluent working directory.

II. Compilation and Interpretation in ANSYS Fluent

- Start ANSYS Fluent and set up your bioreactor mesh.

- Navigate to

Define > User-Defined > Functions > Compiled.

- In the dialog, add the source file (

udf_kinetic_sub_inh.c).

- Click

Build. Resolve any compilation errors reported in the console.

- Upon successful build, click

Load.

III. Hooking the UDF to the CFD Model

- Set up the species transport model (

Define > Models > Species).

- In the Materials panel, define your substrate species.

- In the Cell Zone Conditions panel, select your fluid region and click

Edit....

- Navigate to the

Source Terms tab.

- For the substrate species, enable the source term and select

udf substrate_source from the drop-down menu.

- Proceed with iteration. The solver will now use the UDF to calculate the local reaction sink term.

Protocol 2: Experimental Determination of Kinetic Parameters for UDF Input

Accurate UDFs require experimentally derived parameters. This protocol outlines a standard microplate assay to determine V_max, K_m, and K_i for substrate inhibition kinetics.

I. Reagent Preparation

- Prepare a 10x stock solution of the substrate in the appropriate buffer.

- Prepare a 2x stock solution of the enzyme.

- Prepare a series of substrate working concentrations spanning a range both below and above the suspected

K_m and K_i.

II. Assay Procedure

- In a 96-well plate, add 50 µL of each substrate concentration (in duplicate).

- Initiate the reaction by adding 50 µL of the 2x enzyme solution to each well using a multi-channel pipette. Mix gently.

- Immediately place the plate in a pre-warmed microplate reader.

- Monitor the increase of product (or decrease of substrate) spectrophotometrically at the appropriate wavelength every 10-15 seconds for 5-10 minutes.

- Run control wells containing buffer instead of enzyme to account for non-enzymatic background.

III. Data Analysis

- Calculate the initial velocity (

v0) for each substrate concentration [S] from the linear portion of the progress curve (typically the first 5-10% of reaction).

- Fit the

v0 vs. [S] data to the substrate inhibition equation (Table 1) using non-linear regression software (e.g., GraphPad Prism, Python SciPy).

- The fitting algorithm will output the best-fit values for

V_max, K_m, and K_i, which are then used in the UDF.

Visualizations

UDF Implementation Workflow for CFD-Kinetics

UDF-CFD Solver Coupling Mechanism

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for Enzyme Kinetics Assays

Item

Function in Protocol

Example/Note

Recombinant Enzyme

The biocatalyst under study. Purified to homogeneity for accurate kinetic parameter determination.

Lyophilized powder, stored at -80°C. Rehydrated in specific activity-preserving buffer.

Substrate Stock Solution

Provides the reactant whose conversion is catalyzed. Must be stable and soluble at working concentrations.

e.g., p-nitrophenyl phosphate (pNPP) for phosphatases. Concentration must span Km and Ki.

Assay Buffer

Maintains optimal pH, ionic strength, and cofactor conditions for enzyme activity.

Often includes Mg²⁺ for kinases, or DTT to prevent cysteine oxidation.

Stop Solution

Halts the enzymatic reaction at precise time points for endpoint assays.

e.g., 1M Sodium Carbonate (for pNPP assays), or strong acid/base.

Microplate Reader

Measures the spectroscopic change (absorbance, fluorescence) associated with product formation.

Enables high-throughput, multiplexed initial rate measurements.

Non-Linear Regression Software

Fits initial velocity vs. [S] data to complex rate equations to extract kinetic constants.

GraphPad Prism, MATLAB, Python (SciPy, lmfit). Essential for Km, Ki, Vmax.

CFD Software with UDF API

Platform for implementing the kinetic UDF and simulating mass transfer with reaction.

ANSYS Fluent, COMSOL Multiphysics, OpenFOAM.

C/C++ Compiler

Required to compile the written UDF code into a library that the CFD solver can load.

Microsoft Visual Studio (for Windows), GCC (for Linux/OpenFOAM).

This application note details the integration of Computational Fluid Dynamics (CFD) modeling with experimental validation for a pilot-scale enzymatic stirred-tank reactor (STR). Within the broader thesis on "CFD Modeling of Mass Transfer in Enzymatic Bioreactors," this case study serves as a critical bridge between micro-scale kinetic models and macro-scale industrial reactor design. The primary objective is to develop a validated, multiphase CFD model that can accurately predict local and global mass transfer rates, substrate concentration heterogeneity, and enzymatic reaction efficiency under varying operational conditions. This directly addresses a core research gap in scaling biocatalytic processes from laboratory to pilot scale.

Table 1: Key Physicochemical & Kinetic Parameters for Model Input

| Parameter | Symbol | Value | Unit | Source/Note |

|---|---|---|---|---|

| Reactor Working Volume | V | 50 | L | Pilot-scale vessel |

| Impeller Type | - | Rushton turbine | - | Standard for gas dispersion |

| Impeller Speed Range | N | 100 - 400 | rpm | Experimental range |

| Aeration Rate Range | Q_g | 0.5 - 2.0 | vvm | Volume of gas per liquid volume per minute |

| Substrate Inlet Concentration | [S]_0 | 100.0 ± 5.0 | mM | Glucose analog |

| Michaelis Constant | K_m | 15.2 ± 1.8 | mM | Fitted from batch kinetics |

| Maximum Reaction Rate | V_max | 2.45 ± 0.15 | mmol/L·s | Product formation rate at saturation |

| Enzyme (Glucose Oxidase) | [E] | 0.05 - 0.20 | g/L | Immobilized on carrier beads (200-300 µm) |

| Liquid Density (aqueous) | ρ_L | 998.2 | kg/m³ | At 25°C |

| Liquid Dynamic Viscosity | μ_L | 0.001003 | Pa·s | At 25°C |

| Gas-Liquid Mass Transfer Coeff. (kLa) Range | kLa | 0.005 - 0.040 | s⁻¹ | Measured via dynamic gassing-out method |

Table 2: CFD Model Specifications & Boundary Conditions

| Component | Setting/Model | Rationale |

|---|---|---|

| Solver Type | Transient, Pressure-Based | Captures dynamic flow patterns |

| Multiphase Model | Eulerian-Eulerian | Suitable for high gas holdup ( >10%) |

| Turbulence Model | k-ε Realizable with Standard Wall Functions | Robust for high Reynolds number stirred flows |

| Reaction Model | User-Defined Function (UDF) | Incorporates Michaelis-Menten kinetics coupled to local concentration |

| Impeller Motion | Multiple Reference Frame (MRF) | Steady-state approximation for initial simulation |

| Boundary: Inlet | Velocity inlet (liquid & gas) | Defined by feed and aeration rates |

| Boundary: Outlet | Pressure outlet | Atmospheric pressure |

| Mesh Type | Polyhedral with boundary layer refinement | Better convergence and flow alignment than tetrahedral |

| Convergence Criterion | Residuals < 1e-04 | For momentum, continuity, and species equations |

Experimental Protocols for Model Validation

Protocol 3.1: Determination of Global Volumetric Mass Transfer Coefficient (kLa) Objective: To experimentally measure kLa for oxygen under operational conditions to validate the CFD-predicted gas-liquid mass transfer. Materials: Dissolved oxygen (DO) probe (membrane type, sterilizable), nitrogen gas supply, data acquisition system, bioreactor control system. Procedure:

- Equilibrate the reactor with N₂ sparging until DO reaches 0%.

- Abruptly switch the gas supply from N₂ to air at the desired flow rate (Q_g) and impeller speed (N).

- Record the DO concentration increase over time until saturation (~100%).

- Fit the dynamic DO data to the equation: dC/dt = kLa (C - C), where C is the saturation concentration.

- Repeat for all combinations of N (100, 200, 300, 400 rpm) and Q_g (0.5, 1.0, 1.5, 2.0 vvm).

Protocol 3.2: Enzymatic Reaction Progress Monitoring for CFD Kinetic Validation Objective: To obtain time-course substrate/product concentration data for validating the coupled CFD-reaction model. Materials: Immobilized glucose oxidase beads, glucose substrate solution, spectrophotometer, HPLC system, automated sampling system. Procedure:

- Load the reactor with buffer, add immobilized enzyme to the specified concentration ([E]).

- Start impeller and aeration at target conditions (e.g., 300 rpm, 1.0 vvm).

- Initiate reaction by pumping concentrated substrate feed to achieve initial [S]_0.

- Using an automated sampler, collect liquid samples (1 mL) at fixed time intervals (0, 30, 60, 120, 300, 600 s).

- Immediately filter samples (0.2 µm) to remove enzyme beads and quench reaction.

- Analyze filtrate for substrate (glucose via glucose oxidase assay) and product (gluconic acid via HPLC with RI detector).

- Compare experimental conversion profile vs. time with CFD model predictions for bulk outlet concentration.

Visualizations of Workflow and System Logic

Title: CFD-Experimental Workflow for Bioreactor Modeling

Title: Coupled Mass Transfer & Reaction Logic in CFD Model

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Enzymatic STR Modeling & Validation

| Item | Function/Application | Key Specification/Note |

|---|---|---|

| Immobilized Glucose Oxidase | Model enzyme for aerobic oxidation reaction. Provides stable, reusable biocatalyst. | From Aspergillus niger, immobilized on porous silica beads, activity ≥ 100 U/g beads. |

| D-Glucose (Substrate) | Primary reactant for the enzymatic reaction. | High-purity (>99.5%) for kinetic studies, prepared in phosphate buffer (pH 7.0). |

| Dynamic gassing-out kit | For experimental kLa determination. | Includes calibrated DO probe, N₂/Air gas mixing system, and data logging software. |

| CFD Software with UDF Capability | Platform for solving multiphase flow with custom reaction kinetics. | ANSYS Fluent or OpenFOAM. Required for implementing user-defined Michaelis-Menten functions. |

| Polyhedral Mesh Generation Tool | Creates the computational domain for the reactor. | ANSYS Mesher or similar. Critical for accurate capture of shear and vortex regions near impeller. |

| Automated Sampling System | For aseptic, time-point sampling during enzymatic reaction. | Maintains sterility and allows for high-time-resolution data for model validation. |

| HPLC System with RI Detector | Quantitative analysis of substrate depletion and product formation. | Validated method for separating glucose and gluconic acid (e.g., Aminex HPX-87H column). |

Diagnosing and Solving Common CFD Mass Transfer Problems in Bioreactors

Identifying Mass Transfer Limitation 'Hotspots' from CFD Results

Application Notes

Within the broader thesis on CFD modeling of mass transfer in enzymatic bioreactors for drug synthesis, identifying localized regions of poor mass transfer—'hotspots'—is critical. These hotspots can limit substrate availability to immobilized enzymes, reduce overall reactor yield, and compromise product uniformity. This document outlines a protocol for extracting, analyzing, and validating these limitations from transient or steady-state CFD simulation results.

The primary metrics for identification are the local Damköhler number (Da) and the substrate concentration field. Da represents the ratio of the reaction rate to the mass transfer rate. Regions where Da >> 1 indicate reaction-limited conditions, while Da << 1 signify severe mass transfer limitation.

Table 1: Key Metrics for Identifying Mass Transfer Limitation Hotspots

| Metric | Formula (Local) | Interpretation (Per Computational Cell) | Typical Threshold for "Hotspot" | ||

|---|---|---|---|---|---|

| Damköhler Number (Da) | Da = (ν * kcat * [E]) / (ks * a) | Da >> 1: Reaction-limited. Da << 1: Mass transfer-limited. | Da < 0.1 | ||

| Substrate Concentration ([S]) | Direct scalar field from CFD | [S] ~ 0: Severe depletion, indicating a hotspot. | [S] < 10% of inlet [S] | ||

| Concentration Gradient ( | ∇[S] | ) | Magnitude of spatial derivative | High gradient indicates a steep boundary layer, signaling transfer resistance. | Context-dependent; compare to bulk. |

| Local Sherwood Number (Sh) | Sh = (ks * dh) / D_s | Low Sh indicates poor convective mass transfer relative to diffusion. | Sh << correlation-predicted value |

Protocol: Post-Processing CFD Results to Map Limitation Hotspots

Materials & Software:

- CFD Solver Output: Transient or steady-state fields for velocity, substrate concentration, and turbulent parameters (e.g., k-ε).

- Post-Processor: Paraview, ANSYS CFD-Post, or equivalent.

- Scripting Environment: Python (with NumPy, SciPy) or MATLAB for batch calculation of derived variables.

- Enzyme Kinetics Data: k_cat (turnover number) and K_M (Michaelis constant) for the immobilized enzyme system.

Procedure: