Systematic Catalyst Testing and Evaluation Protocols: A Comprehensive Guide for Research and Development

This article provides a comprehensive guide to systematic catalyst testing and evaluation protocols tailored for researchers, scientists, and drug development professionals.

Systematic Catalyst Testing and Evaluation Protocols: A Comprehensive Guide for Research and Development

Abstract

This article provides a comprehensive guide to systematic catalyst testing and evaluation protocols tailored for researchers, scientists, and drug development professionals. It covers the foundational principles of catalyst performance, including activity, selectivity, and stability. The guide explores standardized methodological approaches, high-throughput experimentation, and protocol adaptation for various catalyst types, including electrocatalysts and heterogeneous systems. It also delves into troubleshooting common issues like deactivation and poisoning, along with strategies for process optimization. Finally, the article outlines rigorous validation procedures, comparative benchmarking, and data integrity practices to ensure reliable and reproducible results, accelerating catalyst discovery and development.

Understanding Catalyst Fundamentals: Principles, Performance Metrics, and Types

The systematic evaluation of catalyst performance is fundamental to advancing research and development in fields ranging from pharmaceutical synthesis to renewable energy. Performance is primarily quantified through three interdependent metrics: activity, which measures the rate of reaction; selectivity, which defines the catalyst's ability to direct the reaction toward the desired product; and stability, which determines the catalyst's lifespan under operational conditions [1]. These metrics are not isolated; they are deeply influenced by the catalyst's physical and chemical properties and the reaction environment. A holistic understanding of these parameters enables researchers to develop high-performance catalysts tailored for specific applications, thereby optimizing processes for greater efficiency, sustainability, and cost-effectiveness [2].

This document outlines standardized protocols and application notes for the accurate assessment of these core performance metrics, framed within a broader thesis on systematic catalyst testing. The guidance is designed for researchers and development professionals who require robust, reproducible methods to bridge the gap between laboratory-scale discovery and industrial application.

Core Performance Metrics and Quantitative Assessment

A rigorous, multi-faceted approach is essential for a comprehensive understanding of catalyst performance. The following table summarizes the key metrics, their definitions, and standard evaluation methods.

Table 1: Core Catalyst Performance Metrics and Evaluation Methodologies

| Performance Metric | Definition | Key Quantitative Measures | Common Evaluation Techniques |

|---|---|---|---|

| Activity | The rate at which a catalyst converts reactants to products. | - Conversion (%) |

- Turnover Frequency (TOF, s⁻¹)

- Reaction Completion Time [3] [4] | - Gas Chromatography (GC)

- Spectroscopic Analysis (UV-Vis, Fluorescence)

- Kinetic Profiling [3] | | Selectivity | The ability to favor the production of a desired product over other possible by-products. | - Selectivity (%)

- Yield (%)

- Ratio of Desired to Undesired Products [1] | - Product Distribution Analysis (GC, HPLC)

- Monitoring of By-products and Intermediates [3] | | Stability | The ability to maintain activity and selectivity over time under operational conditions. | - Lifetime (hours/time-on-stream)

- Loss of Activity over Time

- Recyclability Number of Cycles [5] [6] | - Long-Term Continuous Flow Tests

- Accelerated Aging Studies

- Leaching Tests (for heterogeneous catalysts) |

The quantitative data for these metrics are derived from controlled experiments. For instance, catalyst activity can be reported as the percentage conversion of a key reactant or as a turnover frequency (TOF), which normalizes the reaction rate by the number of active sites. Selectivity is calculated as the percentage of the converted reactant that forms the desired product. Stability is often presented as a performance decay curve, showing conversion or selectivity as a function of time or reaction cycles [1] [3] [4]. High-throughput experimentation (HTE) platforms, which utilize well-plate readers and automated analytics, are increasingly employed to collect this multidimensional performance data efficiently across hundreds of catalysts simultaneously [3] [7].

Experimental Protocols for Performance Evaluation

Protocol for High-Throughput Screening of Catalyst Activity and Selectivity

This protocol utilizes a fluorogenic assay to simultaneously monitor reaction kinetics and product formation for multiple catalysts, ideal for initial screening phases [3].

- Objective: To rapidly screen a library of catalysts for activity and selectivity in a reduction reaction.

- Principle: A non-fluorescent nitro-moiety in a probe molecule is reduced to a strongly fluorescent amine, allowing real-time monitoring of reaction progress. The emergence of fluorescent by-products can also indicate selectivity issues [3].

Step-by-Step Procedure:

- Well Plate Setup: Prepare a 24-well plate. For each catalyst, create a pair of wells:

- Reaction Well: Add 0.01 mg/mL catalyst, 30 µM nitronaphthalimide (NN) probe, 1.0 M aqueous N₂H₄ (reductant), 0.1 mM acetic acid, and H₂O to a total volume of 1.0 mL.

- Reference Well: Prepare an identical mixture, but replace the NN probe with its reduced amine (AN) form to establish a fluorescence standard [3].

- Reaction Initiation and Monitoring: Place the plate in a multi-mode microplate reader.

- Program the reader for orbital shaking (5 seconds) before each measurement to ensure mixing.

- Set the excitation wavelength to 485 nm and emission to 590 nm.

- Scan the fluorescence intensity of all wells every 5 minutes for 80 minutes.

- Simultaneously, collect the full absorption spectrum (300-650 nm) at each interval [3].

- Data Processing and Analysis:

- Activity Calculation: Convert the fluorescence intensity of the reaction well into nominal product concentration using the reference well standard. Plot product concentration versus time to derive kinetic profiles and determine reaction completion times.

- Selectivity Assessment: Analyze the absorption spectra for the appearance of peaks corresponding to undesired intermediates (e.g., azo/azoxy forms around 550 nm). A stable isosbestic point in the absorption spectra indicates a clean conversion, while its shift suggests competing side reactions [3].

Protocol for Evaluating Catalytic Stability via Long-Term Testing

This protocol assesses the durability of a catalyst under continuous operation, a critical factor for industrial application.

- Objective: To determine the catalyst's resistance to deactivation over an extended time-on-stream.

- Principle: The catalyst is subjected to prolonged reaction conditions, and its activity and selectivity are monitored at regular intervals to track performance decay [5].

Step-by-Step Procedure:

- Reactor System Preparation: Set up a fixed-bed or continuous-flow slurry reactor system. Ensure all components are clean and inert.

- Catalyst Loading and Conditioning: Load a precise mass and volume of catalyst into the reactor. Activate the catalyst in situ under a specified gas flow (e.g., H₂, He) and temperature program according to its specific requirements.

- Stability Test Operation:

- Initiate the reaction by introducing the standard reactant feed at set operational conditions (temperature, pressure, flow rate).

- Maintain these conditions continuously for a predetermined period (e.g., 24-100 hours) [5] [4].

- Automatically sample the reactor effluent at regular intervals (e.g., every 1-2 hours).

- Sample Analysis and Data Interpretation:

- Analyze all effluent samples using calibrated online or offline analytical methods (e.g., GC, GC-MS).

- Calculate conversion and selectivity for each sampling point.

- Plot the conversion and selectivity versus time-on-stream. The slope of the activity curve indicates the deactivation rate. A stable catalyst will show a minimal decline in performance over the testing period.

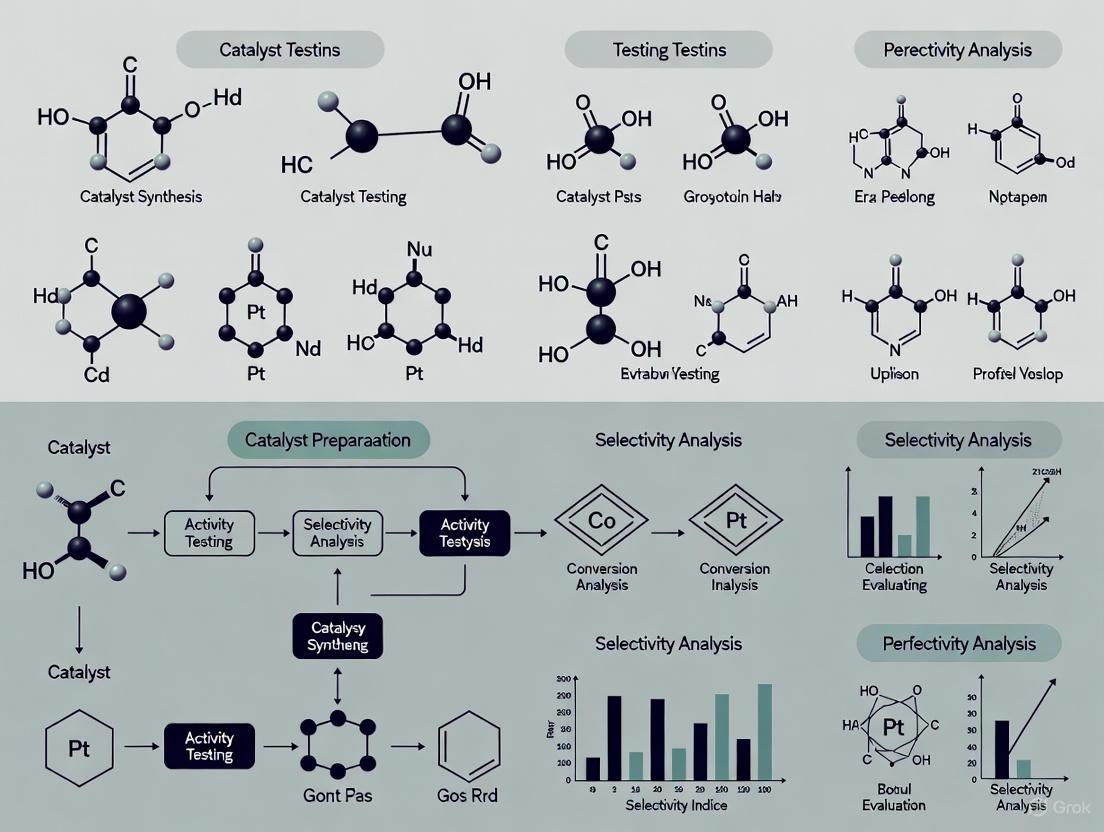

Workflow Visualization

The following diagram illustrates the integrated workflow for the systematic testing and evaluation of catalyst performance, from initial screening to stability assessment.

The Researcher's Toolkit: Essential Reagents and Materials

The following table details key reagents and materials essential for executing the catalyst testing protocols described in this document.

Table 2: Essential Research Reagent Solutions and Materials

| Item | Function/Application | Example in Protocol |

|---|---|---|

| Fluorogenic Probe (e.g., Nitronaphthalimide - NN) | Acts as a reactant and reporter; reduction from non-fluorescent nitro to fluorescent amine form allows real-time kinetic monitoring [3]. | High-throughput screening of reduction catalysts. |

| Microplate Reader | Enables automated, parallel measurement of fluorescence and absorption spectra from multiple reactions simultaneously [3]. | High-throughput screening. |

| Stabilizing Polymer (e.g., PAA, PVA) | Prevents nanoparticle aggregation in sol-immobilization preparation, controlling final particle size and dispersion on the support [2]. | Catalyst synthesis and immobilization. |

| Mass Flow Controllers | Precisely regulate the flow rates of gaseous reactants and carriers in continuous-flow reactor systems [8]. | Stability testing in fixed-bed reactors. |

| Online Gas Chromatograph (GC) | Provides quantitative, repeatable analysis of gas-phase product composition from reactor effluent, crucial for conversion and selectivity calculations [8]. | Performance evaluation in gas-phase reactions. |

| Activated Carbon Support | A high-surface-area support material that anchors metal nanoparticles, influences electronic properties, and can enhance activity/selectivity [2]. | Heterogeneous catalyst preparation. |

Catalysts are fundamental substances that accelerate chemical reactions without being consumed, playing a pivotal role in approximately 90% of all chemical manufacturing processes worldwide. They function by providing an alternative reaction pathway with lower activation energy, thereby increasing reaction rates and improving selectivity toward desired products. In the context of rigorous scientific research and industrial application, systematic catalyst testing and evaluation protocols form the cornerstone of developing efficient, sustainable, and economically viable chemical processes. The global catalyst market continues to expand, driven by advancements in pharmaceutical synthesis, renewable energy technologies, and environmentally conscious manufacturing.

This article provides a comprehensive technical overview of the three primary catalyst classifications—homogeneous, heterogeneous, and biocatalysts—with detailed application notes and standardized experimental protocols. The content is structured to support researchers, scientists, and drug development professionals in implementing systematic catalyst evaluation frameworks that ensure reproducibility, kinetic reliability, and meaningful cross-comparison between catalytic systems. By establishing rigorous testing methodologies, the scientific community can advance catalyst design and selection, ultimately accelerating innovation across chemical, pharmaceutical, and biotechnology sectors.

Catalysts are systematically classified based on their physical state and relationship to the reaction medium. This classification profoundly influences catalyst selection, reactor design, and process engineering.

Table 1: Fundamental Classification of Catalysts and Their Characteristics

| Classification | Phase Relationship | Key Advantages | Inherent Challenges | Exemplary Applications |

|---|---|---|---|---|

| Homogeneous Catalysts | Same phase as reactants (typically liquid) | High activity and selectivity, uniform active sites, mild operation conditions | Difficult separation/recycling, catalyst degradation, sensitive to conditions | Pharmaceutical synthesis, fine chemicals, polymerization |

| Heterogeneous Catalysts | Different phase from reactants (typically solid-fluid) | Easy separation, high stability, recyclability, continuous process compatible | Diffusion limitations, lower selectivity, active site heterogeneity | Bulk chemicals, petroleum refining, environmental catalysis |

| Biocatalysts | Biological catalysts (enzymes/whole cells) | Exceptional selectivity, green chemistry compliant, aqueous mild conditions | Narrow operational windows, sensitivity to inhibitors, cost considerations | Drug intermediate synthesis, food processing, biofuel production |

The selection of an appropriate catalyst class involves multidimensional consideration of reaction mechanisms, process economics, and sustainability goals. Heterogeneous catalysts dominate industrial-scale processes where continuous operation and easy separation are paramount. Homogeneous catalysts offer superior precision in complex synthetic pathways, particularly in asymmetric synthesis for pharmaceuticals. Biocatalysts represent the frontier of sustainable catalysis, operating under mild conditions with unparalleled selectivity while reducing environmental impact through biodegradable materials and aqueous systems.

Homogeneous Catalysts: Application Notes and Protocols

Fundamental Principles and Applications

Homogeneous catalysts exist in the same phase (typically liquid) as the reaction mixture, allowing for intimate contact with reactants and uniform active sites throughout the system. This molecular-level interaction facilitates highly efficient catalytic cycles with exceptional selectivity control, particularly valuable for synthesizing complex chiral molecules in pharmaceutical applications. Transition metal complexes featuring palladium, rhodium, ruthenium, and platinum are prevalent, often with sophisticated ligand architectures that tune reactivity and enantioselectivity. A significant application includes cross-coupling reactions (e.g., Suzuki, Heck) for carbon-carbon bond formation in active pharmaceutical ingredient (API) synthesis, where precise stereochemical outcomes are critical.

Experimental Protocol: High-Throughput Screening of Homogeneous Catalysts

Objective: To systematically evaluate a library of homogeneous catalysts for a specific transformation using quantitative fluorogenic assays and kinetic profiling.

Principle: This protocol utilizes a high-throughput, real-time optical scanning approach to monitor reaction progress. The method is exemplified for nitro-to-amine reduction but can be adapted for various transformations using appropriate probes [3].

Table 2: Research Reagent Solutions for Homogeneous Catalyst Screening

| Reagent/Material | Specification | Function in Protocol | Notes for Researchers |

|---|---|---|---|

| Nitronaphthalimide (NN) Probe | 30 µM in final reaction volume | Fluorogenic substrate; non-fluorescent in nitro-form, highly fluorescent upon reduction to amine (AN) | Enables real-time reaction monitoring via fluorescence increase at 590 nm |

| Catalyst Library | Dissolved in appropriate solvent (e.g., DMSO, MeOH) | The variable catalytic entities to be screened | Concentration typically 0.01 mg/mL; ensure solubility in reaction matrix |

| Aqueous Hydrazine (N₂H₄) | 1.0 M solution | Stoichiometric reducing agent | Handle with appropriate safety precautions in a fume hood |

| Acetic Acid | 0.1 mM in final reaction volume | Acid additive to modulate reaction pH/potential | Concentration optimization may be required for different reaction types |

| 24-Well Polystyrene Plate | Sterile, flat-bottom | Reaction vessel for parallel experimentation | Polystyrene is suitable for optical measurements from top or bottom |

| Multi-Mode Plate Reader | Capable of orbital shaking, fluorescence (Ex/Em: 485/590 nm), and absorption (300-650 nm) scanning | Instrument for automated kinetic data collection | Enables acquisition of fluorescence and full UV-Vis spectra at programmed intervals |

Procedure:

- Well Plate Preparation: In a 24-well plate, prepare reaction wells (S) each containing: 0.01 mg/mL catalyst, 30 µM NN probe, 1.0 M aqueous N₂H₄, 0.1 mM acetic acid, and H₂O to a total volume of 1.0 mL.

- Reference Wells: Prepare corresponding reference wells (R) with identical composition, except replacing the NN probe with the amine product (AN) to establish a fluorescence baseline for 100% conversion.

- Instrumental Setup: Place the loaded plate in a multi-mode plate reader (e.g., Biotek Synergy HTX). Program the reader for orbital shaking (5 seconds) before each measurement to ensure mixing.

- Data Acquisition: Initiate a method that cycles every 5 minutes for 80 minutes total. Each cycle should consist of:

- Fluorescence intensity measurement (Ex: 485±10 nm, Em: 590±17.5 nm).

- Full absorption spectrum scanning from 300-650 nm.

- Data Processing: Export data to CSV files or a dedicated database (e.g., MySQL). Calculate conversion over time by comparing the fluorescence intensity of reaction wells to reference wells. Analyze absorption spectra to monitor decay of the nitro-form (350 nm) and growth of the amine product (430 nm), while verifying reaction consistency via the isosbestic point (385 nm) [3].

Heterogeneous Catalysts: Application Notes and Protocols

Fundamental Principles and Applications

Heterogeneous catalysts constitute a distinct phase from the reactants, most commonly solids interacting with liquid or gaseous reaction mixtures. Their principal advantage lies in the facile separation from products post-reaction, enabling catalyst recycling and continuous process operation—critical factors for large-scale industrial manufacturing. These catalysts often comprise active metal nanoparticles (e.g., Pt, Pd, Ni) supported on high-surface-area materials like alumina, silica, or zeolites, which stabilize the active sites and influence reactivity. A prominent application is in petroleum refining, where fluid catalytic cracking (FCC) zeolite catalysts convert heavy hydrocarbons into gasoline-range molecules. Emerging research explores their use in sustainable energy contexts, such as metal oxides for photocatalytic water splitting and supported metals for carbon dioxide hydrogenation.

The Sabatier Principle in Heterogeneous Biocatalysis

A key concept governing the performance of self-sufficient heterogeneous biocatalysts (ssHBs)—where enzymes and essential cofactors are co-immobilized on a solid support—is the Sabatier principle [9]. This principle dictates that maximum catalytic efficiency is achieved at an intermediate strength of interaction between the cofactor and the immobilizing polymer matrix. If the binding is too weak, the cofactor leaches out. If it is too strong, enzyme access and catalytic turnover are hindered. Experimental evidence demonstrates this via a "volcano plot," where activity initially rises with binding strength, peaks at an optimum, and then declines. This interaction can be modulated by adjusting system parameters like pH and ionic strength, which in turn can induce the formation of a dense, liquid-like phase inside the catalyst particles, affecting overall performance [9].

Experimental Protocol: Rigorous Testing in Fixed-Bed Reactors

Objective: To obtain intrinsic kinetic data for a heterogeneous catalytic reaction while minimizing the influence of transport phenomena, ensuring data reproducibility and relevance for scale-up.

Principle: This protocol outlines the setup, operation, and data analysis for testing solid catalysts in a laboratory-scale fixed-bed reactor, emphasizing the control of external and internal mass/heat transfer limitations [10].

Table 3: Research Reagent Solutions for Heterogeneous Catalyst Testing

| Reagent/Material | Specification | Function in Protocol | Notes for Researchers |

|---|---|---|---|

| Catalyst Bed | Sieved particle size (e.g., 150-250 µm), diluted with inert quartz sand | The solid catalyst to be evaluated, packed into the reactor tube | Dilution and small particle size mitigate heat/mass transfer limitations |

| Tubular Reactor | Stainless steel or quartz, typically 1/4" or 1/2" OD | Contains the catalyst bed and operates under controlled temperature and pressure | Material must be inert to reactants/products at operation conditions |

| Mass Flow Controllers (MFCs) | Calibrated for specific gases (H₂, N₂, CO₂, etc.) | Precisely regulate the flow rates of gaseous reactants to the reactor | Essential for maintaining steady-state conditions and accurate mole balances |

| Liquid Feed Pump | High-precision HPLC or syringe pump | Delivers liquid reactants at a constant, precise flow rate | Liquid is often vaporized before contacting the catalyst bed |

| Back-Pressure Regulator | Upstream of product collection | Maintains constant system pressure | Critical for gas-phase reactions and studying pressure dependence |

| Online Gas Chromatograph (GC) | Equipped with appropriate detectors (FID, TCD) and autosampler | Analyzes the composition of the reactor effluent stream at regular intervals | Primary tool for quantifying conversion and selectivity at steady-state |

Procedure:

- Reactor Setup and Catalyst Loading: Pack the reactor tube with an inert material (e.g., glass wool) at the bottom. Create a homogeneous mixture of the sieved catalyst particles (150-250 µm) with inert quartz sand of a similar size range. Load this mixture into the reactor tube to form the catalyst bed, ensuring uniform packing to avoid channeling. Fill the remainder of the tube with inert packing material.

- Catalyst Pre-Treatment (Activation): Place the reactor in the furnace and connect all gas/liquid lines. Under a controlled inert gas flow (e.g., N₂), ramp the temperature to the specified activation condition (e.g., in flowing H₂ for metal oxide reduction). Hold at this condition for the prescribed duration (e.g., 2-4 hours), then cool to the desired reaction temperature under inert flow.

- Establishing Reaction Conditions: Switch flows to introduce the reactant feed mixture at the specified composition and total pressure. Allow the system to stabilize for at least 5-6 times the space-time (τ = catalyst mass/total flow rate) to reach steady-state operation.

- Steady-State Data Acquisition: Once stabilized, collect at least three product effluent samples using the online GC at consistent intervals. Record temperature, pressure, and all flow rates. Repeat this process for different temperatures, flow rates (conversions), or feed compositions to build a comprehensive kinetic data set.

- Data Analysis and Reporting: Calculate key performance metrics:

- Conversion (X): ( X = \frac{(F{A,in} - F{A,out})}{F_{A,in}} \times 100\% )

- Selectivity (S): ( SB = \frac{FB}{ \sum (F{i,out} - F{i,in}) } \times 100\% ) (for product B)

- Turnover Frequency (TOF): ( TOF = \frac{\text{Moles of reactant converted}}{\text{(Moles of active sites) } \times \text{ time}} ) Report all data with corresponding reaction conditions, catalyst mass, and particle size. Data collected at very high conversion (>90%) or near equilibrium should be avoided for intrinsic kinetic analysis [10].

Biocatalysts: Application Notes and Protocols

Fundamental Principles and Applications

Biocatalysts encompass enzymes and whole cells that catalyze chemical transformations with exceptional efficiency and selectivity under mild, typically aqueous, conditions. Their high specificity—including chemo-, regio-, and stereoselectivity—minimizes side reactions, making them indispensable for synthesizing complex chiral molecules in the pharmaceutical industry, such as active stereoisomers of drugs. According to the Enzyme Commission (EC) system, they are classified into six main classes based on reaction type: oxidoreductases (EC 1), transferases (EC 2), hydrolases (EC 3), lyases (EC 4), isomerases (EC 5), and ligases (EC 6) [11]. Hydrolases, for example, are extensively used in the production of enantiopure compounds, while oxidoreductases enable efficient chiral alcohol and amine synthesis. Their alignment with green chemistry principles, by reducing energy consumption, organic solvent use, and toxic waste, is driving their rapid adoption in sectors from fine chemicals to food processing and biofuel production.

Enzyme Immobilization for Enhanced Performance

A critical technology enabling the industrial application of biocatalysts is enzyme immobilization, which involves confining enzymes to a solid support or within a distinct phase [12]. This engineering strategy addresses key limitations of soluble enzymes, including poor stability, short shelf-life, and difficult recovery/reuse. Immobilization enhances operational stability across varying pH and temperature ranges, simplifies product separation, and allows for catalyst recycling, making processes more cost-effective and suitable for continuous operation [12]. Common techniques include:

- Adsorption: Weak physical binding to a carrier surface via hydrophobic or ionic interactions.

- Covalent Attachment: Formation of strong chemical bonds between enzyme functional groups and an activated support.

- Entrapment/Encapsulation: Physical confinement within a porous polymer matrix or membrane [12].

- Cross-Linking: Creating aggregates (CLEAs) or crystals (CLECs) of enzyme molecules.

Experimental Protocol: Co-Immobilization of Enzymes and Cofactors

Objective: To create a robust, self-sufficient heterogeneous biocatalyst (ssHB) by co-immobilizing an NAD(P)H-dependent dehydrogenase and its essential cofactor onto a functionalized porous agarose support [9].

Principle: This protocol describes the electrostatic co-immobilization of an enzyme and its cofactor (e.g., NADH) using a cationic polymer-coated agarose bead. The performance is governed by the Sabatier principle, where optimal activity is achieved at intermediate cofactor-polymer binding strength [9].

Table 4: Research Reagent Solutions for Biocatalyst Immobilization

| Reagent/Material | Specification | Function in Protocol | Notes for Researchers |

|---|---|---|---|

| Porous Agarose Beads | Functionalized with epoxy or amine groups | Solid, porous support matrix for immobilization | Provides high surface area and hydrophilic environment |

| Cationic Polymer | e.g., Polyethylenimine (PEI) | Creates a positively charged coating to electrostatically bind anionic cofactors (NAD(P)H) | Molecular weight and branching affect binding strength and final activity |

| Enzyme Solution | Purified dehydrogenase in suitable buffer | The biological catalyst to be immobilized | Purity and concentration should be accurately determined |

| Cofactor | e.g., NADH or NADPH, in buffer | Essential redox cofactor for dehydrogenase activity | Binding strength to polymer is modulated by pH and ionic strength |

| Buffers | Range of pH (e.g., 6.0-8.5) and ionic strength (e.g., 0-500 mM NaCl) | Modulate electrostatic interactions between cofactor, polymer, and enzyme | Critical for optimizing the system per the Sabatier principle |

Procedure:

- Support Functionalization: Incubate the porous agarose beads with a solution of the cationic polymer (e.g., 1-5 mg/mL PEI) in a weak buffer (e.g., 10 mM potassium phosphate, pH 7.5) for 2-4 hours at room temperature with gentle agitation. Wash the beads extensively with the same buffer to remove unbound polymer.

- Cofactor Loading: Incubate the polymer-coated beads with a solution of the cofactor (e.g., 1-5 mM NADH) in buffers of varying pH and ionic strength to explore different binding regimes. Agitate gently for 1 hour. Wash with buffer to remove unbound cofactor. The amount of bound cofactor can be quantified by measuring the absorbance of the supernatant before and after binding.

- Enzyme Immobilization: Add the purified dehydrogenase enzyme to the cofactor-loaded beads. Allow the immobilization to proceed for 4-16 hours at 4°C with gentle agitation. Recover the beads and wash thoroughly with buffer to remove any unbound enzyme. The immobilization yield can be determined by measuring the protein concentration in the initial solution and wash fractions.

- Activity Assay and Optimization: Assess the catalytic activity of the ssHB in a standard reaction mixture. Systematically vary the pH and ionic strength of the reaction buffer to modulate the cofactor-polymer interaction and identify the conditions that yield maximum activity, thereby generating the characteristic "volcano plot" [9].

- Reusability and Stability Testing: Recycle the ssHB by collecting the beads via simple filtration or centrifugation after each reaction batch, washing with buffer, and re-introducing them to fresh substrate solution. Monitor the retention of catalytic activity over multiple cycles to assess operational stability.

The Role of Standardized Protocols in Accelerating Catalyst Discovery

Catalyst discovery is a critical driver of innovation in the chemical, pharmaceutical, and energy sectors. However, the traditional approaches to catalyst development have been hampered by non-standardized research practices, creating significant bottlenecks in reproducibility, data comparability, and research efficiency. The adoption of standardized protocols for catalyst testing, data reporting, and synthesis planning represents a transformative opportunity to accelerate the entire discovery pipeline. This application note details the specific methodologies and frameworks enabling this transition, providing researchers with practical tools to enhance rigor and reproducibility in catalyst research.

The Critical Need for Standardization in Catalysis Research

The absence of standardized practices in catalyst testing and reporting presents a substantial barrier to progress in the field. Traditional trial-and-error approaches struggle to navigate the vast chemical space of potential catalysts and are often limited by non-standardized, irreproducible data [13]. Several key challenges emerge from this lack of standardization:

- Irreproducible Kinetics Measurements: Common impediments include measurements taken at or near complete conversion, operations near equilibrium, and reporting of yields or conversions without corresponding reaction times or rates [10].

- Non-Ideal Reactor Hydrodynamics: Deviations from ideal reactor behavior due to improper flow characteristics, mixing inefficiencies, or transport limitations significantly impede the ability to reproduce catalytic performance data [10].

- Inconsistent Synthesis Reporting: The lack of standardization in reporting synthesis protocols hampers machine-reading capabilities and prevents the creation of comprehensive, structured databases [14].

These challenges cumulatively result in wasted research effort, inhibited data sharing, and slowed development of predictive models. Addressing them through systematic protocol standardization is foundational to advancing catalyst discovery.

Standardized Methodologies for Catalyst Testing and Evaluation

Protocol 1: Rigorous Catalyst Performance Testing

Reliable catalyst evaluation requires careful attention to reactor selection, experimental design, and data reporting. The following standardized procedure ensures the acquisition of kinetically relevant and reproducible data.

Materials and Equipment:

- Fixed-bed reactor or appropriate reactor system

- Mass flow controllers for gaseous feeds

- Precision liquid feed pumps for liquid reactants

- Online analytical instrumentation (e.g., GC, GC-MS, HPLC)

- Temperature-controlled furnaces and temperature sensors

- Pressure measurement and control systems

Procedure:

- Reactor Selection and Setup: Select a reactor configuration that minimizes transport limitations and approximates ideal hydrodynamic behavior. For fixed-bed reactors, verify catalyst bed dilution and particle size optimization to eliminate internal and external diffusion limitations [10].

- Catalyst Activation: Pre-treat the catalyst under specified conditions (temperature, atmosphere, duration) to achieve the desired active state. Document all activation parameters precisely.

- Establish Steady-State Operation: Initiate reactant flow and maintain operation until steady-state conditions are confirmed by consistent product composition over time (typically 3-5 residence times).

- Performance Measurement: Measure reaction rates at controlled conversions (preferably below 20%) to ensure differential reactor operation and obtain intrinsic kinetic data [10].

- Data Collection: Record multiple data points at steady state, including:

- Temperature profiles along the reactor

- Input and output compositions

- Flow rates of all streams

- System pressure

- Repeatability Assessment: Conduct replicate experiments to establish measurement uncertainty and reproducibility.

Reporting Standards: All catalyst testing reports must include:

- Detailed reactor configuration and catalyst bed characteristics

- Exact catalyst mass and volume

- Complete feed composition and flow rates

- Verified steady-state condition documentation

- Conversion, yield, and selectivity calculations with mass balances closing within 95-105%

- Turnover frequencies (TOFs) where applicable, with active site quantification methodology

Protocol 2: Standardized Synthesis Procedure Reporting for Machine Readability

The extraction and analysis of synthesis protocols from literature can be dramatically accelerated by adopting standardized reporting formats optimized for both human comprehension and machine readability.

Materials:

- Chemical precursors and solvents

- Synthesis equipment (reactors, furnaces, etc.)

- Text annotation software (for protocol curation)

- ACE (sAC transformEr) model or similar NLP tools [14]

Procedure:

- Action Term Definition: Identify and consistently use standardized action terms for synthesis steps (e.g., mix, dissolve, heat, pyrolyze, filter, wash, dry, calcine) [14].

- Parameter Standardization: For each action term, report all essential parameters using consistent units and formats:

- Temperature: Include ramp rates, hold times, and atmosphere

- Concentrations: Use molarity or standardized weight percentages

- Durations: Report in consistent time units

- Ratios: Use standardized molar or mass ratios

- Sequential Recording: Document synthesis procedures as sequential action-parameter pairs rather than narrative descriptions.

- Annotation: Use dedicated annotation software to tag action terms and corresponding parameters in synthesis descriptions [14].

- Model Application: Process standardized protocols through transformer models (e.g., ACE model) to extract structured, machine-readable data sequences [14].

Implementation Example: The ACE model, when applied to standardized protocols, achieves a Levenshtein similarity score of 0.66 and a BLEU score of 52, indicating high-quality translation of natural language descriptions into structured, actionable data [14]. This approach can reduce literature analysis time by over 50-fold, from an estimated 500 man-hours to just 6-8 hours for analyzing 1000 publications [14].

Quantitative Impact of Standardization on Discovery Metrics

The implementation of standardized protocols generates substantial improvements across key catalyst discovery metrics. The following table summarizes quantitative evidence from recent implementations:

Table 1: Quantitative Benefits of Standardized Protocols in Catalyst Discovery

| Metric | Traditional Approach | With Standardization | Improvement Factor | Source |

|---|---|---|---|---|

| Literature analysis time | ~500 man-hours/1000 papers | 6-8 hours/1000 papers | ~50-80x faster | [14] |

| Catalyst design cycle time | Months to years | Days | 20,000x faster prediction | [15] |

| Data extraction fidelity | Not applicable | 66% information capture | Levenshtein similarity 0.66 | [14] |

| Dataset scale | Limited QC | 11M high-fidelity data points | Unprecedented scale | [15] |

| Experimental optimization cycles | 90 experiments/3 generations | Significantly reduced | Bayesian optimization | [13] |

These quantitative improvements demonstrate that standardized protocols enable researchers to explore broader chemical spaces, design novel compounds not found in existing literature, and identify optimal chemical compounds in dramatically reduced timeframes [15].

Integrated Workflow for Next-Generation Catalyst Discovery

The combination of standardized experimental protocols with artificial intelligence creates a powerful, closed-loop ecosystem for accelerated catalyst discovery. The following diagram illustrates this integrated workflow:

Diagram 1: Integrated AI-Driven Catalyst Discovery Workflow

This workflow leverages multiple advanced technologies that build upon standardized protocols:

- Large-Scale Datasets: Standardized data enables training of Large Quantitative Models (LQMs) on massive datasets like AQCat25, which contains 11 million high-fidelity quantum chemistry calculations across 40,000 intermediate-catalyst systems [15].

- Generative AI Models: Reaction-conditioned generative models (e.g., CatDRX) can design novel catalyst candidates by learning structural representations of catalysts and associated reaction components [16].

- Autonomous Laboratories: Robotic platforms integrated with AI execute experiments using standardized protocols, enabling closed-loop "design-make-test-analyze" cycles without human intervention [13].

Essential Research Reagent Solutions

The successful implementation of standardized catalyst discovery protocols requires specific research tools and platforms. The following table details key solutions and their functions:

Table 2: Essential Research Reagent Solutions for Standardized Catalyst Discovery

| Category | Specific Solution | Function & Application | Key Features |

|---|---|---|---|

| Computational Datasets | AQCat25 Dataset [15] | Training predictive AI models for catalyst design | 11M quantum calculations; includes spin polarization |

| AI/ML Models | CatDRX Framework [16] | Generative catalyst design & activity prediction | Reaction-conditioned variational autoencoder |

| Text Mining Tools | ACE Transformer Model [14] | Automated extraction of synthesis protocols from literature | Converts prose to structured action sequences |

| Laboratory Automation | Autonomous Robotics [13] | High-throughput, reproducible catalyst testing & synthesis | Closes the predict-make-measure discovery loop |

| Optimization Algorithms | Bayesian Optimization [13] | Efficient experimental design & parameter optimization | Minimizes trials needed for convergence |

| Testing Equipment | Standardized Reactor Systems [10] | Rigorous catalyst performance evaluation | Ensures kinetically-relevant data collection |

Standardized protocols represent a fundamental enabler for the next generation of catalyst discovery. By implementing rigorous testing methodologies, machine-readable reporting standards, and integrated AI-driven workflows, research organizations can achieve order-of-magnitude improvements in efficiency, reproducibility, and innovation capacity. The tools and methodologies detailed in this application note provide a concrete foundation for researchers to transform their catalyst discovery pipelines, ultimately accelerating the development of advanced materials for energy, sustainability, and pharmaceutical applications.

Setting Clear Testing Objectives for Research and Development

In catalyst research and development, establishing clear testing objectives is a fundamental prerequisite that transforms exploratory research into structured, results-driven innovation. This foundational step determines every subsequent aspect of the experimental workflow, from sample selection and analytical method choice to data interpretation criteria. Well-defined objectives enable researchers to systematically navigate the complex, multidimensional design space of catalyst development, where performance is influenced by numerous interacting factors including composition, morphology, particle size, support material, and surface characteristics [3]. The catalyst testing protocol must be carefully designed to extract meaningful performance data that accurately reflects how the catalyst will function under real-world industrial conditions, bridging the gap between laboratory discovery and commercial application [8].

The absence of precisely defined testing goals often leads to inconsistent data, irreproducible results, and an inability to make valid comparisons between different catalytic materials. Within the broader context of systematic catalyst testing and evaluation protocols research, this application note provides a structured framework for establishing clear testing objectives, selecting appropriate experimental protocols, and implementing standardized evaluation methodologies across diverse catalyst systems. By adopting this systematic approach, research and development teams can accelerate catalyst discovery and optimization while generating reliable, comparable performance data that directly supports informed decision-making throughout the development pipeline.

Defining Testing Objectives: A Strategic Framework

Testing objectives must be explicitly defined before initiating any experimental work, as these goals fundamentally shape all subsequent aspects of the testing protocol [8]. The specific objectives determine which catalyst samples to select, what parameters to measure, which analytical methods to employ, and how to interpret the resulting data. Several primary categories of testing objectives drive most catalyst research and development initiatives.

Performance Evaluation objectives focus on quantifying key catalytic properties under controlled conditions. For novel catalyst formulations, this begins with verifying that they meet required specifications and standards, while for used catalysts, testing reveals remaining activity levels and helps determine optimal timing for regeneration or replacement [8]. This systematic evaluation approach maintains consistent production quality and prevents unexpected operational shutdowns in industrial applications.

Process Optimization objectives utilize testing data to identify ideal operating conditions for parameters such as temperature, pressure, and feed composition. The insights gained from structured testing reveal opportunities for higher yields while simultaneously controlling operational costs [8]. Manufacturing teams can then implement process improvements based on concrete performance metrics rather than speculation, leading to superior production outcomes and enhanced economic efficiency.

Troubleshooting objectives come into focus when processes underperform relative to expectations. Under these circumstances, catalyst testing serves as an essential diagnostic tool to identify specific problems such as deactivation patterns or poisoning effects [8]. This targeted problem identification enables research teams to implement precise corrective actions, minimizing operational downtime and maintaining consistent production quality.

Regulatory Compliance objectives ensure that catalysts and processes meet stringent environmental regulations and emissions standards, particularly in highly regulated industries. Regular catalyst testing provides necessary documentation to demonstrate adherence to these requirements [8]. Well-maintained testing records offer robust evidence for regulatory audits and help ensure continuous compliance with evolving environmental standards.

Research and Development objectives drive innovation in catalyst formulation and application. Scientists rely on methodical testing results to evaluate different formulations and compare various materials [3]. This systematic experimentation supports the creation of better-performing catalysts that can transform industrial processes and enable new possibilities in chemical manufacturing and environmental technology.

Table 1: Classification of Catalyst Testing Objectives

| Objective Category | Primary Focus | Key Metrics | Application Context |

|---|---|---|---|

| Performance Evaluation | Quantifying catalytic properties & activity | Conversion rate, selectivity, stability | New catalyst verification, used catalyst assessment |

| Process Optimization | Identifying ideal operating parameters | Temperature, pressure, feed composition effects | Yield improvement, cost reduction |

| Troubleshooting | Diagnosing performance issues | Deactivation patterns, poisoning effects | Process deviation analysis, problem resolution |

| Regulatory Compliance | Meeting environmental standards | Emissions levels, documentation | Environmental reporting, audit preparation |

| Research & Development | Innovating new catalyst formulations | Activity, selectivity, stability comparisons | Novel catalyst development, material science research |

Experimental Protocols: Standardized Methodologies for Catalyst Assessment

Standardized Aftertreatment Catalyst Test Protocols

The Advanced Combustion and Emission Control Technical Team, in support of the U.S. DRIVE Partnership, has developed comprehensive standardized test protocols to accelerate aftertreatment catalyst innovation. These protocols enable accurate evaluation and comparison of catalyst performance data across various research facilities, addressing industry's critical need for consistent metrics in aftertreatment catalyst assessment [17]. Each protocol provides detailed descriptions of required reactor systems, procedures for achieving desired catalyst aged states, necessary sample pretreatments, and realistic test conditions for performance evaluation.

The standardized framework includes four distinct protocols for low-temperature catalysts: (1) oxidation catalysts, (2) passive storage (and release) catalysts, (3) three-way catalysts, and (4) NH₃-SCR catalysts [17]. The protocols consist of two primary components: general guidelines applicable to all testing scenarios, and specific procedures tailored to each catalyst type. This dual structure ensures consistency across different testing laboratories while accommodating the unique requirements of each catalyst technology. The complete protocol for any application combines the general guidelines with the relevant specific catalyst description, forming a comprehensive testing methodology.

High-Throughput Screening Protocol for Catalyst Discovery

Modern catalyst development increasingly employs high-throughput experimentation (HTE) to efficiently navigate complex multidimensional design spaces. The protocol outlined below exemplifies this approach for catalytic nitro-to-amine reduction, utilizing real-time optical scanning to monitor reaction progress [3].

Assay Preparation: The system employs a simple on-off fluorescence probe that produces a significant fluorescent signal shift when the non-fluorescent nitro-moiety reduces to the amine form. This approach combines an affordable probe with accessible technique to enable high-throughput catalyst screening [3].

Well Plate Setup: Experiments utilize 24-well polystyrene plates populated with 12 reaction wells and 12 corresponding reference wells. Each reaction well contains a sample consisting of 0.01 mg/mL catalyst, 30 µM nitro-naphthalimide (NN) probe, 1.0 M aqueous N₂H₄, 0.1 mM acetic acid, and H₂O, with a total volume of 1.0 mL. Each sample well pairs with a reference well containing an identical mixture, except the NN dye is replaced with the anticipated end product, the reduced amine form (AN) [3].

Data Collection: Once initiated, the plate is placed in a multi-mode reader programmed for orbital shaking (5 seconds) at room temperature, followed by fluorescence scanning. Excitation wavelength is set at 485 nm (20 nm band-pass), with emission detection at 590 nm (35 nm band-pass). The reader scans the entire plate's fluorescence intensity in approximately 20 seconds, then collects absorption spectra (300-650 nm) for each well. This shaking-fluorescence-absorption cycle repeats every 5 minutes for 80 minutes total to obtain comprehensive reaction profiles [3].

Data Processing: Raw data from the microplate reader is converted to CSV files, typically transferred to a database system like MySQL. For each catalyst, the platform generates four kinetic graphs: (A) absorption spectrum evolution, (B) absorbance values at key wavelengths (350 nm, 430 nm, 385 nm isosbestic point) over time, (C) fluorescence intensity at 590 nm over time, and (D) calculated conversion percentage based on fluorescence [3].

Diagram 1: Systematic catalyst testing workflow from objectives to decisions. This flowchart illustrates the comprehensive process for establishing testing objectives, selecting appropriate methodologies, executing protocols, and making data-driven R&D decisions.

Catalyst Aging Testing Protocol

Catalyst aging testing represents another critical protocol, particularly for applications in refining, petrochemicals, and environmental processes where long-term stability directly impacts operational economics. This testing methodology employs sophisticated hardware and software systems to simulate real-world operating conditions over extended periods [18].

Testing System Configuration: Modern aging test systems incorporate reactors, sensors, and analytical instruments that measure critical parameters including temperature, pressure, and chemical composition during accelerated aging cycles. These systems increasingly feature automation and IoT connectivity for remote monitoring and data collection. Advanced sensors detect minute changes in catalyst properties such as surface area or pore structure, while data acquisition systems ensure consistent results across multiple testing cycles [18].

Data Integration: Contemporary aging testing systems adhere to industry standards like OPC UA or Modbus, enabling seamless data exchange between hardware components and software platforms. APIs facilitate integration with enterprise systems (ERP), laboratory information management systems (LIMS), and cloud services. Compliance with safety and environmental standards remains critical, particularly when handling hazardous gases or high-temperature processes [18].

Outlook: By 2025, catalyst aging testing is expected to become increasingly automated and data-driven, with artificial intelligence and machine learning enhancing predictive capabilities to reduce downtime and costs [18].

Essential Research Reagents and Materials

The selection of appropriate research reagents and materials forms the foundation of reliable catalyst testing protocols. The specific materials vary significantly depending on the catalyst system and testing objectives, but several categories represent common essentials across multiple testing scenarios.

Table 2: Essential Research Reagents and Materials for Catalyst Testing

| Category | Specific Examples | Function/Purpose | Application Notes |

|---|---|---|---|

| Catalyst Materials | Fe₇C₃, Cu-SAPO-34, Cu@charcoal, Zeolites (NaY) | Primary catalytic active phases | Selection depends on target reaction; Prussian blue analogues can serve as precursors [3] [19] |

| Promoters/Additives | Potassium (K), Magnesium (Mg) | Enhance selectivity, stability, or activity | K accelerates carbonization; Mg suppresses water-induced oxidation [19] |

| Support Materials | Charcoal, ZrO₂, Al₂O₃ | Provide high surface area, stabilize active phases | Influence catalyst dispersion and stability |

| Probes & Analytical Reagents | Nitronaphthalimide (NN), FCF Brilliant Blue | Enable reaction monitoring via spectroscopic changes | NN provides fluorescence signal shift upon reduction [3] |

| Testing Gases | H₂, CO₂, NH₃, Standard gas mixtures | Reaction feeds, activation treatments, calibration | Composition must mirror actual plant conditions [8] [19] |

| Catalyst Precursors | Prussian blue analogues (PBA), Metal salts | Source materials for catalyst synthesis | PBA enable controlled thermal decomposition to target phases [19] |

Data Analysis and Interpretation: From Raw Data to Actionable Insights

Statistical Comparison Methods

Valid comparison of experimental results requires appropriate statistical analysis to determine whether observed differences represent significant effects or random variation. The comparison of methods experiment provides critical assessment of systematic error, requiring careful design and execution [20].

Experimental Design: A minimum of 40 different test specimens should be analyzed, selected to cover the entire working range of the method and represent the expected spectrum in routine application. These analyses should span multiple analytical runs over a minimum of 5 days to minimize systematic errors that might occur in a single run. Specimens must be analyzed within two hours of each other by test and comparative methods unless specific stability data supports longer intervals [20].

Data Analysis Approach: The most fundamental analysis technique involves graphing comparison results for visual inspection. For methods expected to show one-to-one agreement, difference plots display test minus comparative results on the y-axis versus the comparative result on the x-axis. For methods not expected to show direct agreement, comparison plots display test results on the y-axis versus comparison results on the x-axis [20].

Statistical Calculations: For data covering a wide analytical range, linear regression statistics provide estimates of systematic error at medically important decision concentrations while revealing constant or proportional error characteristics. The systematic error (SE) at a given decision concentration (Xc) is determined by calculating the corresponding Y-value (Yc) from the regression line (Y = a + bX), then computing SE = Yc - Xc [20].

Advanced Statistical Methods

Modern statistical approaches offer enhanced capabilities for comparing experimental conditions. Traditional methods that focus primarily on establishing statistical significance are increasingly supplemented by approaches that estimate effect size with confidence intervals [21]. Multi-model comparisons based on Wilks' theorem provide solutions to limitations of traditional methods, while empirical likelihood methods offer non-parametric alternatives that don't rely on assumptions of normality [21].

For discrete ordinal data, Thurstone modelling enables analysis using continuous distributions, aligning ordinal data analysis with parametric methods for continuous data [21]. These advanced statistical techniques provide more nuanced insights into catalyst performance differences and the confidence with which those differences can be established.

Case Study: Integrated Testing of Fe₇C₃ Catalyst for CO₂ Hydrogenation

A recent investigation of Fe₇C₃ catalysts with K-Mg dual promotion for CO₂ hydrogenation to olefins demonstrates the comprehensive application of systematic testing protocols [19]. This case study exemplifies the integration of multiple testing methodologies to address stabilization challenges for a promising catalytic phase.

Testing Objectives: The primary research objectives included (1) stabilizing the Fe₇C₃ phase under reactive conditions, (2) understanding promoter effects (K and Mg) on phase stability and selectivity, and (3) demonstrating long-term catalytic stability for industrial relevance [19].

Experimental Protocol: Catalyst precursors were synthesized from Prussian blue analogues, activated under NH₃ atmosphere to form Fe₂N, then subjected to CO₂ hydrogenation conditions (340°C, 2 MPa, H₂/CO₂ = 3) [19]. The testing protocol incorporated multiple characterization techniques including X-ray diffraction (XRD), Mössbauer spectroscopy, X-ray absorption spectroscopy (XAS), X-ray photoelectron spectroscopy (XPS), and high-resolution transmission electron microscopy (HRTEM) to comprehensively monitor structural evolution.

Performance Metrics: Testing revealed that the K promoter accelerated carbonization and enhanced olefin selectivity, while Mg effectively suppressed water-induced oxidation, preserving Fe₇C₃ structural integrity [19]. Under optimized conditions, the Fe₇C₃-KMg catalyst achieved 41.5% CO₂ conversion with 67.1% olefin selectivity, maintaining exceptional stability for over 1000 hours.

Outcomes: The systematic testing approach enabled researchers to identify distinct promoter roles and establish nearly phase-pure Fe₇C₃ as a stable catalytic phase under realistic CO₂ hydrogenation conditions, advancing beyond the traditional Fe₃O₄/χ-Fe₅C₂ paradigm [19]. This case illustrates how clearly defined testing objectives combined with comprehensive characterization protocols can lead to significant catalyst innovations.

Establishing clear testing objectives represents the cornerstone of successful catalyst research and development. These objectives determine every aspect of the experimental workflow, from initial sample selection through final data interpretation. By categorizing testing goals into performance evaluation, process optimization, troubleshooting, regulatory compliance, and research-driven innovation, development teams can design targeted experimental protocols that generate actionable data with maximum efficiency.

The integration of standardized testing protocols, high-throughput screening methodologies, and advanced statistical analysis creates a robust framework for catalyst development that accelerates innovation while ensuring reliable, reproducible results. As catalyst technologies continue evolving toward increasingly complex formulations and applications, the systematic approach to testing objectives outlined in this application note will remain essential for translating laboratory discoveries into commercially viable catalytic processes that address global challenges in energy, chemicals production, and environmental protection.

Implementing Testing Methods: From Standardized Protocols to High-Throughput Systems

Standardized Reactor Systems and Laboratory-Scale Testing Setups

Rigorous and reproducible catalyst testing within well-characterized reactor systems is the cornerstone of catalysis science and reaction engineering. The primary objective of systematic catalyst evaluation is to acquire intrinsic kinetic data that can elucidate reaction mechanisms, establish structure-function relationships, and reliably demonstrate catalyst performance [10]. This application note provides detailed protocols for the design and operation of standardized laboratory-scale reactor systems, focusing on mitigating transport limitations to ensure the accurate measurement of chemical kinetics. Adherence to these protocols is critical for generating high-quality, reproducible data suitable for archival literature and industrial process development, forming a solid foundation for a thesis on systematic catalyst testing and evaluation [10].

Theoretical Foundations of Reactor Design

The design of a chemical reactor begins with a knowledge of the targeted chemical reactions. The reactor must provide sufficient volume to handle the required throughput and allow time for the reaction to reach a predetermined level of conversion or yield [22]. A fundamental concept in reactor analysis is the reaction coordinate or molar extent of reaction (ɛ), which provides a relationship between the initial number of moles of a component (Ni0), the reaction coordinate, and the number of moles (Ni) at any point in the reaction via the equation: Ni = Ni0 + νiɛ where νi is the stoichiometric number of component i (negative for reactants, positive for products) [22]. This concept is essential for tracking reaction progress and performing material balances across the reactor system.

Reliable catalyst evaluation requires the selection of a reactor with appropriate hydrodynamics and confirmation that the system adheres to the behavior described by the reactor design equations. This involves validating the underlying assumptions pertaining to mass, momentum, and energy transport [10]. Deviation from these ideal models is a primary impediment to the reproducibility of catalytic rate measurements.

Experimental Protocols for Catalyst Testing

Pre-Testing: Catalyst Sample Preparation and Mechanical Integrity Evaluation

Before catalytic performance testing, proper sample preparation and mechanical evaluation are crucial.

Protocol 1: Catalyst Sample Preparation

- Define Objectives: Clearly outline testing goals, such as measuring conversion, selectivity, or catalyst lifetime [8].

- Sample Selection: Obtain representative samples from the catalyst batch. For used catalysts, sample from steady-state regions of the reactor to ensure consistency [8].

- Preparation: Sieve the catalyst to a specific particle size fraction (e.g., 150-250 µm) to minimize internal mass transfer resistance and ensure uniform packing [10].

Protocol 2: Mechanical Strength Testing Mechanical failure of catalyst pellets generates fines, causing reactor blockages, increased pressure drops, and flow maldistribution [23].

- Single Particle Testing:

- Side Crushing Strength (SCS): Determines the strength of individual particles compressed between two plates. This quasi-static test provides data on the force required to fracture a pellet [23].

- Impact Testing: Measures the strength of particles under high-strain-rate impacts, simulating conditions during pneumatic conveying or loading. A high-speed camera can capture the fracture dynamics [23].

- Bulk Testing:

- Bulk Crushing Strength (BCS): A catalyst bed is quasi-statically compressed to a specified pressure. After unloading, the material is analyzed to determine the percentage of fines and broken particles generated, indicating the bed's resistance to crushing [23].

- Attrition Testing: Methods like the SPENCE rotating tube or ASTM D 4058-96 rotating drum evaluate the catalyst's resistance to abrasion and attrition, which is critical for fluidized bed reactors [23].

Core Testing: Protocol for Operating a Laboratory-Scale Tubular Reactor

The following protocol describes the operation of a packed-bed tubular reactor, a common setup for evaluating heterogeneous catalysts.

Apparatus and Reagents:

- Mass flow controllers for gases

- HPLC or syringe pump for liquids

- Tubular reactor (typically stainless steel or quartz)

- Furnace with temperature control

- Back-pressure regulator

- Online analytical instrument (e.g., Gas Chromatograph (GC), Mass Spectrometer (MS))

- Catalyst sample

Procedure:

- Reactor Loading: Mix the sieved catalyst with an inert diluent (e.g., silicon carbide, α-alumina) of a similar particle size. This dilution helps manage heat release in exothermic reactions and improves flow distribution. Pack the reactor tube to ensure uniform catalyst bed density.

- System Leak Check: Pressurize the system with inert gas (e.g., N₂, He) to the intended operating pressure. Monitor pressure drop to confirm no leaks are present.

- Catalyst Activation/Pre-treatment: Purge the system with inert gas. Ramp the temperature to the pre-treatment specification under the flowing inert gas or specific atmosphere (e.g., H₂ for reduction, air for calcination) and hold for the prescribed duration.

- Reaction Conditions Stabilization: Adjust the system to the desired reaction temperature, pressure, and feed flow rates. Allow the system to stabilize for a period significantly longer than the space time (τ = Vreactor / Vflow_rate) to reach steady-state operation.

- Data Collection: Once stable, sample the effluent for analysis. Collect data at multiple space times by varying the flow rate or catalyst mass to construct conversion and selectivity profiles. Data collection should track temperature, pressure, feed composition, and product composition [8].

- Performance Evaluation: Key metrics include:

- Conversion (X): (Moles of reactant converted) / (Moles of reactant fed)

- Selectivity (S): (Moles of desired product formed) / (Total moles of reactant converted)

- Yield (Y): (Moles of desired product formed) / (Moles of reactant fed) = X × S

- Stability: Measure of activity maintenance over time [8].

Critical Considerations:

- Transport Limitations: Experiments must be designed to avoid masking intrinsic kinetics.

- Interphase Transport: The Weisz-Prater criterion assesses external mass transfer limitations.

- Intraparticle Transport: The Mears criterion and effectiveness factor (η) calculations evaluate internal mass transfer limitations.

- Heat Transfer: Ensure minimal temperature gradients within the catalyst particle and across the reactor bed [10].

- Reporting: Always report catalyst mass, reactor volume, feed composition, temperature, and pressure. Measurements should be taken at conversions sufficiently low to avoid equilibrium or mass transfer limitations, typically below 20% for differential operation [10].

Data Interpretation and Analysis

Protocol 3: Interpreting Catalyst Test Outcomes

- Data Gathering: Compile recorded data on temperature, pressure, and inlet/outlet concentrations [8].

- Evaluating Performance Indicators: Analyze conversion, selectivity, and long-term stability trends [8].

- Analytical Methods: Use statistical tools to determine result reliability. Compare performance against benchmarks or standards. Employ mathematical modeling to predict reaction behavior under different conditions [8].

Data Standardization and Presentation

Central to catalyst testing is the systematic comparison of rates and selectivity among formulations. A common impediment to reproducibility is the use of inappropriate reporting metrics, such as data collected at complete conversion or near equilibrium [10].

Standardized Data Presentation Table The table below summarizes the essential data that must be reported with all catalytic performance data to ensure reproducibility and enable valid comparisons. This aligns with the thesis context's emphasis on systematic protocols.

Table 1: Essential Data Reporting Requirements for Catalyst Testing

| Category | Parameter | Reporting Standard |

|---|---|---|

| Catalyst Properties | Composition (mass %) | Precise elemental analysis or from synthesis |

| Surface Area (m²/g) | BET method | |

| Particle Size (μm or mm) | Sieve fraction used in testing | |

| Reactor System | Reactor Type | e.g., Packed-bed, Continuous Stirred-Tank Reactor (CSTR) |

| Reactor Volume (cm³) | Geometric or void volume | |

| Diluent & Dilution Ratio | Type and ratio of catalyst to diluent | |

| Operating Conditions | Temperature (°C or K) | Measured at the catalyst bed |

| Pressure (bar or kPa) | Absolute pressure at reactor inlet/outlet | |

| Feed Flow Rates (mol/h or cm³/min) | For all reactant streams | |

| Feed Composition (mol %) | Precise composition of the inlet stream | |

| Performance Metrics | Conversion (%) | Defined with respect to a specific reactant |

| Selectivity (%) | Defined for each major product | |

| Time-on-Stream (h) | Duration of the catalytic experiment |

Guidelines for Effective Data Visualization:

- Tables are ideal for presenting exact numerical values and summarizing study participant or catalyst characteristics, allowing readers to selectively scan data of interest [24].

- Figures, such as line graphs, are superior for depicting trends and relationships between variables over time [24] [25].

- Each exhibit should be self-explanatory, with a clear title, consecutive numbering, and footnotes for abbreviations or explanatory notes [24].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Research Reagent Solutions and Materials for Catalyst Testing

| Item | Function/Application |

|---|---|

| Silicon Carbide (SiC) | An inert, high-thermal-conductivity diluent used to mix with catalyst beds to improve heat transfer, minimize hot spots, and ensure uniform flow distribution. |

| High-Surface-Area Alumina (α-Al₂O₃) | An inert support material and a common catalyst carrier itself. Used as a diluent or for preparing catalyst supports. |

| Mass Flow Controllers (MFCs) | Precisely control and measure the volumetric or mass flow rates of gaseous reactants entering the reactor. Essential for maintaining steady-state operation. |

| Online Gas Chromatograph (GC) | An analytical instrument for separating, identifying, and quantifying chemical compounds in the reactor effluent. Often equipped with FID, TCD, or MS detectors. |

| Back-Pressure Regulator (BPR) | A device used to maintain and control the pressure within a flow reactor system by providing a restriction to the fluid flow. |

| Ultra-High Purity (UHP) Gases | High-purity gases (e.g., H₂, N₂, He, O₂, Air) used as reactants, carrier gases, or for system purging to prevent catalyst poisoning from impurities. |

Workflow and System Visualization

Diagram 1: Systematic catalyst testing workflow from preparation to reporting.

Diagram 2: Schematic of a laboratory-scale packed-bed reactor system for catalyst testing.

Within a systematic framework for catalyst evaluation, adapting core testing principles to the specific chemistry and operational environment of each catalyst is paramount for generating reliable and actionable data. The fundamental goal of catalyst testing—to obtain rigorous, reproducible, and scalable kinetic data—remains constant across different applications [10]. However, the distinct reactions, deactivation mechanisms, and performance metrics for oxidation, three-way, and selective catalytic reduction (SCR) catalysts demand highly specialized test protocols. This document outlines specific application notes and experimental methodologies for these three major catalyst classes, providing researchers with a structured approach to evaluate performance under conditions that mimic real-world application.

General Principles for Catalyst Testing

Before delving into application-specific details, it is critical to establish the general principles that underpin all rigorous catalyst testing. The selection of an appropriate reactor is "core business" in chemical engineering and is the foundation of reliable data [7]. Ideal reactor behavior, such that of a plug flow reactor (PFR), is often assumed in data analysis, and the test reactor must be designed to minimize deviations from this ideal [10].

Key reporting metrics are essential for comparability. Performance data should be acquired under differential conditions, far from equilibrium, to allow for meaningful comparison of intrinsic activity among different formulations [10]. Furthermore, performance must be reported with a clear accounting of the catalyst mass and its properties. As noted by Flaherty and Bhan, "reporting rates normalized by the mass of the catalyst is the minimum requirement for enabling comparisons; however, normalizing rates by the number of active sites (i.e., turnover frequencies) or by the catalyst volume or geometric surface area for structured catalysts provides a more fundamental basis for comparison" [10].

Oxidation Catalyst Test Protocol

Application Context

Oxidation catalysts, used for controlling emissions of carbon monoxide (CO) and volatile organic compounds (VOCs), are prevalent in industrial processes and gas turbines [26] [27]. Their primary function is to catalyze the oxidation of CO to CO₂ and VOCs to CO₂ and H₂O. Performance degradation over time is expected, and testing is crucial for lifecycle management and compliance with air quality regulations [27].

Experimental Protocol

1. Objective: To determine the conversion efficiency of CO/VOCs, project remaining catalyst life, and identify deactivation mechanisms (e.g., poisoning, fouling, thermal degradation) [27].

2. Reactor System: A laboratory-scale fixed-bed tube reactor equipped with a temperature-controlled furnace is standard [26] [27]. The system must include mass flow controllers for gases and vapor delivery systems for liquid VOCs if needed.

3. Feedstock Composition: The simulated gas stream should closely mirror the actual industrial exhaust. A typical synthetic feed gas includes:

- CO and VOCs (e.g., propane, toluene) as key reactants.

- O₂ in excess to ensure oxidation.

- CO₂ and H₂O to simulate real combustion products.

- N₂ as a balance gas [27].

4. Testing Procedure:

- The catalyst sample (a core drilled from a monolith or a quantity of particulate) is placed in the reactor [26].

- The reactor is heated to the target temperature under the synthetic feed gas.

- The Gas Hourly Space Velocity (GHSV) is set to match the full-scale system [26].

- Effluent gas is analyzed using a combination of Gas Chromatography (GC), Flame Ionization Detection (FID) for hydrocarbons, and Fourier-Transform Infrared (FTIR) spectroscopy or CO-specific analyzers [26] [27].

5. Performance Metrics:

- Conversion Efficiency (%): The percentage of CO or VOC converted at a set temperature.

- Light-Off Temperature (T₅₀): The temperature required for 50% conversion.

- Selectivity: The fraction of reactant converted to the desired products (CO₂ and H₂O) versus unwanted by-products [8].

The testing workflow for oxidation catalysts is systematically outlined below.

Table 1: Key Performance Metrics for Oxidation Catalyst Testing

| Metric | Definition | Typical Target | Testing Conditions |

|---|---|---|---|

| CO Conversion Efficiency | Percentage of CO oxidized to CO₂ | >95-99% [27] | Isothermal, specified GHSV |

| VOC Conversion Efficiency | Percentage of VOCs oxidized to CO₂ + H₂O | >90-95% [26] | Isothermal, specified GHSV |

| Light-Off Temperature (T₅₀) | Temperature for 50% conversion | As low as possible | Temperature ramp, constant feed |

| Pressure Drop | Resistance to gas flow across catalyst | Minimized | At operational GHSV |

The Researcher's Toolkit: Oxidation Catalyst Testing

Table 2: Essential Research Reagents and Materials for Oxidation Testing

| Item | Function/Description |

|---|---|

| Fixed-Bed Tube Reactor | Core vessel where the catalytic reaction takes place under controlled conditions [26]. |

| Mass Flow Controllers (MFCs) | Precisely regulate the flow rates of gaseous reactants (CO, O₂, N₂) into the reactor [26]. |

| Temperature-Controlled Furnace | Heats the reactor to the required operational temperatures, typically up to 600°C or higher [26]. |

| Gas Chromatograph (GC) | Separates and quantifies individual gas species in the reactor effluent [26]. |

| Flame Ionization Detector (FID) | Specifically and sensitively detects hydrocarbon VOCs in the effluent stream [26]. |

| FTIR Analyzer | Identifies and quantifies multiple gaseous compounds (including CO, CO₂, and VOCs) simultaneously in real-time [26]. |

Three-Way Catalyst (TWC) Test Protocol

Application Context

Three-way catalysts are the standard aftertreatment technology for gasoline engine exhaust, designed to simultaneously reduce nitrogen oxides (NOₓ) and oxidize CO and hydrocarbons (HC) [28]. A key challenge in testing is managing the complex redox chemistry and monitoring for undesirable by-products, such as ammonia (NH₃), which can form over the catalyst [28].

Experimental Protocol

1. Objective: To evaluate the simultaneous conversion efficiency of NOₓ, CO, and HC under simulated exhaust conditions and to study the formation of by-products like NH₃ [28].

2. Reactor System: A catalyst sample evaluation system is used, comprising a synthetic gas mixing panel, a fixed-bed micro-reactor with precise temperature control, and advanced gas analyzers [28].

3. Feedstock Composition: The standard gas mixture must simulate engine exhaust at different air-to-fuel ratios (λ). It typically contains:

- NO and O₂ as critical components for redox reactions.

- CO, H₂, and a representative HC (e.g., C₃H₆) as reductants.

- CO₂ and H₂O to mimic combustion products.

- N₂ as balance [28].

4. Testing Procedure:

- A small, lab-prepared catalyst sample or a core drilled from a full-scale catalyst is used [28].

- The test involves cycling or oscillating the feed gas composition between slightly rich (reducing) and slightly lean (oxidizing) conditions around the stoichiometric point (λ=1) to simulate real engine management.

- The temperature is varied to create "light-off" curves for each pollutant.

- The effluent is analyzed for NOₓ, CO, HC, and NH₃ using techniques like FTIR or chemiluminescence for NOₓ [28].

5. Performance Metrics:

- Conversion Efficiency (%) for NOₓ, CO, and HC individually and simultaneously.

- NH₃ Formation Selectivity: The amount of NH₃ generated as an unwanted by-product of NOₓ reduction [28].

- Oxygen Storage Capacity (OSC): A key indicator of the catalyst's ability to buffer exhaust composition changes, often correlated with overall health [29].

The testing workflow for three-way catalysts, which includes simulating engine exhaust cycles, is detailed in the following diagram.

Table 3: Key Performance Metrics for Three-Way Catalyst Testing

| Metric | Definition | Typical Target | Testing Conditions |

|---|---|---|---|

| NOₓ Conversion Efficiency | Percentage of NOₓ reduced to N₂ | >95% at operating temperature | Oscillating λ, temperature ramp |

| CO/HC Conversion Efficiency | Percentage of CO/HC oxidized | >95% at operating temperature | Oscillating λ, temperature ramp |