The Dance of Atoms

How Russia is Harnessing Nanocatalysts to Revolutionize Industry

The Invisible Engines of Modern Life

Imagine a world where chemical reactions occur with perfect precision—where fuels are cleaner, medicines more potent, and industrial processes eco-friendly. This isn't science fiction; it's the promise of nanocatalysts, materials engineered at the scale of billionths of a meter.

Atomic Precision

Nanocatalysts operate at scales smaller than a virus, enabling unprecedented control over chemical reactions.

Industrial Impact

Russian industries are adopting these technologies to modernize traditional sectors like oil and gas.

The Nanoscale Revolution: Key Concepts and Breakthroughs

What Makes Nanocatalysts Unique?

Catalysts accelerate chemical reactions without being consumed. At the nanoscale, their surface area explodes—a sugar-cube-sized nanoparticle can have a surface area rivaling a soccer field. This exposes more active sites where reactions occur.

- Shape-shifting particles: Brookhaven Lab scientists found cobalt oxide nanoparticles under 2 nm flatten into 2D sheets when exposed to CO₂, boosting catalytic activity by 300% 6 .

- Hybrid catalysis: MIT researchers showed catalysts cycle between solid and molecular states during vinyl acetate production—a "cyclic dance" merging homogeneous and heterogeneous catalysis 4 .

- Atomic-resolution imaging: Stony Brook University's breakthrough in observing oxidized metal islands on nanoparticles could unlock greener catalysts 3 .

Table 1: Nanoparticle Size Dictates Reaction Outcomes

| Nanoparticle Size | Structure Under CO₂ | Primary Reaction Product | Catalytic Efficiency |

|---|---|---|---|

| < 2 nm | 2D monolayer | Methane (CH₄) | 300% increase |

| > 3 nm | Stable 3D pyramid | Carbon monoxide (CO) | Baseline efficiency |

Inside a Landmark Experiment: Watching Catalysts Morph in Real Time

Methodology: The Multimodal Approach

In 2025, researchers at Brookhaven National Laboratory tackled a mystery: Why do smaller cobalt nanoparticles favor methane production during CO₂ conversion? Their approach combined four cutting-edge tools:

Results: A Shape-Shifting Surprise

When exposed to CO₂, sub-2-nm particles underwent a stunning transformation: pyramidal 3D structures unfolded into 2D monolayers on cerium oxide supports. This maximized CO₂ binding sites. Larger particles remained rigid.

"The nanoparticles rearrange to create more sites for CO₂ binding—like a sponge expanding to absorb water. We never imagined this!"

Table 2: Experimental Techniques and Insights Revealed

| Technique | Function | Key Insight |

|---|---|---|

| Environmental TEM | Real-time atomic imaging in gas environments | Nanoparticle shape-shifting (3D → 2D) |

| X-ray absorption spectroscopy | Chemical state analysis | Cobalt reduction (Co³⁺ → Co²⁺) during reaction |

| X-ray diffraction | Crystalline structure mapping | Lattice expansion in cerium oxide support |

| Infrared spectroscopy | Detection of surface intermediates | Formate ions as critical reaction step |

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions in Nanocatalysis

| Reagent/Material | Function | Industrial Application |

|---|---|---|

| Cobalt oxide nanoparticles | CO₂ hydrogenation catalyst | Converting emissions to fuel |

| Cerium oxide supports | Stabilizes nanoparticles; oxygen reservoir | Automotive catalytic converters |

| DNA origami scaffolds | Precisely arranges nanoparticles | Targeted drug delivery systems |

| Graphene oxide membranes | Selective gas separation | Hydrogen purification for clean energy |

| Palladium-silver alloys | Active sites for oxidation reactions | Vinyl acetate production (plastics) |

Nanoparticle Synthesis

Precision engineering of nanoparticles for specific catalytic applications.

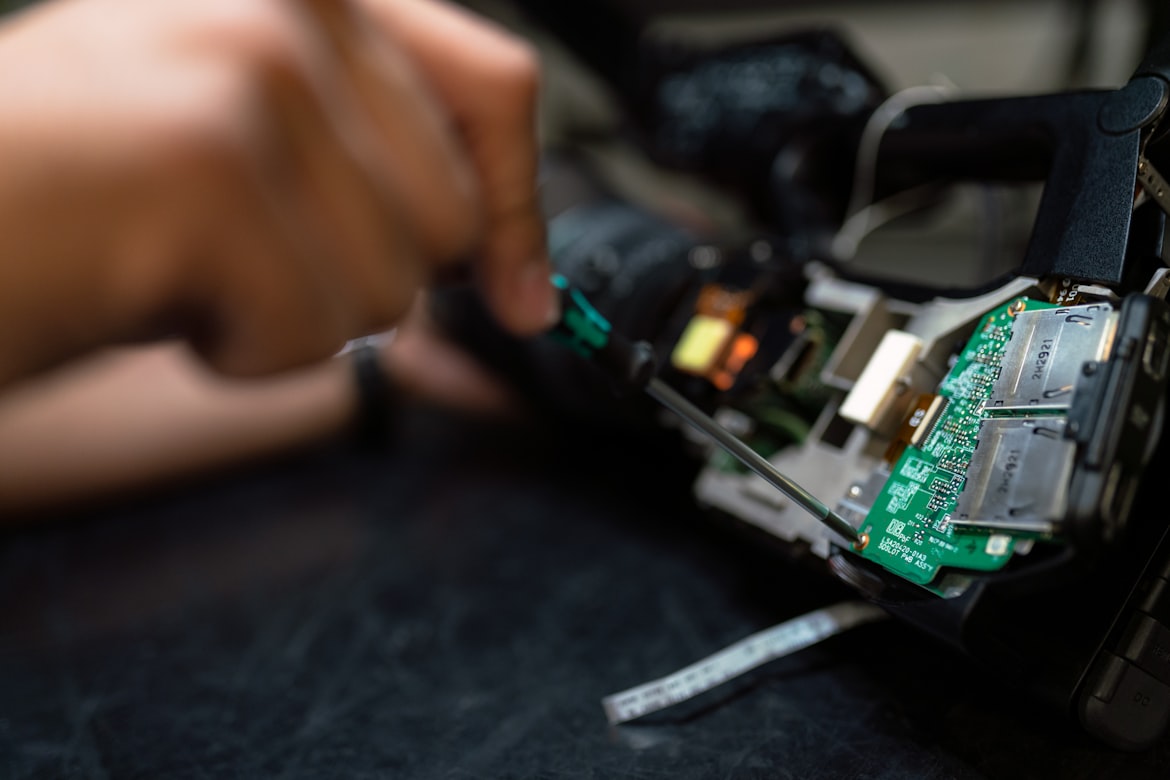

Advanced Microscopy

Cutting-edge imaging techniques to observe atomic-scale transformations.

Spectroscopic Analysis

Detailed chemical analysis of catalytic processes in real-time.

Russia's Nanocatalysis Landscape: From Labs to Industry

Strategic Focus Areas

Russia channels nanocatalyst research into sectors critical to its economy:

Oil and Gas

40%RUSNANO (state nanocorp) partnered with Alcoa to develop antiwear nanocoatings for drill pipes, extending lifespan by 40% 5 .

Environmental Protection

NewIron-silver quantum dots enable ultrasound-triggered oxidation for cancer therapy and pollution control 1 .

Polymers and Tires

₽1TNext-gen polymer catalysts aim to add ₽1 trillion to Russia's GNP by 2030 2 .

"Russia will enter the world nanotechnology market within three years due to sustained state support."

Educational Backbone

Leading institutions drive innovation:

Moscow State University

Trains interdisciplinary teams via its Nanotechnology ERC.

Tomsk State University

Focuses on plasma nanocoatings for electronics.

Ural Federal University

Pioneers bio-nanocomposites for sustainable materials.

Skolkovo Institute

Leads in commercializing nanocatalyst technologies.

Challenges and Future Frontiers

The Roadblocks

-

Regulatory gaps

No global consensus on nanomaterial safety standards 7 .

-

Scalability

Translating lab shapeshifting catalysts to industrial reactors remains complex.

Next-Generation Goals

Dynamic Catalysts

Materials that self-optimize structure for different reactions.

AI-Driven Design

USC's Allegro-FM model simulates billion-atom systems to predict nanocatalyst behavior 8 .

Zero-Waste Cycles

Northwestern's non-toxic catalyst breaks down plastics into reusable monomers .

Conclusion: The Atomic Dance Goes Global

Russia's bet on nanocatalysis reflects a profound shift—from resource extraction to atomic-scale engineering. As Siberian labs manipulate nanoparticles to capture carbon, and Moscow startups 3D-print DNA-based catalysts, the line between fundamental science and industry blurs.

"This dance between molecules and materials—once unseen—could reshape our chemical world"

The nanocatalysis revolution has begun, and Russia is leading the choreography.

Artistic rendering of cobalt nanoparticles (blue spheres) on a cerium oxide surface (grey lattice) as they transform from 3D to 2D structures under CO₂ exposure. Based on Brookhaven Lab E-TEM data 6 .