The Silent Saboteur: Understanding and Mitigating Palladium Catalyst Deactivation in Methane Oxidation

This article provides a comprehensive analysis of Pd-based catalyst deactivation mechanisms during methane oxidation, a critical challenge in catalytic emission control and energy applications.

The Silent Saboteur: Understanding and Mitigating Palladium Catalyst Deactivation in Methane Oxidation

Abstract

This article provides a comprehensive analysis of Pd-based catalyst deactivation mechanisms during methane oxidation, a critical challenge in catalytic emission control and energy applications. We explore the fundamental chemical and physical causes of deactivation, including sintering, carbonaceous deposition, and palladium oxidation state changes. Methodological approaches for characterizing and monitoring deactivation in real-time are reviewed, alongside troubleshooting strategies for catalyst regeneration and operational optimization. The review concludes with a validation and comparative assessment of recent mitigation strategies, such as alloying, core-shell structures, and advanced support materials, offering actionable insights for researchers and engineers developing durable catalytic systems for environmental and biomedical applications.

Unveiling the Enemy: Core Mechanisms of Pd Catalyst Deactivation in Methane Flames

Palladium (Pd)-based catalysts are the cornerstone of efficient methane (CH₄) oxidation, a critical reaction for mitigating emissions from natural gas vehicles (NGVs) and stationary sources like power plants and turbines. Despite their high intrinsic activity, Pd catalysts undergo complex deactivation phenomena under real-world conditions. This whitepaper, framed within a broader thesis on Pd catalyst deactivation, provides a technical guide to the mechanisms, performance data, and experimental methodologies central to contemporary research in this field. Understanding these deactivation pathways is paramount for developing next-generation, durable catalysts.

Mechanisms of CH₄ Oxidation and Pd Catalyst Deactivation

Methane oxidation over Pd proceeds via a Mars-van Krevelen mechanism. Pd active sites facilitate the dissociative adsorption of O₂, forming active oxygen species that oxidize adsorbed CH₄ to CO₂ and H₂O. The primary deactivation pathways for Pd-based catalysts include:

- Sintering/Agglomeration: Thermal degradation leads to growth of Pd nanoparticles, reducing active surface area.

- Water/Hydroxyl Inhibition: Competitive adsorption of H₂O or formation of surface hydroxyls blocks active sites.

- Poisoning: Sulfur-containing compounds (e.g., SO₂) form stable surface sulfates.

- Phase Transformation: Active PdO can decompose to less active metallic Pd at high temperature or undergo reversible PdOPd transformations during redox cycling.

- Carbon Deposition: Though less common in lean conditions, coking can occur under transient exposure.

Performance Data and Key Metrics

Recent studies highlight the influence of support material, promoter elements, and operating conditions on catalyst activity and stability. Key performance indicators include Light-Off Temperature (T₅₀), Full-Conversion Temperature (T₉₀), and stability over time-on-stream.

Table 1: Comparative Performance of Pd-Based Catalysts for Methane Oxidation

| Catalyst Formulation | Support | Promoter/Additive | T₅₀ (°C) | T₉₀ (°C) | Key Stability Observation (Test Conditions) | Reference (Year) |

|---|---|---|---|---|---|---|

| 1 wt% Pd | Al₂O₃ | - | ~380 | ~450 | Rapid deactivation above 550°C due to sintering & PdO reduction. | J. Catal. (2022) |

| 1 wt% Pd | CeO₂-ZrO₂ (CZO) | - | ~350 | ~410 | Enhanced low-temp activity; CZO promotes oxygen storage & PdO stabilization. | Appl. Catal. B (2023) |

| 0.5 wt% Pd | Al₂O₃ | 2 wt% Co | ~340 | ~400 | Co promotes CH₄ activation and improves hydrothermal stability. | ACS Catal. (2023) |

| 1 wt% Pd | Zeolite (SSZ-13) | - | ~370 | ~440 | Excellent resistance to sintering but vulnerable to hydrothermal dealumination. | Nat. Commun. (2024) |

| 2 wt% Pd-Pt (4:1) | Al₂O₃ | - | ~360 | ~430 | Bimetallic system shows superior resistance to sulfur poisoning and sintering. | Top. Catal. (2024) |

Note: Data is representative and synthesized from recent literature. Performance is dependent on specific testing protocols (see Section 4).

Experimental Protocols for Activity and Stability Testing

Standard Catalyst Activity Test (Light-Off)

Objective: Determine the light-off (T₅₀) and full-conversion (T₉₀) temperatures. Protocol:

- Pretreatment: Load 50-100 mg of catalyst (sieved to 150-250 µm) in a fixed-bed quartz microreactor. Pretreat in 10% O₂/He at 500°C for 1 hour, then cool to 150°C in flowing He.

- Reaction Mixture: Introduce a feed gas consisting of 1% CH₄, 10% O₂, and balance He at a total flow rate of 100 mL/min (GHSV ≈ 30,000 h⁻¹).

- Temperature Programmed Oxidation: Ramp temperature from 150°C to 600°C at a rate of 5°C/min.

- Product Analysis: Monitor effluent gases using a Mass Spectrometer (MS) or Non-Dispersive Infrared (NDIR) analyzer for CO₂ and CH₄ concentrations.

- Data Analysis: Calculate CH₄ conversion. T₅₀ and T₉₀ are derived from the conversion vs. temperature profile.

Long-Term Stability/Deactivation Test

Objective: Assess catalyst durability under simulated aging conditions. Protocol:

- Aging Conditions: After initial light-off, hold the catalyst at a constant temperature (e.g., 400°C or 550°C) in the reaction feed (1% CH₄, 10% O₂) or a harsh aging feed (e.g., with 10% H₂O vapor) for 24-100 hours.

- Periodic Measurement: At set intervals (e.g., every 2 hours), perform a quick temperature ramp or hold to measure CH₄ conversion at a benchmark temperature (e.g., 400°C).

- Post-Mortem Analysis: Characterize spent catalysts using X-ray Diffraction (XRD), Transmission Electron Microscopy (TEM), X-ray Photoelectron Spectroscopy (XPS), and Temperature Programmed Reduction (TPR) to identify deactivation mechanisms (sintering, phase change, poisoning).

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for Pd Catalyst Research

| Item | Function/Description |

|---|---|

| Palladium Precursor (e.g., Pd(NO₃)₂ solution) | The source of active Pd, typically deposited on supports via impregnation. |

| High-Surface-Area Supports (γ-Al₂O₃, CeO₂-ZrO₂, Zeolites) | Provide a stable, dispersive matrix for Pd nanoparticles; influence metal-support interactions. |

| Promoter Precursors (e.g., Co(NO₃)₂, La(NO₃)₃) | Additives to enhance activity, stability, or poison resistance. |

| Simulated Exhaust Gases (CH₄, O₂, He, 10% H₂O(g), SO₂) | For creating controlled reaction environments mimicking real exhaust. |

| Quartz Reactor Tube & Wool | Inert vessel for packing catalyst in fixed-bed flow systems. |

| Mass Spectrometer (MS) or Micro-GC | For real-time, quantitative analysis of gas-phase reactants and products. |

| Temperature Programmed Reaction (TPR/TPO) System | Equipment for controlled atmosphere heating to study redox properties. |

| Reference Catalysts (e.g., commercial Pd/Al₂O₃) | Benchmarks for validating experimental setups and performance. |

Within the scope of research on palladium (Pd)-based catalysts for low-temperature methane oxidation, understanding deactivation mechanisms is critical for developing durable emission control systems. This whitepaper details the four primary deactivation pathways—sintering, fouling, poisoning, and phase transformation—framed within ongoing thesis research aimed at extending catalyst lifetime under realistic exhaust conditions.

Pathways of Deactivation in Pd-Based Methane Oxidation Catalysts

Sintering

Sintering is the loss of active surface area due to the agglomeration of Pd nanoparticles, driven by high temperatures (>600°C) common in methane oxidation.

Quantitative Data Summary: Table 1: Impact of Thermal Aging on Pd/Al₂O₃ Catalyst Properties

| Aging Condition (°C/h) | Initial Pd Dispersion (%) | Final Pd Dispersion (%) | Average Particle Size Increase (nm) | % Activity Loss (350°C) |

|---|---|---|---|---|

| 750 / 16 | 45 | 22 | 4.2 to 8.5 | 58 |

| 850 / 16 | 45 | 12 | 4.2 to 14.1 | 82 |

| 750 / 50 (wet) | 45 | 8 | 4.2 to 18.7 | 95 |

Experimental Protocol for Thermal Aging Study:

- Catalyst Preparation: Impregnate γ-Al₂O₃ support with Pd(NO₃)₂ solution to achieve 1 wt% Pd loading. Dry (120°C, 12h) and calcine (500°C, 4h in air).

- Aging: Place catalyst in a fixed-bed reactor. Expose to a flow of 10% O₂, 10% H₂O (for "wet" conditions), balance N₂. Heat to target temperature (e.g., 750°C or 850°C) at 10°C/min, hold for specified duration (16-50 hours).

- Characterization:

- CO Chemisorption: Measure CO uptake at 50°C via pulse chemisorption to calculate Pd dispersion.

- Transmission Electron Microscopy (TEM): Prepare samples by dispersing powder on a Cu grid. Image at 200 kV; measure particle size distribution from >200 particles.

- Activity Testing: Post-aging, evaluate methane oxidation activity under 1% CH₄, 10% O₂, balance N₂ at a space velocity of 100,000 mL g⁻¹ h⁻¹. Measure light-off temperature (T₅₀) and conversion at 350°C.

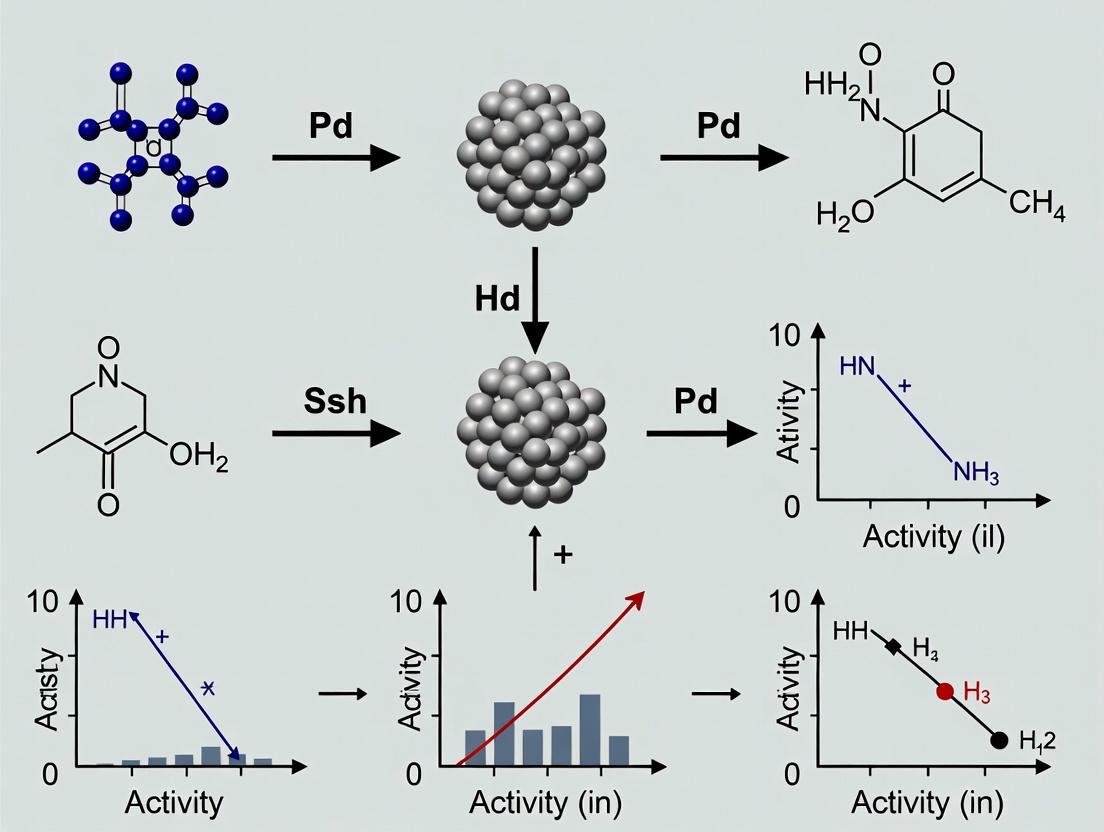

Diagram 1: Sintering Process in Pd Catalysts

Fouling

Fouling involves physical deposition of species (e.g., carbonaceous coke from incomplete combustion) onto the active sites, prevalent under fuel-rich or low-temperature conditions.

Quantitative Data Summary: Table 2: Coke Formation Impact Under Different Reaction Conditions

| Reaction Condition (CH₄:O₂) | Temp. (°C) | Time (h) | Carbon Deposit (wt%) | Activity Loss (%) |

|---|---|---|---|---|

| Rich (1:1) | 450 | 24 | 3.8 | 75 |

| Stoichiometric (1:2) | 450 | 24 | 0.7 | 15 |

| Lean (1:4) | 450 | 24 | 0.1 | 5 |

Experimental Protocol for Coke Deposition and Analysis:

- Fouling Induction: Test fresh Pd catalyst in a reactor under methane-rich conditions (1% CH₄, 1% O₂, N₂ balance) at 450°C for 24 hours.

- Post-Reaction Analysis:

- Thermogravimetric Analysis (TGA): Heat spent catalyst in air from room temperature to 800°C at 10°C/min. Weight loss corresponds to burned carbon.

- Temperature-Programmed Oxidation (TPO): After reaction, flush with He, then heat in 5% O₂/He flow to 800°C at 10°C/min. Monitor CO₂ production (mass spectrometry) to profile coke reactivity.

Poisoning

Poisoning denotes the strong chemisorption of impurities (e.g., S, P, Si) onto Pd, blocking active sites. Sulfur (from fuel or lubricants) is a primary poison.

Quantitative Data Summary: Table 3: Impact of Sulfur Exposure on Pd Catalyst Performance

| Poisoning Agent | Exposure Concentration (ppm) | Exposure Time (h) | Pd-S Species Identified (XANES) | Deactivation Rate Constant (min⁻¹) |

|---|---|---|---|---|

| SO₂ | 10 | 50 | PdO/PdSO₄ | 0.12 |

| SO₂ + H₂O | 10 | 50 | PdSO₄ dominant | 0.31 |

Experimental Protocol for Sulfur Poisoning Study:

- Poisoning Step: Pass a gas mixture containing 1% CH₄, 10% O₂, 10 ppm SO₂, with/without 5% H₂O over the Pd catalyst at 400°C.

- In-Situ Characterization: Use X-ray Absorption Spectroscopy (XAS) at the Pd K-edge to monitor the formation of Pd-S or Pd-O-S species during exposure. Analyze XANES region for white line intensity and EXAFS for Pd-S coordination numbers.

- Activity Monitoring: Record methane conversion continuously during poisoning to calculate deactivation rate.

Diagram 2: Catalyst Poisoning Mechanism by SO₂

Phase Transformation

This involves changes in the active Pd phase. For methane oxidation, the detrimental transformation is from active PdO to less active metallic Pd (Pd⁰) at high temperatures (>800°C) in lean conditions, and re-oxidation kinetics that may be slow.

Quantitative Data Summary: Table 4: Phase Stability of Pd under Cycling Conditions

| Condition | Temperature Range | Stable Phase (XRD) | CH₄ Oxidation Activity (Relative) |

|---|---|---|---|

| Lean, < 800°C | 400-750°C | PdO | 1.0 (Baseline) |

| Lean, > 800°C | 800-900°C | Pd⁰ | 0.2 |

| Redox Cycling (800°C) | N/A | PdO/Pd⁰ mixture | 0.4-0.6 |

Experimental Protocol for Phase Transformation Analysis:

- In-Situ XRD: Place catalyst in a high-temperature reaction chamber. Heat under 10% O₂/N₂ to 900°C while collecting XRD patterns every 50°C. Monitor the disappearance of PdO peaks (~34°) and appearance of Pd⁰ peaks (~40°).

- Redox Cycling: Subject catalyst to alternating flows of 5% O₂/N₂ and 5% H₂/N₂ at 800°C for 30-minute cycles. Use Mass Spectrometry to track O₂ consumption/H₂O production and Quick-XRD to capture phase changes.

- Activity Correlation: Test catalyst activity (1% CH₄, 10% O₂) at a standard temperature (e.g., 350°C) after each defined phase transformation treatment.

Diagram 3: Phase Transformation Between PdO and Pd⁰

The Scientist's Toolkit: Research Reagent Solutions

Table 5: Essential Materials for Pd Catalyst Deactivation Studies

| Item (Example Product) | Primary Function in Research |

|---|---|

| Palladium(II) Nitrate Solution (Pd(NO₃)₂ in ~10% HNO₃) | Precursor for incipient wetness impregnation of Pd onto supports. |

| γ-Alumina Support (High Surface Area, e.g., 150 m²/g) | High-surface-area support to stabilize Pd nanoparticles. |

| Certified Gas Cylinders (CH₄, O₂, N₂, 10 ppm SO₂/N₂) | Provide precise reactant and poison streams for aging/activity tests. |

| Silicon Carbide (SiC) Granules, inert | Used as a diluent in fixed-bed reactors to ensure proper thermal management and flow distribution. |

| Quartz Wool & Reactor Tubes | For packing catalyst beds in laboratory tubular reactors. |

| Reference Materials for XRD/XAS (PdO powder, Pd foil) | Critical for phase identification and energy calibration in spectroscopic studies. |

Integrated Experimental Workflow for Deactivation Analysis

Diagram 4: Catalyst Deactivation Study Workflow

Within the research on Pd-based catalyst deactivation during methane oxidation, a fundamental paradox exists: while palladium oxide (PdO) is widely recognized as the active phase for methane activation, metallic palladium (Pd⁰) forms under certain reaction conditions and is associated with catalyst deactivation. This whitepaper explores the thermodynamic, kinetic, and structural aspects of this paradox, synthesizing current research to guide experimental design and interpretation.

The Paradox: Underlying Principles

The oxidation of methane over palladium follows a Mars-van Krevelen mechanism, where lattice oxygen from PdO participates in the reaction. The paradox arises because the operating conditions (temperature, oxygen-to-methane ratio) can drive the reduction of PdO to Pd⁰, which is less active for C-H bond cleavage in methane. The subsequent re-oxidation of Pd⁰ to PdO is often slow and can lead to morphological changes, sintering, and permanent activity loss.

Table 1: Thermodynamic and Kinetic Parameters for PdO/Pd⁰ Transition

| Parameter | Value Range | Conditions (Typical) | Implications |

|---|---|---|---|

| PdO Decomposition Temperature (in air) | ~750-800 °C | 1 atm O₂ | Defines upper thermal limit for PdO stability. |

| Pd Oxidation Onset Temperature | 250-400 °C | 5% O₂ in N₂ | Hysteresis exists; oxidation is slower than reduction. |

| Apparent Activation Energy for CH₄ Oxidation on PdO | 80-110 kJ/mol | Lean conditions | True kinetics often masked by mass transfer. |

| Turnover Frequency (TOF) on PdO vs. Pd⁰ (at 400°C) | PdO: ~0.1-1.0 s⁻¹; Pd⁰: ~0.01 s⁻¹ | Stoichiometric mix | PdO is orders of magnitude more active. |

| Critical O₂:CH₄ Ratio for Pd⁰ Formation | < 1:1 (rich conditions) | 400-500°C | Sub-stoichiometric gas phases favor deactivation. |

Table 2: Common Catalyst Deactivation Indicators

| Indicator | Measurement Technique | Threshold for Significant Deactivation | Typical Change After Aging (e.g., 850°C, 50h) |

|---|---|---|---|

| T₅₀ (Temperature for 50% Conversion) | Light-off curve | Increase > 20 °C | Increase of 30-100 °C |

| Pd Crystallite Size | XRD Scherrer, TEM | > 20 nm | Growth from 5-10 nm to 30-50 nm |

| PdO Decomposition Temperature Shift | H₂-TPR, DSC | Lowering > 50 °C | Lowered due to weaker metal-support interaction |

| Surface Area Loss (BET) | N₂ Physisorption | > 50% loss | 70-90% loss common for unsupported catalysts |

Experimental Protocols for Key Investigations

Protocol:In SituXPS Study of Oxidation State Under Reaction Conditions

Objective: To correlate catalyst activity with the surface Pd oxidation state in real-time. Materials: Pd/Al₂O₃ wafer, in situ XPS cell, methane/oxygen gas mix. Procedure:

- Mount a pressed catalyst wafer in the in situ reactor cell of the XPS system.

- Pre-treat in 5% O₂/He at 500°C for 1 hour, then cool to desired reaction temperature (e.g., 400°C) in He.

- Acquire a reference Pd 3d spectrum under He flow.

- Switch to a reactant gas mixture (e.g., 1% CH₄, 4% O₂ in He). Monitor the reaction outlet with a mass spectrometer.

- Sequentially acquire Pd 3d spectra (e.g., every 15-30 min) while the reaction proceeds.

- Periodically switch to a reducing mixture (e.g., 1% CH₄, 0.5% O₂) to induce Pd⁰ formation and repeat spectral acquisition.

- Quantify the Pd⁰/Pd²⁺ ratio via spectral deconvolution (Pd⁰ 3d₅/₂ ~335.0-335.5 eV; Pd²⁺ 3d₅/₂ ~336.5-337.2 eV).

- Correlate the oxidation state ratio with the measured methane conversion rate.

Protocol: Light-off Curve Analysis with Redox Cycling

Objective: To assess the hysteresis and stability of PdO/Pd⁰ transitions. Materials: Fixed-bed reactor, 50 mg catalyst (Pd on modified Al₂O₃), 100 ml/min total flow. Procedure:

- Under oxidizing flow (5% O₂ in N₂), heat the catalyst to 600°C and hold for 30 min.

- Cool to 200°C in the same flow.

- Begin light-off: Introduce 1% CH₄, 4% O₂ (balance N₂). Ramp temperature at 5°C/min to 600°C, analyzing effluent with online GC (FID/TCD).

- At 600°C, hold for 30 min.

- Initiate cool-down curve: Ramp down at 5°C/min to 200°C under the same reaction mixture.

- Calculate T₅₀ for both heating (oxidation of pre-reduced surface) and cooling (reduction of pre-oxidized surface) cycles. The difference (ΔT₅₀) indicates hysteresis and deactivation propensity.

Visualization of Mechanisms and Workflows

Title: Pd Oxidation State Cycle and Deactivation Pathway

Title: Integrated Research Workflow for Pd Catalyst Study

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials and Reagents

| Item | Function/Description | Key Consideration for the Paradox |

|---|---|---|

| Pd Precursors (e.g., Pd(NO₃)₂, PdCl₂, Pd(AcAc)₂) | Source of palladium for catalyst synthesis. | Anion affects dispersion & chloride can inhibit oxidation. Nitrate is preferred for supported catalysts. |

| High-Surface-Area Supports (γ-Al₂O₃, CeO₂-ZrO₂, SiO₂) | Disperses Pd particles, enhances stability, can participate in redox. | Al₂O₃ is standard; CeZrO₂ promotes oxygen storage and Pd re-oxidation, mitigating deactivation. |

| Model Surfaces (Pd(111) single crystal, Pd thin films) | For fundamental surface science studies of oxidation/reduction kinetics. | Provides clean baseline data free from support effects. |

| Isotopic Gases (¹⁸O₂, ¹³CH₄) | To trace the origin of oxygen in products and the pathways of carbon. | Essential for proving Mars-van Krevelen mechanism and identifying poisoning species. |

| Temperature-Programmed Reaction (TPR/TPO) Gases (H₂, O₂, CH₄/O₂ mixes) | To probe redox properties and surface reactivity. | Determines PdO reduction temperature and re-oxidation kinetics directly. |

| Hydrazine Solution or H₂ Flow | For controlled pre-reduction of PdO to Pd⁰ before certain experiments. | Creates a defined metallic starting state to study oxidation kinetics. |

| Calibration Gas Mixtures (for GC, MS) | For quantitative analysis of reactant and product streams. | Critical for accurate measurement of conversion and selectivity, especially at low conversions near T₅₀. |

| Reference Catalysts (Commercial Pd/Al₂O₃) | Benchmark for comparing novel catalyst performance and deactivation rates. | Ensures experimental setup and protocols yield validated activity data. |

Within the broader research on Pd-based catalyst deactivation during methane oxidation, the role of water vapor is a critical deactivation pathway. This whitepaper details the mechanisms of water-induced deactivation, focusing on competitive hydroxyl (OH) inhibition and the formation of palladium hydroxide (Pd(OH)ₓ) species, which impede the catalytic oxidation cycle.

Mechanisms of Water-Induced Deactivation

Water vapor impacts Pd catalysts through two primary, often concurrent, mechanisms:

- Hydroxyl Inhibition: H₂O molecules or dissociated OH groups competitively adsorb on active Pd sites and PdO surfaces, blocking oxygen activation and methane adsorption.

- Pd(OH)ₓ Formation: The thermodynamic stabilization of surface or bulk palladium hydroxide phases under humid, low-temperature conditions, which are less active for C-H bond activation than PdO.

Table 1: Impact of Water Vapor on Methane Oxidation over Pd/Al₂O₃ Catalysts

| Catalyst Form | Temp. Range (°C) | H₂O Conc. (vol%) | Light-off T50 Increase (°C)* | Proposed Dominant Mechanism | Reference Year |

|---|---|---|---|---|---|

| Pd/Al₂O₃ (Fresh) | 300-450 | 0 → 2 | +15 | Hydroxyl Inhibition | 2023 |

| Pd/Al₂O₃ (Aged) | 300-450 | 0 → 5 | +45 | Pd(OH)ₓ Formation | 2022 |

| Pd-Pt/Al₂O₃ | 250-400 | 0 → 10 | +30 | Combined Inhibition/Formation | 2024 |

| Pd/CeO₂-ZrO₂ | 350-500 | 2 → 10 | +25 | Hydroxyl Inhibition | 2023 |

*T50: Temperature required for 50% methane conversion.

Table 2: Spectroscopic Evidence for Pd(OH)ₓ Formation

| Characterization Technique | Identified Species | Conditions for Formation | Key Spectral Feature | Reference Year |

|---|---|---|---|---|

| In situ Raman | PdO, α-Pd(OH)₂ | <200°C, >5% H₂O | Band at ~3650 cm⁻¹ (O-H stretch) | 2023 |

| XPS (Pd 3d) | Pd(OH)₂ surface layer | 150°C, humid air | Pd 3d₅/₂ BE ~337.5 eV | 2022 |

| DRIFTS | Surface Pd-OH | 100-300°C, H₂O present | Broad band ~3700-3200 cm⁻¹ | 2024 |

| XRD | β-Pd(OH)₂ bulk phase | <100°C, high humidity | Characteristic d-spacing ~2.7 Å | 2021 |

Experimental Protocols

Protocol 4.1: Evaluating Water Inhibition in Flow Reactor

- Objective: Quantify the reversible and irreversible deactivation caused by water vapor.

- Materials: Fixed-bed quartz reactor, mass flow controllers, online GC/MS, water vapor saturator, 1% Pd/Al₂O₃ catalyst (50 mg, 100-150 μm).

- Procedure:

- Pre-treat catalyst in dry air (20% O₂/N₂) at 500°C for 1h.

- Cool to target temperature (e.g., 350°C) under dry feed (1% CH₄, 20% O₂, balance N₂).

- Measure steady-state methane conversion.

- Introduce 2% H₂O vapor by bypassing N₂ through the saturator. Monitor conversion for 2h.

- Switch back to dry feed. Monitor recovery for 3h.

- Repeat at different temperatures to map reversible (inhibition) vs. irreversible (hydroxylation) effects.

Protocol 4.2: In situ DRIFTS for Surface Hydroxyl Detection

- Objective: Identify surface Pd-OH and adsorbed water species under reaction conditions.

- Materials: DRIFTS cell with environmental control, FTIR spectrometer, MCT detector, PdO powder catalyst.

- Procedure:

- Load catalyst into the DRIFTS cell. Pre-oxidize in 20% O₂/He at 400°C for 30 min.

- Collect background spectrum in dry He at 200°C.

- Introduce a humidified feed (5% H₂O in 10% O₂/He). Collect time-resolved spectra (4 cm⁻¹ resolution) for 60 min.

- Flush with dry He at the same temperature to observe persistence of OH bands.

- Perform temperature-programmed desorption (TPD) by ramping to 400°C in dry He while collecting spectra.

Protocol 4.3: Hydroxyl Phase Stability via TGA-DSC

- Objective: Determine the thermal stability and decomposition temperature of Pd(OH)ₓ phases.

- Materials: Thermogravimetric Analyzer with DSC, humidified air gas line, pre-hydroxylated Pd catalyst sample.

- Procedure:

- Hydroxylate catalyst ex-situ by exposing to 90% relative humidity at 80°C for 24h.

- Load 20 mg sample into TGA pan.

- Purge with dry N₂, then switch to humid air (5% H₂O).

- Run temperature ramp from 50°C to 500°C at 5°C/min.

- Correlate mass loss steps (TGA) with endothermic/exothermic events (DSC) to identify Pd(OH)₂ → PdO + H₂O decomposition.

Visualization Diagrams

Diagram 1: Water-Induced Deactivation Pathways

Diagram 2: Flow Reactor Test Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function/Benefit in Research | Typical Specification |

|---|---|---|

| Pd(NO₃)₂ Solution | Precursor for incipient wetness impregnation to prepare supported Pd catalysts. | 10 wt% in 10% HNO₃, trace metals basis. |

| γ-Al₂O₃ Support | High-surface-area, inert support for dispersing Pd nanoparticles. | BET SA >150 m²/g, 100-150 μm pellets. |

| Certified Gas Mixtures | Provide precise reactant (CH₄, O₂) and inert (N₂, He) streams for kinetic studies. | 1% CH₄ / Air, 10% O₂ / He, ±1% certified. |

| Permeation Tube (H₂O) | Generates precise, stable concentration of water vapor for feed gas. | Operates at 40-100°C, ~0.1-3.0 g/h output. |

| High-Temperature Sealant | Ensures leak-free connections in flow reactor systems up to 800°C. | Graphite-based, non-setting paste. |

| DRIFTS Cell with Windows | Allows in situ IR spectroscopic monitoring of surface species under reaction. | ZnSe or CaF₂ windows, max temp. 500°C. |

Within the research context of Pd-based catalyst deactivation during methane oxidation, thermal degradation via sintering represents a primary deactivation mechanism. Under the high operational temperatures (>500°C) required for complete methane conversion, supported Pd nanoparticles undergo kinetic processes that lead to particle growth, a loss of active surface area, and a consequent decline in catalytic activity. This technical guide provides an in-depth analysis of the fundamental sintering kinetics, experimental methodologies for its study, and the implications for catalyst longevity.

Fundamental Kinetics of Sintering

Sintering is a thermally activated process where metal atoms or entire particles migrate to reduce the total surface free energy. Two primary mechanisms dominate:

- Particle Migration and Coalescence (PMC): Whole crystallites diffuse across the support and coalesce upon contact.

- Ostwald Ripening (OR): Atomic species detach from smaller particles (higher chemical potential) and diffuse through the gas phase or along the support to deposit onto larger particles.

The dominant mechanism is influenced by temperature, metal-support interaction, and the gaseous atmosphere. The general kinetic rate law for particle growth is often expressed as:

[ \frac{d\bar{d}}{dt} = \frac{k_s}{\bar{d}^n} ]

where (\bar{d}) is the average particle diameter, (k_s) is the sintering rate constant (strongly temperature-dependent via Arrhenius behavior), and (n) is the mechanism-dependent exponent.

Table 1: Sintering Mechanism Kinetics

| Mechanism | Rate-Determining Step | Kinetic Exponent (n) | Key Influencing Factors |

|---|---|---|---|

| Particle Migration & Coalescence | Surface diffusion of whole particles | 3-5 | Support roughness, particle-surface bond strength |

| Ostwald Ripening (Gas-Phase) | Emission of volatile species (e.g., PdOₓ) | 2-3 | Volatility of metal oxide/hydride, temperature |

| Ostwald Ripening (Surface) | Surface diffusion of adatoms | 4-7 | Support surface diffusion barriers, adsorbate coverage |

Experimental Protocols for Studying Sintering

In Situ/OperandoParticle Size Analysis

Objective: To track real-time changes in Pd nanoparticle size under controlled atmospheres and temperature programs.

Protocol:

- Sample Preparation: Deposit a well-characterized Pd/γ-Al₂O₃ catalyst (e.g., 2 wt% Pd) onto a quartz wool plug or into a dedicated in situ cell.

- Pretreatment: Reduce/oxidize the catalyst in a flow of 5% H₂/N₂ or 5% O₂/He at 400°C for 1 hour.

- Sintering Experiment: Switch to a reactant gas mixture (e.g., 1% CH₄, 10% O₂ in balance N₂). Ramp temperature to the target operational range (e.g., 600-800°C) and hold for a defined period (e.g., 0-100 hours).

- Measurement: Use Small-Angle X-ray Scattering (SAXS) or Environmental Transmission Electron Microscopy (ETEM) to collect particle size data at regular intervals without exposing the sample to air.

- Data Analysis: Fit scattering profiles or micrograph histograms to determine the evolution of number-average ((dn)) and volume-surface average ((d{vs})) diameters.

Ex Situ Analysis via Chemisorption and Electron Microscopy

Objective: To quantify the loss of active metal surface area and correlate with particle growth.

Protocol:

- Accelerated Aging: Subject multiple identical catalyst samples to the target methane oxidation mixture at a constant high temperature (e.g., 750°C) for varying durations (t = 0, 10, 50, 100 h).

- Cooling & Passivation: Cool samples rapidly in inert gas and expose to a gentle 1% O₂/He flow to passivate surfaces.

- Pulse Chemisorption: Using a automated analyzer, perform CO or H₂ pulse chemisorption at 35°C to determine the dispersion (D) and metal surface area.

- Electron Microscopy: Prepare samples by dry deposition onto a TEM grid. Acquire high-resolution TEM (HRTEM) images from multiple regions. Measure particle diameters (N > 300) to generate particle size distributions (PSD).

- Calculation: Calculate the average particle size from dispersion: ( \bar{d} (nm) = \frac{6 \cdot 10^3}{\rho \cdot S \cdot D} ), where ρ is Pd density, S is stoichiometry factor.

Table 2: Key Research Reagent Solutions & Materials

| Item | Function/Description | Example & Notes |

|---|---|---|

| Pd Precursor | Source of active metal for catalyst synthesis. | Palladium(II) nitrate solution (Pd(NO₃)₂ in ~10% HNO₃). Ensures high dispersion on oxide supports. |

| High-Surface-Area Support | Provides a stable, dispersing medium for Pd nanoparticles. | γ-Alumina (Al₂O₃), 150 m²/g. Choice affects metal-support interaction and sintering rate. |

| Model Reactant Gas Mixture | Simulates operational conditions for aging studies. | 1.0% CH₄, 10% O₂, balance N₂ (or He). Must be precisely controlled via mass flow controllers. |

| Chemisorption Probe Molecule | Quantifies accessible metal surface sites. | 10% CO/He or 5% H₂/Ar gas mixture. CO can bridge-adsorb, requiring careful stoichiometry (Pd:CO). |

| In Situ Cell/Reactor | Allows treatment and analysis under controlled conditions. | Quartz microreactor with SAXS windows or dedicated ETEM holder with gas injection system. |

| Calibration Standard | For electron microscope magnification and SAXS q-range. | Gold nanoparticle reference material (e.g., 5nm ± 0.7nm Au on carbon film). |

Data Presentation: Quantitative Sintering Behavior

Table 3: Sintering Data for Pd/γ-Al₂O₃ under Methane Oxidation Conditions (750°C)

| Time on Stream (h) | Dispersion, D (%) | Metal Surface Area (m²/g Pd) | Average Particle Size, dₜₑₘ (nm) | Apparent Rate Constant, k_app (nm³/h) |

|---|---|---|---|---|

| 0 (Fresh) | 35.2 | 158.4 | 3.2 | - |

| 10 | 22.5 | 101.3 | 5.0 | 7.4 |

| 50 | 12.1 | 54.5 | 9.3 | 7.9 |

| 100 | 8.4 | 37.8 | 13.4 | 8.1 |

Note: Data is illustrative. k_app calculated assuming n=3 for PMC-dominated growth, using d⁽ⁿ⁾ - d₀⁽ⁿ⁾ = k_app * t.

Visualization of Pathways and Workflows

Thermal Degradation Pathways for Pd Catalysts

Experimental Protocol for Sintering Study

Thesis Context: This whitepaper details the mechanisms of carbonaceous deposit (coke) formation, a primary deactivation pathway for Pd-based catalysts during catalytic methane oxidation, a critical reaction for emission control and energy applications.

Coking refers to the formation and accumulation of carbonaceous species on a catalyst's active sites and support, leading to activity loss. For Pd catalysts under methane-rich or high-temperature oxidizing conditions, carbon forms via heterogeneous catalytic reactions. The nature of the carbon (e.g., polymeric, filamentous, graphitic) depends on reaction conditions, Pd particle size, and support chemistry.

Primary Mechanisms of Carbon Formation

Reaction Pathways

Carbon formation occurs through several parallel and sequential routes during methane oxidation.

Title: Reaction Pathways Leading to Coking in Methane Oxidation

Key Chemical Reactions

The primary reactions leading to carbonaceous deposits include:

- Methane Dehydrogenation: CH₄ (g) → C (s) + 2H₂ (g)

- Boudouard Reaction: 2CO (g) ⇌ C (s) + CO₂ (g)

- Ethylene/Polymeric Route: C₂H₄ → Oligomers → Polymeric Coke

- Incomplete Oxidation: CH₄ + (x/2)O₂ → C (s) + 2H₂O

Quantitative Data on Coking Effects

Table 1: Impact of Reaction Conditions on Coke Yield and Pd Catalyst Deactivation

| Condition Variable | Typical Test Range | Coke Yield (wt%)* | Relative Activity Loss (%)* | Predominant Coke Type |

|---|---|---|---|---|

| Temperature (°C) | 400-700 | 0.5 - 15.2 | 20 - 95 | Polymeric → Filamentous → Graphitic |

| O₂:CH₄ Ratio | 0.5 - 2.0 | 8.5 (0.5) - 0.8 (2.0) | 90 (0.5) - 15 (2.0) | Amorphous/Polymeric |

| Pd Particle Size (nm) | 2 - 20 | 2.1 (2nm) - 12.4 (20nm) | 30 (2nm) - 85 (20nm) | Encapsulating (small), Filamentous (large) |

| Support Type | Al₂O₃, CeO₂, ZrO₂ | Varies by redox activity | Al₂O₃: Higher polymeric; CeO₂: Lower due to O storage |

*Representative values from recent literature. Actual values depend on specific catalyst formulation and time-on-stream.

Table 2: Characterization Techniques for Coke Analysis

| Technique | Information Provided | Typical Experimental Output |

|---|---|---|

| Temperature-Programmed Oxidation (TPO) | Coke reactivity, approximate amount | CO₂ evolution peaks (200-400°C: polymeric; 500-700°C: graphitic) |

| Thermogravimetric Analysis (TGA) | Quantitative coke burn-off weight loss | Weight % loss curve vs. temperature |

| Raman Spectroscopy | Coke structure (D/G band ratio) | ID/IG ratio: ~2 (amorphous), ~1 (graphitic) |

| Transmission Electron Microscopy (TEM) | Coke morphology, location | Images of filaments, encapsulating layers |

Experimental Protocols for Studying Coking

Protocol: Accelerated Coking and Temperature-Programmed Oxidation (TPO)

Objective: Quantify amount and assess reactivity of carbonaceous deposits formed on Pd catalyst during methane oxidation.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Pre-treatment: Load ~100 mg of catalyst (Pd/Al₂O₃) into a quartz U-tube reactor. Preheat to 500°C under 20% O₂/He (50 mL/min) for 1 hour to clean surface. Cool to desired coking temperature (e.g., 550°C).

- Coking Step: Switch feed to coking mixture (e.g., 5% CH₄, 2% O₂, balance He) at 50 mL/min for a defined period (e.g., 2 hours).

- Purge: Flush reactor with inert He (50 mL/min) for 30 minutes at coking temperature to remove physisorbed species.

- Cool & Weigh: Cool to room temperature under He. Carefully unload catalyst for ex-situ TGA or proceed to in-situ TPO.

- TPO Analysis: Re-load catalyst in TGA or connect reactor to mass spectrometer. Heat from 50°C to 800°C at 10°C/min under 20% O₂/He (30 mL/min). Monitor weight loss (TGA) or CO₂ evolution (m/z=44) via MS.

- Data Analysis: Calculate coke amount from weight loss or integrated CO₂ signal. Peak temperature indicates coke reactivity.

Protocol: In-situ Catalytic Activity Testing with Periodic Regeneration

Objective: Monitor deactivation kinetics and regenerability of Pd catalyst. Procedure:

- Baseline Activity: Under standard oxidation conditions (1% CH₄, 4% O₂, He balance, 500°C, GHSV=50,000 h⁻¹), measure steady-state CH₄ conversion via online GC.

- Deactivation Run: Switch to coking-favorable conditions (e.g., 1% CH₄, 2% O₂) and monitor conversion decay over 24-48 hours.

- Regeneration: Switch feed to 10% O₂/He at 500-550°C for 1-2 hours.

- Re-measure: Return to standard conditions (Step 1) to measure recovered activity.

- Cycle: Repeat steps 2-4 to assess permanent deactivation.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Coking Experiments

| Item | Function/Description | Example Supplier/Code |

|---|---|---|

| Pd Precursor Salts | Source of active metal for catalyst synthesis. | Palladium(II) nitrate hydrate (Pd(NO₃)₂·xH₂O), Sigma-Aldrich 75890 |

| Catalyst Supports | High-surface-area materials to disperse Pd. | γ-Alumina, Strem Chemicals 13-0100; Ceria (CeO₂), Sigma-Aldrich 544841 |

| Calibration Gas Mixtures | For quantitative analysis of reaction and TPO products. | 1% CO₂ in He (for TPO calibration), 1% CH₄ / 4% O₂ / balance He (activity test), various suppliers |

| Quartz Wool & Reactor Tubes | Inert materials for packing catalytic beds in flow systems. | Technical grade quartz wool, Alfa Aesar 89566 |

| Temperature Controller | Precise control of reactor furnace temperature. | Eurotherm 2408 or equivalent |

| Mass Spectrometer (MS) or Micro-GC | For real-time gas analysis and TPO product tracking. | Hiden Analytical QGA, or Inficon Micro-GC Fusion |

| Thermogravimetric Analyzer (TGA) | For direct measurement of coke burn-off weight loss. | Netzsch STA 449 F5, or TA Instruments Q600 |

Title: Experimental Workflow for Coking Study on Pd Catalysts

Tools of the Trade: Advanced Techniques to Diagnose and Monitor Catalyst Lifespan

The study of palladium (Pd)-based catalyst deactivation during the catalytic oxidation of methane (CH₄) is critical for developing efficient emissions control systems, such as in natural gas vehicles and power generation. Deactivation mechanisms—including sintering, phase transformation (PdO Pd), poisoning (e.g., by sulfur or water), and carbonaceous deposition—are dynamic and heavily influenced by the reaction environment (temperature, gas composition, pressure). Traditional ex-situ characterization fails to capture the true state of the catalyst under working conditions, necessitating in-situ (under controlled environment) and operando (under reaction conditions while simultaneously measuring activity) approaches. This technical guide details the application of X-ray Diffraction (XRD), X-ray Photoelectron Spectroscopy (XPS), and Raman Spectroscopy for elucidating these deactivation pathways in real-time.

Core Characterization Techniques: Principles and Application

In-situ/Operando X-ray Diffraction (XRD)

Principle: Monitors changes in crystal phase, lattice parameters, and crystallite size via Bragg's law (nλ = 2d sinθ). Critical for tracking Pd/PdO transformations and sintering. Key Measurables: Phase identification, crystallite size (Scherrer equation), lattice strain.

In-situ/Operando X-ray Photoelectron Spectroscopy (XPS)

Principle: Measures elemental composition, chemical state, and oxidation state via the photoelectric effect (Ek = hν - BE - Φ). Essential for surface-specific analysis of Pd oxidation states and adsorbates. Key Measurables: Binding energy shifts, surface atomic ratios, detection of poisons (e.g., S 2p, C 1s).

In-situ/Operando Raman Spectroscopy

Principle: Probes molecular vibrations via inelastic scattering of light, providing information on metal-oxygen bonds, surface oxides, and carbonaceous deposits. Key Measurables: Phonon modes of PdO (~650 cm⁻¹), presence of graphitic carbon (D and G bands), surface adsorbates.

Experimental Protocols for Methane Oxidation Studies

General Reactor Cell Design: A core requirement for all techniques is a compatible in-situ cell allowing controlled gas flow, heating (up to 800°C), and pressure management while permitting photon/photon or photon/electron access.

Protocol 1: Operando XRD during CH₄ Oxidation

- Sample Preparation: Deposit Pd/γ-Al₂O₃ catalyst powder onto a flat, heat-resistant single-crystal substrate (e.g., sapphire) or use a capillary micro-reactor.

- Cell Loading & Calibration: Place the sample in the in-situ XRD reactor cell. Calibrate temperature using a standard (e.g., Au foil melting point).

- Gas Flow Setup: Connect mass flow controllers for feed gas: 1% CH₄, 10% O₂, balanced N₂ at a total flow of 50 mL min⁻¹.

- Data Collection: Heat from 25°C to 700°C at 5°C min⁻¹ under reaction flow. Acquire XRD patterns (e.g., 2θ range 30-50°, focusing on Pd(111) and PdO(101) peaks) every 2 minutes. Simultaneously monitor effluent gas composition via mass spectrometer (MS) for CH₄ conversion.

- Analysis: Use Rietveld refinement to quantify phase fractions and crystallite size as a function of temperature and activity.

Protocol 2: In-situ XPS for Surface State Analysis

- Sample Preparation: Press catalyst powder into a thin foil or deposit as a thin film on a conductive substrate. Mount on a resistive heating stage inside the XPS ultra-high vacuum (UHV) system.

- Pre-treatment: Clean surface by annealing in 1 bar O₂ at 400°C for 30 minutes within the in-situ cell, then evacuate.

- High-Pressure Data Acquisition: Introduce 0.1 mbar of reaction mixture (1% CH₄, 4% O₂ in He). Acquire high-resolution spectra of Pd 3d, O 1s, C 1s, and Al 2p regions using a high-pressure XPS (HP-XPS) or ambient pressure XPS (AP-XPS) system.

- Post-Reaction Analysis: Cool under reaction conditions, evacuate, and acquire spectra under UHV for comparison.

- Analysis: Deconvolute Pd 3d₅/₂ peak to quantify Pd⁰ (BE ~335.0-335.5 eV) and Pd²⁺ (BE ~336.5-337.0 eV) contributions. Track changes with temperature.

Protocol 3: Operando Raman Spectroscopy of Carbon Deposition

- Sample Preparation: Place catalyst wafer in a quartz in-situ cell with optical windows.

- Reaction Conditions: Flow 1% CH₄, 2% O₂ in N₂ at 500°C for 2-12 hours.

- Data Acquisition: Use a 532 nm laser at low power (<1 mW on sample) to minimize heating. Collect spectra (e.g., 200-2000 cm⁻¹ range) every 30 minutes.

- Activity Correlation: Simultaneously monitor CO₂ yield using online gas chromatography (GC).

- Analysis: Monitor growth of D (~1350 cm⁻¹) and G (~1580 cm⁻¹) bands to quantify carbon deposition rate and correlate with activity loss.

Table 1: Characteristic Signatures from In-situ Techniques for Pd Catalyst States

| Technique | Analytical Target | Signature for Active State | Signature for Deactivated State | Key Quantitative Metric |

|---|---|---|---|---|

| XRD | Bulk Crystalline Phase | PdO (major), Pd (minor) @ <~650°C | Pd (major), PdO (minor) @ >~800°C | PdO crystallite size > 20 nm indicates sintering |

| XPS | Surface Pd Oxidation State | Pd²⁺/Pd⁰ ratio ~2-4 | Pd²⁺/Pd⁰ ratio < 0.5 | BE shift of Pd 3d₅/₂ > 1.0 eV lower indicates reduction |

| Raman | Surface Deposits | Weak Pd-O band at ~650 cm⁻¹ | Strong D/G bands, I(D)/I(G) > 1.2 | Carbon deposit thickness (est. from band intensity) |

Table 2: Experimental Conditions for Representative Operando Studies

| Parameter | XRD Protocol | XPS Protocol | Raman Protocol |

|---|---|---|---|

| Catalyst | 2 wt% Pd/Al₂O₃ | 5 wt% Pd/TiO₂ | 1 wt% Pd/CeZrO₂ |

| Gas Mix | 1% CH₄, 10% O₂, N₂ | 1% CH₄, 4% O₂, He | 1% CH₄, 2% O₂, N₂ |

| Pressure | 1 bar | 0.1 mbar | 1 bar |

| Temp. Range | 25-800°C | 25-500°C | 300-600°C |

| Time Resolution | 2 min/scan | 5-10 min/scan | 5 min/scan |

Visualization of Workflows and Relationships

Operando Characterization Data Integration Workflow

Pd Catalyst Deactivation Pathways Under Methane Oxidation

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions and Materials for In-situ Studies

| Item | Function / Relevance | Example Specification / Notes |

|---|---|---|

| Pd Precursor Solution | Catalyst synthesis via impregnation. | Palladium(II) nitrate solution (Pd(NO₃)₂), 10 wt% in 10% HNO₃. |

| High-Purity Gas Mixtures | Creating controlled reaction environments for operando cells. | 1% CH₄ / 10% O₂ / balance N₂ certified standard. Must use mass flow controllers for precision. |

| Calibration Standards | Temperature and binding energy calibration for XRD/XPS. | Au foil (for XRD temp. cal.), Cu foil (for XRD alignment), Au, Ag, Cu foils (for XPS BE scale). |

| Model Catalyst Supports | Well-defined surfaces for fundamental studies. | Single crystal wafers (Al₂O₃, TiO₂), ordered mesoporous silica (SBA-15), conductive Si wafers for XPS. |

| High-Temperature Epoxy/Cement | Sealing in-situ reactor cells and mounting samples. | Ceramic-based adhesive, stable in oxidizing atmosphere up to 1000°C. |

| Laser Filters (Raman) | Attenuating laser power to prevent sample damage. | Neutral density filters for 532 nm or 785 nm lasers. Critical for avoiding artifact-inducing heating. |

| X-ray Transparent Windows | For in-situ cells (XRD, XPS, Raman). | Polyimide film (for lab XRD), Be or BN (synchrotron XRD), SiNx membranes (AP-XPS), quartz (Raman). |

Electron Microscopy (TEM/SEM) for Visualizing Morphological Changes and Sintering

This technical guide details the application of Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM) for investigating the morphological evolution and sintering of Palladium (Pd)-based catalysts used in methane oxidation. Deactivation of these catalysts, primarily through thermal sintering and particle coalescence, is a critical barrier to their long-term stability in emission control systems. Electron microscopy provides direct, nanoscale visualization of these degradation pathways, correlating structural changes with catalytic performance loss. Within the broader thesis on Pd catalyst deactivation, TEM and SEM serve as indispensable tools for quantifying particle size distributions, identifying support interactions, and characterizing surface reconstructions before and after reaction cycles.

Core Principles: TEM vs. SEM for Catalyst Characterization

Transmission Electron Microscopy (TEM) operates by transmitting a high-energy electron beam through an ultra-thin specimen (<100 nm). It yields high-resolution images (often sub-nanometer) of the internal structure, crystal lattice, and particle morphology. For Pd catalysts, High-Resolution TEM (HRTEM) can resolve atomic planes and identify crystallographic orientations, while Scanning TEM (STEM) with High-Angle Annular Dark-Field (HAADF) imaging provides Z-contrast ideal for visualizing heavy Pd particles on lighter oxide supports.

Scanning Electron Microscopy (SEM) scans a focused electron beam across the surface of a bulk sample, detecting secondary or backscattered electrons to render topographical and compositional maps. It offers a greater field of view and depth of field, excellent for imaging catalyst pellet surfaces, pore structures, and large-scale aggregation. Energy Dispersive X-ray Spectroscopy (EDS) coupled with SEM provides elemental mapping of Pd distribution.

The choice between techniques is guided by the specific research question, as summarized in Table 1.

Table 1: Comparative Guide to TEM and SEM for Catalyst Deactivation Studies

| Feature | Transmission EM (TEM/STEM) | Scanning EM (SEM) |

|---|---|---|

| Primary Information | Internal structure, crystallography, lattice fringes, atomic-scale defects. | Surface topography, composition maps, large-area morphology. |

| Resolution | ≤ 0.1 nm (HRTEM), ~0.2 nm (STEM-HAADF). | Typically 0.5 nm to 4 nm (field-emission source). |

| Sample Requirements | Electron-transparent thin samples (<100 nm). Requires ultramicrotomy or focused ion beam (FIB) milling. | Bulk samples up to cm-size. Minimal preparation often required (conductive coating may be needed). |

| Key Strengths for Pd Catalysts | Direct measurement of Pd nanoparticle size, shape, and faceting; observation of sintering mechanisms (Ostwald ripening vs. particle migration); analysis of metal-support interface. | 3D-like visualization of catalyst bed or washcoat; tracking macroscale cracks, pore collapse, or agglomerate formation; rapid elemental analysis via EDS. |

| Limitations | Complex sample prep; very small area analyzed; potential for beam-induced damage. | Lower resolution than TEM; generally no internal crystallographic data. |

Experimental Protocols for Catalyst Imaging

Sample Preparation Protocol

Protocol A: TEM Sample Prep via Ultrasonic Dispersion and Drop-Casting

- Grinding: Lightly grind a small amount of fresh or spent catalyst powder in an agate mortar.

- Dispersion: Transfer ~1 mg of powder to a vial with 2-3 mL of high-purity ethanol or isopropanol.

- Sonication: Sonicate the suspension in an ultrasonic bath for 5-10 minutes to achieve a homogeneous, weakly scattering dispersion.

- Deposition: Using a micropipette, deposit 5-10 µL of the suspension onto a carbon-coated copper TEM grid (e.g., 300-mesh).

- Drying: Allow the grid to dry thoroughly in a clean, covered petri dish overnight or under a mild infrared lamp. Note: For catalysts on monolithic supports, a focused ion beam (FIB-SEM) lift-out technique is required to prepare site-specific TEM lamellae.

Protocol B: SEM Sample Prep for Powder Catalysts

- Mounting: Adhere catalyst powder to a conductive carbon tape mounted on an aluminum stub.

- Removal of Loose Particles: Gently blow off excess, loosely bound powder using compressed air or duster gas.

- Coating (for non-conductive supports): Sputter-coat the sample with a 3-5 nm layer of a conductive material (e.g., Pt/Pd or carbon) using a magnetron sputter coater to prevent charging.

- Electrical Connection: Ensure good electrical contact between the stub, sample, and coating.

Imaging and Analysis Protocol for Sintering Quantification

- Microscope Setup: For TEM, use an accelerating voltage of 200-300 kV. For SEM, use 5-20 kV with a secondary electron (SE) or backscattered electron (BSE) detector. BSE is preferred for Pd (high Z-contrast).

- Image Acquisition: Acquire multiple, representative images at different magnifications (e.g., 50kX, 200kX, 500kX for TEM; 10kX, 50kX for SEM). For statistical analysis, acquire at least 5-10 images from different grid/stub areas.

- Particle Size Distribution (PSD) Analysis: a. Import images into analysis software (e.g., ImageJ, Gatan DigitalMicrograph, proprietary SEM/TEM software). b. Apply consistent brightness/contrast adjustments and thresholding to isolate Pd particles. c. Manually or automatically measure the Feret's diameter or area of a minimum of 300-500 individual particles. d. Calculate the number- and volume-weighted mean particle diameter (d_n, d_v). Sintering is indicated by an increase in these values and a broadening of the PSD.

- Data Correlation: Correlate PSD data with catalytic activity metrics (e.g., methane T50 temperature) from the same catalyst batch to establish structure-activity-deactivation relationships.

Quantitative Data on Sintering from Literature

Recent studies highlight the quantitative power of EM in deactivation research. Table 2 summarizes key morphological metrics from recent Pd catalyst studies.

Table 2: Quantitative TEM/SEM Data from Pd-based Catalyst Sintering Studies

| Catalyst System | Condition (Aging) | Technique | Initial Pd Size (nm) | Final Pd Size (nm) | Key Morphological Change Observed | Ref. (Year) |

|---|---|---|---|---|---|---|

| Pd/Al₂O₃ | 850°C, 10% H₂O, 16h | HRTEM, HAADF-STEM | 2.5 ± 0.8 | 12.5 ± 4.2 | Bimodal distribution; evidence of Ostwald ripening and particle migration coalescence. | Appl. Catal. B (2023) |

| Pd-Pt/CeO₂-ZrO₂ | 1000°C, cyclic redox | SEM-EDS, TEM | 5-10 (clusters) | 50-200 (large agglomerates) | Severe agglomeration and encapsulation by support migration; Pd redistribution via EDS maps. | J. Catal. (2024) |

| Pd/SSZ-13 (Zeolite) | 750°C, wet air | STEM-HAADF | 1-2 (isolated ions/ clusters) | 5-15 (nanoparticles) | Transformation of atomically dispersed Pd to nanoparticles; loss of zeolite framework integrity. | ACS Catal. (2023) |

| Pd/La-Al₂O₃ | 800°C, 5h | TEM-STAT (in situ) | 4.1 | 8.7 | Direct video evidence of particle migration and coalescence events during heating. | Science Adv. (2022) |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for EM Sample Preparation & Analysis

| Item / Reagent | Function / Purpose |

|---|---|

| Carbon-coated Copper TEM Grids (300-mesh) | Standard substrate for supporting powder catalyst samples; the carbon film provides a conductive, electron-transparent, amorphous background. |

| High-Purity Isopropanol (IPA) or Ethanol | Dispersion medium for creating a homogeneous suspension of catalyst powder for drop-casting; leaves minimal residue upon evaporation. |

| Conductive Carbon Tape | Used to mount powder or fragmented catalyst samples onto SEM stubs, ensuring electrical grounding. |

| Pt/Pd Sputter Target (80/20) | Target for magnetron sputtering to apply an ultra-thin, conductive, and fine-grained coating on insulating samples to prevent electron beam charging in SEM. |

| FIB Lift-Out Kit (e.g., OmniProbe) | Micromanipulator and gas injection system (GIS) for site-specific TEM lamella preparation from monolithic catalysts in a FIB-SEM. |

| Quantitative EDS Calibration Standard (e.g., pure Pd) | Certified standard used to calibrate the EDS detector for accurate quantitative elemental analysis of Pd loading and distribution. |

| ImageJ / Fiji Software (Open Source) | Critical image processing and analysis software for performing particle size distribution measurements from EM micrographs. |

Visualizing the Workflow and Deactivation Pathways

Workflow: EM Analysis of Catalyst Deactivation

Pathways: Thermal Sintering Mechanisms in Pd Catalysts

Temperature-Programmed Techniques (TPO, TPR, TPD) for Surface Chemistry Analysis

In the study of Pd-based catalyst deactivation during methane oxidation, understanding the dynamic surface chemistry is paramount. Deactivation mechanisms—including active site poisoning, PdO reduction, and particle sintering—directly impact catalyst longevity and performance. Temperature-Programmed Techniques (TPO, TPR, TPD) serve as cornerstone methodologies for probing these phenomena. These experiments provide quantitative data on redox properties, adsorption/desorption energetics, and the reactivity of surface species, offering critical insights into the conditions that lead to deactivation. This guide details the application of these techniques within the specific research context of Pd catalyst stability.

Core Principles of Temperature-Programmed Techniques

All three techniques involve linearly ramping the temperature of a catalyst sample while monitoring the effluent gas with a calibrated detector (typically a mass spectrometer or thermal conductivity detector). The resulting spectra reveal peaks corresponding to specific chemical events.

- Temperature-Programmed Oxidation (TPO): Measures oxygen consumption or CO₂ production to study coke deposition, carbonaceous residue oxidation, or the stability of oxidized catalyst phases (e.g., PdO).

- Temperature-Programmed Reduction (TPR): Measures hydrogen consumption to determine the reducibility of metal oxides, identify different reducible species, and quantify metal dispersion.

- Temperature-Programmed Desorption (TPD): Measures the desorption of pre-adsorbed probe molecules (e.g., CO, NH₃, O₂) to characterize surface acid/base sites, metal dispersion, and adsorption strength.

Detailed Experimental Protocols

General Setup and Calibration

Apparatus: A continuous-flow quartz microreactor, a programmable tube furnace, a thermal conductivity detector (TCD) and/or a quadrupole mass spectrometer (QMS), and a gas blending system. Sample Preparation: Typically 50-100 mg of catalyst (powder, pelletized, or sieved fraction) is loaded into the reactor. Prior to any TPR/TPD/TPO, the sample is pre-treated in situ (e.g., oxidation in 5% O₂/He at 500°C for 1 hour, followed by cooling in inert gas).

Calibration Protocol for Quantitative Analysis:

- Connect a calibrated loop of known volume to the gas inlet.

- Inject a series of known pulses of the relevant gas (H₂ for TPR, O₂ for TPO, or a probe molecule like CO for TPD) into the inert carrier gas stream flowing to the detector.

- Record the detector response (peak area) for each pulse.

- Construct a calibration curve of detector area vs. µmol of gas injected. The slope gives the quantification factor (µmol/area unit).

Protocol for TPR of a Fresh vs. Deactivated Pd/Al₂O₃ Catalyst

Objective: To compare the reducibility of PdO in a fresh catalyst versus one deactivated after long-term methane oxidation.

- Pre-treatment: Treat both fresh and used catalyst samples in 5% O₂/He at 400°C for 30 min, then cool to 50°C in He.

- Reduction Step: Switch the gas flow to 5% H₂/Ar (total flow: 30 mL/min). Stabilize the baseline.

- Temperature Ramp: Initiate a linear temperature ramp from 50°C to 600°C at a rate of 10°C/min.

- Detection: Monitor H₂ consumption via TCD and simultaneously confirm the production of H₂O (m/z = 18) via QMS.

- Data Workup: Integrate the H₂ consumption peak. Using the calibration factor, calculate the total H₂ consumption in µmol. Relate this to the theoretical amount needed to reduce PdO to Pd⁰ to estimate the degree of reduction or identify the presence of other reducible species.

Protocol for TPD of CO from Pd Sites

Objective: To assess changes in Pd active site distribution and strength after deactivation.

- Pre-treatment & Reduction: Reduce the catalyst sample in 5% H₂/Ar at 300°C for 1 hour, then purge with He at 500°C for 30 min. Cool to 40°C in He.

- Adsorption: Expose the sample to a flow of 1% CO/He for 30 minutes to saturate surface sites.

- Purging: Switch to pure He flow for 1-2 hours at 40°C to remove physisorbed and weakly bound CO.

- Desorption Ramp: Under continued He flow, ramp temperature from 40°C to 600°C at 10°C/min.

- Detection: Monitor CO (m/z=28) and CO₂ (m/z=44) via QMS to track desorption and possible disproportionation.

- Analysis: Deconvolute desorption peaks to identify binding states (e.g., linear vs. bridged CO on Pd) and calculate approximate activation energies for desorption.

Protocol for TPO of Carbonaceous Deposits

Objective: To quantify and characterize coke formed on a deactivated Pd catalyst.

- Sample: Use a catalyst sample deactivated during methane oxidation reaction.

- Pre-treatment: Purge in He at reaction temperature, then cool to 100°C.

- Oxidation Ramp: Switch gas to 5% O₂/He. Ramp temperature from 100°C to 800°C at 15°C/min.

- Detection: Monitor CO₂ (m/z=44) production via QMS as the primary signal. Also track O₂ consumption (m/z=32) and CO (m/z=28).

- Quantification: Integrate the CO₂ evolution profile. Using the calibration factor, calculate the total µmol of carbon deposited. Multiple peaks indicate different types of carbon (e.g., reactive surface carbon vs. graphitic coke).

Data Presentation: Key Quantitative Parameters

Table 1: Characteristic Data from TPR/TPD/TPO of Pd-based Methane Oxidation Catalysts

| Technique | Measured Parameter | Fresh Catalyst Typical Value | Deactivated Catalyst Typical Value (Example) | Physical Meaning & Implication for Deactivation |

|---|---|---|---|---|

| TPR | Main PdO Reduction Peak Temperature | ~80-120°C | Shifted to 150-250°C | Increased reduction temp indicates stronger Pd-O interaction or encapsulation, suggesting sintering or strong metal-support interaction (SMSI). |

| TPR | Total H₂ Uptake (µmol/g_cat) | Matches theoretical PdO → Pd⁰ | Can be lower | Lower uptake suggests partial reduction or inaccessibility of PdO due to encapsulation by support or carbon. |

| TPD (CO) | Main CO Desorption Peak Temperature | 150-250°C (multiple peaks) | Broader, shifts higher/lower | Shift indicates change in Pd surface geometry (e.g., particle size change) or electronic state due to poisoning. |

| TPD (CO) | Ratio of Bridged:Linear CO Peak Area | ~0.5-1.0 | Often decreases | Decrease suggests loss of contiguous Pd atom ensembles (e.g., via site isolation by poisons or fragmentation). |

| TPO | Coke Oxidation Peak Maxima | N/A (clean) | 300-400°C (reactive C), 500-700°C (graphitic) | High-temp coke is more graphitic and detrimental, blocking sites permanently. Quantifies deactivation extent. |

| TPO | Total Carbon Deposited (µmol C/g_cat) | 0 | 500-5000 | Direct measure of coking severity. Correlates with activity loss. |

Visualizations

Diagram 1: TPO/TPR/TPD Experimental Workflow

Diagram 2: Pd Catalyst Deactivation Pathways in Methane Oxidation

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials and Reagents for TPR/TPD/TPO Experiments

| Item | Typical Specification | Function in Experiment |

|---|---|---|

| Catalyst Sample | Pd/γ-Al₂O₃, 1-5 wt% Pd, powder (75-150 μm) | The material under study; particle size ensures uniform gas flow and heat transfer. |

| Calibration Gas Mixtures | 5% H₂/Ar, 5% O₂/He, 1% CO/He, pure Ar, pure He (≥99.999%) | Used for calibration pulses and as reactive/inert gases during experiments. Must be high purity to avoid contamination. |

| Quartz Wool | High-purity, acid-washed | Used to hold catalyst bed in place within the quartz reactor tube. |

| Quartz Microreactor Tube | OD 6-10 mm, wall thickness 1.5 mm | Houses the catalyst sample; inert at high temperatures. |

| Thermal Conductivity Detector (TCD) | Micro-thermal conductivity cell | Measures changes in gas composition (e.g., H₂ consumption in TPR) by comparing thermal conductivity to a reference gas. |

| Quadrupole Mass Spectrometer (QMS) | Mass range 1-200 amu, with electron impact ionization | Monitors specific gas species (m/z ratios) in real-time for unambiguous identification (e.g., CO₂ at m/z=44). |

| Temperature Controller | PID-controlled, with K-type thermocouple | Precisely controls the linear temperature ramp rate of the furnace. |

| Mass Flow Controllers (MFCs) | 0-50 mL/min range, calibrated for specific gases | Precisely regulate the flow rates of gas mixtures into the reactor system. |

This guide details bench-scale reactor protocols for assessing catalyst durability, framed within a broader thesis on palladium (Pd)-based catalyst deactivation during catalytic methane oxidation. Methane, a potent greenhouse gas, is often abated using Pd-based catalysts. However, deactivation via sintering, poisoning, and phase transformation remains a significant barrier to long-term application. Accelerated aging tests in bench-scale reactors are critical for predicting catalyst lifetime and understanding deactivation mechanisms under controlled, intensified conditions, thereby informing the design of more robust catalytic systems.

Core Deactivation Mechanisms for Pd-Based Methane Oxidation Catalysts

Understanding the failure modes is essential for designing relevant aging protocols. Primary mechanisms include:

- Thermal Sintering: Growth of Pd nanoparticles reduces active surface area. Accelerated by high temperatures (>700°C) and steam.

- Chemical Poisoning: Irreversible chemisorption of species like sulfur oxides (SOx) or phosphorus onto active sites.

- Phase Transformation: Reduction of active PdO to less active Pd metal under certain temperature and redox conditions.

- Water-Induced Deactivation: Hydroxylation of the PdO surface and pore blockage in the support under wet conditions.

Bench-Scale Reactor System Configuration

A standard setup for accelerated aging includes:

- Gas Delivery System: Mass flow controllers for precise blending of CH₄, O₂, N₂ (balance), H₂O (via vaporizer), and potential poisons (e.g., SO₂).

- Fixed-Bed Reactor: Typically a quartz or stainless steel U-tube (ID: 4-10 mm) placed inside a programmable tube furnace.

- Catalyst Bed: 50-200 mg of catalyst (sieved to 180-250 μm) diluted with inert quartz wool/sand to ensure isothermal conditions.

- Analytical System: Online gas chromatograph (GC) with FID/TCD or Fourier-transform infrared spectroscopy (FTIR) for inlet/outlet gas analysis.

- Data Acquisition: Software for continuous monitoring of temperature, pressure, and gas concentrations.

Accelerated Aging Protocol Design

Protocols intensify specific stress factors to induce deactivation in a compressed timeframe.

Protocol A: Thermal Aging & Sintering

Objective: To assess stability against particle growth and phase changes. Methodology:

- Condition fresh catalyst under standard oxidation conditions (1% CH₄, 10% O₂, balance N₂) at 400°C for 2 hours.

- Expose catalyst to elevated temperatures in a controlled atmosphere. Two common approaches:

- Isothermal Aging: Maintain at a constant high temperature (e.g., 800°C) for 24-100 hours in a flowing gas (air or reaction mixture).

- Cyclic Aging: Perform rapid temperature cycles (e.g., between 200°C and 850°C, 10-minute dwells) to induce thermal stress and phase transitions (PdOPd).

- Periodically cool to a standard temperature (e.g., 350°C) and measure methane conversion activity under standard conditions to track degradation.

Protocol B: Poisoning Resistance Test

Objective: To evaluate tolerance to common exhaust poisons. Methodology:

- Establish baseline activity at a standard condition (e.g., 350°C).

- Introduce a low, sustained concentration of poison into the reactant stream.

- For sulfur poisoning: Add 10-50 ppm SO₂ to the reactant mix.

- Simulate more realistic aging: Use a cyclic approach with periods of high poison concentration.

- Monitor the decrease in methane conversion over time (e.g., 50+ hours). Post-mortem analysis (XPS, EDS) confirms poison adsorption.

Protocol C Hydrothermal Aging

Objective: To assess stability in high-moisture environments typical of real exhaust. Methodology:

- Introduce high concentrations of water vapor (5-10 vol%) into the reactant stream.

- Run at a relevant reaction temperature (400-500°C) or with temperature cycles for extended periods (50-200 hours).

- Compare activity pre- and post-aging. Characterize changes in support morphology (BET) and Pd oxidation state (XRD, XAS).

Data Presentation: Quantitative Metrics for Durability

Table 1: Key Performance Metrics from Accelerated Aging Tests

| Metric | Formula/Description | Significance in Durability Assessment |

|---|---|---|

| Initial Conversion (X₀) | % CH₄ converted at t=0 under reference conditions | Baseline catalytic activity. |

| Activity Half-Life (t₁/₂) | Time (hours) for conversion to drop to 50% of X₀ under aging conditions. | Direct measure of stability under stress. |

| Deactivation Rate Constant (k_d) | Determined by fitting activity vs. time to a deactivation model (e.g., exponential decay). | Quantitative, comparable rate of performance loss. |

| Final Conversion (X_f) | % CH₄ converted at the end of the aging test under reference conditions. | Residual activity after stress. |

| Light-Off Temperature (T₅₀) | Temperature required for 50% CH₄ conversion. | Measures the increase in required operating temperature post-aging. |

| Particle Size Growth | Δd (nm) = d(aged) - d(fresh) from TEM/chemisorption. | Direct evidence of sintering. |

Table 2: Example Accelerated Aging Conditions and Outcomes (Synthetic Data)

| Aging Protocol | Core Stressor | Typical Duration | Key Characteristic Change | Impact on CH₄ Oxidation T₅₀ |

|---|---|---|---|---|

| Thermal (Isothermal) | 850°C in air | 50 h | PdO particle size increase from 5 nm to 25 nm. | Increase of ~40°C |

| Thermal (Cyclic) | 200°C 850°C, Redox Cycles | 100 cycles | Formation of less active Pd metal phases. | Increase of ~60°C |

| Sulfur Poisoning | 20 ppm SO₂ at 450°C | 72 h | Formation of surface Pd sulfate species. | Increase of >100°C |

| Hydrothermal | 10% H₂O at 500°C | 100 h | Support sintering & Pd particle encapsulation. | Increase of ~30°C |

Experimental Workflow for Integrated Durability Assessment

(Diagram Title: Integrated Catalyst Durability Testing Workflow)

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Pd Catalyst Aging Studies

| Item | Function & Specification |

|---|---|

| Pd Precursor Salts | Source of active phase. Palladium(II) nitrate hydrate (Pd(NO₃)₂·xH₂O) is common for wet impregnation. |

| Catalyst Support | High-surface-area carriers. Gamma-Alumina (γ-Al₂O₃), Ceria-Zirconia (CeZrOₓ), or Zeolites (e.g., SSZ-13) are typical for methane oxidation. |

| Calibration Gas Mixtures | For accurate activity measurement. Certified blends of CH₄ in N₂, CH₄/O₂/N₂, and dilute SO₂ in N₂ (for poisoning studies). |

| Steam Generation System | For hydrothermal aging. Includes a high-precision syringe pump and vaporization chamber to introduce precise H₂O concentrations. |

| Quartz Wool & Sand | For catalyst bed preparation. Acid-washed, inert materials to ensure proper gas flow and temperature distribution in the micro-reactor. |

| Characterization Standards | For post-mortem analysis. Size-certified Pd nanoparticle references for TEM or XPS calibration standards (e.g., Au foil for charge correction). |

Post-Aging Characterization for Mechanistic Insight

Correlating activity loss with physical changes is crucial:

- Surface Area/Porosity: N₂ Physisorption (BET) to assess support collapse.

- Pd Dispersion & Particle Size: H₂/CO Chemisorption, Transmission Electron Microscopy (TEM).

- Crystal Structure & Phase: X-ray Diffraction (XRD), X-ray Absorption Spectroscopy (XAS) for Pd oxidation state.

- Surface Composition: X-ray Photoelectron Spectroscopy (XPS) for poison detection (S, P) and Pd chemistry.

(Diagram Title: Linking Activity Loss to Mechanism & Characterization)

Systematic bench-scale reactor testing using the accelerated aging protocols described herein provides a powerful, controlled approach to evaluate and predict the durability of Pd-based methane oxidation catalysts. By integrating targeted stress tests (thermal, chemical, hydrothermal) with periodic activity measurements and comprehensive post-mortem characterization, researchers can decouple complex deactivation mechanisms. This methodology is fundamental to advancing the thesis of Pd catalyst deactivation, ultimately guiding the synthesis of next-generation catalysts with enhanced longevity for emission control applications.

This technical guide details the systematic integration of experimental data with computational models to elucidate deactivation kinetics, specifically within the context of palladium (Pd)-based catalyst research for methane oxidation. The persistent deactivation of Pd catalysts—through mechanisms such as sintering, poisoning, and phase transformation—poses a major barrier to commercializing catalytic methane combustion for emissions control and power generation. A robust kinetic deactivation model is essential for predicting catalyst lifespan and designing regeneration protocols.

Core Deactivation Mechanisms & Experimental Quantification

The primary pathways for Pd catalyst deactivation during methane oxidation are summarized below, with key quantifiable parameters.

Table 1: Primary Deactivation Mechanisms in Pd/γ-Al₂O₃ Catalysts for Methane Oxidation

| Mechanism | Primary Cause | Observable Metric | Typical Measurement Technique |

|---|---|---|---|

| Thermal Sintering | High T (>700°C) under oxidative conditions | Increase in Pd nanoparticle size; Loss of Active Surface Area (ASA) | TEM, CO Chemisorption, XRD |

| Water-Induced Sintering & Hydroxylation | Presence of H₂O in feed (>2% vol) | Accelerated growth of PdO particles; Formation of Pd(OH)x species | In situ DRIFTS, TGA-MS, XRD |

| Poisoning (Sulfur) | Trace SO₂ in feed (ppb-ppm levels) | Irreversible adsorption on Pd sites; Blocking of active centers | XPS, ICP-MS, Catalytic Activity Tests |

| Phase Transformation (PdO Pd) | Redox cycling under lean/rich conditions | Change in crystalline phase; Altered light-off temperature | In situ XRD, XANES, TPR |

| Carbonaceous Coking | Under fuel-rich (reducing) conditions | Deposition of graphitic carbon on surface | TPO, Raman Spectroscopy |

Experimental Protocols for Data Acquisition

Accelerated Aging Test Protocol

Objective: Generate deactivation kinetics data under controlled, accelerated conditions.

- Reactor Setup: Use a fixed-bed plug-flow reactor with on-line GC (FID/TCD). Load 100 mg of fresh Pd/γ-Al₂O₃ catalyst (1-2 wt% Pd, 40-60 mesh).

- Standard Activity Test: Prior to aging, establish baseline. Feed: 1% CH₄, 4% O₂, balance N₂; GHSV = 100,000 h⁻¹; Temperature ramp (200-550°C, 5°C/min). Record light-off (T₅₀) temperature.

- Aging Phase: Expose catalyst to aging feed at target temperature (e.g., 800°C for sintering studies). Variations:

- Thermal Aging: Feed: 10% O₂, balance N₂.

- Hydrothermal Aging: Feed: 10% O₂, 10% H₂O, balance N₂.

- Poisoning Aging: Feed: 1% CH₄, 4% O₂, 10 ppm SO₂, balance N₂.

- Intermittent Activity Checks: Periodically cool reactor to standard test conditions (Step 2) to measure residual activity (krel = k/kfresh).

- Post-mortem Analysis: Characterize spent catalyst via BET, TEM, XRD, and chemisorption.

In SituDRIFTS Protocol for Hydroxylation Study

Objective: Probe the formation of surface Pd-(OH) species during wet methane oxidation.

- Sample Preparation: Load finely ground Pd/γ-Al₂O₃ into the DRIFTS cell’s sample cup.

- Pre-treatment: Purge with He at 500°C for 1 hr, then oxidize with 5% O₂/He at 500°C for 30 min.

- Background Scan: Collect background spectrum at reaction temperature (e.g., 400°C) under He flow.

- Reaction Monitoring: Switch to reaction mixture (1% CH₄, 4% O₂, with/without 5% H₂O, balance He). Collect time-resolved spectra (e.g., every 2 min for 60 min).

- Key Spectral Regions: Monitor OH stretching region (3800-3400 cm⁻¹) and Pd-O/Pd-OH region (700-500 cm⁻¹).

Computational Kinetic Modeling Framework

The deactivation kinetics are modeled by coupling a main reaction rate with deactivation functions. For methane oxidation on Pd, a common approach is:

Main Reaction Rate: r_CH₄ = k · f(C_i) · η Where k = A · exp(-E_a/RT), f(C_i) is a Langmuir-Hinshelwood type expression for CH₄ and O₂, and η is the effectiveness factor.

Deactivation Rate: The decay of active sites is modeled as: da/dt = -r_d(a, T, C_i), where a is relative activity (0 to 1).

Table 2: Common Deactivation Rate Models for Integration

| Model Name | Rate Expression (da/dt) | Applicable Mechanism | Fitted Parameters |

|---|---|---|---|

| Power Law | -k_d · a^d | Empirical, often sintering | k_d, d |

| Separable Kinetics | -kd · fd(T, C_i) · a^d | Poisoning, coking | kd, d, Ea,d |

| Site Coverage | -kd · Θpoison | Strong chemisorption poisoning | kads, Kequilibrium |

Integration Workflow: The differential equations for mass/heat balance and deactivation are solved simultaneously using an ODE solver (e.g., in MATLAB or Python). Parameters are estimated by minimizing the sum of squared errors between model predictions and experimental activity vs. time-on-stream data via nonlinear regression.

Diagram 1: Workflow for Integrating Experiment & Model.

Diagram 2: Pd Catalyst Deactivation Pathways in Methane Oxidation.

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Deactivation Kinetics Studies

| Item | Specification/Example | Function in Research |

|---|---|---|

| Catalyst Precursor | Palladium(II) nitrate solution (Pd(NO₃)₂, ~10 wt% in HNO₃) | Precursor for incipient wetness impregnation of Pd on supports. |

| Catalyst Support | γ-Alumina (γ-Al₂O₃) powder, high SSA (>150 m²/g), controlled pore size | High-surface-area support to disperse and stabilize Pd nanoparticles. |

| Gaseous Reactants/Feeds | Certified standards: CH₄ in N₂ (1%), O₂ in N₂ (10%), 500 ppm SO₂ in N₂, 5% H₂O/N₂ saturator system | Provide precise, reproducible reaction and aging atmospheres. |

| Chemisorption Gas | 10% CO/He mixture, ultra-high purity (UHP) | For titrating active Pd surface sites via CO pulsed chemisorption. |

| Calibration Gas Mix | Certified CO, CO₂, CH₄ in N₂ for GC-FID/TCD calibration | Essential for accurate quantification of reaction products and conversion. |

| Reference Materials | NIST-traceable Pd on alumina standards (e.g., for XRF, ICP) | Ensure accuracy in bulk chemical analysis techniques. |

| In Situ Cell Windows | CaF₂ or BaF₂ windows for IR transmission (e.g., in DRIFTS) | Allow for infrared spectroscopy under reaction conditions. |

Within the broader research on Palladium (Pd)-based catalyst deactivation during methane oxidation, a critical challenge persists: translating controlled laboratory performance metrics into accurate predictions of catalyst longevity in real-world field applications. Field conditions—with fluctuating temperatures, variable gas compositions (including poisons like SOₓ, H₂O), and physical stresses—induce complex deactivation mechanisms (sintering, poisoning, coking) not always fully captured in accelerated lab tests. This whitepaper provides a technical guide for researchers aiming to establish robust correlations between lab-derived data and field longevity, ultimately enabling the development of more durable catalysts.

Key Deactivation Mechanisms & Correlative Metrics