Unlocking Catalyst Performance: A Comprehensive Guide to CatTestHub Data for Kinetic Modeling of Pellets

This article provides researchers, scientists, and drug development professionals with a strategic framework for leveraging CatTestHub data in the kinetic modeling of catalyst pellets.

Unlocking Catalyst Performance: A Comprehensive Guide to CatTestHub Data for Kinetic Modeling of Pellets

Abstract

This article provides researchers, scientists, and drug development professionals with a strategic framework for leveraging CatTestHub data in the kinetic modeling of catalyst pellets. We explore the foundational principles of intraparticle transport phenomena, detail methodological approaches for data integration and model construction, address common challenges in model calibration and optimization, and establish best practices for model validation against experimental benchmarks. The guide synthesizes these intents to empower more accurate, reliable, and predictive catalyst design for pharmaceutical synthesis and beyond.

Foundations of Kinetic Modeling: Understanding Intraparticle Phenomena with CatTestHub Data

Application Notes: Navigating the CatTestHub Data Ecosystem

CatTestHub serves as a centralized repository for structured catalytic performance data, specifically curated to support the kinetic modeling of catalyst pellets. Its architecture is designed to integrate heterogeneous experimental data from high-throughput testing rigs, standardized laboratory reactors, and computational chemistry outputs into a unified schema.

Core Data Categories:

- Catalyst Formulation & Pellet Properties: Precursor materials, synthesis protocols, dopant concentrations, pellet dimensions (diameter, length), porosity (BET surface area, pore volume), mechanical strength.

- Operational Conditions: Reaction temperature (K), pressure (bar), feed gas composition (vol%), space velocity (GHSV, WHSV).

- Performance Metrics: Conversion (%), Selectivity to products (%), Yield (%), Turnover Frequency (TOF, s⁻¹), Apparent Activation Energy (Ea, kJ/mol), Deactivation rate constants.

- Kinetic Data: Raw time-series data of concentrations, initial rate data, extracted rate constants from fitted models (e.g., Langmuir-Hinshelwood parameters).

Link to Kinetic Modeling: The database schema explicitly tags data points suitable for specific modeling tasks: (1) Micro-kinetic model validation (elementary step data), (2) Macro-kinetic model fitting (pellet-scale performance under diffusion limitations), and (3) Deactivation model training (time-on-stream data).

Table 1: Scope of Catalytic Performance Data in CatTestHub (v2.3)

| Data Category | Number of Datasets | Typical Parameter Range | Primary Unit | Model-Ready Status* |

|---|---|---|---|---|

| Catalyst Pellet Physical Properties | 4,201 | Diameter: 0.5-5 mm; Porosity: 0.2-0.6; SA: 10-500 m²/g | mm, cm³/g, m²/g | 100% |

| Steam Methane Reforming (SMR) | 1,847 | Temp: 973-1173 K; Pressure: 1-25 bar; CH₄ Conv.: 45-95% | K, bar, % | 95% |

| CO₂ Hydrogenation (Methanol) | 1,225 | Temp: 473-573 K; Pressure: 30-80 bar; CO₂ Conv.: 10-25% | K, bar, % | 88% |

| Selective Catalytic Reduction (SCR) | 985 | Temp: 523-723 K; GHSV: 30,000-100,000 h⁻¹; NOx Conv.: 70-99% | K, h⁻¹, % | 92% |

| Catalytic Cracking (FCC) | 732 | Temp: 753-853 K; WHSV: 8-20 h⁻¹; Gasoline Yield: 45-55 wt% | K, h⁻¹, wt% | 85% |

| Deactivation Time-Series | 3,150 | TOS: 0-1000 h; Activity Retention: 10-100% | h, % | 78% |

*Model-Ready Status: Percentage of datasets fully annotated with metadata required for direct import into kinetic modeling software (e.g., catalyst ID, full condition specification, uncertainty estimates).

Experimental Protocols

Protocol 1: Standardized Data Generation for Pellet-Scale Kinetic Profiling

This protocol outlines the procedure for generating CatTestHub-compliant data from a fixed-bed tubular reactor, ensuring consistency for kinetic modeling.

Materials:

- Fixed-bed reactor (quartz or stainless steel, ID = 6 mm)

- Mass flow controllers (MFCs) for gases

- HPLC pump for liquid feeds

- Downstream GC/MS or FTIR analyzer

- Catalyst pellets (sieved fraction, e.g., 1.0-1.4 mm diameter)

- Inert diluent (α-Al₂O₃, same sieve fraction)

- Thermocouple (K-type) placed within the catalyst bed.

Procedure:

- Pellet Preparation & Loading: Weigh 0.5 g of catalyst pellets. Dilute with inert α-Al₂O₃ at a 1:4 (v/v) ratio to ensure isothermal operation. Load the mixture into the reactor tube, bracketed by quartz wool plugs.

- System Leak Check & Catalyst Activation: Purge system with inert gas (N₂ or Ar) at 50 mL/min. Pressure-test to 1.5x operating pressure. Initiate catalyst-specific activation procedure (e.g., reduction in H₂ at 673 K for 2 h) under controlled atmosphere.

- Steady-State Activity Test: Set reaction temperature and pressure. Establish desired feed composition using MFCs and HPLC pump. Allow system to stabilize for a minimum of 3 times the space time (τ) or 60 minutes, whichever is longer.

- Data Acquisition: Take a minimum of three consecutive analytical samples at 15-minute intervals. Record average conversion and product distribution. Criteria for steady state: <2% relative deviation between measurements.

- Intrinsic Kinetics Mode (Diffusion-Free): To collect data for intrinsic kinetic modeling, repeat Step 4 after verifying the absence of mass/heat transfer limitations using the Weisz-Prater and Mears criteria. This typically requires using finer pellet fractions (<0.3 mm).

- Data Logging for CatTestHub: Record all parameters as per the CatTestHub template CSV, including: Catalyst_ID, Pellet_Diameter, Pellet_Density, Bed_Weight, Bed_Volume, Feed_Composition (all components), Total_Flowrate, Temperature, Pressure, Conversion_(Species), Selectivity_(All_Products), Carbon_Balance, Timestamp.

- Deactivation Protocol: For long-term tests, after Step 4, maintain conditions and record conversion at pre-defined time intervals (e.g., 1h, 2h, 4h, 8h, 24h, etc.) for the duration of the run (e.g., 100 h).

Visualization: CatTestHub Data Integration for Pellet Modeling

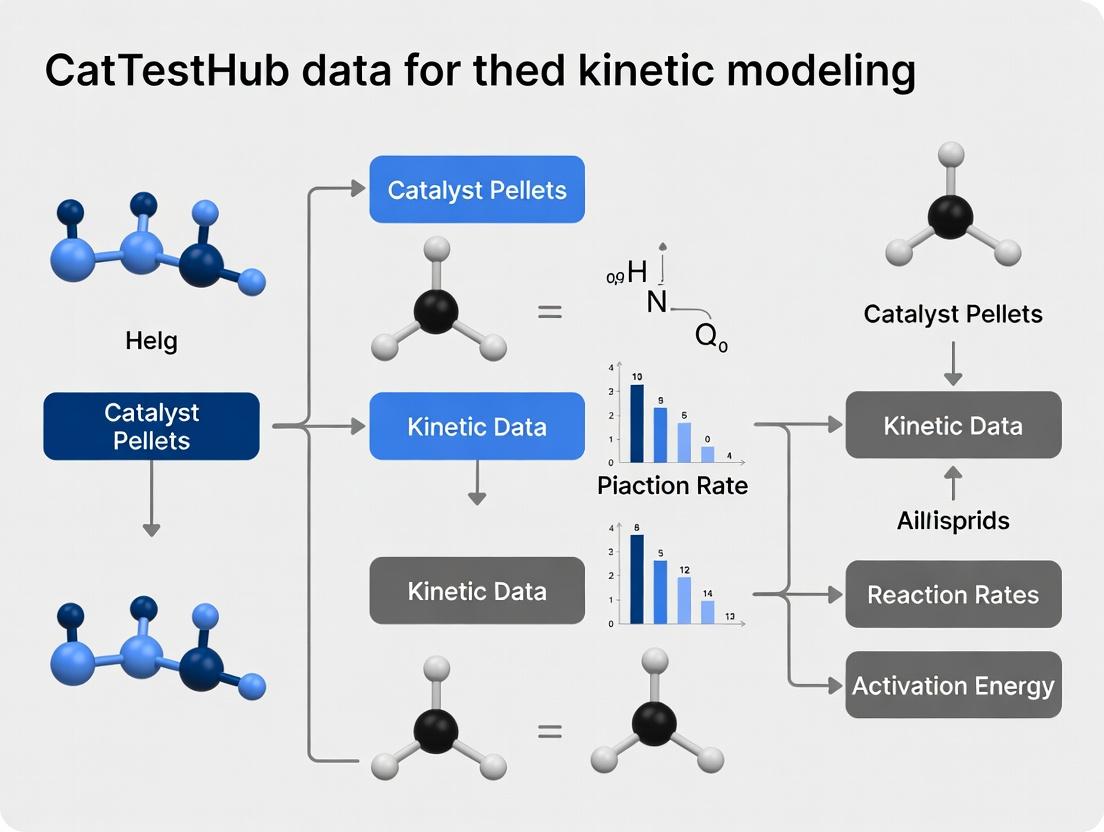

Diagram 1: CatTestHub Data Pipeline for Kinetic Modeling

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalytic Pellet Testing & Data Generation

| Item | Function/Application | Example Product/CAS | Key Notes for CatTestHub Logging |

|---|---|---|---|

| Fixed-Bed Reactor System | Bench-scale testing under controlled conditions. | PID Eng. Microactivity, Autoclave Engineers BTRS | Must log reactor type, ID, and thermocouple position. |

| Standard Catalyst Pellets (Reference) | Inter-laboratory data validation and baseline kinetic models. | EuroPt-1 (Pt/SiO₂), NIST RM 8852 (Zeolite Y) | Essential for tagging data with "Reference_Catalyst: Y/N". |

| Certified Calibration Gas Mixtures | Accurate quantification of reactants/products via GC/TCD. | 1% CO/10% CO2/89% Ar; 500 ppm NO/5% O2/N2 | Log supplier, certification date, and uncertainty. |

| High-Purity Inert Diluent | Ensures isothermal bed and correct pellet spacing for flow. | α-Alumina balls (0.8-1.2 mm), CAS: 1344-28-1 | Must match pellet size fraction to avoid channeling. |

| Mass Flow Controller (MFC) Set | Precise control of gaseous feed rates. | Bronkhorst EL-FLOW Select | Log MFC calibration gas and accuracy (±% full scale). |

| Sieved Catalyst Fractions | Isolating kinetic vs. diffusion-limited regimes. | ASTM E11 sieves (e.g., 20-25 mesh for <0.8 mm) | Log sieve mesh range and resulting particle diameter. |

| Thermogravimetric Analyzer (TGA) | Quantifying coke deposition or oxidation state changes post-reaction. | TA Instruments TGA5500 | Links deactivation data to physical catalyst changes. |

| Data Validation Software | Automated check of mass/carbon balance before upload. | Custom Python script, CATalytic DATA (CATDATA) tool | Flag datasets with carbon balance outside 98-102%. |

This application note, framed within the broader thesis on CatTestHub data for kinetic modeling of catalyst pellets research, details the fundamental principles and experimental protocols governing mass and heat transfer in porous catalyst pellets. Understanding these transport phenomena is critical for researchers and scientists in catalysis and process development to accurately derive intrinsic kinetics from experimental data and design efficient catalytic systems.

Core Principles & Governing Equations

Mass Transfer

Mass transfer within a pellet involves the diffusion of reactants from the bulk fluid to the active catalyst sites and the counter-diffusion of products. The effectiveness factor (η) is a key metric, defined as the ratio of the actual reaction rate to the rate if the entire interior surface were exposed to the external surface conditions.

Key Equations:

- Thiele Modulus (φ): A dimensionless number that relates the reaction rate to the diffusion rate. For a first-order reaction in a spherical pellet: φ = R √(k / Dₑ) where R is pellet radius, k is the rate constant, and Dₑ is the effective diffusivity.

- Effectiveness Factor (η): For a first-order reaction in a sphere: η = (3/φ²) (φ coth(φ) - 1)

Heat Transfer

Exothermic or endothermic reactions create temperature gradients between the pellet interior and the bulk fluid. The magnitude of these gradients is governed by the balance between the heat generation from reaction and the heat removal by conduction.

Key Parameter:

- Prater Temperature (β): ΔT_max = (ΔT)ₚᵣₐₜₑᵣ = (-ΔH) Dₑ Cₛ / λₑ where ΔH is the heat of reaction, Cₛ is surface concentration, and λₑ is the effective thermal conductivity.

Table 1: Typical Parameter Ranges for Porous Catalyst Pellets

| Parameter | Symbol | Typical Range | Units | Notes for CatTestHub Data | ||

|---|---|---|---|---|---|---|

| Pellet Diameter | dₚ | 1 – 10 | mm | Critical variable in diffusion-limitation studies. | ||

| Porosity | ε | 0.3 – 0.7 | - | Measured via mercury porosimetry; affects Dₑ. | ||

| Tortuosity | τ | 1.5 – 10 | - | Obtained from Dₑ/Dₐᵦ ratio. | ||

| Effective Diffusivity | Dₑ | 10⁻⁸ – 10⁻⁶ | m²/s | Dₑ = (ε/τ) * Dₐᵦ (Knudsen/Bulk). | ||

| Thiele Modulus | φ | 0.1 – 100 | - | φ < 0.3 indicates no pore diffusion limitation. | ||

| Effectiveness Factor | η | 0.1 – 1.0 | - | Key output for kinetic model correction. | ||

| Effective Thermal Conductivity | λₑ | 0.1 – 1.0 | W/(m·K) | For γ-Al₂O₃ ~0.3 W/(m·K). | ||

| Prater Temperature | β | (-0.1) – 0.2 | - | β | > 0.05 suggests significant ΔT. |

Table 2: Common Experimental Techniques for Transport Property Measurement

| Technique | Measures | Principle | Applicability to CatTestHub |

|---|---|---|---|

| Wicke-Kallenberg Cell | Effective Diffusivity (Dₑ) | Steady-state diffusion of inert gases through a pellet. | Pre-experiment characterization for model input. |

| Pulse Chromatography | Effective Diffusivity & Adsorption Constant | Analysis of residence time distribution of a tracer pulse. | Fast screening method for multiple pellets. |

| Transient Sorption (ZLC) | Micro-pore Diffusivity | Monitoring desorption kinetics from a small sample into an inert carrier. | For zeolites and microporous materials. |

| 3ω Method | Effective Thermal Conductivity (λₑ) | Applying an oscillating heat flux and measuring temp. response. | For specialized studies on heat transfer limitations. |

Experimental Protocols

Protocol 1: Determining the Effectiveness Factor via the Weisz-Prater Criterion

Objective: To diagnose the presence of internal mass transfer limitations using observable (global) reaction rate data. Materials: See Scientist's Toolkit. Procedure:

- Measure Observed Rate: Using a gradientless microreactor (e.g., spinning basket reactor), measure the observed reaction rate (robs) at standard conditions (T, P, Cbulk).

- Characterize Pellet: Obtain pellet radius (R) and bulk density (ρ_p). Estimate or measure effective diffusivity (Dₑ).

- Calculate Observable Modulus: Compute the Weisz-Prater modulus: ΦWP = (robs * R²) / (Dₑ * Cs) where Cs is the reactant concentration at the pellet surface (≈ C_bulk for no external limitation).

- Diagnosis:

- If ΦWP << 1, no internal diffusion limitations exist (η ≈ 1).

- If ΦWP >> 1, strong internal diffusion limitations exist (η < 1).

- CatTestHub Integration: This diagnostic check is a prerequisite before registering kinetic data as "intrinsic" in the CatTestHub database.

Protocol 2: Determining Effective Diffusivity using a Wicke-Kallenberg Cell

Objective: To measure the effective diffusivity (Dₑ) of a gas pair in a porous catalyst pellet. Procedure:

- Cell Setup: Seal a single pellet (cylindrical or spherical) in the cell using gaskets. Create two separate gas streams on either side (Stream A: N₂ + Trace H₂; Stream B: Pure N₂).

- Establish Steady-State: Flow both streams at equal, controlled rates. Hydrogen diffuses from Stream A, through the pellet pores, to Stream B.

- Measurement: Use a gas chromatograph (GC) or thermal conductivity detector (TCD) to measure the hydrogen concentration in Stream B.

- Calculation: Apply Fick's Law for diffusion through a porous medium. For a cylindrical pellet of length L and cross-section A: Dₑ = (F * L) / (A * ΔC) where F is the molar flow rate of H₂ into Stream B, and ΔC is the log-mean concentration difference of H₂ across the pellet.

- Data Recording: Record Dₑ alongside pellet ID, temperature, and gas pair in CatTestHub material characterization logs.

Mandatory Visualizations

Title: Mass & Heat Transfer Pathways in a Catalyst Pellet

Title: Diagnostic Protocol for Internal Diffusion Limitations

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for Transport Studies in Catalysis

| Item | Function/Benefit | Example/Catalog Reference |

|---|---|---|

| Gradientless Microreactor (e.g., Spinning Basket/CSTR) | Eliminates external mass/heat transfer gradients, allowing measurement of the true pellet reaction rate. | Autoclave Engineers BTRS-Jr; Parr Series 4590. |

| Wicke-Kallenberg Diffusion Cell | Standard apparatus for direct measurement of effective gas-phase diffusivity (Dₑ) in porous pellets. | Custom-built or supplied by catalysis equipment specialists (e.g., PID Eng & Tech). |

| Bench-top Gas Chromatograph (GC) | For precise analysis of gas mixture composition in diffusion and reaction rate experiments. | Agilent 8860 GC with TCD & FID detectors. |

| Mercury Porosimeter | Measures pore size distribution, total pore volume, and porosity (ε) of catalyst pellets. | Micromeritics AutoPore V Series. |

| Certified Gas Mixtures (Diluted in Inert) | Provide accurate, traceable reactant concentrations (e.g., 1% H₂ in N₂) for diffusion and kinetic studies. | Supplied by Air Products, Linde, or Sigma-Aldrich. |

| High-Precision Mass Flow Controllers (MFCs) | Deliver exact, repeatable flow rates of gases to reactors and diffusion cells. | Bronkhorst EL-FLOW Select series; Alicat Scientific M-Series. |

| Thermal Conductivity Detector (TCD) | Universal, concentration-sensitive detector ideal for measuring binary gas diffusion (e.g., H₂ in N₂). | Standard module in most GCs. |

| Reference Catalyst Pellets (e.g., γ-Al₂O₃ spheres) | Well-characterized, standardized materials for method validation and inter-laboratory comparison. | Available from catalyst suppliers like BASF, Clariant, or Alfa Aesar. |

This application note is framed within the broader thesis that the systematic data curation within CatTestHub is foundational for the accurate kinetic modeling and simulation of catalyst pellet performance. By extracting and standardizing key kinetic parameters from disparate experimental sources, CatTestHub enables researchers to transition from static data repositories to predictive dynamic models, accelerating catalyst development and optimization for pharmaceutical synthesis and other fine chemical processes.

The following table summarizes the core kinetic parameters curated within CatTestHub, essential for modeling reactions in catalyst pellets.

Table 1: Key Kinetic Parameters Extracted from CatTestHub for Pellet Modeling

| Parameter | Symbol | Units | Typical Range (CatTestHub) | Critical for Modeling |

|---|---|---|---|---|

| Activation Energy | Eₐ | kJ mol⁻¹ | 40 - 120 | Temperature dependence of rate |

| Pre-exponential Factor | A | Variable (e.g., s⁻¹) | 10⁵ - 10¹⁵ | Intrinsic reactivity scale |

| Reaction Order (n) | n | Dimensionless | 0 - 2 | Concentration dependence |

| Adsorption Equilibrium Constant | Kᵢ | Variable (e.g., Pa⁻¹) | 10⁻³ - 10² | Surface coverage |

| Effective Diffusivity | Dₑff | m² s⁻¹ | 10⁻⁸ - 10⁻¹¹ | Intra-pellet mass transport |

| Turnover Frequency | TOF | s⁻¹ | 10⁻³ - 10² | Site-specific activity |

| Thermal Conductivity (Pellet) | κ | W m⁻¹ K⁻¹ | 0.1 - 5.0 | Intra-pellet heat transport |

Experimental Protocols for Parameter Determination

Protocol 3.1: Determination of Activation Energy (Eₐ) and Pre-exponential Factor (A)

Objective: To extract the Arrhenius parameters from temperature-dependent rate data. Materials: See "The Scientist's Toolkit" below. Procedure:

- Catalyst Testing: Using a fixed-bed microreactor, measure the reaction rate (r) for the catalyst pellet of interest at a minimum of five different temperatures, maintaining identical inlet concentration, flow rate, and catalyst mass.

- Ensure Kinetic Control: Verify the absence of external and internal mass transfer limitations at all temperatures (see Protocol 3.3).

- Data Processing: a. For each temperature (T in K), calculate the observed rate constant (kobs) where r = kobs * f(C). b. Construct an Arrhenius plot: ln(k_obs) vs. 1/T.

- Parameter Extraction: Perform a linear regression. The slope is equal to -Eₐ/R, and the intercept is ln(A), where R is the universal gas constant (8.314 J mol⁻¹ K⁻¹).

Protocol 3.2: Determination of Adsorption Constants via Pulse Chemisorption

Objective: To quantify the strength of reactant/catalyst surface interaction. Procedure:

- Catalyst Preparation: Pre-treat catalyst pellet samples (crushed to granules) in-situ with inert gas at elevated temperature.

- Pulse Injection: Introduce calibrated pulses of the adsorbate gas (e.g., CO, H₂, NH₃) into an inert carrier stream flowing through the catalyst sample held at the analysis temperature.

- Detection: Monitor effluent concentration with a thermal conductivity detector (TCD).

- Calculation: For each pulse, calculate the amount adsorbed until saturation. The adsorption constant (K) is derived by fitting the adsorption profile using a Langmuir isotherm model integrated into CatTestHub's analysis suite.

Protocol 3.3: Verification of Intrinsic Kinetics (Weisz-Prater Criterion)

Objective: To confirm the absence of internal diffusion limitations within the catalyst pellet, ensuring measured rates are intrinsic. Procedure:

- Experimental Rate Measurement: Measure the observed reaction rate (r_obs) under standard conditions.

- Pellet Characterization: Obtain the effective diffusivity (Deff) for a key reactant (e.g., via separate uptake experiments) and the pellet radius (Rp).

- Calculation: Compute the Weisz-Prater modulus (Φ): Φ = (robs * Rp²) / (Deff * Cs), where C_s is the reactant concentration at the pellet surface.

- Criterion: If Φ << 1 (typically < 0.3), internal diffusion limitations are negligible, and kinetics are intrinsic. Data in CatTestHub are flagged with the associated Φ value.

Visualizations

Diagram 1: CatTestHub Data-to-Model Pipeline

Diagram 2: Key Pathways in Catalyst Pellet Modeling

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Kinetic Parameter Determination

| Item | Function in Protocols |

|---|---|

| Fixed-Bed Microreactor System | Provides controlled environment (T, P, flow) for measuring intrinsic reaction rates on catalyst pellets. |

| High-Precision Mass Flow Controllers (MFCs) | Deliver precise and stable flows of reactant and inert gases for kinetic and adsorption experiments. |

| Online Gas Chromatograph (GC) / Mass Spectrometer (MS) | Analyzes effluent stream composition for calculating conversion, selectivity, and rate. |

| Pulse Chemisorption Analyzer | Quantifies active metal surface area and strength of gas adsorption (for Kᵢ). |

| Thermogravimetric Analyzer (TGA) | Can be used for controlled atmosphere studies to measure weight changes related to adsorption/desorption. |

| Catalyst Pellet Crushing & Sieving Kit | Prepares representative granules from pellets for precise mass measurement and diffusion studies. |

| Calibration Gas Mixtures | Certified standards for accurate quantitative analysis of reactor effluent by GC/MS. |

| Data Acquisition & Analysis Software | Interfaces with instruments and CatTestHub for automated data logging and parameter regression. |

The Role of Pellet Geometry and Microstructure in Reaction-Diffusion Models

Within the CatTestHub research framework for kinetic modeling of catalyst pellets, understanding the interplay between pellet geometry (e.g., sphere, cylinder, ring), microstructure (e.g., porosity, pore size distribution, tortuosity), and reactive transport is paramount. These factors dictate the effectiveness factor, selectivity, and ultimately the performance of heterogeneous catalysts and controlled-release drug delivery systems. This document provides application notes and standardized protocols for characterizing and modeling these critical parameters.

Table 1: Common Pellet Geometries and Characteristic Parameters

| Geometry | Defining Dimension(s) | Specific Surface Area (a_s) | Typical Thiele Modulus (φ) Form | Common Applications |

|---|---|---|---|---|

| Sphere | Radius (R) | 3/R | φ = R√(k/D_eff) | Fixed-bed reactors, drug carriers |

| Infinite Cylinder | Radius (R) | 2/R | φ = R√(k/D_eff) | Monolithic supports, implants |

| Ring / Hollow Cylinder | Inner Radius (Ri), Outer Radius (Ro) | 2/(Ro - Ri) | Complex, numerical solution | High-throughput reactors, reduced pressure drop |

| Slab / Flat Plate | Half-thickness (L) | 1/L | φ = L√(k/D_eff) | Washcoat layers, transdermal patches |

Table 2: Microstructural Properties and Typical Measurement Ranges

| Property | Definition | Typical Range (Catalyst Pellets) | Measurement Technique |

|---|---|---|---|

| Porosity (ε_p) | Volume fraction of void space | 0.3 - 0.7 | Mercury Porosimetry, N₂ Physisorption |

| Tortuosity (τ) | Deviation of diffusion path from ideal | 2 - 10 | Electrochemical Impedance, Diffusion Cell |

| Mean Pore Diameter (d_p) | Average pore width | 2 nm - 10 μm | BJH Analysis (N₂ Desorption), Mercury Porosimetry |

| Effective Diffusivity (D_eff) | Deff = (εp / τ) * D | Varies with species & temp | Uptake/Release Kinetics, ZLC Method |

Experimental Protocols

Protocol 2.1: Determination of Effective Diffusivity (D_eff) via ZLC Method

Purpose: To measure the effective diffusivity of a key reactant within a catalyst pellet microstructure under controlled, non-reactive conditions.

Materials: See "The Scientist's Toolkit" (Section 4).

Procedure:

- Pellet Preparation: Weigh and load a small sample (5-20 mg) of catalyst pellets into the ZLC cell. Ensure the cell is leak-tight.

- Saturation: At a constant temperature (e.g., 35°C), expose the sample to a carrier gas (e.g., He) saturated with a dilute concentration of the probe molecule (e.g., 1% C₃H₈).

- Desorption & Detection: After equilibrium is reached (≈30 min), switch the gas stream to pure carrier at a high flow rate (≈50 mL/min). This rapidly purges the system, initiating desorption from the pellet macropores.

- Data Acquisition: Monitor the concentration of the probe molecule at the outlet via mass spectrometry (MS) or flame ionization detection (FID) as a function of time for 30-60 minutes.

- Analysis: Plot the normalized concentration (C/C₀) vs. time on a log scale. For long times, the slope is linear and related to Deff/R², where R is the pellet radius. Use the established ZLC model equations to extract Deff.

Protocol 2.2: 3D Microstructure Reconstruction via FIB-SEM Tomography

Purpose: To create a precise digital 3D model of a pellet's pore network for simulation of reaction-diffusion processes.

Procedure:

- Sample Preparation: Impregnate a representative pellet with a low-viscosity epoxy resin to support the pore structure. Section and polish to create a smooth cross-section. Sputter-coat with a conductive layer (e.g., Au/Pd).

- FIB-SEM Setup: Mount the sample in a Dual-Beam FIB-SEM. Define a region of interest (≈20x20x20 μm³) on the polished surface.

- Serial Sectioning & Imaging: a. Use the focused ion beam (Ga⁺) to mill away a thin slice (e.g., 10 nm) of material. b. Use the scanning electron beam to image the newly exposed cross-section at high resolution (e.g., 5 nm/pixel). c. Repeat steps a & b sequentially 500-1500 times to generate an image stack.

- Image Processing & Segmentation: Align the image stack. Apply filters to reduce noise. Use a thresholding algorithm (e.g., Otsu's method) to segment the images into binary phases (solid vs. pore).

- 3D Model Generation & Analysis: Reconstruct the 3D volume from the binary stack. Compute microstructural properties (porosity, tortuosity, pore size distribution) directly using analysis software (e.g., Avizo, Dragonfly).

Visualizations

(Diagram Title: Modeling Workflow for Pellet Performance)

(Diagram Title: From Geometry & Structure to Effectiveness)

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function/Description | Example Product/Chemical |

|---|---|---|

| Zeolite (e.g., H-ZSM-5) Pellets | Model catalyst pellet with well-defined microporous structure. | ACS Material, Zeolyst International |

| Mesoporous Silica Spheres (MCM-41) | Model pellet with ordered, tunable mesopores for diffusion studies. | Sigma-Aldrich (MCM-41) |

| Mercury Intrusion Porosimeter | Measures pore size distribution (macropores & large mesopores). | Micromeritics AutoPore series |

| TriBeam or DualBeam FIB-SEM | Instrument for serial sectioning and imaging for 3D reconstruction. | Thermo Fisher Scientific, Zeiss |

| Zero-Length Column (ZLC) System | Bench-scale apparatus for accurate measurement of intracrystalline diffusion. | Custom-built or commercial (e.g., Micromeritics) |

| Probe Molecules for ZLC | Inert, detectable molecules for diffusion experiments (C₃H₈, C₄H₁₀). | 1% Propane in Helium (gas cylinder) |

| Avizo 3D Software | Software for visualization and quantitative analysis of 3D image data. | Thermo Fisher Scientific |

| COMSOL Multiphysics | Finite element analysis software for simulating reaction-diffusion in complex geometries. | COMSOL Inc. |

Application Notes

Within the broader thesis on utilizing CatTestHub data for the kinetic modeling of catalyst pellets, this case study presents an initial exploratory analysis of a standard model reaction: the oxidative dehydrogenation of propane (ODHP) over a vanadium-based catalyst pellet. The primary objective was to validate the data structure, assess measurement consistency, and identify primary reaction trends before committing to full-scale mechanistic modeling.

The CatTestHub dataset for this experiment comprised 124 unique reaction conditions, systematically varying temperature (T), partial pressures of propane (C₃H₈) and oxygen (O₂), and gas hourly space velocity (GHSV). Key performance metrics recorded were propane conversion (XC3H8), selectivity to propylene (SC3H6), and yield of propylene (Y_C3H6).

Table 1: Summary of Key Experimental Outcomes from the CatTestHub ODHP Dataset

| Parameter | Range Investigated | Observed Correlation with Propylene Yield | Preliminary Kinetic Insight |

|---|---|---|---|

| Temperature | 400 – 550 °C | Positive, up to an optimum (~525°C) | Apparent activation energy estimated at ~85 kJ/mol, followed by decline due to over-oxidation. |

| C₃H₈ Partial Pressure | 0.1 – 0.5 bar | Positive, with diminishing returns | Reaction order w.r.t. C₃H₈ approximated as 0.7, suggesting adsorption effects. |

| O₂ Partial Pressure | 0.05 – 0.25 bar | Positive, then plateauing near 0.2 bar | Near-zero order at higher O₂ pressures, indicative of saturated active sites. |

| GHSV | 5,000 – 60,000 h⁻¹ | Negative (residence time effect) | Integral reactor data confirmed; differential conditions approached at highest GHSV. |

| Max. C₃H₆ Yield | --- | 24.3% at 525°C, 0.4 bar C₃H₈, 0.2 bar O₂ | Identified as a key benchmark for subsequent model fitting. |

This exploratory phase confirmed data quality and revealed the classic selectivity-conversion trade-off. The data is suitable for progressing to Langmuir-Hinshelwood type kinetic modeling, where oxygen and hydrocarbon compete for surface sites.

Experimental Protocols

Protocol 1: CatTestHub Fixed-Bed Microreactor Operation for ODHP Kinetic Data Point Generation

Objective: To obtain a single data point of conversion and selectivity under defined conditions for kinetic analysis.

Materials: (See Scientist's Toolkit) Procedure:

- Catalyst Loading: Precisely weigh 100.0 mg of the 200-300 µm sieved VOx/MgO catalyst pellet fraction. Mix with 900.0 mg of inert, similarly sized α-Al₂O₃ diluent to ensure isothermal operation. Load the mixture into the quartz microreactor (ID = 6 mm) between quartz wool plugs.

- System Preparation: Connect the reactor to the CatTestHub gas manifold. Perform a leak check on the entire system up to 10 bar using He. Set all mass flow controllers (MFCs) to standby.

- Pre-Treatment / Activation: Under a flow of 100 sccm of 20% O₂/He, heat the reactor from room temperature to 500°C at 10 °C/min. Hold at 500°C for 2 hours. Cool to the desired starting reaction temperature (e.g., 400°C) in the same atmosphere.

- Reaction Condition Setting: Set the total system pressure to 2.0 bar absolute. Adjust the MFCs to achieve the desired partial pressures of C₃H₈, O₂, and balance He. Set the total flow to achieve the target GHSV (e.g., 20,000 h⁻¹). Allow flows to stabilize for 5 minutes.

- Steady-State Measurement: By-pass the reactor flow to the online GC (Bypass Loop) for initial composition analysis. Switch the flow to pass through the reactor. Allow a minimum of 45 minutes for the system to reach steady-state, as confirmed by three consecutive GC analyses (spaced 15 min apart) showing <2% relative deviation in major peak areas.

- Data Acquisition: At steady-state, inject a minimum of three replicate samples into the online GC (Agilent 8890) equipped with a GS-GASPRO capillary column and FID/TCD detectors. Calibrated response factors are used to calculate molar flows.

- Calculation:

- Conversion of C₃H₈: X = (Fin,C3H8 - Fout,C3H8) / Fin,C3H8

- Selectivity to C₃H₆: S = Fout,C3H6 / (Fin,C3H8 - Fout,C3H8)

- Yield of C₃H₆: Y = X * S

- Condition Variation: For the next data point, adjust only one parameter (T, PC3H8, PO2, or total flow) following steps 4-7. Always return to a base condition periodically to check for catalyst deactivation.

Protocol 2: Online GC-FID/TCD Analysis for Product Distribution

Objective: To separate and quantify reactants and products in the effluent stream. Procedure:

- Sampling: The automated 10-port valve with a 250 µL sample loop is flushed with reactor effluent for 30 seconds before injection.

- Chromatography: Inject onto the GS-GASPRO column (60m x 0.32mm). Oven program: Hold at 40°C for 4 min, ramp at 15°C/min to 220°C, hold for 5 min. Carrier Gas: He at 2.0 mL/min constant flow.

- Detection: Light gases (H₂, O₂, N₂, CO, CO₂, CH₄, C₂H₄, C₂H₆) are routed to the TCD. Hydrocarbons (C3+) are routed to the FID (H₂/air flame, 250°C).

- Quantification: Use external standard calibration curves for C₁ to C₄ hydrocarbons and permanent gases. Peak areas are integrated by the OpenLab CDS software and converted to partial pressures using the known total pressure and internal standard (Ar) flow.

Visualizations

CatTestHub Experimental and Data Analysis Workflow

Proposed ODHP Surface Reaction Pathway

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

| Item | Specification/Composition | Primary Function in Protocol |

|---|---|---|

| VOx/MgO Catalyst Pellets | 5 wt.% Vanadia on Magnesium Oxide support, crushed & sieved to 200-300 µm. | The core heterogeneous catalyst for the model ODHP reaction, providing active sites. |

| α-Al₂O₃ Diluent | Inert, high-purity alumina, sieved to 200-300 µm. | Ensures isothermal conditions in the fixed bed by diluting the catalyst and improving flow distribution. |

| Reaction Gases | Research-grade C₃H₈, O₂, He (≥ 99.999%), with in-line purifiers/moisture traps. | Provide high-purity reactants and inert diluent to prevent catalyst poisoning and ensure reproducible kinetics. |

| Calibration Gas Standard | Certified mix of C₁-C₄ hydrocarbons, CO, CO₂, H₂, O₂, N₂ in He balance at known mol%. | Essential for accurate quantitative analysis by online GC, creating response factors for each species. |

| Quartz Microreactor & Wool | 6 mm ID, high-temperature quartz tube; acid-washed quartz wool. | Contains the catalyst bed, is inert at high temperatures, and retains the solid material within the isothermal zone. |

| GS-GASPRO Capillary Column | 60m x 0.32mm, porous layer stationary phase. | Provides critical separation of all light gases and hydrocarbons in a single GC run for comprehensive analysis. |

Building Predictive Models: A Step-by-Step Guide to Applying CatTestHub Data

Within the broader thesis on the kinetic modeling of catalyst pellets, this document details the standardized workflow for importing and preprocessing experimental data from the CatTestHub platform. This integrated pipeline is critical for transforming raw catalytic test data into a clean, structured format suitable for kinetic model fitting, parameter estimation, and predictive simulation. A robust workflow ensures reproducibility and reliability in downstream modeling efforts, which are fundamental for researchers and process development scientists in catalysis and related fields.

Data Source: CatTestHub Structure

CatTestHub is a centralized repository for heterogeneous catalyst testing data. A typical experiment yields multi-dimensional data streams. The core quantitative outputs per experimental run are summarized in Table 1.

Table 1: Core Quantitative Data from a Standard CatTestHub Experiment

| Data Category | Specific Measurement | Typical Units | Data Type | Description |

|---|---|---|---|---|

| Inlet Conditions | Feed Gas Composition | mol %, ppm | Time-series | Concentration of CO, CO₂, H₂, N₂, etc. |

| Total Gas Flow Rate | mL/min, sccm | Constant/Time-series | ||

| Reactor Pressure | bar, kPa | Constant/Time-series | ||

| Reactor Temperature | °C, K | Time-series | Setpoint and measured bed temperature. | |

| Outlet Conditions | Effluent Gas Composition | mol %, ppm | Time-series | Post-reaction composition from MS/GC. |

| Total Outlet Flow | mL/min | Calculated | ||

| Catalyst Properties | Pellet Mass | g | Constant | Mass of catalyst charge. |

| Pellet Dimensions | mm | Constant | Diameter, height, or equivalent. | |

| Bed Void Fraction | - | Calculated | Porosity of the packed bed. | |

| Performance Metrics | Reactant Conversion | % | Calculated | For key reactants (e.g., CO). |

| Product Yield | % | Calculated | For desired products. | |

| Product Selectivity | % | Calculated | Based on carbon or molar balance. | |

| Space Velocity | h⁻¹ (GHSV) | Calculated | Gas Hourly Space Velocity. |

Application Notes & Protocols

Protocol: Data Import and Validation

Objective: To programmatically import raw CatTestHub export files (e.g., .csv, .xlsx) and perform initial validation.

Materials: Computational environment (Python/R/MATLAB), CatTestHub data export.

- File Reading: Use

pandas.read_csv()(Python) or equivalent to load data. Specify the correct delimiter and header row. - Schema Validation: Check that all expected columns (Table 1) are present. Verify data types (numeric, string).

- Range & Plausibility Checks: Flag physically impossible values (e.g., negative concentrations, conversions >100%, temperature spikes >50°C/s).

- Timestamp Synchronization: If data streams from multiple instruments (GC, MS, TCD) are in separate files, align them using a common experimental timestamp (UNIX or relative time in seconds).

- Output: A validated, combined

DataFrameor table ready for preprocessing.

Protocol: Data Preprocessing for Kinetic Modeling

Objective: To clean, transform, and feature-engineer the validated data into model-ready format. Materials: Validated dataset from Protocol 3.1.

- Handling Missing Data:

- Identify gaps (e.g., GC sampling downtime).

- For short gaps (<3 data points) in smoothly varying signals (e.g., temperature), use linear interpolation.

- For longer gaps or in critical composition data, flag the period and exclude from steady-state analysis.

- Steady-State Identification:

- For kinetic modeling, data from steady-state operation is required.

- Calculate a rolling window (e.g., 5-minute) standard deviation for key measured variables (conversion, temperature).

- Define a steady-state threshold (e.g., std. dev. < 1% of mean value).

- Tag time periods where all key variables are within their thresholds.

- Averaging at Steady-State:

- For each distinct steady-state period (catalyst, temperature, feed condition), average all measured and calculated values.

- This generates one representative data point per experimental condition for lumped-parameter model fitting.

- Calculation of Derived Variables:

- Compute required metrics not provided in raw export:

- Conversion (X): ( Xi = \frac{F{i,in} - F{i,out}}{F{i,in}} \times 100\% )

- Selectivity (S): ( S{j\to k} = \frac{vi \cdot F{k,out}}{vk \cdot (F{i,in} - F{i,out})} \times 100\% ) (where (v) are stoichiometric coefficients).

- Reaction Rate (r): ( ri = \frac{F{i,in} \cdot Xi}{m{cat}} ) (mol/s/g_cat).

- Compute required metrics not provided in raw export:

- Normalization/Scaling: For machine-learning-aided models, scale features (e.g., temperature, pressure) to a [0,1] or standard normal distribution.

- Output: A clean, preprocessed table of steady-state data points with calculated reaction rates, ready for kinetic regression.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials

| Item | Function in Workflow | Example/Specification |

|---|---|---|

| Data Processing Environment | Scripting and analysis platform. | Python with pandas, NumPy, SciPy; MATLAB; R with tidyverse. |

| Version Control System | Tracks changes to data processing scripts. | Git, with repository hosted on GitHub or GitLab. |

| Documentation Framework | Creates reproducible analysis reports. | Jupyter Notebooks, R Markdown, or Quarto. |

| Numerical Solver Library | Fits kinetic models to preprocessed data. | SciPy.optimize, MATLAB Optimization Toolbox, Kinetics Toolkit. |

| Data Visualization Library | Generates diagnostic and publication-quality plots. | Matplotlib/Seaborn (Python), ggplot2 (R). |

| Standardized Data Format | Ensures interoperability between workflow stages. | Hierarchical Data Format (HDF5) or Feather for processed data. |

Workflow Visualization

CatTestHub Data Processing Workflow

Steady-State Data Validation Logic

Within the broader thesis utilizing the CatTestHub data repository for kinetic modeling of catalyst pellets, selecting an appropriate modeling framework is paramount. This choice dictates the accuracy, computational cost, and physical relevance of simulations predicting reactor performance. The fundamental decision lies between Pseudo-Homogeneous and Heterogeneous approaches, each with distinct assumptions about the coupling of reaction kinetics and transport phenomena inside porous catalyst pellets.

Core Modeling Frameworks: A Comparative Analysis

Table 1: Fundamental Comparison of Modeling Frameworks

| Aspect | Pseudo-Homogeneous Model | Heterogeneous Model (Dusty-Gas Model) |

|---|---|---|

| Core Assumption | Catalyst pellet is treated as a uniform, continuum phase. No explicit distinction between fluid and solid phases. | Explicitly treats fluid (gas) and solid (catalyst) as separate, interpenetrating phases. |

| Mass Transport | Effective diffusivity ((D_{eff})) lumping both pore and surface diffusion. Fick's law is typically used. | Separates transport mechanisms: Knudsen diffusion, molecular diffusion, and viscous flow (Dusty-Gas Model equations). |

| Heat Transport | Effective thermal conductivity ((\lambda_{eff})) lumping solid and fluid contributions. | Separate heat conduction in solid and fluid phases, with convective coupling. |

| Reaction Term | Reaction rate expressed per unit pellet volume, using bulk fluid concentration. | Reaction rate is a function of interfacial (surface) concentration, often with an adsorption isotherm. |

| Governing Equations | Single mass/energy balance equation for the pellet. | Coupled mass/energy balance equations for fluid and solid phases. |

| Computational Complexity | Low to moderate. Easier to implement and solve. | High. Requires solving coupled, non-linear equations with more parameters. |

| Primary Application | Fast reactions where internal gradients are negligible or for initial screening. Systems with strong internal diffusion limitations where accurate intra-pellet profiles are critical. High-accuracy design and fundamental analysis. | |

| Typical Use Case from CatTestHub | Initial screening of catalyst activity for CO₂ hydrogenation over Ni-based catalysts under moderate temperatures. | Detailed analysis of ethylene epoxidation on Ag catalysts, where strong internal heat and mass gradients exist. |

Table 2: Quantitative Performance Metrics from CatTestHub Case Studies

| Catalyst System (from CatTestHub) | Model Type | Key Parameter Estimated | Avg. Error vs. Experimental Data | Avg. Computational Time (per simulation) |

|---|---|---|---|---|

| Ni/Al₂O₃ (CO₂ Methanation) | Pseudo-Homogeneous (1D) | Effective Reaction Rate Constant | 12.5% | 0.8 sec |

| Ni/Al₂O₃ (CO₂ Methanation) | Heterogeneous (1D+DG) | Intrinsic Kinetic Constant & Effectiveness Factor | 5.2% | 12.4 sec |

| Ag/α-Al₂O₃ (Ethylene Oxide) | Pseudo-Homogeneous (1D) | Apparent Activation Energy | 22.7% | 1.1 sec |

| Ag/α-Al₂O₃ (Ethylene Oxide) | Heterogeneous (1D+DG) | True Activation Energy & Selectivity Parameters | 6.8% | 25.7 sec |

Experimental Protocols for Model Validation

Protocol 1: Determining Effective Diffusivity ((D_{eff})) for Pseudo-Homogeneous Models

Objective: To experimentally determine the lumped effective diffusivity of a reactant gas within a catalyst pellet, a critical parameter for pseudo-homogeneous models.

Materials: See The Scientist's Toolkit below. Procedure:

- Pellet Preparation: Weigh a dry catalyst pellet (e.g., 5mm diameter cylinder). Record exact dimensions. Place it in the Wicke-Kallenbach diffusion cell.

- System Purge: Flow an inert carrier gas (e.g., Helium) through both cell compartments at 50 sccm for 30 minutes to remove air and moisture.

- Diffusion Measurement: Maintain a steady flow of inert gas on one side (Side A). Introduce a dilute mixture of the probe gas (e.g., 5% N₂ in He) to the other side (Side B). Use Mass Flow Controllers (MFCs) to ensure equal total pressures on both sides, eliminating viscous flow.

- Analysis: After steady-state is reached (confirmed by stable GC readings), measure the concentration of the probe gas diffusing into the inert stream on Side A.

- Calculation: Apply Fick's first law. The flux (J) measured by the GC, combined with the pellet geometry and the imposed concentration gradient, allows calculation of (D_{eff}).

- Repeat: Perform at multiple temperatures to obtain an Arrhenius relationship for (D_{eff}).

Protocol 2: Intrapellet Concentration Profile Measurement for Heterogeneous Model Validation

Objective: To spatially resolve the concentration of reactants within a single catalyst pellet under reaction conditions, providing direct validation for heterogeneous model predictions.

Materials: See The Scientist's Toolkit below. Procedure:

- Pellet Mounting: Securely mount a large, representative catalyst pellet (e.g., 8mm sphere) within the Spaci-MS micro-reactor. Precisely align the sampling capillary with the pellet's geometric center.

- Reaction Conditions: Establish desired temperature, pressure, and feed composition (e.g., H₂/CO mixture) using MFCs and the back-pressure regulator.

- Spatial Profiling: Initiate the reaction. Using the high-precision linear actuator, step the capillary through the pellet in increments (e.g., 100 µm). At each position, allow equilibration, then sample gases via the Spaci-MS.

- Data Acquisition: The Mass Spectrometer provides quantitative concentration data for reactants and products at each spatial coordinate.

- Model Fitting: Use the measured axial concentration profile as the target to fit the parameters of the heterogeneous (Dusty-Gas) model using non-linear regression software. This yields intrinsic kinetics and true transport parameters.

Modeling Workflow and Decision Logic

(Diagram Title: Decision Logic for Model Selection)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Model Parameterization Experiments

| Item / Reagent | Function / Purpose |

|---|---|

| Standard Catalyst Pellets (from CatTestHub) | Provides consistent, well-characterized porous solid samples for diffusivity and reaction studies (e.g., γ-Al₂O₃ spheres, extrudates). |

| Wicke-Kallenbach Diffusion Cell | A two-chamber apparatus designed to measure gas-phase diffusion through porous solids under a concentration gradient at equal total pressure. |

| High-Precision Mass Flow Controllers (MFCs) | Deliver precise, stable flow rates of gases (H₂, N₂, He, reactant mixtures) for creating controlled gradients and reaction conditions. |

| Micro-packed Bed Reactor with Spaci-MS | Enables spatially resolved sampling of gas concentrations inside a catalyst bed or large pellet via a movable capillary coupled to a mass spectrometer. |

| Calibration Gas Mixtures (Certified Standards) | Essential for calibrating GC and MS detectors to ensure quantitative accuracy of concentration measurements. |

| Thermogravimetric Analyzer (TGA) with Sorption Module | Measures adsorption isotherms and pore size distribution, providing critical inputs for Dusty-Gas Model parameters (e.g., Knudsen diffusivity). |

| Computational Software (e.g., gPROMS, COMSOL, custom MATLAB/Python codes) | Solves coupled partial differential equations (PDEs) for both model types, performing parameter estimation and simulation. |

This application note details numerical methods for solving the Reaction-Diffusion (R-D) equation, a cornerstone model for simulating species concentration within porous catalyst pellets. Within the broader CatTestHub data thesis, accurate numerical solvers are essential for validating kinetic models against experimental data, enabling the prediction of reaction rates, selectivity, and effectiveness factors under varying operational conditions.

Core Mathematical Model

The general transient R-D equation for a single species in a catalyst pellet is:

[ \frac{\partial Ci}{\partial t} = D{e,i} \nabla^2 Ci + Ri(C1, C2, ..., C_n, T) ]

Where (Ci) is the concentration of species *i*, (D{e,i}) is its effective diffusivity, and (R_i) is the net rate of production/consumption from kinetic reactions.

Discretization Schemes

| Method | Spatial Discretization | Temporal Discretization | Stability/Accuracy | Best Use Case in Catalyst Modeling |

|---|---|---|---|---|

| Finite Difference Method (FDM) | Central/backward/forward differences on regular grid. | Explicit (FTCS), Implicit (BTCS), Crank-Nicolson. | Explicit: conditionally stable (∆t ~ (∆x)²). Implicit: Unconditionally stable. | Simple 1D/2D pellet geometries, initial model prototyping. |

| Finite Volume Method (FVM) | Integrates over control volume; conservative by construction. | Implicit methods preferred. | Unconditionally stable with full implicit. | Complex pellet geometries, ensures mass conservation. |

| Finite Element Method (FEM) | Weak form; shape functions on irregular mesh. | Generalized-α, backward Euler. | High accuracy for complex shapes. | Realistic 3D pellet geometries from tomography data. |

| Method of Lines (MOL) | Converts PDE to ODE system via spatial discretization. | Adaptive ODE solvers (SUNDIALS CVODE). | Stability depends on ODE solver. | Systems with stiff reaction kinetics, coupled multi-species models. |

Solver Performance Data

Performance benchmarks for solving a standard 2D pellet problem (Thiele modulus = 5) are summarized below.

Table 1: Solver Performance Comparison (Single Species, Isothermal)

| Solver Algorithm | Discretization | Avg. Solve Time (s) | Max Memory (MB) | L² Error (Steady-State) | Implementation Complexity |

|---|---|---|---|---|---|

| Explicit FTCS | FDM, Uniform Grid | 12.5 | 50 | 1.2e-3 | Low |

| Implicit (ADI) | FDM, Uniform Grid | 3.1 | 75 | 5.8e-4 | Medium |

| Conjugate Gradient | FEM, Unstructured Mesh | 8.7 | 220 | 2.1e-5 | High |

| CVODE (BDF) | MOL, Adaptive | 4.5 | 180 | 1.8e-6 | High |

Experimental Protocols for Numerical Validation

Protocol: Validation Against Analytical Solution (Slab Pellet)

Objective: Verify solver accuracy for a first-order, isothermal reaction in a 1D slab. Materials: See Scientist's Toolkit. Procedure:

- Define Parameters: Set slab half-thickness (L), (De), surface concentration (Cs), rate constant (k_v).

- Compute Analytical Solution: Calculate effectiveness factor (η{analytical} = \frac{\tanh(\phi)}{\phi}), where (\phi = L\sqrt{kv/D_e}).

- Numerical Simulation: a. Implement a 1D FDM grid with at least 50 nodal points. b. Apply boundary conditions: (C = Cs) at surface, (dC/dx = 0) at center. c. Use an implicit (BTCS) solver to reach steady-state. d. Calculate numerical effectiveness factor: (η{numerical} = \frac{\int0^L R(c) dx}{L \cdot R(Cs)}).

- Validation: Compare (η{numerical}) to (η{analytical}). For (\phi=2), error should be < 0.5%.

Protocol: Coupled Heat and Mass Transfer Simulation

Objective: Model non-isothermal pellet behavior with exothermic reaction. Procedure:

- Set Up Coupled Equations:

- Mass: (De \nabla^2 C = R(C,T))

- Energy: (ke \nabla^2 T = (-\Delta H) R(C,T))

- Implement FEM Solver: a. Mesh the pellet geometry (sphere/cylinder). b. Use Lagrange linear elements for both (C) and (T). c. Employ a Newton-Raphson iterator for the nonlinear coupled system.

- Run for Multiple (\beta) (Prater Number): Simulate for (\beta = 0.1, 0.3, 0.6).

- Output: Generate internal effectiveness factor plots and identify regions of multiple steady-states.

Workflow for Integration with CatTestHub Data

Diagram Title: R-D Solver Integration with Experimental Catalyst Data Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Computational Tools for R-D Modeling

| Item/Category | Specific Examples/Formats | Function in Research |

|---|---|---|

| PDE Solver Suites | COMSOL Multiphysics, FEniCS, MATLAB PDE Toolbox | High-level environments for implementing FEM/FVM solvers with minimal coding. |

| Scientific Libraries | SUNDIALS (CVODE, IDA), PETSc, NumPy/SciPy (Python) | Core libraries for time integration, nonlinear solvers, and sparse matrix operations. |

| Mesh Generation | Gmsh, ANSYS ICEM CFD | Creates structured/unstructured spatial grids for complex pellet geometries. |

| Visualization | ParaView, VisIt, Matplotlib | Analyzes and plots 2D/3D concentration and temperature fields. |

| Data Fitting Tools | LMFIT (Python), Monolix, Kinetics Toolkit | Estimates kinetic parameters (rate constants, diffusivity) from CatTestHub data. |

| Programming Language | Python, Julia, C++ with Eigen Lib | Primary languages for implementing custom solvers and automation scripts. |

Logical Structure of a Modular R-D Solver

Diagram Title: Modular Architecture of a Custom R-D Solver

This application note, framed within the broader CatTestHub thesis on kinetic modeling of catalyst pellets, details protocols for estimating intrinsic kinetic constants and effective diffusivities. These parameters are critical for accurate reactor design and catalyst optimization in pharmaceutical synthesis and chemical manufacturing. The methodologies leverage data from controlled experiments on porous catalyst pellets to deconvolve reaction and diffusion effects.

Core Principles and Data Framework

The Thiele modulus (φ) and effectiveness factor (η) relate observed reaction rates to intrinsic kinetics and mass transport. For an nth-order irreversible reaction in a spherical pellet, the relationship is defined by: [ \eta = \frac{3}{\phi^2} (\phi \coth \phi - 1) \quad \text{with} \quad \phi = R \sqrt{\frac{(n+1)kn C{s}^{n-1}}{2De}} ] where (kn) is the intrinsic rate constant, (De) is the effective diffusivity, (Cs) is surface concentration, and R is pellet radius. CatTestHub data provides structured measurements to fit these parameters.

Table 1: Exemplar CatTestHub Experimental Dataset for Pellet 12X-4 (Reaction: A → B)

| Pellet Diameter (mm) | Temperature (K) | Measured Surface Conc. CA_s (mol/m³) | Observed Rate robs (mol/(m³·s)) | Pellet Density ρ_p (kg/m³) |

|---|---|---|---|---|

| 2.0 | 450 | 1.25 | 0.18 | 1550 |

| 2.0 | 475 | 1.20 | 0.42 | 1550 |

| 2.0 | 500 | 1.18 | 0.91 | 1550 |

| 5.0 | 450 | 1.25 | 0.11 | 1550 |

| 5.0 | 475 | 1.20 | 0.23 | 1550 |

| 5.0 | 500 | 1.18 | 0.45 | 1550 |

Experimental Protocols

Protocol 1: Determining Effective Diffusivity (Dₑ) via Wicke-Kallenbach Cell

Objective: Measure the effective diffusivity of a reactant gas within a porous catalyst pellet under non-reactive conditions. Materials: Wicke-Kallenbach diffusion cell, catalyst pellet, pure carrier gases (e.g., He, N₂), tracer gas (e.g., H₂, Ar), mass flow controllers, gas chromatograph (GC). Procedure:

- Mount the catalyst pellet securely between the two chambers of the cell, ensuring a gas-tight seal.

- Maintain constant temperature and pressure. Flow pure Carrier Gas A through one chamber and Carrier Gas A doped with a known, low concentration of Tracer Gas B through the opposite chamber. Ensure equal volumetric flow rates and pressures to prevent bulk flow.

- Allow the system to reach steady state (typically 30-60 mins).

- Sample the outlet streams from both chambers and analyze tracer concentration via GC.

- Calculate (De) using the measured flux (N) and the concentration difference (\Delta C) across the pellet of thickness (L): [ De = \frac{N \cdot L}{\Delta C \cdot \varepsilonp / \tau} ] where (\varepsilonp) is pellet porosity and (\tau) is tortuosity (often initially estimated, then refined).

- Repeat with varying pellet batches and gases to obtain average (D_e) values.

Protocol 2: Simultaneous Estimation of k and Dₑ via Differential Reactor Studies

Objective: Extract intrinsic kinetic constant ((k)) and effective diffusivity ((D_e)) from observed reaction rates across varied pellet sizes. Materials: Differential reactor (packed with single pellet size), feed delivery system, precise temperature control (e.g., fluidized sand bath), online analytical instrument (e.g., FTIR, MS). Procedure:

- Sieve and sort catalyst pellets into distinct, narrow size fractions (e.g., 1mm, 2mm, 5mm).

- For a given size fraction, load pellets into the differential reactor. Operate under conditions ensuring less than 5% conversion per pass.

- At a fixed temperature and inlet concentration, measure the steady-state reaction rate. Vary the temperature (maintaining identical surface concentration via feed adjustment) to obtain an apparent activation energy.

- Repeat Step 3 for all pellet size fractions.

- Perform nonlinear regression on the dataset (like Table 1), fitting the observed rate equation (r{obs} = \eta \cdot (k Cs^n)) globally, where (\eta = f(\phi, n)) and (\phi) is a function of (k), (De), and (Cs).

- The regression minimizes the sum of squared errors between measured and modeled (r{obs}), yielding best-fit values for (k) (and its Arrhenius parameters (A) and (Ea)) and (D_e).

Table 2: Fitted Parameters from Exemplar Data Analysis (Model: 1st Order Kinetics)

| Parameter | Estimated Value | 95% Confidence Interval | Units |

|---|---|---|---|

| Pre-exponential Factor (A) | 2.5 x 10⁷ | [1.9 x 10⁷, 3.3 x 10⁷] | s⁻¹ |

| Activation Energy (Eₐ) | 85.2 | [82.1, 88.3] | kJ/mol |

| Effective Diffusivity (Dₑ) at 450K | 5.8 x 10⁻⁷ | [5.1 x 10⁻⁷, 6.5 x 10⁻⁷] | m²/s |

| Tortuosity (τ) | 3.2 | [2.8, 3.6] | - |

Visualizing the Parameter Estimation Workflow

Title: Parameter Estimation Workflow for Pellet Kinetics

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Research Toolkit for Kinetic & Diffusivity Studies

| Item | Function & Rationale |

|---|---|

| Model Porous Catalyst Pellets | Well-characterized, uniform particles (e.g., γ-Al₂O₃, silica pellets) with controlled porosity and pore size distribution for foundational studies. |

| Wicke-Kallenbach Diffusion Cell | Standard apparatus for precise measurement of gas-phase effective diffusivity under isobaric, non-reactive conditions. |

| Microreactor/Differential Reactor System | Enables measurement of intrinsic kinetics by operating at high flow rates and very low conversions, minimizing heat and mass transfer limitations. |

| High-Precision Mass Flow Controllers (MFCs) | Critical for maintaining accurate and stable gas composition and flow rates in diffusion and kinetic experiments. |

| Online Mass Spectrometer (MS) or FTIR Analyzer | Provides real-time, quantitative analysis of reactant and product concentrations for dynamic rate measurements. |

| Thermogravimetric Analyzer (TGA) with Gas Manifold | Used to measure adsorption isotherms and determine pellet porosity and density under relevant conditions. |

| Non-Linear Regression Software (e.g., Python SciPy, MATLAB, gPROMS) | Essential for performing multi-variable parameter estimation by solving the coupled kinetic-diffusion model. |

| Catalyst Pellet Crushing & Sieving Kit | To produce uniform particle size fractions necessary for isolating diffusion effects (Thiele modulus analysis). |

This application note is a component of the broader CatTestHub research initiative, which aims to build a comprehensive, data-driven framework for the kinetic modeling of heterogeneous catalyst pellets. Within pharmaceutical Active Pharmaceutical Ingredient (API) synthesis, catalyst pellets are pivotal in key hydrogenation, oxidation, and cross-coupling steps. Accurately modeling mass transfer, reaction kinetics, and deactivation within these pellets is essential for scaling laboratory reactions to robust, efficient, and sustainable manufacturing processes. The data and protocols herein feed directly into the CatTestHub kinetic parameter database, enabling predictive scale-up and catalyst life-cycle management.

Key Experimental Data from Recent Studies

Table 1: Characteristic Data for Common API Synthesis Catalyst Pellets

| Catalyst System (Pellet) | Typical Diameter (mm) | Avg. Porosity (%) | BET Surface Area (m²/g) | Common API Synthesis Step | Observed Effectiveness Factor (η) | Major Deactivation Mechanism |

|---|---|---|---|---|---|---|

| Pd/Al₂O₃ (5% wt) | 3.0 ± 0.2 | 45 ± 5 | 120-180 | Nitro-group hydrogenation | 0.15 - 0.35 | Coke deposition, Pd leaching |

| Pt/C (3% wt) | 1.5 ± 0.1 | 55 ± 3 | 900-1100 | Aromatic ring hydrogenation | 0.05 - 0.15 | Sulfur poisoning, sintering |

| Raney Nickel (Extrudate) | 4.0 ± 0.5 | 60 ± 10 | 40-80 | Reductive amination | 0.20 - 0.50 | Leaching, oxidation |

| Cu-ZnO/Al₂O₃ | 4.5 ± 0.3 | 40 ± 4 | 80-120 | Methyl ester hydrogenation | 0.10 - 0.25 | Sintering, chloride poisoning |

| Polymer-supported Pd | 0.5 - 1.0 (bead) | N/A (gel-type) | Low (<50) | Suzuki-Miyaura coupling | Often ~1 (kinetic control) | Ligand degradation, Pd agglomeration |

Table 2: CatTestHub Kinetic Modeling Input Parameters (Exemplary for Pd/Al₂O₃ Nitro-Hydrogenation)

| Parameter Symbol | Description | Typical Value Range | Determination Method |

|---|---|---|---|

| kₛ | Surface reaction rate constant (mol·s⁻¹·m⁻²) | 1.2e-3 - 5.8e-3 | Regression from intrinsic kinetic data |

| Dₑ,ᴀ | Effective diffusivity of reactant A in pellet (m²/s) | 2.0e-9 - 8.0e-9 | Wicke-Kallenbach experiment, pore network modeling |

| Φ (Thiele Modulus) | Dimensionless ratio of reaction rate to diffusion rate | 2.5 - 6.0 | Calculated: Φ = L√(kₛ/Dₑ) |

| η | Effectiveness Factor (actual rate / rate if no diffusion limit) | See Table 1 | Calculated from Φ (e.g., η = tanh(Φ)/Φ for 1st order) |

| t₁/₂ (deactivation) | Half-life of catalytic activity under process conditions (h) | 200 - 1200 | Long-term packed-bed reactor monitoring |

Detailed Experimental Protocols

Protocol 2.1: Determination of Effective Diffusivity (Dₑ) Using the Wicke-Kallenbach Cell

Purpose: To measure the effective diffusivity of a key reactant (e.g., H₂, nitroarene) through a catalyst pellet under simulated process conditions.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Pellet Preparation: Select 5-10 representative catalyst pellets. Seal the sides with an impermeable, inert epoxy coating, leaving only the two circular faces exposed. Dry at 120°C for 2 hours.

- Cell Assembly: Mount the pellet in the Wicke-Kallenbach cell, creating two gas compartments (Feed and Sweep). Ensure no gas bypass. Connect mass flow controllers (MFCs) to the Feed side for a carrier gas (N₂) and a dilute stream of the diffusing species (e.g., 5% H₂ in N₂). Connect the Sweep side to an MFC for pure carrier gas (N₂).

- System Stabilization: Flow carrier gas through both compartments at a constant rate (e.g., 100 mL/min) and temperature (e.g., 80°C) until stable.

- Measurement: Introduce the dilute diffusing species to the Feed stream. Use a calibrated gas chromatograph (GC) or mass spectrometer (MS) to analyze the composition of the Sweep stream outlet until a steady state is reached.

- Calculation: Dₑ is calculated using Fick's Law from the measured steady-state flux across the pellet, the pellet geometry (length, cross-sectional area), and the concentration difference between the two faces.

Protocol 2.2: Intrinsic Kinetic Rate Constant (kₛ) Measurement via Differential Reactor

Purpose: To obtain the true chemical kinetics on the catalyst surface, devoid of mass transfer limitations.

Materials: See "The Scientist's Toolkit."

Procedure:

- Catalyst Preparation: Crush and sieve catalyst pellets to fine particles (<100 µm). Use a small mass (10-50 mg) to ensure differential conditions (conversion <10%).

- Reactor Setup: Load the catalyst powder into a fixed-bed micro-reactor. Pre-reduce/activate the catalyst in situ per manufacturer specifications.

- Experimental Matrix: Conduct a series of experiments varying one parameter at a time: temperature (multiple points), partial pressures of reactant(s) and H₂, and total flow rate (to verify absence of external diffusion).

- Analysis: At each condition, allow the system to reach steady state. Quantify reactant and product concentrations at the inlet and outlet using GC/HPLC.

- Data Fitting: Fit the initial rate data (outlet concentration vs. flow rate) to a proposed kinetic model (e.g., Langmuir-Hinshelwood) using non-linear regression software to extract the intrinsic rate constant kₛ and adsorption constants.

Protocol 2.3:In-situDeactivation Profiling in a Packed-Bed Reactor

Purpose: To monitor catalyst activity loss over time and collect data for deactivation kinetic modeling.

Procedure:

- Baseline Activity: Load intact catalyst pellets into a pilot-scale packed-bed reactor. Establish nominal process conditions (T, P, flow). Measure the initial, steady-state conversion of a key reactant.

- Long-Term Operation: Operate the reactor continuously under process conditions, sampling the effluent stream at defined intervals (e.g., hourly for the first 24h, then daily).

- Accelerated Stress Tests: Periodically introduce known, controlled pulses of potential poisons (e.g., ppm-level sulfur compounds) or operate at slightly higher temperatures to accelerate deactivation for study.

- Post-Mortem Analysis: At the end of the run, recover the catalyst bed. Section the bed (top, middle, bottom) and analyze pellets via TGA (coke), ICP-MS (leaching), TEM (metal particle size), and N₂ physisorption (surface area/pore change).

- Modeling: Correlate activity loss (conversion vs. time-on-stream) with operational parameters and analytical data to develop a deactivation rate equation (e.g., separable kinetics: ( rd = -kd \cdot a^n )).

Modeling Workflow and Data Integration Diagrams

Diagram Title: CatTestHub Pellet Modeling Workflow from Data to Simulation

Diagram Title: Mass Transfer and Reaction Steps in a Catalyst Pellet

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for Catalyst Pellet Modeling Experiments

| Item/Category | Specific Example/Product | Function & Explanation |

|---|---|---|

| Model Catalyst Pellets | Pd/Al₂O₃, Pt/C, Raney Ni extrudates (commercial suppliers: Clariant, Johnson Matthey, BASF) | Representative solid forms for API synthesis; used in diffusivity and deactivation studies. |

| Wicke-Kallenbach Cell | Custom-made or specialty supplier (e.g., PID Eng & Tech micro-reactors) | Standardized apparatus for measuring effective diffusivity (Dₑ) in porous pellets. |

| Bench-Scale Fixed-Bed Reactor System | Parr Instruments Series 4570, Autoclave Engineers BTRS | For intrinsic kinetics and deactivation runs; allows precise control of T, P, and flow. |

| Gas/Liquid Chromatography | Agilent GC 8890 with TCD/FID, Agilent HPLC 1260 with PDA/ELSD | For quantitative analysis of reaction mixtures and effluent streams. |

| Sorbent/Tracer Gases | Ultra-high purity H₂, N₂, He; 5% H₂ in N₂; 1% Kr in He (for pore volume) | Used as reactants, carrier gases, or analytical tracers in kinetic and diffusivity experiments. |

| Epoxy Coating | HIGH-TEMP EPOXY (e.g., Omega OB-300) | To seal pellet sides for Wicke-Kallenbach experiments, ensuring one-dimensional diffusion. |

| Analytical Sieves | USA Standard Testing Sieves, ASTM E11, 100 µm mesh | For crushing and sieving pellets to fine powder for intrinsic kinetic studies. |

| Surface/Pore Analyzer | Micromeritics 3Flex, Quantachrome NovaTouch | For measuring BET surface area, pore volume, and pore size distribution of fresh/spent pellets. |

| Thermogravimetric Analyzer (TGA) | TA Instruments TGA 550, Mettler Toledo TGA/DSC 3+ | To quantify coke deposition (% weight loss on oxidation) on deactivated catalysts. |

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) | Agilent 7900 ICP-MS | To detect trace metal leaching (Pd, Pt, Ni) from catalyst pellets into the reaction medium. |

Solving Common Challenges: Calibration, Convergence, and Optimization of Pellet Models

Diagnosing and Resolving Model Non-Convergence Issues

Within the broader thesis on kinetic modeling of catalyst pellets using CatTestHub data, model non-convergence is a critical roadblock. This impediment prevents the reliable extraction of kinetic parameters (e.g., activation energies, pre-exponential factors, adsorption constants) from experimental reactor data, directly impacting the design and optimization of catalytic processes in pharmaceuticals synthesis and fine chemical manufacturing. These Application Notes provide a structured methodology for diagnosing root causes and implementing robust solutions.

Common Causes of Non-Convergence: Diagnosis Table

The following table summarizes primary failure modes, their diagnostic signatures, and initial investigative actions.

Table 1: Diagnostic Matrix for Non-Convergence in Kinetic Modeling

| Category | Specific Cause | Typical Symptoms (Error/Warning) | Diagnostic Check |

|---|---|---|---|

| Data Issues | Poor Signal-to-Noise Ratio | High parameter sensitivity, unrealistic confidence intervals. | Plot residuals vs. time/independent variable; look for non-random patterns. |

| Insufficient/Redundant Data | "Matrix is singular or near-singular" warnings. | Compute correlation matrix of estimated parameters; values >0.9 indicate redundancy. | |

| Outliers or Experimental Artifacts | Large, systematic residuals at specific data points. | Use leverage and Cook's distance plots to identify influential outliers. | |

| Model Structural Issues | Over-parameterization | Parameters hitting bounds, extremely large standard errors. | Perform a sensitivity analysis; remove parameters with low relative sensitivity. |

| Incorrect Reaction Mechanism | Physically implausible parameter values (e.g., negative A). | Compare alternative models using statistical criteria (AIC, BIC). | |

| Poor Initial Guesses | Immediate divergence or "cannot improve chi-square" errors. | Use literature values, perform preliminary parameter estimation from simplified models. | |

| Numerical Issues | Stiff ODE System | Extremely slow convergence, repeated step-size reduction. | Examine eigenvalues of the Jacobian; large disparities indicate stiffness. |

| Inappropriate Solver Tolerances | Solution fails at specific time points. | Tighten relative and absolute error tolerances incrementally. | |

| Local Minima | Convergence to different parameter sets from different starting points. | Implement multi-start optimization from random initial guesses. |

Experimental Protocol for Systematic Diagnosis

This protocol outlines steps to isolate the cause of non-convergence using CatTestHub pellet data.

Protocol: Stepwise Diagnosis of Kinetic Model Failure

Objective: To identify the root cause(s) of optimization algorithm failure when fitting a kinetic model to catalyst pellet performance data from CatTestHub.

Materials: CatTestHub dataset (conversion vs. time, T, P), modeling software (e.g., MATLAB, Python with SciPy, gPROMS), computational resources.

Procedure:

Data Integrity Audit:

- Step 1.1: Visualize all raw experimental data (e.g., reactant and product concentrations as a function of time-on-stream for each temperature). Flag any data points where mass balance closures exceed experimental error margins (typically >5%).

- Step 1.2: For steady-state experiments, plot reaction rate vs. partial pressure of reactants. Look for obvious inconsistencies or discontinuities.

Residual Analysis:

- Step 2.1: Fit a preliminary, simplified model (e.g., power-law).

- Step 2.2: Plot residuals (observed - predicted) against: a) independent variables (T, P), b) predicted rate, and c) run order. A random scatter confirms data quality; trends indicate structural model flaws.

Parameter Identifiability Check:

- Step 3.1: Prior to full optimization, calculate the local sensitivity coefficients (∂y/∂θ) for all parameters (θ) across the experimental space.

- Step 3.2: Compute the parameter correlation matrix from the sensitivity matrix. Parameters with correlation >0.95 are not independently identifiable. Consider fixing one or re-parameterizing the model.

Multi-Start Optimization:

- Step 4.1: Define physically plausible bounds for all kinetic parameters.

- Step 4.2: Run the optimization algorithm from a large number (50-100) of randomly generated initial parameter sets within these bounds.

- Step 4.3: Analyze the distribution of final objective function values (e.g., sum of squared errors). A single, tight cluster indicates a unique solution. Multiple clusters suggest local minima.

Model Simplification & Growth:

- Step 5.1: If the full model fails, fix complex parameters (e.g., adsorption constants) to literature values and estimate only the core kinetic parameters (k, Ea).

- Step 5.2: Upon convergence, gradually free fixed parameters one-by-one, monitoring convergence behavior at each step to identify the problematic term.

Visualization of Diagnostic Workflow

Diagram Title: Systematic Diagnostic Workflow for Model Non-Convergence

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Tools for Resolving Kinetic Model Non-Convergence

| Tool/Reagent | Function & Role in Troubleshooting |

|---|---|

| High-Fidelity CatTestHub Data | Clean, high-resolution kinetic data across a wide range of temperatures, pressures, and conversions is the fundamental substrate. Essential for residual analysis and identifiability. |

| Global Optimization Software | Software/libraries capable of multi-start algorithms (e.g., particle swarm, genetic algorithms) to escape local minima and map the parameter objective function surface. |

| Parameter Sensitivity Analysis Toolkit | Scripts to calculate local (e.g., derivative-based) and global (e.g., Sobol indices) sensitivity measures. Identifies non-influential parameters for potential removal. |

| Model Discrimination Criteria | Statistical metrics (Akaike Information Criterion - AIC, Bayesian Information Criterion - BIC) to objectively compare rival mechanistic models and select the most parsimonious one. |

| Stiff ODE Solver | Robust numerical solvers (e.g., CVODE, Rosenbrock methods) for integrating differential equations describing catalyst pellet models with widely varying time constants. |

| Parameter Correlation Calculator | Routine to compute the Pearson correlation matrix from the sensitivity matrix. The primary diagnostic for parameter interdependence and non-identifiability. |

Optimizing Experimental Design to Inform and Constrain CatTestHub Models

Within the broader thesis on utilizing CatTestHub data for the kinetic modeling of catalyst pellets in pharmaceutical synthesis, the optimization of experimental design is critical. CatTestHub consolidates data from standardized catalyst testing protocols. For models to be predictive beyond the training dataset, the underlying experiments must be meticulously planned to generate data that is both informative for parameter estimation and constraining for model discrimination. This document provides Application Notes and Protocols to guide researchers in designing experiments that maximally inform microkinetic models of surface reactions on catalytic pellets, thereby accelerating catalyst development for drug molecule synthesis.

Core Principles of Model-Informing Experimental Design

Optimal experimental design (OED) for kinetic modeling aims to determine experimental conditions that minimize the uncertainty in estimated parameters (e.g., activation energies, pre-exponential factors, adsorption constants) or maximize the ability to discriminate between rival mechanistic models. Key principles include:

- Parameter Sensitivity: Experiments should be conducted where model outputs (e.g., reaction rate, selectivity) are most sensitive to changes in the uncertain parameters.

- Parameter Correlations: Designs should aim to decouple correlated parameters (e.g., adsorption enthalpy and entropy) by combining different types of data.

- Model Discriminating Power: Conditions where competing model predictions diverge most significantly should be prioritized.

- Practical Constraints: Design must operate within safe, feasible ranges of temperature, pressure, flow rates, and catalyst stability.

Key Experimental Data Types and Their Model Constraints

Comprehensive kinetic modeling requires multiple data types. The table below summarizes their role in informing and constraining CatTestHub models.

Table 1: Data Types for Kinetic Model Development

| Data Type | Primary Experimental Method | Key Parameters Informed | Model Constraint Role |

|---|---|---|---|

| Steady-State Rate Data | Continuous-flow fixed-bed reactor measurements. Varying T, P, partial pressures. | Apparent activation energy, reaction orders. | Provides the fundamental dataset for initial parameter fitting. Low constraint on mechanism alone. |

| Catalyst Surface Coverage | In-situ DRIFTS, XPS, or calibrated TPD. | Adsorption equilibrium constants, site fractions. | Directly constrains adsorption/desorption steps and active site inventory. Crucial for decoupling parameters. |

| Transient Response Data | Temporal Analysis of Products (TAP) reactor, step-change experiments. | Rate constants of individual elementary steps. | Powerful for isolating specific steps (e.g., adsorption, surface reaction, desorption). Highly constrains microkinetic models. |

| Isotopic Tracing (SSTIKA) | Steady-State Isotopic Transient Kinetic Analysis using labeled molecules. | Surface residence times, concentrations of active intermediates. | Distinguishes between active spectators and participating intermediates. Informs reaction pathways. |