Unveiling Electrochemical Interfaces: A Comprehensive Guide to In-Situ ATR-IR Spectroscopy for Biomedical Research

This article provides a detailed exploration of Attenuated Total Reflection Infrared (ATR-IR) spectroscopy as a premier in-situ analytical technique for probing liquid-solid electrochemical interfaces.

Unveiling Electrochemical Interfaces: A Comprehensive Guide to In-Situ ATR-IR Spectroscopy for Biomedical Research

Abstract

This article provides a detailed exploration of Attenuated Total Reflection Infrared (ATR-IR) spectroscopy as a premier in-situ analytical technique for probing liquid-solid electrochemical interfaces. Tailored for researchers and drug development professionals, it covers foundational principles, cutting-edge methodologies for real-time biomolecular interaction analysis, critical troubleshooting for complex biological matrices, and comparative validation against complementary techniques like Raman spectroscopy and EQCM. The guide synthesizes current advancements to empower the study of bio-electrocatalysis, biosensor development, and pharmaceutical interfacial phenomena with unprecedented molecular-level insight.

Core Principles: Understanding ATR-IR Spectroscopy for Electrochemical Interfaces

Core Principles of the Evanescent Wave

Attenuated Total Reflection (ATR) spectroscopy is a pivotal surface-sensitive technique, particularly for studying liquid-solid electrochemical interfaces. Its foundation is the generation of an evanescent wave upon total internal reflection of an infrared beam at the interface between an optically dense internal reflection element (IRE) and a less dense sample.

Physical Basis

When infrared light traveling through the IRE (e.g., ZnSe, Ge, diamond) strikes the IRE/sample interface at an angle greater than the critical angle, total internal reflection occurs. Despite this "total" reflection, an electromagnetic field, the evanescent wave, propagates into the sample. This wave decays exponentially with distance from the interface.

Key Quantitative Parameters

The properties of the evanescent wave are defined by three critical equations:

Depth of Penetration (dₚ): The distance from the IRE surface where the electric field amplitude falls to 1/e of its value at the interface.

dₚ = λ / [2πn₁√(sin²θ - (n₂/n₁)²)]where λ is the wavelength, n₁ is the IRE refractive index, n₂ is the sample refractive index, and θ is the angle of incidence.Effective Pathlength: The equivalent pathlength in a traditional transmission cell.

Number of Active Reflections (N): Controlled by the IRE geometry (e.g., single-bounce vs. multi-bounce).

Table 1: Comparison of Common Internal Reflection Elements (IREs) for Electrochemical ATR-IR

| IRE Material | Refractive Index (n₁ @ 1000 cm⁻¹) | Useful Spectral Range (cm⁻¹) | Chemical Resistance | Typical Application Context |

|---|---|---|---|---|

| Zinc Selenide (ZnSe) | 2.4 | ~20,000 - 650 | Poor (acid, base soluble) | Aqueous electrolytes, non-corrosive environments. |

| Germanium (Ge) | 4.0 | 5,500 - 850 | Good | High aqueous absorption, thin film studies (shallow dₚ). |

| Diamond (type IIa) | 2.4 | > 2,200 (type IIa) | Excellent | Harsh chemical/electrochemical conditions, high pressure. |

| Silicon (Si) | 3.4 | 8,900 - 1,500 | Good | Mid-IR studies, compatible with microfabrication. |

Table 2: Calculated Depth of Penetration (dₚ) for Common IRE/Sample Combinations*

| IRE (n₁) | Sample (n₂) | Angle of Incidence (θ) | Wavelength (λ) | dₚ (µm) |

|---|---|---|---|---|

| ZnSe (2.4) | H₂O (1.33) | 45° | 5.0 µm (2000 cm⁻¹) | 0.81 |

| ZnSe (2.4) | Organic Film (~1.5) | 45° | 5.0 µm (2000 cm⁻¹) | 0.98 |

| Ge (4.0) | H₂O (1.33) | 60° | 5.0 µm (2000 cm⁻¹) | 0.24 |

| Diamond (2.4) | Aq. Electrolyte (~1.33) | 45° | 5.0 µm (2000 cm⁻¹) | 0.81 |

*Calculations assume ideal conditions.

Application Notes for In-Situ Electrochemical ATR-IR

The evanescent wave's shallow probing depth makes it ideal for monitoring molecular adsorption, reaction intermediates, and film formation at electrode surfaces under potential control.

Key Advantages for Electrochemistry

- In-Situ Compatibility: Allows real-time monitoring of interfacial processes during voltammetric or chronoamperometric experiments.

- Surface Sensitivity: Probes only the first few microns, minimizing signal interference from the bulk electrolyte.

- Molecular Specificity: Provides IR vibrational fingerprints of adsorbed species and interfacial layers.

Experimental Considerations

- Thin-Layer Cell Configuration: The electrode is typically pressed against the IRE, creating a thin electrolyte layer (1-10 µm) to minimize bulk absorption.

- Spectra Acquisition: Usually performed as ΔR/R (reflectance difference) spectra: (R(Esample) - R(Eref)) / R(Eref), highlighting changes induced by applied potential.

- Mass Transport Limitations: The thin-layer configuration can limit diffusion, which must be considered in kinetic analysis.

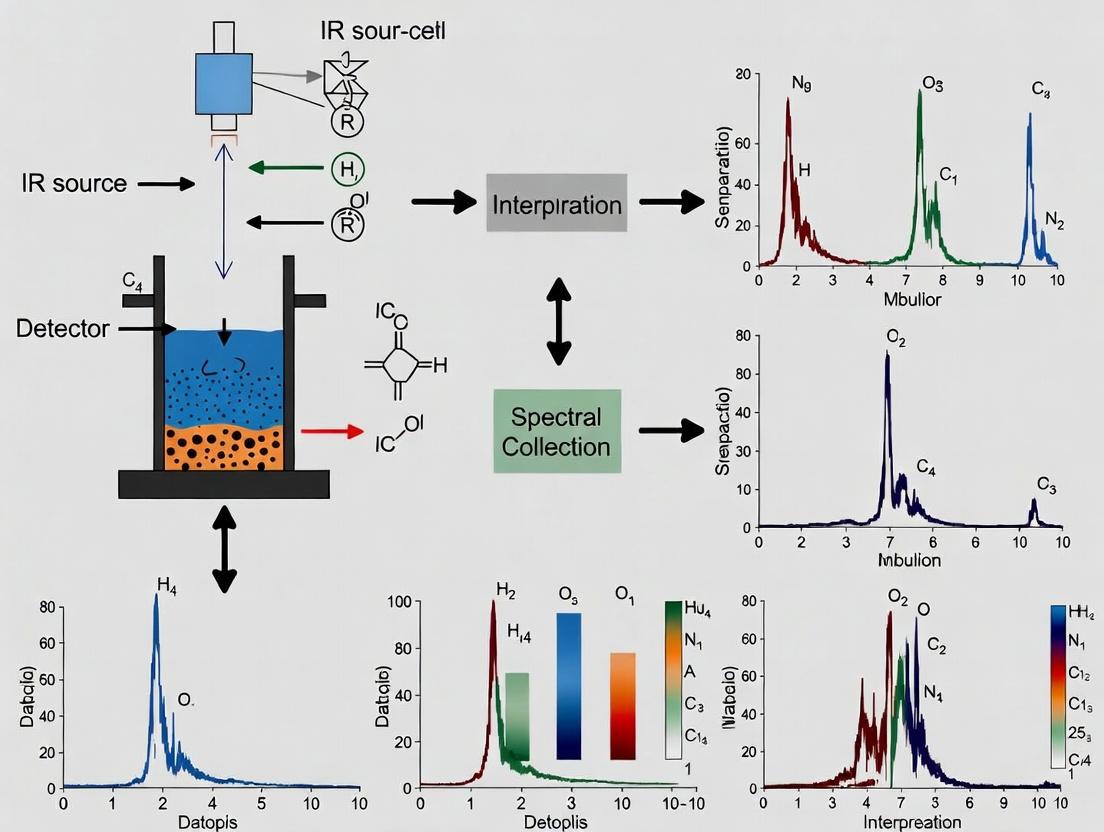

Diagram 1: In-Situ Electrochemical ATR-IR Setup

Diagram 2: Evanescent Wave Generation at IRE Interface

Detailed Experimental Protocols

Protocol: In-Situ ATR-IR Study of CO Adsorption on a Pt Electrode

Objective: To monitor the adsorption and oxidation of carbon monoxide (CO) on a polycrystalline Pt film electrode in sulfuric acid electrolyte.

Materials & Reagents: (See Scientist's Toolkit, Table 3) Instrumentation: FTIR spectrometer with liquid N₂-cooled MCT detector, electrochemical ATR flow cell, potentiostat.

Procedure:

- IRE Preparation: Clean the ZnSe IRE sequentially with methanol, dilute NaOH, 1M H₂SO₄, and Milli-Q water. Dry under a N₂ stream.

- Electrode Deposition: Sputter-deposit a thin (~10 nm) Pt film directly onto the IRE face.

- Cell Assembly: Assemble the electrochemical cell, ensuring the Pt-coated IRE is the working electrode. Place Pt mesh counter and reversible hydrogen reference (RHE) electrodes. Ensure leak-free sealing.

- Electrolyte Purge: Introduce 0.1M H₂SO₄ electrolyte, pre-purged with Ar for 30 min, into the cell under continuous Ar flow.

- Reference Spectrum (Rref): Hold potential at 0.1 V vs. RHE. Acquire a single-beam spectrum (256 scans, 8 cm⁻¹ resolution) as the reference.

- CO Adsorption: Bubble CO through electrolyte for 2 min while holding at 0.1 V. Purge with Ar for 15 min to remove bulk CO.

- Sample Spectrum Acquisition (Rsample): Step the potential in 50 mV increments from 0.1 V to 1.0 V vs. RHE. At each potential, after a 30 s hold, acquire a single-beam spectrum.

- Data Processing: Compute ΔR/R = (Rsample - Rref)/Rref for each potential. Plot as a 2D contour map (Wavenumber vs. Potential) or series of difference spectra. Positive bands indicate loss of species (e.g., oxidation of adsorbed CO at ~2050 cm⁻¹), negative bands indicate gain.

Protocol: Monitoring Polymer Film Formation During Electropolymerization

Objective: To track the growth of a conductive polymer (e.g., polyaniline) on a gold-coated IRE in real-time.

Procedure:

- Cell Setup: Use a Au-coated diamond IRE as working electrode in a 3-electrode flow cell.

- Background Acquisition: Fill cell with 0.1M aniline + 1M HClO₄ monomer solution. Acquire reference spectrum at open circuit potential.

- In-Situ Spectroelectrochemistry: Apply a constant potential (e.g., 0.8 V vs. Ag/AgCl) to initiate polymerization. Acquire sequential single-beam spectra (e.g., 4 scans each, every 10 s) continuously for 30 min.

- Kinetic Analysis: Process spectra to generate ΔR/R spectra vs. time. Plot the intensity of key polymer bands (e.g., C=C stretching of quinoid ring at ~1580 cm⁻¹) as a function of time to extract growth kinetics.

The Scientist's Toolkit

Table 3: Essential Research Reagents & Materials for Electrochemical ATR-IR

| Item | Function/Description | Example in Protocol |

|---|---|---|

| ATR IRE (ZnSe, Ge, Diamond) | High-index optical element generating evanescent wave. Choice depends on pH, potential range, and spectral range. | ZnSe for Pt/CO study; Diamond for harsh polymerization. |

| Metal Target (Pt, Au) | For sputter-coating a thin, IR-transparent working electrode directly onto the IRE. | Pt target for deposition of Pt film WE. |

| Potentiostat/Galvanostat | Applies controlled potential/current to the electrochemical cell. | Applies oxidation potential for CO stripping or polymerization. |

| Deoxygenated Electrolyte | High-purity acid/base/salt solutions purged with inert gas (Ar, N₂) to remove interfering O₂. | 0.1M H₂SO₄ purged with Ar. |

| High-Purity Gases (Ar, CO) | Ar for deoxygenation; CO (or other probe molecules) for adsorption studies. | CO for adsorption; Ar for purging. |

| IR-Transparent Working Electrode | A thin metal film (<20 nm) or a micro-structured electrode allowing IR beam penetration. | Sputtered 10 nm Pt film. |

| Electrochemical ATR Flow Cell | Sealed cell with fluidic ports, electrode mounts, and a clamp to press WE against IRE. | Enables in-situ spectroelectrochemistry with thin-layer configuration. |

| Cooled MCT Detector | High-sensitivity IR detector for rapid, low-noise acquisition of small ΔR/R signals. | Essential for time-resolved measurements during reactions. |

Why ATR-IR? Advantages for Probing Buried Liquid-Solid Interfaces in Real Time.

1. Introduction: The Buried Interface Challenge Within the context of advancing in-situ spectroscopic techniques for electrochemical and catalytic research, Attenuated Total Reflection Infrared (ATR-IR) spectroscopy has emerged as a premier tool for investigating the molecular structure and dynamics of buried liquid-solid interfaces under operational conditions. Unlike transmission IR, ATR-IR probes the evanescent wave that decays exponentially from the internal reflection element (IRE), making it inherently surface-sensitive (typically the first 0.5-2 µm). This enables real-time, in-situ monitoring of interfacial phenomena such as adsorption, desorption, reaction kinetics, and film formation without interference from the bulk solution, fulfilling a critical need in modern interfacial science.

2. Core Advantages of ATR-IR for Liquid-Solid Interfaces The primary advantages are summarized in the table below.

Table 1: Key Advantages of ATR-IR for Buried Interface Studies

| Advantage | Quantitative/Qualitative Impact | Relevance to Electrochemical/Life Science Interfaces |

|---|---|---|

| In-Situ & Real-Time Capability | Time resolution down to ~10 ms per spectrum (with rapid-scan FTIR). | Enables monitoring of potential-dependent adsorption, enzymatic turnover, or drug-membrane binding kinetics. |

| Elimination of Bulk Solvent Interference | Effective pathlength of ~0.1-1 µm vs. 10-100 µm for transmission. | Strong water absorbance is minimized; focus on interfacial species. |

| Probe Buried Interfaces | Non-destructive; no need for thin-layer or vacuum conditions. | Ideal for electrochemical double layer, biofilm-substrate, or protein-cell membrane studies. |

| High Signal-to-Noise (S/N) | Multiple internal reflections (typically 3-11) enhance sensitivity. | Allows detection of monolayer coverages (≥ 0.1 nmol cm⁻²) of adsorbates. |

| Broad Material Compatibility | IREs: Si (1500-900 cm⁻¹), Ge (1500-800 cm⁻¹), ZnSe (20000-650 cm⁻¹), Diamond (4500- <100 cm⁻¹). | Diamond: chemically inert, withstands extreme pH/potential; Si: for SiO₂/silicon electrode studies. |

| Polarization Modulation | Allows calculation of molecular orientation via dichroic ratios. | Determines orientation of adsorbed proteins, lipids, or reaction intermediates. |

3. Application Notes: Key Experimental Setups

3.1. Electrochemical ATR-IR (EC-ATR-IR) This is the cornerstone for real-time electrochemical interface analysis. The IRE is coated with a thin, IR-transparent conductive layer (e.g., Pt, Au, C) that serves as the working electrode.

Table 2: Typical EC-ATR-IR Experimental Parameters

| Component | Specification/Value | Purpose/Rationale |

|---|---|---|

| IRE Material | Prism: Si or Hemispherical: Diamond | Si for cost/oxide studies; Diamond for durability/wide IR range. |

| Electrode Layer | ~20 nm Au (sputtered), ~5-10 nm Pt (e-beam), or mesoporous carbon film. | Thin enough for evanescent wave penetration, conductive, catalytically active. |

| Reference Electrode | Ag/AgCl (3 M KCl) or Reversible Hydrogen Electrode (RHE). | Provides stable, known potential control. |

| Counter Electrode | Pt wire or mesh. | Completes the electrochemical circuit. |

| Spectra Acquisition | Single-beam spectrum at reference potential (R) -> sample potential (S). | Calculated as ΔR/R = (R - S)/R or -log(S/R) for absorbance-like plots. |

| Potential Modulation | Steps, sweeps (e.g., 10 mV/s), or square waves. | Correlates spectral features directly with applied potential. |

Protocol: In-Situ Study of CO Adsorption on a Pt Electrode

- Cell Assembly: Mount a diamond ATR prism coated with a 10 nm Pt film in a spectroelectrochemical flow cell.

- Electrolyte Purge: Flow 0.1 M HClO₄ under N₂ for 30 min to remove dissolved O₂ and CO₂.

- Reference Spectrum: Apply a reference potential of 0.1 V vs. RHE where no CO adsorbs. Acquire 64 background scans at 8 cm⁻¹ resolution.

- CO Saturation: Introduce CO-saturated electrolyte for 2 minutes while holding at 0.1 V, then switch to CO-free electrolyte.

- Sample Spectra Acquisition: Step the potential from 0.1 V to 0.9 V in 50 mV increments. At each potential, hold for 30s for equilibration, then acquire 64 scans.

- Data Processing: For each potential, compute the normalized absorbance: Abs = -log(Sₚᵥ/Sᵣ=₀.₁ᵥ). Observe the loss of linearly bonded CO (~2080 cm⁻¹) and bridge-bonded CO (~1850 cm⁻¹) bands as potential increases due to oxidation.

3.2. Biomolecular Interaction Monitoring (e.g., Drug-Lipid Bilayer) ATR-IR is used to study model cell membranes (solid-supported lipid bilayers, SLBs) and their interactions with pharmaceuticals.

Protocol: Real-Time Interaction of an Antimicrobial Peptide with a Lipid Bilayer

- Lipid Bilayer Formation: Use a silica-coated (SiO₂) ZnSe or Si IRE. First, clean the IRE with piranha solution (Caution: Extremely oxidizing).

- Vesicle Fusion: Flow a 0.5 mg/mL suspension of small unilamellar vesicles (SUVs) composed of, e.g., POPC/POPG (7:3) in 10 mM Tris buffer, pH 7.4, over the IRE at 30°C for 1 hour. Rinse with buffer to remove unfused vesicles. ATR-IR will confirm bilayer formation by the C-H stretching bands (~2850, 2920 cm⁻¹) and phosphate band (~1220 cm⁻¹).

- Baseline Acquisition: Acquire a stable background spectrum of the hydrated SLB.

- Interaction Study: Introduce the antimicrobial peptide (e.g., 10 µM in the same buffer) into the flow cell.

- Time-Resolved Scanning: Collect spectra continuously (e.g., 1 spectrum/30 sec) for 60 minutes.

- Data Analysis: Monitor shifts in the lipid ester C=O stretching band (~1735 cm⁻¹) indicating peptide interaction with the bilayer headgroups. Observe changes in amide I (~1650 cm⁻¹, α-helix) and amide II (~1550 cm⁻¹) bands of the peptide to track its conformational change upon binding.

4. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for ATR-IR Interface Studies

| Item | Function/Application |

|---|---|

| Diamond ATR Prism (Type IIa) | Inert, robust IRE for harsh conditions (extreme pH, potential, abrasion). |

| Silicon ATR Prism | Optimal for studies involving silicon oxide surfaces or as a cost-effective alternative. |

| Sputter/E-Beam Coater | For depositing thin, uniform, conductive metal films onto IREs for EC-ATR-IR. |

| Peristaltic or Syringe Pump | Enables controlled, continuous flow of electrolytes or analyte solutions for kinetic studies. |

| Potentiostat/Galvanostat | Provides precise potential/current control for in-situ electrochemical experiments. |

| IR-Transparent Conductive Coatings (Au, Pt, ITO, F-doped SnO₂) | Serve as the working electrode in EC-ATR-IR. |

| Supported Lipid Bilayer Kits (e.g., POPC, DOPC, with varied headgroups) | Pre-formed vesicles for creating biomimetic membrane models on IREs. |

| Deuterated Solvents (D₂O, deuterated buffers) | Shifts the strong O-H bending band of water away from the protein amide I region (1600-1700 cm⁻¹). |

| Polarizer (Wire-grid, KRS-5 substrate) | Enables polarization-modulation experiments to determine molecular orientation at the interface. |

5. Visualizing Workflows and Concepts

Evanescent Wave Probing at Buried Interface

General EC-ATR-IR Experimental Workflow

Layered Structure in EC-ATR-IR Measurement

Application Notes

This document details the application and integration of Attenuated Total Reflectance Infrared (ATR-IR) spectroscopy components for in situ studies of liquid-solid electrochemical interfaces, a core methodology for a thesis on dynamic interfacial processes in electrocatalysis, battery research, and bioelectrochemistry.

The integrated system enables real-time, molecular-level observation of adsorption, reaction intermediates, and film formation under controlled electrochemical potential. The selection of ATR crystal material is paramount, as it serves as both the internal reflection element (IRE) and the working electrode (or electrode support).

ATR Crystal Selection & Electrochemical Suitability

| Crystal Material | IR Transparency Range (cm⁻¹) | Refractive Index (at 1000 cm⁻¹) | Chemical & Electrochemical Compatibility | Typical Electrode Configuration |

|---|---|---|---|---|

| Silicon (Si) | ~ 4000 - < 1500 | 3.4 | Inert in acidic to neutral pH; forms insulating SiO₂ layer. Use with thin metal film (<20 nm) electrode. | Si/prism → Au or Pt thin-film electrode |

| Germanium (Ge) | ~ 4000 - 850 | 4.0 | Dissolves in strong base; stable in acid. High refractive index enables thin-layer sampling. Ideal for studying organic adsorbates. | Ge/prism → Metal thin-film electrode |

| Zinc Selenide (ZnSe) | ~ 4000 - 650 | 2.4 | Soluble in strong acids and bases; soft, scratches easily. Used with bulk electrode pressed to IRE. | ZnSe/prism → Bulk electrode (e.g., carbon paste, pellet) |

Key Consideration: The crystal's refractive index dictates the depth of penetration (dp) of the evanescent wave. Higher index materials like Ge provide a shallower dp (~0.2-0.5 µm), enhancing surface sensitivity but reducing signal from the bulk electrolyte.

IR Source & Detector Specifications

| Component | Type | Key Performance Parameters | Suitability for Electrochemical ATR |

|---|---|---|---|

| IR Source | Globar (SiC) or Synchrotron | Spectral emissivity, stability, brightness. | High-intensity sources (e.g., synchrotron) are critical for time-resolved studies (sub-second) of fast electrode kinetics. |

| Detector | Mercury Cadmium Telluride (MCT) | Cooling (LN2), D* (specific detectivity), cutoff wavelength. | LN2-cooled MCT-A (fast) is essential for rapid-scan FTIR during potential step/cycle experiments. |

| Detector | Deuterated Triglycine Sulfate (DTGS) | Thermally stabilized, broader spectral range. | Suitable for non-time-resolved, high-sensitivity measurements where liquid nitrogen is not available. |

Integrated Electrochemical ATR Cell Design

The cell must provide a controlled 3-electrode electrochemical environment while maintaining optical alignment. The crystal is the cell's base. A gasket (e.g., Viton, Kalrez) defines the thin-layer electrolyte compartment (typically 1-10 µm thick). The counter electrode (Pt wire or mesh) and reference electrode (e.g., reversible hydrogen electrode, RHE) are integrated into the cell body. Electrical contact to the thin-film working electrode on the crystal is made via a spring-loaded contact or wire.

Experimental Protocols

Protocol 1: Preparation of a Thin-Film Working Electrode on a Si ATR Crystal

Objective: To fabricate a conductive, optically transparent Au working electrode for in situ ATR-SEIRAS (Surface-Enhanced IR Absorption Spectroscopy).

Materials:

- Optically polished Si ATR prism (hemicylinder or trapezoid).

- Physical Vapor Deposition (PVD) system.

- Chromium evaporation source (optional).

- Gold evaporation source (99.999% purity).

- Substrate cleaner (acetone, ethanol, Milli-Q water).

Procedure:

- Crystal Cleaning: Sonicate Si crystal sequentially in acetone, ethanol, and Milli-Q water for 10 minutes each. Dry under a stream of Ar or N₂.

- PVD Chamber Evacuation: Load crystal into PVD chamber. Evacuate to a base pressure of at least 5 x 10⁻⁶ mbar.

- Adhesion Layer Deposition (Optional): For improved Au adhesion, thermally evaporate a 1-2 nm layer of Cr or Ti.

- Au Working Electrode Deposition: Thermally evaporate Au to a nominal thickness of 10-20 nm. Control thickness and rate (0.1-0.3 nm/s) using a calibrated quartz crystal microbalance.

- Post-Processing: Vent the chamber carefully. The crystal is now ready for integration into the electrochemical ATR cell. Handle by edges only.

Protocol 2:In SituATR-IR during a Linear Sweep Voltammetry (LSV) Experiment

Objective: To correlate electrochemical current with the formation/consumption of surface species during an oxidation reaction.

Materials:

- Integrated ATR-IR/Electrochemical cell with prepared crystal.

- Potentiostat/Galvanostat.

- FT-IR Spectrometer with MCT detector.

- Electrolyte solution (e.g., 0.1 M HClO₄ with/without analyte).

- Reference and counter electrodes.

Procedure:

- Cell Assembly & Alignment: Assemble cell with crystal, gasket, and cell body. Mount on spectrometer's ATR stage. Align optically to maximize IR throughput.

- Electrochemical Setup: Fill cell with pure supporting electrolyte. Purge with inert gas (Ar/N₂) for 20 min. Insert reference and counter electrodes.

- Reference Spectrum Collection: At the starting potential (e.g., 0.05 V vs. RHE), collect a single-beam reference spectrum (R0) averaging 64-128 scans at 4 cm⁻¹ resolution.

- Synchronized LSV/IR Acquisition: a. Configure potentiostat for LSV (e.g., 0.05 to 1.2 V vs. RHE at 5 mV/s). b. Configure spectrometer for rapid-scan acquisition (e.g., 1 scan per 0.5-1 second, 8 cm⁻¹ resolution). c. Initiate LSV and start continuous IR scan collection simultaneously using a trigger or manual coordination.

- Data Processing: For each single-beam sample spectrum (R), calculate absorbance as A = -log(R/R0). Plot spectra as a function of applied potential (2D waterfall plot). Integrate key band absorbances to create plots vs. potential.

Diagrams

Title: ATR-IR Electrochemical System Data Flow

Title: In Situ ATR-IR Electrochemical Experiment Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in Experiment | Key Considerations |

|---|---|---|

| Si ATR Prism | Internal reflection element; substrate for thin-film working electrode. | High resistivity (>1 Ω·cm), optically polished faces, single-crystal. |

| Perchloric Acid (HClO₄, 0.1 M) | Common supporting electrolyte for electrocatalysis studies (Pt, Au). | High purity (e.g., Suprapur); minimizes interfering anion adsorption. Use with extreme caution. |

| Gold Target (99.999%) | For sputtering/evaporation of thin-film working electrode. | High purity ensures reproducible electrode morphology and activity. |

| Kalrez Perfluoroelastomer Gasket | Defines thin-layer electrochemical compartment; seals cell. | Chemically inert, maintains ~5 µm thickness for optimal signal and mass transport. |

| Reversible Hydrogen Electrode (RHE) | In-situ reference electrode for non-aqueous studies. | Prepared in the same electrolyte; potential is pH-independent. |

| Deuterated Solvent (e.g., D₂O) | Solvent for electrolyte to avoid H₂O vapor bands in key IR regions (e.g., ~1600-1700 cm⁻¹). | Enables observation of C=O, C=N stretches; requires potential calibration adjustment. |

| Carbon Black (Vulcan XC-72R) | For preparing bulk composite working electrodes on ZnSe. | Conductivity and high surface area for studying fuel cell catalyst layers. |

| Sodium Sulfate (Na₂SO₄, 0.1 M) | Inert supporting electrolyte for studies where anion adsorption must be avoided. | Does not specifically adsorb on many metals, simplifying interpretation. |

Application Notes: ATR-SEIRAS for Electrochemical Interface Analysis

This document outlines the application of Attenuated Total Reflection Surface-Enhanced Infrared Absorption Spectroscopy (ATR-SEIRAS) for in situ molecular-level characterization of adsorbates at electrochemical interfaces, a core methodology within a thesis on advanced operando spectroscopic techniques.

Core Principle: ATR-SEIRAS utilizes a thin, nanostructured metal film (typically Au or Pt) deposited on an internal reflection element (IRE) as the working electrode. IR light undergoing total reflection generates an evanescent wave that probes only the first few hundred nanometers at the electrode surface, enabling sensitive detection of adsorbed species in the presence of bulk electrolyte.

Key Applications:

- Identification of Functional Groups: Monitoring characteristic vibrational frequencies (e.g., C=O stretch ~1700 cm⁻¹, COO⁻ asymmetric stretch ~1550 cm⁻¹, S-H stretch ~2550 cm⁻¹) to confirm the chemical identity of adsorbates.

- Determination of Adsorption Geometry: Using surface selection rules—where only vibrational modes with a dipole moment change perpendicular to the metal surface are strongly enhanced—to deduce molecular orientation. Example: A carboxylate group (RCOO⁻) shows a strong asymmetric stretch and a weak symmetric stretch when chemisorbed in a bridging or bidentate configuration.

- Monitoring Potential-Dependent Transformations: Tracking spectral changes as a function of applied electrode potential to follow reaction pathways, decomposition, or reorientation of surface species.

Experimental Protocols

Protocol 1: Preparation of ATR-SEIRAS Substrates (Chemical Deposition of Au)

- Objective: Fabricate a nanostructured Au film on a Si hemispherical IRE.

- Materials: Si hemisphere (IRE), piranha solution (3:1 H₂SO₄:H₂O₂), 10% HF, [AuCl₄]⁻ solution, 40 mM NH₂OH·HCl solution, ultrapure water.

- Steps:

- Clean the Si IRE with piranha solution for 30 min. CAUTION: Piranha is highly corrosive and exothermic.

- Rinse thoroughly with ultrapure water.

- Etch the Si surface in 10% HF for 2 min to create a hydrogen-terminated surface, then rinse.

- Immerse the Si IRE in a mixture of 2 mL [AuCl₄]⁻ solution and 1 mL NH₂OH·HCl solution for 5-8 minutes. The hydroxylamine reduces Au³⁺ to Au⁰, depositing a nanostructured film.

- Rinse gently with water and dry under a nitrogen stream.

- Quality Control: The film should have a purple, matte appearance. Optimal enhancement is achieved with films comprising interconnected Au islands (~50-150 nm in size).

Protocol 2: In Situ ATR-SEIRAS Electrochemical Experiment

- Objective: Acquire potential-dependent IR spectra of an adsorbate at the electrode-electrolyte interface.

- Materials: ATR-SEIRAS cell, potentiostat, FT-IR spectrometer with liquid nitrogen-cooled MCT detector, prepared SEIRAS substrate (working electrode), Pt wire counter electrode, reversible hydrogen electrode (RHE) reference electrode, electrolyte, analyte.

- Steps:

- Assemble the electrochemical cell with the SEIRAS substrate, ensuring the thin film is in contact with the electrolyte.

- Fill the cell with a clean, deaerated background electrolyte (e.g., 0.1 M HClO₄). Purge with inert gas (Ar/N₂).

- Mount the cell on the ATR stage of the FT-IR spectrometer, aligning for optimal throughput.

- Connect the electrodes to the potentiostat.

- At the starting potential (e.g., 0.05 V vs. RHE), acquire a single-beam spectrum as the reference (

R). - Introduce the analyte (e.g., by injection) and allow adsorption at a controlled potential.

- Step the applied potential to the new value (

E). Wait for current decay (≥30 s) to achieve steady state. - Acquire the new single-beam spectrum (

S). - Calculate the relative change in reflectance as

ΔR/R = (S - R)/R. This yields a spectrum where positive bands indicate loss of species (or configuration) present at the reference potential, and negative bands indicate gain. - Repeat steps 7-9 across the desired potential window.

Data Presentation

Table 1: Characteristic Infrared Bands for Common Functional Groups at Electrode Surfaces

| Functional Group | Vibration Mode | Approximate Frequency Range (cm⁻¹) | Notes on Adsorption Geometry |

|---|---|---|---|

| Carbonyl (C=O) | Stretch | 1650 - 1750 | Lower frequency suggests bonding via O atom. |

| Carboxylate (COO⁻) | Asymmetric Stretch | 1550 - 1650 | Strong intensity indicates perpendicular component. |

| Carboxylate (COO⁻) | Symmetric Stretch | 1300 - 1400 | Weak if molecule is upright. |

| Cyanide (CN) | Stretch | 2100 - 2200 | Frequency shifts with potential and surface field. |

| Carbon Monoxide (CO) | Stretch | 2000 - 2100 (on-top), 1850-1950 (bridge) | Direct indicator of binding site. |

| Amine (N-H) | Stretch | ~3300 | Broadening indicates hydrogen bonding. |

| Aromatic Ring | C=C Stretch | ~1480, ~1580 | Ring orientation affects relative intensities. |

Table 2: Example Potential-Dependent Shifts for Adsorbed CO on Pt

| Applied Potential (V vs. RHE) | ν(CO) Frequency (cm⁻¹) | Peak Assignment | Inferred Surface Coverage Change |

|---|---|---|---|

| 0.10 | 2045 | Linear-bonded CO (on-top) | High |

| 0.40 | 2068 | Linear-bonded CO (on-top) | Medium |

| 0.70 | 2085 | Linear-bonded CO (on-top) | Low |

| 0.10 | 1815 | Bridge-bonded CO | High |

| 0.40 | 1850 | Bridge-bonded CO | Low |

Mandatory Visualization

ATR-SEIRAS Experimental Workflow

Surface Selection Rules for Adsorbate Orientation

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in ATR-SEIRAS Experiments |

|---|---|

| Si or Ge Hemispherical IRE | Internal reflection element; high IR transparency and suitable refractive index for generating evanescent wave. |

| Chloroauric Acid (HAuCl₄) | Precursor for chemical deposition of nanostructured Au SEIRAS films. |

| Hydroxylamine Hydrochloride (NH₂OH·HCl) | Reducing agent for the electroless deposition of Au films. |

| Perchloric Acid (HClO₄) - Ultra Pure | Common supporting electrolyte; minimal specific adsorption, wide electrochemical window. |

| Deuterated Solvents (e.g., D₂O) | Used to shift the strong IR absorption of H₂O out of regions of interest (e.g., C-H stretch region). |

| Carbon Monoxide (¹²CO/¹³CO) | Classic probe molecule for calibrating surface enhancement and assessing binding sites. |

| Potentiostat with Low-Current Capability | Precisely controls electrode potential during spectral acquisition in low-conductivity solutions. |

| Liquid N₂-cooled MCT Detector | High-sensitivity detector required for measuring the small ΔR/R signals (10⁻⁴ - 10⁻⁶). |

Application Notes

Within the framework of a thesis on advancing in situ ATR-IR spectroscopy for probing dynamic liquid-solid electrochemical interfaces, electrode material compatibility is paramount. The choice of electrode dictates the electrochemical window, interfacial structure, signal-to-noise ratio, and ultimately, the spectroscopic insights into adsorption, reaction mechanisms, and degradation pathways relevant to electrocatalysis, biosensing, and pharmaceutical electroanalysis.

Table 1: Key Electrode Material Properties for In Situ ATR-IR Spectroscopy

| Material Class | Example Materials | Potential Window (vs. Ag/AgCl) in Aqueous pH 7 | Key Advantages for ATR-IR | Compatibility/Limitations for In Situ Studies |

|---|---|---|---|---|

| Traditional Metals | Polycrystalline Au, Pt | Au: ~-0.9 to +1.4 VPt: ~-0.8 to +1.1 V | Excellent conductors, well-defined surface chemistry for modification, strong SERS activity (roughened). | Limited cathodic window due to H₂ evolution. Prone to specific anion adsorption (e.g., sulfate, chloride) that can obscure analyte signals. |

| Carbon-Based | Glassy Carbon (GC), Highly Ordered Pyrolytic Graphite (HOPG) | GC: ~-1.2 to +1.0 VHOPG: ~-1.3 to +1.1 V | Wider potential window, especially cathodically. Chemically inert, low background currents. HOPG provides atomically flat basal planes. | Weak IR reflectance, leading to lower sensitivity. Surface oxides form anodically, altering interface. |

| Functionalized Surfaces | Self-Assembled Monolayers (SAMs) on Au, Boron-Doped Diamond (BDD) | Dependent on substrate & terminus (e.g., SAM-coated Au: window can shrink). BDD: ~-1.5 to +2.2 V | SAMs: Provide tailored interfacial chemistry, block interfering species, enable biomolecule immobilization. BDD: Extremely wide window, low background, resistant to fouling. | SAMs can be electrochemically desorbed at extreme potentials. Thick organic layers may attenuate IR signal. BDD requires specialized doping/processing. |

Experimental Protocols

Protocol 1: Preparation and Electrochemical Activation of a Polycrystalline Gold Film ATR Electrode

Objective: To create a clean, reproducible Au surface for subsequent in situ ATR-IR experiments. Materials: ATR crystal (e.g., Si, ZnSe) with sputtered Au film (50-200 nm), 0.5 M H₂SO₄ electrolyte, N₂ gas, potentiostat. Procedure: 1. Mounting: Assemble the electrochemical ATR flow cell, ensuring the Au-coated crystal face forms the working electrode wall. 2. Initial Rinsing: Flow ultrapure water through the cell for 10 minutes. 3. Electrolyte Introduction: Replace flow with deaerated 0.5 M H₂SO₄ under N₂ atmosphere. 4. Electrochemical Cleaning: Perform cyclic voltammetry (CV) between -0.2 V and +1.5 V (vs. Ag/AgCl) at 100 mV/s for 50-100 cycles until a stable, characteristic Au oxide formation/reduction CV profile is obtained. 5. Final Conditioning: Hold potential at -0.2 V for 60 seconds to ensure complete oxide reduction. The electrode is now activated and ready for modification or measurement.

Protocol 2: Functionalization of a Gold ATR Electrode with a Carboxylate-Terminated SAM

Objective: To create a chemically functionalized interface for studying biomolecular interactions or as a precursor layer for further modification. Materials: Activated Au ATR electrode (from Protocol 1), 1 mM 11-mercaptoundecanoic acid (11-MUA) in ethanol, absolute ethanol, phosphate buffer saline (PBS, pH 7.4). Procedure: 1. SAM Formation: Immediately after activation and rinsing with water/ethanol, immerse the Au-coated crystal in the 11-MUA solution for 18-24 hours in the dark. 2. Rinsing: Remove the crystal and rinse thoroughly with pure ethanol to remove physisorbed thiols. 3. Drying: Gently dry under a stream of N₂ or Ar. 4. Electrochemical Cell Assembly: Reassemble the ATR cell with the SAM-modified electrode. 5. In Situ Characterization: Introduce PBS buffer. Collect ATR-IR spectra while applying a controlled potential to monitor the stability of the SAM and the protonation state of the carboxylate groups (C=O stretch ~1720-1740 cm⁻¹ for acid, ~1550-1610 cm⁻¹ for carboxylate).

Protocol 3: In Situ ATR-IR Study of Adsorption on a Glassy Carbon Electrode

Objective: To monitor the potential-dependent adsorption of an organic molecule (e.g., benzoquinone) on a carbon surface. Materials: Glassy Carbon (GC) film-coated ATR crystal, 0.1 M KClO₄ supporting electrolyte, 1 mM benzoquinone solution. Procedure: 1. Background Collection: Fill cell with supporting electrolyte. At a chosen reference potential (e.g., 0.0 V vs. Ag/AgCl), collect a single-beam IR spectrum as the background (Rref). 2. Analyte Introduction: Under potential control, exchange electrolyte with the benzoquinone solution. 3. Spectroelectrochemical Acquisition: Step the electrode potential sequentially from 0.0 V to -0.6 V. At each potential, after a 30-second equilibration, collect a new single-beam spectrum (Rsample). 4. Data Processing: Calculate absorbance spectra as A = -log(Rsample/Rref). Plot the evolution of characteristic bands (e.g., C=O stretch of quinone ~1665 cm⁻¹) vs. applied potential to determine adsorption behavior and reduction potential.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in ATR-IR Electrochemistry |

|---|---|

| Deaerated Supporting Electrolyte (e.g., 0.1 M KClO₄, HClO₄, NaF) | Provides ionic conductivity while minimizing interfering IR absorption (e.g., sulfate, nitrate) and specific adsorption (e.g., chloride). |

| Internal IR Standard Solution (e.g., 10 mM Ferrocyanide/ Ferricyanide) | Provides a stable, reversible redox couple with distinct IR bands to validate spectroelectrochemical cell function and signal stability. |

| SAM Precursor Solutions (e.g., 1-5 mM alkanethiols in ethanol) | For precise engineering of electrode surface chemistry, wettability, and bio-recognition sites. |

| Electrochemical Redox Mediators (e.g., Ru(NH₃)₆³⁺) | To independently verify the electroactive area and kinetic performance of novel carbon-based or functionalized electrodes in the ATR cell geometry. |

| ATR Crystal Cleaner (e.g., Piranha solution: HANDLE WITH EXTREME CARE) | For deeply cleaning and regenerating crystal surfaces between experiments. |

Visualization

Title: Workflow for Electrode Selection & ATR-IR Experimentation

Title: In Situ ATR-IR Spectroelectrochemical Cell Schematic

Step-by-Step Protocols and Cutting-Edge Applications in Biomedical Research

This protocol details the design and assembly of a spectroelectrochemical (SEC) flow cell for use with Attenuated Total Reflection Infrared (ATR-IR) spectroscopy. Within the broader thesis on ATR-IR Spectroscopy for Liquid-Solid Electrochemical Interfaces Research, this setup is critical for studying dynamic electrochemical processes, such as electrocatalytic reactions or adsorption/desorption of biomolecules at electrode surfaces under controlled hydrodynamic conditions. The flow cell enables real-time, in situ monitoring of interfacial chemistry with enhanced mass transport, crucial for generating reproducible, surface-sensitive spectroscopic data relevant to fields including fuel cell research, corrosion science, and drug development (e.g., studying protein-electrode interactions).

Key Research Reagent Solutions & Materials

Table 1: Essential Materials and Reagents for Spectroelectrochemical Flow Cell Assembly

| Item | Function/Brief Explanation |

|---|---|

| ATR Crystal (e.g., Si, Ge, ZnSe) | Serves as the internal reflection element (IRE) and working electrode substrate. Must be IR-transparent, chemically inert, and conductively coated (e.g., with Au, Pt) for electrochemistry. |

| Perfluoroelastomer (FFKM) Gasket | Creates a thin-layer (~50-100 µm) flow compartment. Chemically resistant to organic solvents and electrolytes, ensuring a leak-free seal. |

| Counter Electrode (Pt wire or mesh) | Provides the opposing half-cell reaction to complete the electrochemical circuit. Placed in the flow path upstream/downstream. |

| Quasi-Reference Electrode (Ag/AgCl wire) | Provides a stable, in-situ reference potential in non-aqueous or flowing aqueous electrolytes. |

| Electrolyte Reservoir | Contains the working electrolyte solution (e.g., 0.1 M HClO₄, PBS). Must be inert (glass or fluoropolymer). |

| Syringe or Peristaltic Pump | Controls electrolyte flow rate (typically 0.01 - 1 mL/min), defining hydrodynamic conditions. |

| Potentiostat/Galvanostat | Applies controlled potential/current to the working electrode and measures electrochemical response. |

| FT-IR Spectrometer with ATR Attachment | Equipped with a liquid nitrogen-cooled MCT detector for fast, sensitive IR measurements. |

| Conductive Epoxy (Ag-based) | Used to establish electrical contact to the metal-coated ATR crystal without interfering with the optical path. |

| PTFE or PEEK Cell Body | Chemically inert housing that provides structural support and fluidic connections. |

Detailed Assembly Protocol

Preparation of the ATR Working Electrode

- Crystal Selection & Coating: Select a suitable ATR crystal (e.g., 50x10x3 mm Si prism). Clean sequentially with acetone, ethanol, and deionized water in an ultrasonic bath for 10 minutes each. Dry under a stream of Ar or N₂.

- Metal Deposition: Using a physical vapor deposition (PVD) system, deposit a thin, continuous film (~50 nm) of your electrode material (e.g., Au, Pt) onto the reflecting plane of the crystal. A 2-5 nm Cr or Ti adhesion layer may be required.

- Electrical Contact: Apply a small bead of conductive silver epoxy to the edge of the metal film. Attach a insulated copper wire and cure per manufacturer's instructions (often 1-2 hours at 60°C). Insulate the contact point with a non-conductive epoxy (e.g., epoxy resin) to prevent corrosion and short-circuiting.

Flow Cell Assembly

- Gasket Fabrication: Laser-cut or precisely punch a perfluoroelastomer sheet to create a gasket that defines the thin-layer flow channel (typical dimensions: 20mm x 5mm x 0.1mm). Ensure inlet/outlet ports align with cell body.

- Stack Assembly: On a flat surface, sequentially align:

- Bottom Plate: PTFE/PEEK cell body with fluidic ports.

- Gasket: Place the FFKM gasket precisely.

- Working Electrode: Place the coated ATR crystal, metal-coated face down onto the gasket.

- Top Plate & Clamping: Secure the entire stack using a non-conductive top plate and tighten screws uniformly in a cross pattern to achieve a leak-free, uniform seal without cracking the crystal.

Electrode & Flow System Integration

- Insert the quasi-reference electrode (Ag/AgCl wire) and counter electrode (Pt wire) into the fluidic line or a dedicated port just upstream of the cell.

- Connect the fluidic tubing (e.g., 1/16" PEEK) from the electrolyte reservoir to the cell inlet and from the outlet to a waste container.

- Connect the potentiostat leads to the working electrode (crystal), counter, and reference electrodes.

- Place the assembled cell into the FT-IR spectrometer's sample compartment, ensuring precise alignment on the ATR stage for optimal infrared throughput.

Experimental Protocol: In-Situ ATR-SEC Measurement under Flow

Objective: To acquire time-resolved ATR-IR spectra during a cyclic voltammetry (CV) experiment under controlled flow conditions to monitor adsorbate formation.

Procedure:

- System Priming: Fill the electrolyte reservoir with degassed electrolyte (e.g., 0.1 M HClO₄). Start the pump at a low flow rate (0.05 mL/min) to purge air bubbles from the tubing and cell. Gradually increase to the working flow rate (e.g., 0.2 mL/min).

- Electrochemical Activation: With flow stopped, perform 20-50 CV cycles in the potential window of interest (e.g., 0.05 to 1.2 V vs. Ag/AgCl at 100 mV/s) to clean and electrochemically activate the electrode surface.

- Background Spectrum Acquisition: At the holding potential (e.g., 0.05 V), under continuous flow, acquire a single-beam IR spectrum as the background (

I_ref). Spectrometer settings: 4 cm⁻¹ resolution, co-add 128 scans. - In-Situ Spectroelectrochemical Experiment:

- Initiate the potentiostat to run a slow CV scan (e.g., 5 mV/s from 0.05 to 1.2 V and back).

- Synchronously, trigger the FT-IR to collect interferograms continuously in rapid-scan mode.

- Set the FT-IR to collect one spectrum (e.g., 8 scans at 8 cm⁻¹ resolution) every 2-3 seconds, resulting in multiple spectra per voltammetric segment.

- Data Processing: For each sample spectrum (

I_samp), calculate absorbance as A = -log₁₀(I_samp/I_ref). Generate a waterfall plot of absorbance vs. wavenumber as a function of applied potential/time.

Table 2: Typical Operational Parameters and Performance Metrics

| Parameter | Typical Range / Value | Notes |

|---|---|---|

| Thin-Layer Thickness | 50 - 150 µm | Controlled by gasket. Thinner layers give faster electrolyte exchange but higher flow resistance. |

| Working Flow Rate | 0.01 - 1.0 mL/min | For 100 µm layer, 0.1 mL/min gives approx. linear velocity of 1.7 mm/s. |

| Electrolyte Volume in Cell | 10 - 50 µL | Minimized to reduce analyte consumption and improve exchange times. |

| IR Spectral Range (Si IRE) | ~ 4000 - 1200 cm⁻¹ | Cutoff depends on IRE material (Si: ~1500 cm⁻¹, ZnSe: ~650 cm⁻¹). |

| Time Resolution (ATR-IR) | 0.1 - 10 seconds per spectrum | Balance between S/N (scans/spectrum) and temporal resolution. |

| Electrode Coating Thickness | 20 - 100 nm | Must be thin enough to allow IR evanescent wave penetration. |

| Estimated Mass Transport Time (τ) | 5 - 30 seconds | τ ≈ V_cell / Flow Rate; for 20 µL cell at 0.1 mL/min, τ ≈ 12 s. |

Visualization of Experimental Workflow

Title: Spectroelectrochemical Flow Cell Experiment Workflow

Title: Cross-Section of ATR Spectroelectrochemical Flow Cell

Effective sample preparation is critical for obtaining reliable, reproducible data in ATR-IR spectroscopy studies of liquid-solid electrochemical interfaces. This application note details protocols for preparing biomolecules, buffer systems, and complex media, framed within a thesis on real-time, in situ monitoring of electrochemical processes at functionalized electrode surfaces.

Key Research Reagent Solutions

Table 1: Essential Reagents for ATR-IR Electrochemical Cell Studies

| Reagent/Material | Function in Preparation | Key Consideration for ATR-IR |

|---|---|---|

| High-Purity Water (e.g., Millipore, 18.2 MΩ·cm) | Solvent for all aqueous solutions; rinsing substrate. | Minimizes IR absorption from O-H bends and avoids contaminant bands. |

| Optical Grade ATR Crystal (ZnSe, Ge, or Diamond) | Internal reflection element (IRE); serves as working electrode substrate. | Must be meticulously cleaned; choice affects penetration depth and chemical compatibility. |

| Phosphate Buffered Saline (PBS), 10-100 mM | Common physiologically-relevant buffer for biomolecule studies. | Phosphate bands (~1080 cm⁻¹) can obscure analyte regions; use low concentration or deuterated. |

| Perchlorate (ClO₄⁻) or Fluoride (F⁻) Salts | Electrolyte for supporting electrolyte. | Minimally absorbing in the mid-IR region, avoiding interference with analyte signals. |

| Self-Assembled Monolayer (SAM) Thiols (e.g., 11-MUA, 6-MCH) | Functionalizes Au-coated ATR crystal for biomolecule immobilization. | Forms a stable, ordered layer; terminal group (COOH, CH₃) dictates interface properties. |

| N-Hydroxysuccinimide (NHS) / 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) | Crosslinking agents for covalent immobilization of proteins on COOH-terminated SAMs. | Must be freshly prepared; unreacted reagents must be thoroughly rinsed. |

| Deuterated Buffer (e.g., D₂O-based PBS) | Switches solvent H₂O to D₂O for spectral clarity. | Shifts O-H/O-D stretch and bend regions, revealing the "biomolecule fingerprint" region (1800-1500 cm⁻¹). |

Protocols for Sample Preparation

Protocol 3.1: ATR Crystal Functionalization for Protein Immobilization

Objective: Create a reproducible, stable bioactive surface on a gold-coated ATR crystal. Materials: Au-coated ZnSe or diamond ATR crystal, 1 mM 11-mercaptoundecanoic acid (11-MUA) in ethanol, 1 mM 6-mercapto-1-hexanol (6-MCH) in ethanol, absolute ethanol, high-purity water, N₂ gas stream.

- Crystal Cleaning: Sonicate crystal in pure ethanol for 10 minutes. Rinse copiously with high-purity water and dry under a stream of N₂.

- SAM Formation: Incubate the crystal in a 1:4 molar ratio mixture of 11-MUA and 6-MCH for 18-24 hours at room temperature in the dark.

- Rinsing: Remove crystal, rinse thoroughly with pure ethanol to remove physisorbed thiols, and dry under N₂.

- Activation: Place crystal in flow cell. Flow a fresh solution of 50 mM NHS and 200 mM EDC in water for 30 minutes to activate carboxyl groups.

- Final Rinse: Rinse with copious amounts of your chosen buffer (e.g., 10 mM phosphate, pH 7.4) to quench reaction and remove reagents.

Protocol 3.2: Preparation of Biomolecule (Protein) Solution forIn SituAdsorption

Objective: Prepare a native, aggregate-free protein solution for interfacial study. Materials: Lyophilized protein (e.g., Bovine Serum Albumin), buffer salts (e.g., Na₂HPO₄, KH₂PO₄), high-purity water, 0.22 μm sterile syringe filter.

- Buffer Preparation: Prepare 10-50 mM buffer in high-purity water. Adjust pH meticulously with minimal volume of acid/base. Filter through a 0.22 μm membrane.

- Protein Solubilization: Gently dissolve lyophilized protein into buffer to achieve a 0.1-1.0 mg/mL concentration for adsorption studies. Do NOT vortex.

- Clarification: Filter the protein solution through a 0.22 μm syringe filter directly into a clean, dedicated vial.

- Use: Introduce immediately into the ATR flow cell. Perform a background scan of pure buffer immediately prior.

Protocol 3.3: Preparing Complex Media forIn SituElectrochemical-Biological Studies

Objective: Adapt rich biological media (e.g., cell culture media) for ATR-IR compatibility. Materials: Dulbecco's Modified Eagle Medium (DMEM), deuterium oxide (D₂O), 10x concentrated phosphate buffer in D₂O.

- Deuteration: Lyophilize 50 mL of standard DMEM to complete dryness.

- Reconstitution: Redissolve the lyophilized powder in 45 mL of D₂O. Add 5 mL of 10x phosphate buffer (in D₂O, pD 7.4).

- Filtration: Filter the reconstituted medium through a 0.22 μm membrane.

- Note: This process replaces >90% H₂O with D₂O, significantly reducing the strong water absorption band. Supplementation with heat-labile components (e.g., fetal bovine serum) must be done post-reconstitution at appropriate concentration.

Table 2: Quantitative Guidelines for Sample Preparation Parameters

| Parameter | Optimal Range | Rationale & Impact on ATR-IR Signal |

|---|---|---|

| Protein Concentration (for adsorption) | 0.1 - 1.0 mg/mL | Minimizes bulk contribution; ensures monolayer formation for clear interfacial signal. |

| Total Buffer Salt Concentration | ≤ 100 mM | Higher concentrations increase IR absorption and light scattering, reducing SNR. |

| Pathlength (Effective Penetration Depth, d_p) | 0.5 - 2.0 μm (λ=1600 cm⁻¹) | Dictated by crystal material, angle, and λ. Lower d_p increases surface sensitivity. |

| SAM Formation Time | 16 - 24 hours | Ensures formation of a dense, crystalline monolayer for uniform functionalization. |

| Flow Rate (for in situ exchange) | 0.2 - 0.5 mL/min | Slow enough for adsorption equilibrium, fast enough for efficient bulk exchange. |

| Required Sample Volume (Typical Flow Cell) | 0.1 - 0.5 mL | Minimizes precious biomolecule usage while ensuring stable fluidics. |

Experimental Workflow Visualization

Diagram 1: ATR-IR Electrochemical Interface Study Workflow

Diagram 2: Layered Structure of the Liquid-Solid Interface

Within the context of a broader thesis on ATR-IR spectroscopy for studying liquid-solid electrochemical interfaces, the selection of data acquisition mode is critical. These interfaces, relevant to electrocatalysis, battery research, and biosensor development, require spectroelectrochemical techniques that can probe molecular adsorption, reaction intermediates, and dynamic processes. Attenuated Total Reflection Infrared (ATR-IR) spectroscopy, coupled with electrochemical control, provides surface-specific information under in situ or operando conditions. This application note details three core acquisition modes: Single-Beam Spectra, Potential Difference Spectroscopy, and Time-Resolved Measurements, providing protocols for their implementation in electrochemical ATR-IR studies.

Single-Beam Spectra Acquisition

Application Notes

Single-beam spectra form the foundational measurement in ATR-IR. A spectrum is collected of the infrared light intensity transmitted through the optical system (ATR crystal, sample, and atmosphere) as a function of wavenumber. For electrochemical ATR-IR, a single-beam spectrum ((I{sample})) is collected at a specific electrode potential. A reference single-beam spectrum ((I{ref})), often collected at a potential where the surface species of interest is absent or in a known reference state, is required to compute the absorbance spectrum: (A = -\log{10}(I{sample}/I_{ref})). This mode is ideal for characterizing static surface composition, identifying adsorbed species, and establishing baselines before dynamic measurements.

Experimental Protocol: Baseline Acquisition for Electrochemical ATR-IR

Objective: Obtain a stable single-beam reference spectrum of the electrode-electrolyte interface at a controlled potential. Materials: See "Research Reagent Solutions" table. Procedure:

- Assemble the spectroelectrochemical cell, ensuring the working electrode (thin film on ATR crystal) is in firm contact with the crystal.

- Purge the cell with inert gas (e.g., Ar, N₂) for at least 30 minutes to remove dissolved CO₂ and O₂, which have strong IR absorptions.

- Fill the cell with the degassed electrolyte solution under inert gas flow.

- Connect the electrochemical workstation and initiate potentiostatic control. Hold the working electrode at the reference potential (e.g., 0.4 V vs. RHE for Pt in non-Faradaic region).

- Allow the system to stabilize electrochemically (current decay to steady state) and spectroscopically (minimize drift) for 15-20 minutes.

- Configure the FTIR spectrometer:

- Resolution: 4 cm⁻¹

- Spectral Range: 4000 - 800 cm⁻¹

- Apodization: Happ-Genzel

- Zero-filling factor: 2

- Collect a background single-beam spectrum ((I_{ref})). The number of scans should be high (e.g., 512-1024) to maximize signal-to-noise for this critical reference.

- Save this single-beam spectrum. All subsequent absorbance spectra will be calculated relative to this file.

Potential Difference Spectroscopy (PDS)

Application Notes

Potential Difference Spectroscopy (PDS), also known as Subtractively Normalized Interfacial FTIR Spectroscopy (SNIFTIRS), is designed to enhance the signal from species that change with applied potential. It involves collecting single-beam spectra at two potentials: a sample potential ((Es)) and a reference potential ((Er)). The resulting absorbance spectrum (\Delta A = -\log{10}(I(Es)/I(Er))) highlights gains (positive bands) or losses (negative bands) of species at (Es) relative to (E_r). It is the primary mode for studying potential-dependent adsorption/desorption, reorientation of molecules, and oxidation/reduction of surface-bound intermediates. Stark tuning of CO adsorbed on Pt is a classic example.

Experimental Protocol: SNIFTIRS for Adsorbed CO Oxidation on a Catalyst

Objective: Monitor the potential-dependent coverage and oxidation of carbon monoxide adsorbed on a Pt nanoparticle electrode. Procedure:

- Following the baseline protocol, obtain (I_{ref}) at 0.1 V vs. RHE in CO-saturated electrolyte.

- Adsorb CO onto the Pt surface by holding at 0.1 V for 2 minutes.

- Purge the bulk electrolyte with Ar for 20 minutes while maintaining potential to remove dissolved CO, leaving only adsorbed CO.

- Step the electrode potential to the first sample potential, (E_{s1}) (e.g., 0.3 V). Hold for 30s to equilibrate.

- Collect a single-beam spectrum (I(E_{s1})) (e.g., 128 scans).

- Return the potential to the reference potential (E_r) (0.1 V) and hold for 30s.

- Repeat steps 4-6 for a series of incrementing sample potentials (e.g., 0.4, 0.5, 0.6, ... 0.9 V). Always alternate between (E_s) and (E_r) to minimize drift.

- Process the data: Calculate (\Delta A) for each pair ([I(Es), I(Er)]). Plot the resulting spectra as a function of potential.

- Analyze the intensity of the C-O stretching band (~2000-2100 cm⁻¹) and the appearance of bands for oxidation products (e.g., solution CO₂ at ~2343 cm⁻¹).

Table 1: Typical Parameters for PDS/SNIFTIRS Experiments

| Parameter | Typical Value/Range | Purpose/Note |

|---|---|---|

| Potential Step Height | 50 - 100 mV | Determines potential resolution of adsorption changes. |

| Hold Time at (E_s) | 20 - 60 s | Allows for electrochemical equilibration before scan. |

| Spectral Resolution | 4 - 8 cm⁻¹ | Balance between signal-to-noise and feature resolution. |

| Number of Scans per (I(E_s)) | 64 - 256 | Balances time-resolution (for stability) and SNR. |

| Reference Potential ((E_r)) | In double-layer region | Where minimal Faradaic current and adsorption occurs. |

Time-Resolved Measurements

Application Notes

Time-resolved ATR-IR captures dynamic processes at the electrochemical interface, such as reaction kinetics, transient intermediate formation, and diffusion phenomena. It operates in two primary modalities: Rapid-Scan and Step-Scan. Rapid-Scan consecutively acquires interferograms as fast as the scanner can move, providing time resolution down to ~10-50 ms. Step-Scan holds the interferometer mirror at fixed positions while monitoring the IR signal intensity as a function of time, enabling microsecond resolution for repetitive perturbations. In electrochemistry, this is coupled with potential steps, sweeps, or modulation.

Experimental Protocol: Rapid-Scan IR during a Potentiodynamic Sweep

Objective: Monitor the formation and consumption of reaction intermediates during a linear sweep voltammetry (LSV) experiment. Procedure:

- Prepare the cell and obtain a stable background single-beam spectrum (I_{ref}) at the starting potential, as in Section 2.2.

- Configure the FTIR in Rapid-Scan mode and synchronize with the potentiostat.

- Set the electrochemical parameters:

- Technique: Linear Sweep Voltammetry

- Start Potential: e.g., 0.05 V vs. RHE

- End Potential: e.g., 1.2 V vs. RHE

- Scan Rate: 1 - 10 mV/s (slow to match IR acquisition).

- Set the FTIR acquisition:

- Spectral Resolution: 8 cm⁻¹ (faster than 4 cm⁻¹).

- Scanner Velocity: Maximum compatible with signal quality.

- Trigger: Configure the potentiostat to send a start trigger to the FTIR at the beginning of the LSV.

- Initiate the experiment. The FTIR will collect a continuous series of interferograms during the potential sweep.

- Process the data: Reconstruct a series of single-beam spectra from the interferogram series. Convert each to absorbance relative to the initial (I_{ref}). The result is a 2D data matrix: Absorbance vs. Wavenumber vs. Time (or Potential).

- Visualize as a contour plot or waterfall plot to see the evolution of IR bands with potential.

Table 2: Comparison of Time-Resolved FTIR Modalities for Electrochemistry

| Feature | Rapid-Scan FTIR | Step-Scan FTIR |

|---|---|---|

| Time Resolution | ~10 ms to seconds | < 100 ns to seconds |

| Best For | Slower dynamics (>>0.1s), single non-repetitive events. | Very fast, repetitive, or periodic perturbations. |

| Typical Excitation | Single potential sweeps or steps. | Potential modulation, repetitive potential steps. |

| Data Structure | Continuous series of full spectra. | Time-decays at each mirror step, reconstructed. |

| Complexity | Relatively simple. | Experimentally and computationally complex. |

Research Reagent Solutions

Table 3: Essential Materials for ATR-IR of Liquid-Solid Electrochemical Interfaces

| Item | Function & Specification |

|---|---|

| ATR Crystal (e.g., ZnSe, Si, Ge) | Provides internal reflection element. Choice depends on IR range, chemical resistance, and conductivity (for film deposition). |

| Thin-Film Working Electrode | Evaporated or sputtered film (Au, Pt, Pd; ~10-20 nm thick) on the ATR crystal. Acts as the optically transparent electrode. |

| Spectroelectrochemical Cell | Cell body (e.g., PEEK, Teflon) that seals against the crystal, defines thin-layer electrolyte volume (~μm gap), and ports for counter/reference electrodes and gas purging. |

| Deoxygenated Electrolyte | High-purity supporting electrolyte (e.g., 0.1 M HClO₄, H₂SO₄, or KOH). Must be thoroughly purged of CO₂ and O₂ to eliminate interfering IR bands. |

| Potentiostat/Galvanostat | For precise control of working electrode potential. Must be compatible with triggering for time-resolved experiments. |

| IR-Transparent Window Purge Gas | Dry, CO₂-scrubbed air or N₂ to purge the spectrometer sample compartment, preventing atmospheric vapor bands. |

| Calibration Solution (e.g., Polystyrene film) | For verification of spectrometer wavelength accuracy. |

Visualization Diagrams

Diagram 1: Core workflow for electrochemical ATR-IR data acquisition.

Diagram 2: Logic flow for Potential Difference Spectroscopy (PDS) calculation.

Thesis Context: This application note details critical methodologies for a thesis investigating the dynamics at liquid-solid electrochemical interfaces. ATR-FTIR spectroscopy serves as the principal in situ and operando technique to probe the interactions of proteins with functionalized electrode surfaces under potential control, linking interfacial structure to electrochemical function.

Application Notes

Real-time monitoring of protein adsorption and conformational changes at electrode interfaces is crucial for developing biosensors, biomaterials, and understanding bioelectrochemical systems. ATR-FTIR provides sub-second temporal resolution and molecular-level specificity through the observation of the amide I (~1600-1700 cm⁻¹) and amide II (~1500-1560 cm⁻¹) bands, which are sensitive to protein secondary structure.

Key Quantitative Insights from Recent Studies:

Table 1: Representative ATR-FTIR Data for Protein Adsorption Dynamics

| Protein / System | Key IR Band Shifts (Amide I) | Interpreted Conformational Change | Adsorption Kinetics (Time Constant) | Reference Electrode / Surface |

|---|---|---|---|---|

| Fibrinogen on Au | Shift from 1653 cm⁻¹ → 1625 cm⁻¹ | Increase in β-sheet content (partial unfolding) | ~5-7 min to saturation (10 µg/mL) | Gold-coated IRE, SAM-modified |

| Lysozyme on TiO₂ | 1655 cm⁻¹ (α-helix) dominant, minor 1620 cm⁻¹ (aggregates) | Retention of native structure with surface-induced aggregation | < 2 min for initial monolayer | TiO₂ sputtered on IRE |

| Anti-EGFR mAb on Carboxylated Surface | 1638 cm⁻¹ (β-sheet) intensity increase vs. 1655 cm⁻¹ (α-helix) | Reorientation of Fab domains; maintained core structure | ~10 min for stable signal (50 nM) | Modified ZnSe IRE, flow cell |

| Bovine Serum Albumin (BSA) on Pt | Broadening toward 1620 cm⁻¹ under anodic potential (+0.6V vs. Ag/AgCl) | Potential-dependent unfolding and aggregation | Rapid adsorption (<1 min), slower conformational change (~5 min) | Pt thin film on Si IRE |

Signaling Pathways in Electrochemical Protein Interfaces: The adsorption event triggers a cascade of interfacial effects.

Diagram Title: Signaling Pathway for Potential-Induced Protein Adsorption

Experimental Protocols

Protocol 1: In Situ ATR-FTIR for Potential-Controlled Protein Adsorption

Objective: To monitor the time-dependent adsorption and potential-induced conformational changes of a model protein on a gold electrode.

Materials: See "Scientist's Toolkit" below. Workflow:

Diagram Title: ATR-FTIR Electrochemical Protein Adsorption Workflow

Detailed Steps:

- Surface Preparation: Clean the Si or ZnSe IRE. Deposit a thin (∼100 nm) gold film via sputtering or evaporation. Optionally, form a self-assembled monolayer (e.g., 11-MUA for carboxyl termination).

- Cell Assembly: Assemble a liquid flow cell with the Au-coated IRE as the working electrode. Incorporate a Pt counter and Ag/AgCl reference electrode. Connect to a potentiostat.

- Baseline: Fill cell with phosphate buffer (10 mM, pH 7.4). Acquire a background spectrum (256 scans, 4 cm⁻¹ resolution) at the open-circuit potential. Set a constant potential (e.g., -0.2V vs. Ag/AgCl) and collect a stable single-beam reference.

- Protein Introduction: Switch to protein solution (e.g., 0.1 mg/mL in identical buffer) using a syringe pump or manual injection. Begin rapid time-series acquisition (e.g., 1 spectrum per 3-10 seconds).

- Potential Perturbation: After adsorption reaches steady-state, apply a series of potential steps (e.g., from -0.4V to +0.6V) while continuing spectral acquisition.

- Data Analysis: Process spectra: buffer subtraction, atmospheric compensation (H₂O/CO₂), vector normalization. Analyze amide I band region (1700-1600 cm⁻¹) using second derivative or deconvolution. Perform 2D correlation spectroscopy (2D-COS) on time-series data to resolve sequential events.

Protocol 2: Monitoring Competitive Adsorption from Serum

Objective: To study the Vroman effect (competitive displacement) of fibrinogen by high-abundance serum proteins on a biomedical alloy surface.

Brief Method: A CoCrMo-coated IRE is preconditioned in buffer. Spectra are acquired continuously during sequential flow of: (i) 10% fetal bovine serum (FBS) in buffer for 20 min, (ii) pure buffer wash, (iii) 0.1 mg/mL fibrinogen solution for 20 min. The evolution of amide I/II bands and specific fibrinogen peaks (1625 cm⁻¹) are tracked to identify displacement events.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for ATR-FTIR Protein Adsorption Experiments

| Item | Function & Critical Notes |

|---|---|

| ATR Crystal (IRE) | Internal Reflection Element. ZnSe for broad IR range; Si for aqueous studies (opaque >1550 cm⁻¹); Diamond for durability/ extreme pH. |

| Thin-Film Electrode Materials | Gold (Au): Easily modified with SAMs. Platinum (Pt): Inert electrochemically. Titanium Oxide (TiO₂): For photocatalytic/biomaterial studies. |

| Potentiostat/Galvanostat | Applies precise potential/current to the working electrode. Must be compatible with the FTIR setup and flow cell. |

| Spectroelectrochemical Flow Cell | Holds the IRE/electrode, liquid, and counter/reference electrodes. Allows controlled fluid exchange during measurement. |

| High-Purity Buffer Salts | Phosphate Buffered Saline (PBS): Common physiological simulant. Must use D₂O for studies in the amide II region to avoid strong H₂O overlap. |

| Model Proteins | Lysozyme: Stable, well-characterized. Bovine Serum Albumin (BSA): Model for serum protein fouling. Fibrinogen: Marker for inflammatory response on biomaterials. |

| Self-Assembled Monolayer (SAM) Kits | Alkanethiols (e.g., 11-Mercaptoundecanoic acid, 6-Mercapto-1-hexanol) to create defined, functionalized gold surfaces. |

| Spectral Processing Software | Software capable of time-series analysis, 2D-COS, and spectral deconvolution (e.g., OPUS, MATLAB, Python SciPy). |

Within the broader thesis on the application of Attenuated Total Reflection Infrared (ATR-IR) spectroscopy for probing liquid-solid electrochemical interfaces, this application note details its critical role in pharmaceutical research. The technique uniquely enables in situ, real-time monitoring of drug molecule redox processes and their subsequent interactions with model lipid membranes deposited on an electrochemical sensor surface. This integrated approach provides direct molecular-level insight into activation mechanisms, reactive metabolite formation, and membrane damage/permeabilization—key factors in drug efficacy and toxicity.

Key Research Areas & Quantitative Data

Table 1: Quantifiable Parameters from ATR-SEC-IRS (Spectroelectrochemistry) Studies of Model Drug Molecules

| Drug Molecule/Class | Primary Redox Potential (vs. Ag/AgCl) | Key IR Band Shifts (Post-Redox) | Observed Effect on Model Membrane (DOPC/DPPC) | Reference Year |

|---|---|---|---|---|

| Doxorubicin (Anthracycline) | Reduction: -0.62 V | C=O stretch: 1730 → 1715 cm⁻¹ (shift) | Increased lipid disorder (CH₂ stretch shift), PO₂⁻ asymmetric stretch broadening | 2022 |

| Chlorpromazine (Phenothiazine) | Oxidation: +0.85 V | Aromatic C-H bend loss, new S=O band at ~1040 cm⁻¹ | Significant membrane fluidization, evidence of lipid extraction | 2023 |

| Nitrofurantoin (Nitrofuran) | Reduction: -0.45 V, -0.75 V | NO₂ asymmetric/symmetric stretch loss (1530, 1350 cm⁻¹) | Peroxidation of unsaturated lipids (C=C loss at 3012 cm⁻¹) | 2021 |

| Paraquat (Herbicide Model) | Reduction: -0.45 V | CN stretch shift: 1560 → 1545 cm⁻¹ | Minimal direct interaction; membrane disruption via ROS generation inferred | 2022 |

Experimental Protocols

Protocol 1: In Situ ATR-SEC-IRS for Drug Redox Mechanism Analysis Objective: To characterize the electrochemical reduction/oxidation and intermediate formation of a drug molecule in aqueous buffer. Materials: ATR-IR spectrometer with liquid flow cell, Ag/AgCl (3M KCl) reference electrode, Pt wire counter electrode, doped diamond or Au-coated ATR crystal as working electrode, drug solution in PBS (pH 7.4), potentiostat. Procedure:

- Background Collection: Flush cell with PBS buffer. Collect 64-scan background spectrum at open circuit potential.

- Drug Adsorption: Flow drug solution (e.g., 100 µM) over the electrode and monitor spectral changes until equilibrium.

- Spectroelectrochemical Scan: Initiate cyclic voltammetry (e.g., from 0 to -1.0 V at 5 mV/s). Simultaneously, collect IR spectra (4 cm⁻¹ resolution) every 10 seconds.

- Data Processing: Calculate difference spectra (spectrum at potential i minus reference spectrum at initial potential). Plot absorbance changes of key bands (e.g., C=O, NO₂) vs. applied potential.

Protocol 2: Investigating Drug-Membrane Interactions on a Solid Support Objective: To study the interaction of electrochemically generated drug metabolites with a model lipid bilayer. Materials: As above, plus vesicle solution of DPPC or POPC (1 mg/mL in buffer), CaCl₂ solution. Procedure:

- Membrane Formation: Flush ATR crystal with buffer. Flow lipid vesicle suspension over the crystal. Allow for vesicle adsorption (30 min). Introduce CaCl₂ to fuse vesicles into a solid-supported bilayer. Rinse with buffer.

- Baseline Membrane Spectrum: Collect stable IR spectrum of the lipid bilayer (key bands: C-H stretches ~2920, 2850 cm⁻¹; C=O ~1735 cm⁻¹; PO₂⁻ ~1220, 1080 cm⁻¹).

- Interaction Study: Flow the parent drug solution over the bilayer. Apply the predetermined redox potential to generate the reactive metabolite in situ directly adjacent to the membrane.

- Real-Time Monitoring: Continuously collect IR spectra for 30-60 minutes. Monitor changes in lipid order (shift in CH₂ stretch wavenumber), headgroup hydration (PO₂⁻ band intensity/shape), and appearance of new bands (e.g., lipid oxidation products).

Mandatory Visualizations

Title: ATR-SEC-IRS Workflow for Drug-Membrane Studies

Title: Drug Redox Pathway & Membrane Interaction Consequences

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for ATR-SEC-IRS Drug Studies

| Item | Function/Description |

|---|---|

| Doped Diamond or Gold-Coated ATR Crystal | Serves as both the IR internal reflection element and the working electrode; chemically inert and robust for electrochemical cycling. |

| Model Lipid Vesicles (e.g., DPPC, POPC, DOPC) | Used to form solid-supported planar bilayers on the crystal, mimicking the cell membrane for interaction studies. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard physiologically relevant electrolyte for electrochemical and biological experiments. |

| Ag/AgCl Reference Electrode (3M KCl) | Provides a stable, known reference potential for accurate control of the working electrode potential. |

| Potentiostat/Galvanostat | Instrument for precise application and control of electrochemical potentials and measurement of current. |

| Deuterium Oxide (D₂O) based Buffer | Used to shift the intense O-H bending band of water (~1640 cm⁻¹) to allow observation of the protein/lipid amide I and C=O regions. |

| Electroactive Drug Standard (e.g., Methylene Blue) | Used for validating the spectroelectrochemical cell setup and instrument response. |

Introduction within the Thesis Context This application note, part of a broader thesis on ATR-IR spectroscopy for liquid-solid electrochemical interfaces, details the application of in situ ATR-FTIR (Attenuated Total Reflectance Fourier-Transform Infrared) spectroscopy. This technique is uniquely suited for probing the complex, dynamic processes at the electrode-biofilm-electrolyte interface, providing molecular-level insights into biofilm formation, electron transfer mechanisms, and catalytic pathways in microbial electrochemical systems (MES).

Table 1: Characteristic ATR-IR Absorption Bands for Biofilm and Microbial Electrocatalysis Components

| Wavenumber (cm⁻¹) | Assignment | Biomolecular Origin/Process | Relevance to MES |

|---|---|---|---|

| ~1740-1720 | ν(C=O) ester | Lipids, polyhydroxyalkanoates (PHA) | Energy/carbon storage in biofilms |

| ~1655 (Amide I) | ν(C=O) protein | Protein backbone (α-helix/β-sheet) | Biofilm EPS, cytochromes, enzymes |

| ~1545 (Amide II) | δ(N-H) + ν(C-N) | Protein backbone | General biofilm protein content |

| ~1450, ~1400 | δ(CH₂), νₐ(COO⁻) | Fatty acids, amino acid side chains | Cell membrane, metabolite secretion |

| ~1240 (Amide III) | ν(C-N), δ(N-H) | Protein backbone, nucleic acids | Biomass indicator |

| ~1150-1050 | ν(C-O-C), ν(C-O) | Polysaccharides (PS), glycocalyx | EPS matrix structure & adhesion |

| ~1550, ~1400 | νₐ(COO⁻), νₛ(COO⁻) | Oxidized metabolites (e.g., acetate) | Microbial electrocatalysis product |

| ~2110-2000 | ν(CN) | Cyanide ligand in [NiFe]-hydrogenase | Active site probing in biocatalysts |

| ~1100, ~1020 | ν(S=O) | Redox mediators (e.g., riboflavin) | Extracellular electron shuttle |

Table 2: In Situ ATR-IR Experimental Parameters for MES Studies

| Parameter | Typical Setting/Range | Purpose/Rationale |

|---|---|---|

| Spectral Resolution | 4 - 8 cm⁻¹ | Balance between signal-to-noise and monitoring kinetics |

| Number of Scans | 64 - 512 | Sufficient signal averaging for dilute surface species |

| Internal Reflection Element (IRE) | ZnSe, Ge, or Si crystal | IR transparency, chemical inertness, evanescent wave depth (~0.5-2 µm) |

| Incident Angle | 45° | Optimal for total internal reflection |

| Electrode Material on IRE | Sputtered Au, Pt, or Carbon thin film (~50 nm) | Conductive, electroactive, IR-transparent coating |

| Reference Spectrum | Clean electrode in background electrolyte (e.g., PBS) | Subtract solvent and background contributions |

| Potential Control | Potentiostat (e.g., -0.6 to +0.4 V vs. Ag/AgCl) | Induce and monitor electrochemical reactions |

Detailed Experimental Protocols

Protocol 1: In Situ ATR-IR Setup for Microbial Biofilm Growth Monitoring Objective: To observe the initial adhesion and growth of electroactive bacteria (e.g., Geobacter sulfurreducens) on an electrode in real-time.

- IRE/Electrode Preparation: Sputter-coat a 50 nm gold film onto a trapezoidal ZnSe ATR crystal. Clean with ethanol, DI water, and oxygen plasma for 10 minutes.

- Flow Cell Assembly: Assemble a custom electrochemical ATR flow cell, ensuring the Au-coated crystal forms the bottom, sealed working electrode compartment. Integrate Ag/AgCl reference and Pt counter electrodes.

- Baseline Acquisition: Flow sterile, deoxygenated growth medium (e.g., freshwater medium with acetate) at 2 mL/min. Acquire a single-beam background spectrum (512 scans, 4 cm⁻¹) under potentiostatic control at the desired growth potential (e.g., +0.2 V vs. Ag/AgCl).

- Inoculation & Time-Lapse IR: Switch the inflow to medium containing a mid-log phase microbial culture (~10⁸ cells/mL). Maintain flow and potential.

- Spectral Acquisition: Collect interferograms every 15-30 minutes for 24-72 hours. Process spectra (Happ-Genzel apodization, Mertz phase correction) and convert to absorbance relative to the initial background.

- Data Analysis: Plot the time-dependent increase in Amide I/II (protein) and polysaccharide bands to quantify biofilm development.

Protocol 2: Tracking Microbial Electrocatalysis via Mediator or Product Formation Objective: To spectroscopically identify redox-active mediators and catalytic products during microbial extracellular electron transfer.

- Pre-grown Biofilm: Use Protocol 1 to grow a mature biofilm on the ATR electrode.

- Substrate Switch Experiment: Establish a stable baseline in substrate-free medium. At t=0, switch inflow to medium containing the primary substrate (e.g., 10 mM acetate for Geobacter, or lactate for Shewanella).

- Potential Step: Simultaneously with substrate addition, step the electrode potential to a suitable reductive or oxidative overpotential.

- Rapid-Scan IR: Acquire spectra at a higher frequency (e.g., every 1-2 min, 64 scans). Monitor for:

- Appearance of ν(COO⁻) bands from substrate consumption/products.

- Changes in the 1100-1200 cm⁻¹ region for flavin mediators.

- Redox-state sensitive shifts in cytochromes (subtle, requires deconvolution).

- Quantification: Create calibration curves for key metabolites (e.g., acetate, formate) in the flow cell to convert absorbance changes to concentration fluxes.

Visualization: Diagrams

Title: Electron Transfer Pathways in Microbial Electrocatalysis

Title: Workflow for In Situ ATR-IR Biofilm Electrochemistry

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for ATR-IR of Microbial Electrochemistry

| Item | Function/Explanation |

|---|---|

| ZnSe or Ge ATR Crystal | Internal Reflection Element (IRE). ZnSe is less toxic and suitable for aqueous media; Ge provides higher surface sensitivity due to shorter evanescent depth. |

| Gold Sputtering Target | For depositing a thin, conductive, and IR-transparent working electrode film onto the IRE. |