X-Ray Diffraction (XRD) for Catalyst Analysis: Principles, Applications, and Optimization for Materials Research

This comprehensive guide explores the fundamental principles and advanced applications of X-ray Diffraction (XRD) in catalyst characterization.

X-Ray Diffraction (XRD) for Catalyst Analysis: Principles, Applications, and Optimization for Materials Research

Abstract

This comprehensive guide explores the fundamental principles and advanced applications of X-ray Diffraction (XRD) in catalyst characterization. Targeted at researchers and scientists in catalysis and materials development, the article systematically covers the foundational physics of XRD, practical methodologies for catalyst analysis, troubleshooting common experimental challenges, and validation through complementary techniques. Readers will gain actionable insights for extracting critical structural information—including phase identification, crystallite size, strain, and active site dispersion—to accelerate catalyst design and optimization in fields ranging from chemical synthesis to energy conversion.

Unveiling the Crystal Structure: Core Principles of XRD for Catalyst Characterization

X-ray diffraction (XRD) is a cornerstone analytical technique in catalyst research. The understanding of Bragg's Law is fundamental to interpreting XRD data, which provides critical information on catalyst phase composition, crystallite size, strain, and active site structure. This whitepaper details the essential physics of X-ray scattering from crystalline lattices and its direct application to characterizing heterogeneous and homogeneous catalysts, crucial for advancements in energy, chemical synthesis, and pharmaceutical development.

Fundamental Interaction: Elastic Scattering and Constructive Interference

When a monochromatic X-ray beam strikes a crystalline solid, the electrons of the atoms scatter the X-rays elastically (without energy loss). In a crystal, these scattered waves interfere with each other. Constructive interference occurs only when the path difference between waves reflected from successive crystallographic planes is an integer multiple of the X-ray wavelength, λ. This condition is formalized by Bragg's Law.

Mathematical Formulation of Bragg's Law

Bragg's Law is expressed as: nλ = 2d sin θ Where:

- n = an integer (the order of reflection)

- λ = wavelength of the incident X-ray beam (typically in Ångströms, Å)

- d = interplanar spacing (in Å) between crystal lattice planes (hkl)

- θ = Bragg angle (the angle between the incident beam and the scattering planes)

This equation defines the precise angular positions (2θ) where diffraction peaks are observed in an XRD pattern. For catalyst analysis, shifts in these peak positions indicate lattice strain or changes in unit cell parameters, while peak broadening relates to crystallite size and microstrain.

| Source/Target | Characteristic Wavelength (Kα1, Å) | Typical Voltage (kV) | Primary Application in Catalysis |

|---|---|---|---|

| Copper (Cu) | 1.5406 | 40 | High-resolution phase ID of most inorganic catalysts |

| Cobalt (Co) | 1.7889 | 35 | Reducing fluorescence for Fe-rich catalysts (e.g., F-T synthesis) |

| Molybdenum (Mo) | 0.7093 | 50 | High-d spacing resolution (e.g., MOFs, layered materials) |

| Synchrotron | Tunable (~0.1 - 2+) | High Energy | Operando studies, anomalous scattering, ultra-fast kinetics |

Derivation and Geometric Interpretation

The path difference between two parallel X-rays scattering from two adjacent crystal planes is AB + BC. For constructive interference, AB + BC = nλ. Geometry shows AB = BC = d sin θ. Therefore, 2d sin θ = nλ. The "reflection" is best understood as a diffraction event from a family of planes with specific Miller indices (hkl).

The Reciprocal Lattice and Ewald Sphere Construction

A more powerful conceptualization uses the reciprocal lattice, where each set of real-space planes (hkl) is represented by a point at a distance 1/dₕₖₗ from the origin. The Ewald sphere, with radius 1/λ, visualizes the Bragg condition: diffraction occurs when a reciprocal lattice point intersects the sphere's surface.

Experimental Protocol: Powder XRD for Catalyst Characterization

Objective: Identify crystalline phases and estimate crystallite size in a solid catalyst sample. Method: Bragg-Brentano (θ/2θ) parafocusing geometry.

- Sample Preparation: Grind ~50-100 mg of catalyst to a fine, homogeneous powder (<10 µm). Pack uniformly into a flat-sample holder (e.g., Si zero-background) to minimize preferred orientation.

- Instrument Setup: Align a diffractometer with Cu Kα radiation (λ=1.5406 Å), Ni filter, and a scintillation or PSD detector. Typical settings: 40 kV, 40 mA.

- Data Acquisition: Scan 2θ range from 5° to 80° (or higher) with a step size of 0.01-0.02° and counting time of 1-2 seconds per step. For operando studies, a reaction chamber with gas flow and heating is integrated.

- Data Analysis:

- Phase Identification: Match peak positions (2θ) and intensities (I) to reference patterns in the ICDD or COD database.

- Crystallite Size Estimation: Apply the Scherrer equation to the full width at half maximum (β) of a representative peak: τ = Kλ / (β cos θ), where τ is crystallite size, K is the shape factor (~0.9).

- Lattice Parameter Refinement: Use whole-pattern fitting (Rietveld refinement) for precise determination of d-spacings and unit cell metrics.

Table 2: Quantitative Data from a Model Catalysis XRD Experiment

| Analyzed Parameter | Measured Value (Example: Pt/Al₂O₃ Catalyst) | Derived Information |

|---|---|---|

| Primary Phase (Al₂O₃) | γ-Al₂O� phase (ICDD 00-010-0425) | Support structure and stability |

| Active Phase (Pt) | 2θ = 39.8° (Pt (111)) | Confirmation of metallic Pt presence |

| Pt Crystallite Size (Scherrer) | β(111) = 0.5°, τ ≈ 18 nm | Dispersion estimation |

| Lattice Parameter (a, Pt) | a = 3.923 Å (from Rietveld) | Comparison to bulk Pt (3.924 Å) indicates strain |

| Minor Phase Detection Limit | ~1-2 wt% | Presence of potential impurities |

The Scientist's Toolkit: Essential Reagents & Materials for XRD Catalyst Analysis

| Item | Function & Relevance |

|---|---|

| Si Zero-Background Holder | Single-crystal silicon slice cut off-axis. Provides a flat, non-diffracting surface for minute sample amounts, crucial for high-sensitivity catalyst studies. |

| Micronizing Agate Mortar & Pestle | Ensures homogeneous, isotropic powder to reduce particle statistics errors and preferred orientation in the sample. |

| LaB₆ (NIST SRM 660c) | Standard Reference Material for instrumental line broadening correction. Essential for accurate crystallite size/strain analysis. |

| In-situ/Operando Reaction Cell | High-temperature, gas-flow cell allowing XRD data collection under reactive atmospheres (e.g., H₂, O₂). Links structure to function. |

| Capillary Tube (Glass/Quartz) | For samples sensitive to air or requiring spinning to improve particle statistics in Debye-Scherrer geometry. |

| Kapton Polyimide Film | Low-scattering, heat-resistant film used to seal sample holders for in-situ experiments or contain sensitive materials. |

| Synchrotron Beamtime | Access to high-intensity, tunable X-ray source. Enables time-resolved, anomalous, or high-resolution studies of working catalysts. |

Within the context of a thesis on the Basic principles of X-ray diffraction (XRD) for catalyst analysis research, the diffractogram is the fundamental dataset. It is a plot of diffracted X-ray intensity versus the diffraction angle (2θ). For researchers and scientists in catalysis and related fields, decoding the three primary features of a diffractogram—peak position, intensity, and width—is essential for extracting critical structural and microstructural information about catalyst materials.

Core Parameters: Interpretation and Quantitative Data

Each parameter in an XRD peak provides distinct, complementary information about the catalyst's structure.

Table 1: The Triad of Diffractogram Peak Parameters

| Parameter | Governed By | Primary Information | Key Formula/Relationship |

|---|---|---|---|

| Peak Position (2θ) | Interplanar spacing (d) | Crystal structure, phase identity, lattice parameters, unit cell geometry. | Bragg's Law: nλ = 2d sinθ |

| Peak Intensity (I) | Atomic arrangement within the unit cell. | Phase composition, atomic scattering factors, texture, preferred orientation. | Structure Factor: Fhkl = Σ fn exp[2πi(hxn+kyn+lzn)] |

| Peak Width (β) | Instrumental & sample effects. | Crystallite size, microstrain, defect density, sample condition. | Scherrer Equation: τ = Kλ / (β cosθ) (Size broadening) |

Table 2: Quantitative Implications for Catalyst Analysis

| Peak Feature | Typical Range/Value | Catalyst-Specific Insight | Example for Al2O3-supported Catalyst |

|---|---|---|---|

| 2θ Shift | ±0.01° to 0.5° | Lattice strain from metal-support interaction, doping, thermal expansion. | Shift in Pt (111) peak indicates alloying or strong metal-support interaction (SMSI). |

| Relative Intensity Change | Variable ratio to reference. | Changes in active phase concentration, amorphization, or textural evolution. | Decrease in NiO peak intensity after reduction to metallic Ni. |

| Peak Broadening (β) | 0.02° to >2° (FWHM) | Active particle size (via Scherrer), degradation via sintering/amorphization. | β of Pt (111) used with Scherrer equation gives average nanoparticle size (~2-10 nm). |

Experimental Protocols for Reliable Diffractogram Acquisition

A robust XRD analysis for catalysts requires meticulous sample preparation and measurement protocols.

Protocol 1: Sample Preparation for Supported Catalyst Powders

- Grinding: Lightly grind the catalyst powder in an agate mortar to reduce preferred orientation, but avoid excessive force that may induce strain or change morphology.

- Loading: Use a flat, zero-background silicon sample holder. Fill the cavity and gently level the surface with a glass slide or razor blade. Do not press, to minimize texture.

- Smoothing: Use a glass slide to create a perfectly smooth, level surface flush with the holder rim to ensure accurate axial geometry.

Protocol 2: Standard Data Collection Parameters (Bragg-Brentano Geometry)

- Radiation: Cu Kα (λ = 1.5418 Å), with Ni filter or Kβ monochromator.

- Voltage/Current: 40 kV, 40 mA.

- Scan Range (2θ): 5° to 80° or higher, depending on lowest d-spacing of interest.

- Step Size: 0.02°.

- Time per Step: 1-2 seconds for routine analysis; longer for high-resolution or weakly scattering samples.

- Divergence Slits: Use variable or automatic divergence slits to maintain constant illuminated area.

Protocol 3: In Situ XRD for Catalyst Activation/Reaction Studies

- Mount catalyst powder in a high-temperature in situ reaction chamber with gas flow capabilities (e.g., Anton Paar XRK, or similar).

- Align chamber carefully to maintain focus on the sample surface.

- Flow desired gas (H2 for reduction, O2 for oxidation, reaction mixture).

- Heat to target temperature (e.g., 500°C for reduction) at a controlled ramp rate (e.g., 5°C/min).

- Acquire sequential diffractograms at set temperature intervals or isothermally over time to monitor phase changes (e.g., oxide → metal).

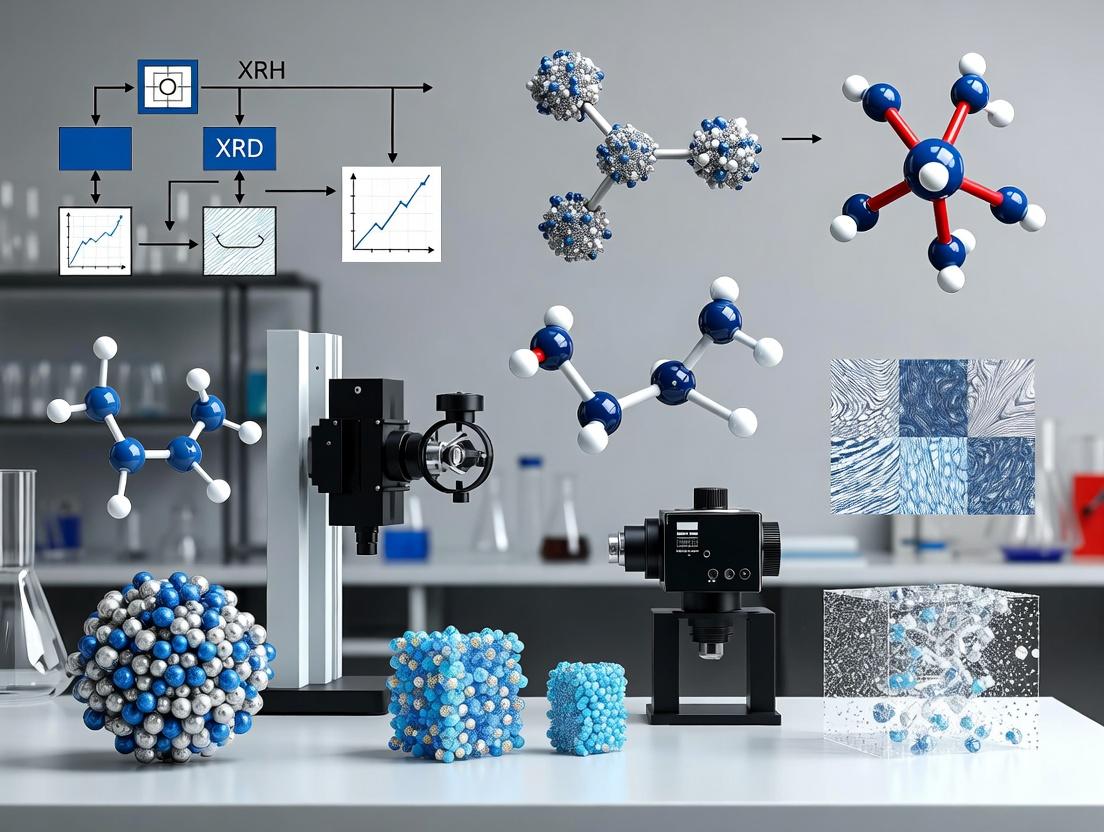

Visualizing the XRD Workflow and Relationships

XRD Analysis Workflow for Catalysts

Peak Parameters Link to Physical Properties

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for XRD Catalyst Analysis

| Item | Function/Description | Example Product/Catalog |

|---|---|---|

| Zero-Background Holder | Silicon single crystal cut off-axis to eliminate Bragg peaks, providing a flat, featureless background for weak catalyst signals. | MTI Corporation Si510, or equivalent. |

| Micro-Mortar and Pestle | Agate or fused quartz for gentle, contaminant-free grinding to minimize preferred orientation. | Agate mortar & pestle, 50mm diameter. |

| In Situ Reaction Chamber | High-temperature stage with gas flow and Be/X-ray transparent windows for real-time phase analysis under reactive conditions. | Anton Paar XRK 900, Rigaku In Situ Cell. |

| Standard Reference Material | Certified powder (e.g., NIST Si 640c, LaB6) for instrumental line broadening calibration and 2θ alignment. | NIST SRM 660c (LaB6). |

| Kα₂ Stripping Software | Essential for accurate peak position and width determination, especially for overlapping peaks in complex catalyst mixtures. | Integrated in MDI Jade, HighScore Plus, or PDXL. |

| Rietveld Refinement Software | Advanced quantitative phase analysis (QPA), lattice parameter refinement, and crystallite size/strain modeling from the entire pattern. | TOPAS, GSAS-II, FullProf Suite. |

1. Introduction within the Thesis Context

The analysis of solid catalysts demands precise knowledge of their structural characteristics, which directly govern their activity, selectivity, and stability. Within the broader thesis on the Basic principles of X-ray diffraction (XRD) for catalyst analysis research, this guide details the extraction of three fundamental parameters from XRD data: Phase identification, Crystallinity, and Lattice Parameters. XRD serves as the foundational, non-destructive technique that probes the long-range order of crystalline materials, providing a structural fingerprint essential for rational catalyst design and optimization.

2. Core Structural Parameters Revealed by XRD

2.1 Phase Identification: The Primary Fingerprint The most direct application of XRD is phase identification via Bragg's law (nλ = 2d sinθ). The position of diffraction peaks (2θ) is unique to the atomic arrangement within a crystal lattice.

- Protocol: The experimental XRD pattern of the catalyst is compared to reference patterns in the International Centre for Diffraction Data (ICDD) Powder Diffraction File (PDF) database. Modern software uses search-match algorithms for this purpose.

- Critical Interpretation: Confirms the synthesis of the intended phase (e.g., CeO₂ fluorite structure) and detects unwanted crystalline impurities or mixed phases (e.g., γ-Al₂O₃ vs. α-Al₂O³).

Table 1: Common Catalyst Phases and Characteristic Peaks (Cu Kα radiation, λ=1.5406 Å)

| Catalyst Phase | Crystal System | Miller Indices (hkl) | Approximate 2θ (°) | d-spacing (Å) |

|---|---|---|---|---|

| Pt (Platinum) | Cubic (FCC) | (111) | ~39.8 | ~2.27 |

| γ-Al₂O₃ | Cubic | (400) | ~45.8 | ~1.98 |

| TiO₂ (Anatase) | Tetragonal | (101) | ~25.3 | ~3.52 |

| Zeolite Y (FAU) | Cubic | (533) | ~23.7 | ~3.75 |

| CeO₂ | Cubic (FCC) | (111) | ~28.6 | ~3.12 |

2.2 Crystallinity: Degree of Structural Order Crystallinity quantifies the fraction of ordered crystalline material versus amorphous content. It influences surface reactivity and stability.

- Protocol (Peak Area Integration): A known weight of an internal crystalline standard (e.g., corundum, NIST SRM 676a) is mixed with the catalyst sample. The crystallinity is calculated from the ratio of the integrated area under all crystalline peaks of the sample to the total area under the pattern (crystalline + amorphous background).

- Qualitative Assessment: Broad, low-intensity peaks suggest small crystallite sizes and/or high defect density, often desirable in catalysis.

Table 2: Crystallinity Assessment for Different Catalyst Preparations

| Catalyst Sample | Preparation Method | FWHM of Main Peak (°) | Relative Crystallinity (%)* |

|---|---|---|---|

| TiO₂ (A) | Sol-Gel (400°C calc.) | 0.8 | 95 |

| TiO₂ (B) | Sol-Gel (300°C calc.) | 1.5 | 75 |

| TiO₂ (C) | Commercial P25 | 0.6 (Anatase) | >99 |

*Calculated against a well-crystallized standard.

2.3 Lattice Parameters and Strain Precise determination of unit cell dimensions (lattice parameters a, b, c) can reveal doping, solid solution formation, or strain.

- Protocol (Rietveld Refinement): A full-pattern fitting method. A structural model is adjusted to minimize the difference between the observed and calculated patterns. Key refined parameters include lattice constants, atomic positions, and thermal factors.

- Key Insight: Lattice contraction or expansion indicates successful incorporation of dopant atoms (e.g., Zr⁴⁺ in CeO₂ leading to a smaller lattice parameter).

3. Experimental Protocols for Catalyst XRD Analysis

3.1 Sample Preparation Protocol

- Grinding: Use an agate mortar and pestle to homogenize and reduce particle size to <10 μm to minimize preferred orientation.

- Mounting: For powder samples, use a low-background silicon or quartz sample holder. Fill the cavity and level the surface with a glass slide.

- Thin-Film Catalysts: Mount as-is on a suitable holder. Grazing-incidence XRD (GI-XRD) may be required for surface-sensitive analysis.

3.2 Data Collection Parameters (Typical)

- Radiation: Cu Kα (λ = 1.5406 Å) or Mo Kα for lighter elements.

- Voltage/Current: 40 kV / 40 mA.

- Scan Range: 5° to 80° or 100° (2θ).

- Step Size: 0.02°.

- Scan Speed: 1-2° per minute for high-resolution patterns.

3.3 Data Analysis Workflow

Diagram Title: XRD Data Analysis Workflow for Catalysts

4. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for XRD Catalyst Analysis

| Item | Function & Explanation |

|---|---|

| Agate Mortar & Pestle | For contamination-free grinding of catalyst powders to ensure random orientation and reduce particle size effects. |

| Low-Background Silicon Wafer Holder | Sample holder made from single-crystal silicon, producing minimal parasitic diffraction signals, crucial for detecting weak catalyst peaks. |

| NIST SRM 676a (Corundum) | Crystalline standard reference material for quantitative determination of catalyst crystallinity via the internal standard method. |

| LaB₆ (NIST SRM 660c) | Line position and shape standard for instrumental broadening correction, essential for accurate crystallite size analysis. |

| ICDD Powder Diffraction File (PDF) Database | Digital library of reference patterns for phase identification; the definitive resource for matching catalyst diffraction data. |

| Rietveld Refinement Software (e.g., GSAS, TOPAS, MAUD) | Advanced computational tools for full-pattern fitting to extract precise lattice parameters, phase fractions, and microstructural data. |

5. Advanced Correlation: From XRD Parameters to Catalytic Properties

The true power of XRD in catalysis lies in correlating structural parameters with performance metrics (activity, selectivity).

Diagram Title: Linking XRD Parameters to Catalytic Properties

6. Conclusion

XRD is an indispensable tool in the catalyst researcher's arsenal, providing unambiguous, quantitative data on phase composition, structural order, and nanoscale dimensions. Mastery of its principles—from sample preparation to advanced Rietveld analysis—enables the rational design of catalysts by establishing critical structure-property relationships. This foundational knowledge forms a core pillar of the broader thesis on XRD for catalyst analysis, guiding the interpretation of data that ultimately drives innovation in catalysis research and development.

X-ray diffraction (XRD) is a foundational technique in catalyst research, providing indispensable information on crystalline phase composition, structure, and stability. The core principle hinges on Bragg's Law (nλ = 2d sinθ), where diffraction peaks are generated by the constructive interference of X-rays scattered from crystalline planes. For catalyst scientists, identifying the specific phases present—be it active components, supports (e.g., γ-Al₂O₃, zeolites), or undesired by-products—is paramount. This identification is achieved by comparing the measured diffraction pattern (the catalyst's "fingerprint") against a library of known standards, primarily the International Centre for Diffraction Data (ICDD) Powder Diffraction File (PDF). This guide details the technical workflow for definitive phase identification, a critical step in rational catalyst design and characterization.

The Phase Identification Workflow: From Pattern to PDF Match

The process transforms raw detector data into confirmed material phases.

Diagram: XRD Phase Identification Workflow for Catalysts

Key Experimental Protocols for Catalyst XRD Analysis

Protocol 1: Sample Preparation for Catalysts

- Grinding: For powder catalysts, gently grind the sample in an agate mortar and pestle to a fine, uniform particle size (<10 µm) to minimize preferred orientation and ensure a statistically random distribution of crystallites.

- Mounting: For loose powder, use a low-background silicon or quartz sample holder. Fill the cavity and level with a glass slide, avoiding pressing to prevent texture.

- In-situ Cells: For operando or in-situ studies, mount catalyst within a dedicated environmental cell (e.g., capillary, hot-stage) compatible with the diffractometer.

Protocol 2: Data Collection Parameters (Typical Bragg-Brentano Geometry)

- X-ray Source: Cu Kα radiation (λ = 1.5418 Å), generated at 40 kV, 40 mA.

- Scan Range: 5° to 80° or 100° 2θ for broad coverage.

- Step Size: 0.01° to 0.02° 2θ.

- Time per Step: 0.5 to 2 seconds, depending on catalyst scattering power.

- Divergence Slits: Use variable or fixed slits (e.g., 1°) to optimize intensity and resolution.

Protocol 3: Database Search/Match Procedure

- Import the processed diffraction pattern (as a list of d-I values) into the XRD software (e.g., JADE, HighScore Plus, PDXL).

- Initiate the "Search/Match" function against a selected subset (e.g., "Inorganics") of the ICDD PDF-4+ or PDF-2 database.

- Apply filters relevant to catalysis: Elements Present (e.g., Ni, Co, Mo, Al, Si), Catalyst Type (e.g., "Oxides," "Sulfides," "Zeolites").

- The software calculates a Figure-of-Merit (FOM) for each candidate phase (e.g., FOM = 1 for perfect match; common metrics include ( F_N = 1/|Δ2θ| )).

- Manually inspect top matches: compare peak positions (primary), relative intensities (secondary), and peak shapes. Allow for minor shifts due to strain, doping, or thermal expansion in catalysts.

Quantitative Data from ICDD PDF Entries for Catalyst Phases

Table 1: Key Data Fields in an ICDD PDF Entry for Catalyst Characterization

| Data Field | Description | Example for a Catalytic Material (PDF #00-010-0425, Gamma-Alumina) |

|---|---|---|

| PDF Number | Unique identifier for the entry. | 00-010-0425 |

| Chemical Formula | Formula of the phase. | Al₂O₃ |

| Compound Name | Common or IUPAC name. | Gamma Aluminum Oxide |

| Crystal System | Symmetry classification. | Cubic |

| Space Group | Symmetry descriptor. | F d -3 m |

| a, b, c (Å) | Lattice parameters. | a = 7.900 Å |

| α, β, γ (°) | Lattice angles. | α = β = γ = 90° |

| Reference Intensity Ratio (RIR) | I/I_c value for quantitation. | I/I_c = 1.50 (Corundum Std) |

| d-spacings & Intensities | List of the 8-20 strongest peaks (d in Å, I/I₁). | d: 1.98 (I=100%), 2.39 (55%), 1.40 (45%)... |

Table 2: Comparison of Common Catalyst Support/Oxide Phases via PDF Data

| Phase (PDF #) | Primary d-spacings (Å) | Key Application in Catalysis | Distinguishing XRD Feature |

|---|---|---|---|

| γ-Al₂O₃ (00-010-0425) | 1.98, 2.39, 1.40 | Common high-surface-area support. | Broad, asymmetric peaks due to defective spinel structure. |

| α-Al₂O₃ (Corundum) (00-046-1212) | 2.55, 2.38, 1.60 | Low-surface-area support, abrasive. | Very sharp, intense peaks; stable high-temperature phase. |

| Anatase TiO₂ (00-021-1272) | 3.52, 1.89, 2.38 | Photo-catalyst, support. | Strongest peak at ~25.3° 2θ (Cu Kα). |

| Zeolite Y (FAU) (00-043-0168) | 14.24, 8.75, 5.68 | Acid catalyst, cracking. | Very low-angle peak (<10° 2θ) from superstructure. |

| Cerium(IV) Oxide (00-043-1002) | 3.12, 2.71, 1.91 | Oxygen storage component (automotive 3-way cat.). | Characteristic doublet near 56° 2θ. |

The Scientist's Toolkit: Essential Research Reagent Solutions & Materials

Table 3: Key Materials for XRD Analysis of Catalysts

| Item | Function in Catalyst XRD Analysis |

|---|---|

| ICDD PDF-4+ Database | The comprehensive digital library of reference diffraction patterns for search/match identification. |

| High-Purity Si (NIST SRM 640e) | Certified standard for instrument alignment, zero error, and line profile/shape calibration. |

| α-Al₂O₃ (Corundum, NIST SRM 676a) | Certified standard for quantitative analysis (RIR determination) and intensity calibration. |

| Low-Background Sample Holders | Made of single-crystal silicon or quartz; minimize parasitic scattering for weak catalyst signals. |

| Agate Mortar & Pestle | For obtaining a fine, homogeneous, and non-oriented powder sample. |

| In-situ/Operando Reaction Cell | Allows XRD data collection while exposing catalyst to controlled gas/vapor atmospheres and temperature. |

| Rietveld Refinement Software | (e.g., TOPAS, GSAS-II) for full-pattern quantitative analysis, structure refinement, and microstructural analysis of catalysts. |

| Microscope Slides or Glassy Carbon | For smearing slurry-based catalyst samples (e.g., washcoats) to form a flat, thin layer. |

Advanced Considerations: From Identification to Quantification

Definitive qualitative identification is the prerequisite for quantitative analysis. The Reference Intensity Ratio (RIR) value listed in many PDF entries enables semi-quantitative phase abundance estimates using the principle of direct comparison. For accurate quantification in complex, multiphase catalysts (e.g., CoMoS on γ-Al₂O₃), Rietveld refinement is the preferred method. This full-pattern fitting technique models the entire diffraction profile, accounting for overlapping peaks, to determine weight fractions, crystallite size (via Scherrer analysis), and microstrain.

Diagram: Relationship Between XRD Analysis Levels

In conclusion, mastery of the ICDD/PDF database search-and-match process is non-negotiable for the catalyst researcher. It transforms the fundamental XRD pattern into a definitive catalog of crystalline phases—the catalyst's fingerprint. This identification forms the bedrock upon which advanced quantitative and structural analysis is built, directly linking catalyst synthesis and performance to its solid-state chemistry.

X-ray diffraction (XRD) is a cornerstone technique in catalyst research, providing indispensable information on phase composition, crystallinity, and structure. While basic XRD analysis identifies phases via pattern matching ("fingerprinting"), it offers limited quantitative insight. In catalyst studies, knowing the precise weight fraction of active phases, supports, and impurities is critical for understanding performance, stability, and structure-property relationships. Rietveld refinement transcends simple pattern matching by fitting a complete calculated diffraction pattern to the observed data using a structural model. This powerful method allows for the accurate quantification of multiple crystalline phases, even in complex multiphase catalyst systems, and simultaneously refines structural parameters such as lattice constants, atomic positions, and crystallite size/strain.

Core Principles of the Rietveld Method

The Rietveld method minimizes the difference between the observed powder diffraction profile (Yobs) and a calculated profile (Ycalc) at every step 2θi. The calculated pattern is generated from crystal structure models, incorporating:

- Crystallographic Model: Space group, atomic coordinates, site occupancies, thermal displacement parameters.

- Profile Function: Describes the shape of Bragg peaks (e.g., pseudo-Voigt). Parameters include peak width and asymmetry.

- Background Function: A polynomial or other function to model the non-Bragg-scattering background.

The minimization is performed on a least-squares residual, typically the weighted-profile R-factor (Rwp). The key quantitative output for catalyst analysis is the scale factor for each phase, which is directly related to its weight fraction in the mixture, adjusted for phase-specific mass absorption coefficients.

Detailed Protocol for Rietveld Refinement of a Catalyst Sample

Objective: To determine the quantitative phase composition and crystallite size of a spent catalyst containing γ-Al2O3 (support), NiO (active phase), and NiAl2O4 (deactivation product).

Materials & Instrumentation:

- Sample: Finely ground, homogeneous catalyst powder (~200 mg).

- Standard: NIST SRM 674b (CeO2) for instrumental broadening determination.

- Instrument: Bragg-Brentano geometry lab XRD with Cu Kα radiation (λ = 1.5418 Å), Ni filter, solid-state detector.

- Software: HighScore Plus, FullProf Suite, or GSAS-II.

Procedure:

- Data Collection:

- Mount powder in a shallow cavity holder; level surface without preferred orientation.

- Scan range: 10° to 120° 2θ.

- Step size: 0.013° 2θ.

- Counting time: 2-5 seconds per step to ensure high statistics (>10,000 counts for highest peaks).

Data Preparation:

- Import raw data. Apply Kα2 stripping if not done automatically.

- Define a background polynomial (typically 5th to 8th order) for initial subtraction.

Initialization:

- Input crystal structure models (CIF files) for γ-Al2O3 (Fd-3m), NiO (Fm-3m), and NiAl2O4 (Fd-3m).

- Set initial scale factors, zero-point error correction, and unit cell parameters from literature.

- Determine instrumental resolution function from the standard CeO2 pattern.

Sequential Refinement Strategy (Critical):

- Step 1: Refine only the background function.

- Step 2: Refine the zero-point error.

- Step 3: Refine the scale factors for all phases.

- Step 4: Refine lattice parameters for each phase sequentially.

- Step 5: Refine profile parameters (peak width, shape). Use the Caglioti equation parameters (U, V, W) and Lorentzian crystallite size/strain terms.

- Step 6: Refine atomic parameters (initially only isotropic thermal factors, Biso

- Iterate steps 3-6, monitoring the R-factors. Never refine all parameters at once initially.

Convergence & Validation:

- Refinement is complete when parameter shifts are less than their estimated standard deviations.

- Assess fit quality via R-factors and the visual agreement of calculated and observed patterns.

- The final weight fraction (Wp) for phase p is derived from its refined scale factor (Sp), the refined unit cell volume (Vp), the number of formula units per cell (Zp), and the formula mass (Mp), corrected for absorption.

Table 1: Typical Refinement Results for a Model Spent Ni/Al2O3 Catalyst

| Phase | Space Group | Weight Fraction (%) | Crystallite Size (nm) | Lattice Parameter (Å) | RB (%)* |

|---|---|---|---|---|---|

| γ-Al2O3 | Fd-3m | 72.5 ± 0.8 | 4.2 ± 0.3 | a = 7.901(2) | 2.1 |

| NiO | Fm-3m | 18.1 ± 0.6 | 22.5 ± 1.1 | a = 4.177(1) | 1.8 |

| NiAl2O4 | Fd-3m | 9.4 ± 0.5 | 8.7 ± 0.8 | a = 8.043(3) | 3.5 |

Overall R-factors: Rwp = 8.7%, Rp = 6.5%, GOF = 1.4

RB: Bragg R-factor for the individual phase fit.

Title: Sequential Rietveld Refinement Workflow

The Scientist's Toolkit: Essential Reagents & Materials

Table 2: Key Research Reagent Solutions for Rietveld-Analyzed Catalyst Studies

| Item | Function & Specification | Notes for Catalyst Research |

|---|---|---|

| Internal Standard | Provides an invariant reference for absolute quantification and checks for instrumental shift. | NIST SRM 676a (α-Al₂O₃) or 640e (Si). Must be inert, crystalline, and have non-overlapping peaks with sample. |

| Micro-Abrasive | For sample grinding to reduce crystallite size and minimize preferred orientation. | Synthetic Ethanol or Isopropanol: Used as a grinding medium for wet milling in an agate mortar. Prevents oxidation/phase change. |

| Sample Holder | Presents a flat, random-oriented powder surface to the X-ray beam. | Zero-Background Silicon Plate or Cavity Mount. Essential for accurate intensity measurement. |

| Reference Materials | Certified pure phases for creating known mixtures to validate the refinement. | Used to prepare standard mixtures (e.g., 50/50 wt% corundum/zincite) to test quantification accuracy. |

| Structure Databases | Sources of initial structural models (CIF files). | Inorganic Crystal Structure Database (ICSD), Crystallography Open Database (COD). The model quality dictates refinement success. |

| Calibration Standard | Characterizes instrumental broadening function. | NIST SRM 674b (CeO₂) or LaB₆. Refined profile parameters are sample-specific but initialized from this. |

Advanced Considerations in Catalyst Analysis

- Amorphous Content: Rietveld quantifies only crystalline phases. The amorphous content (e.g., silica, amorphous carbon in spent catalysts) is determined by adding a known amount of an internal standard (e.g., 20 wt% ZnO) and comparing the observed vs. expected standard concentration.

- Microstructural Analysis: Anisotropic peak broadening, modeled during refinement, provides crystallite size (Scherrer equation) and microstrain data for each phase—critical for correlating catalyst synthesis with active site dispersion.

- In Situ/Operando Refinement: Using specialized chambers, time-resolved Rietveld refinement tracks dynamic phase transformations (e.g., reduction of oxide to metal, carbide formation) under reactive gas atmospheres and temperature.

Title: From XRD Pattern to Catalyst Insight via Rietveld

From Powder to Insight: A Step-by-Step Guide to XRD Catalyst Analysis

Sample Preparation Best Practices for Catalytic Powders and Supported Catalysts

Within the broader thesis on Basic principles of X-ray diffraction (XRD) for catalyst analysis research, meticulous sample preparation emerges as the most critical, yet often overlooked, determinant of data quality. For catalytic materials—ranging from bulk catalytic powders to complex supported catalysts on carriers like alumina, silica, or zeolites—improper preparation introduces preferential orientation, particle statistics errors, and micro-absorption effects that fundamentally distort diffraction patterns. This guide details best practices to ensure XRD analysis yields accurate, reproducible structural and phase data essential for rational catalyst design and performance correlation.

Core Principles & Challenges

The primary goal is to present a representative, randomly oriented sample to the X-ray beam to obtain a diffraction pattern where peak intensities accurately reflect the true phase abundance and structure. Key challenges include:

- Preferential Orientation (Texture): Plate- or needle-shaped crystallites align preferentially, drastically altering relative peak intensities. This is acute with layered materials (e.g., MoS₂) or supported catalysts where active phases coat carrier surfaces.

- Particle Statistics: Too few crystallites in the beam lead to "spotty" rings in Debye-Scherrer geometry and unreliable intensity measurements. A sufficient number (>10⁵) is required for smooth powder averaging.

- Micro-Absorption: Significant differences in absorption coefficients between the support and active phase can suppress diffraction from the heavier component.

- Sample Transparency & Irradiated Volume: Inaccurate peak shifts and asymmetry can arise from non-flat sample surfaces or excessive penetration depth in low-absorbing materials.

Detailed Methodologies & Protocols

General Preparation Workflow for Powder Samples

Diagram Title: General Powder Sample Prep Workflow

Protocol A: Side-Loading (Zero-Preferred Orientation) Method

This is the gold standard for minimizing texture.

- Materials: Sample holder (aluminum or glass), frosted glass slide, blade.

- Procedure: a. Place the sample holder on a flat, stable surface. b. Using a spatula, pour the finely ground and sieved powder into the cavity until slightly overfilled. c. Hold the frosted side of a glass slide against the powder and the front edges of the holder. d. Gently slide the glass across the holder, shearing the powder and filling the cavity. The frictional force promotes random orientation. e. Remove excess powder by a final smooth pass with the slide. The surface should be flush with the holder. f. Do not press or compact the powder from the top.

Protocol B: Preparation of Supported Catalysts for In-Situ/Operando Cells

For studies requiring controlled atmospheres and temperatures.

- Materials: In-situ cell, fine-mesh quartz wool, micro-spatula, flat die (optional).

- Procedure: a. Lightly pack a thin layer of quartz wool into the sample well of the cell to act as a porous support. b. Sprinkle a uniform, thin layer of catalyst powder over the quartz wool. The ideal quantity should achieve an absorbance (μthickness) ~1 for optimal intensity. c. For weakly cohesive powders, a shallow *gentle press with a flat die can be used to create a stable bed, but avoid forming a dense pellet. d. Ensure the sample surface is flat and level with the cell's reference plane to maintain correct focusing geometry.

Protocol C: Making a Thin Film for Highly Absorbing Catalysts

To mitigate micro-absorption and transparency.

- Materials: Low-background Si wafer, ethanol, pipette.

- Procedure: a. Finely grind the catalyst. b. Create a dilute slurry by dispersing a small amount of powder in ethanol (or acetone). c. Pipette a few drops of the slurry onto the center of the silicon wafer. d. Allow the solvent to evaporate slowly, leaving a thin, discontinuous film of catalyst particles. The goal is a sub-micron layer, not full coverage.

Quantitative Data & Key Parameters

Table 1: Optimal Sample Preparation Parameters for Different Catalyst Types

| Catalyst Type | Recommended Particle Size | Preferred Mounting Method | Critical Consideration | Typical Sample Amount |

|---|---|---|---|---|

| Bulk Oxide Catalyst (e.g., V₂O₅) | < 45 µm (325 mesh) | Side-Loading | Avoid over-grinding to prevent amorphization. | 200 - 500 mg |

| Supported Metal (e.g., Ni/Al₂O₃) | < 75 µm (200 mesh) | Side-Loading or Thin Film | Micro-absorption between metal & support; use thin film for high metal loading. | 300 - 600 mg |

| Layered Material (e.g., MoS₂) | < 30 µm (500 mesh) | Spray-Dried onto Wafer | Extreme preferential orientation; spray drying in solvent is optimal. | For thin film: < 1 mg |

| Zeolite / Molecular Sieve | < 50 µm (300 mesh) | Top-Press (Very Light) | Hydration state must be controlled (seal if needed). | 150 - 300 mg |

| Carbon-Supported Catalyst | < 100 µm (140 mesh) | Thin Film on Wafer or Capillary | Extremely low scattering; avoid overwhelming background. | For thin film: < 2 mg |

Table 2: Troubleshooting Common XRD Sample Preparation Artifacts

| Observed Artifact | Likely Cause | Corrective Action |

|---|---|---|

| Systematic peak shift to lower 2θ | Sample height error (too low) | Ensure sample surface is flush with holder reference plane. |

| Asymmetric peak broadening (tail to low 2θ) | Sample transparency in flat plate geometry | Use thinner sample, add an absorbing layer, or use a capillary. |

| Intense (00l) peaks in layered materials | Severe preferential orientation | Switch to spray-drying or side-loading with minimal shear. |

| "Spotty" or discontinuous Debye rings | Insufficient particle statistics | Grind finer, use more sample, or rotate the sample during measurement. |

| Missing or weak peaks from heavy phases | Micro-absorption | Dilute in amorphous matrix (e.g., boron nitride) or prepare as a thin film. |

The Scientist's Toolkit: Essential Research Reagent Solutions & Materials

Table 3: Essential Materials for Catalyst XRD Sample Preparation

| Item | Function / Purpose | Technical Notes |

|---|---|---|

| Agate Mortar & Pestle | For gentle dry grinding to reduce particle size without inducing strain. | Preferred over harder materials (sapphire) to minimize contamination and lattice damage. |

| Micro-Mesh Sieves (325, 400 mesh) | To standardize and control the maximum particle size in the sample. | Essential for ensuring adequate particle statistics. Use ultrasonic cleaning to unclog. |

| Zero-Background Holders (Si wafer cut) | Provides a flat, low-noise mounting surface, especially for thin films. | Si (510) cut eliminates Bragg peaks from the holder itself. |

| Frosted Glass Microscope Slides | Key tool for the side-loading method to induce random orientation. | The frosted surface provides controlled friction to align particles randomly. |

| Amorphous Diluents (Boron Nitride, SiO₂) | To dilute strong absorbers, reduce micro-absorption, and create an internal standard matrix. | Must be phase-pure amorphous to avoid introducing extra diffraction peaks. |

| Capillary Tubes (Glass/Quartz, 0.5-1.0 mm) | For samples sensitive to air/moisture or for superior particle averaging in Debye-Scherrer geometry. | Requires specialized spinner mounts. Ideal for highly absorbing materials. |

| In-Situ/Operando Reaction Cell | Allows sample preparation directly in the measurement environment (gas, temperature, pressure). | Ensure sample bed is thin and uniform for gas flow and X-ray penetration. |

| Flat-Blade Stainless Steel Spatula | For precise transfer and handling of small powder quantities. | Keeps samples contained and minimizes loss. |

Thesis Context: Within the broader framework of Basic Principles of X-ray Diffraction (XRD) for catalyst analysis research, selecting the optimal measurement geometry is paramount for extracting accurate structural and phase information. This guide provides an in-depth comparison of the two predominant geometries.

Core Principles and Geometrical Configurations

XRD analysis of catalysts, which often involve bulk, powdered, or thin-film materials, requires geometry-specific approaches to probe relevant structural features.

Bragg-Brentano (BB) Geometry: Also known as the θ-2θ or parafocusing geometry, this configuration is characterized by symmetric reflection where the X-ray source, sample surface, and detector lie on the circumference of the focusing circle. The incident (θ) and detection (2θ) angles are coupled, scanning while maintaining equal angles between the sample surface and both source and detector. This geometry is optimal for analyzing randomly oriented, polycrystalline bulk powders with infinite thickness (>~10 µm for most materials). It provides high-intensity, high-resolution data from the bulk crystallographic phases.

Grazing Incidence X-ray Diffraction (GIXRD): This geometry employs a very shallow, fixed incident angle (α), typically between 0.5° and 5°, while the detector (2θ) scans. The incident beam is decoupled from the detector motion. The shallow angle confines the X-ray penetration depth to the near-surface region (from a few nanometers to ~100-200 nm), making it exquisitely sensitive to thin films, surface layers, coatings, and the active surfaces of catalysts. It minimizes the signal contribution from the substrate or bulk material.

Diagram 1: Core principles of Bragg-Brentano and GIXRD geometries.

Quantitative Comparison and Selection Criteria

The choice between BB and GIXRD depends on sample characteristics and analytical goals. The following table summarizes the key operational and application parameters.

Table 1: Comparative Analysis of BB and GIXRD Geometries

| Parameter | Bragg-Brentano (θ-2θ) | Grazing Incidence (GIXRD) |

|---|---|---|

| Incident Angle (θ/α) | Varies during scan (θ = 2θ/2) | Fixed, shallow (typically 0.5° - 5°) |

| Beam Penetration Depth | Deep (tens of µm), sample thickness dependent | Shallow (nm to ~200 nm), angle & material dependent |

| Primary Sample Type | Infinite-thickness, randomly oriented powders | Thin films, surface layers, coatings (< ~1 µm) |

| Key Strength | High-intensity, high-resolution bulk phase identification, quantitative phase analysis (QP A) | Surface-specific phase analysis, minimal substrate interference, thin film crystallinity |

| Key Limitation | Surface sensitivity is poor, severe substrate interference for thin films | Lower intensity, peak broadening due to low angle, more complex data analysis |

| Typical Application in Catalysis | Analysis of bulk catalyst powder phase composition (e.g., zeolite framework type, bulk mixed metal oxides) | Analysis of catalyst coatings on monoliths, identification of active surface phases, study of surface modification layers |

| Required Sample Preparation | Standard powder mounting (front-loaded, side-loaded) | Flat, smooth surface is critical; minimal preparation often desired. |

Diagram 2: Decision tree for selecting XRD measurement geometry for catalysts.

Detailed Experimental Protocols

Protocol 1: Bulk Phase Analysis of a Powdered Catalyst using Bragg-Brentano Geometry

- Sample Preparation: Grind approximately 0.5-1.0 g of catalyst powder to a fine, homogeneous consistency (particle size <10 µm). Load into a standard XRD sample holder (e.g., aluminum cavity mount) using the back-pressing or side-loading method to minimize preferred orientation.

- Instrument Setup: Configure the diffractometer in θ-2θ coupled mode. Select a Cu Kα radiation source (λ = 1.5418 Å). Set a divergence slit (e.g., 1/2°) and anti-scatter slit. Install a Ni filter or Kevex detector to attenuate Kβ radiation.

- Measurement Parameters: Set a scan range (2θ) from 5° to 80° or higher, depending on expected phases. Use a step size of 0.02° and a counting time of 1-2 seconds per step. Employ a spinner to rotate the sample during measurement to improve particle statistics.

- Data Analysis: Perform background subtraction and Kα2 stripping. Identify phases by comparing peak positions (d-spacings) and relative intensities with reference patterns from the ICDD PDF database. Use Rietveld refinement for quantitative phase analysis.

Protocol 2: Surface Phase Analysis of a Catalyst Monolith Coating using GIXRD

- Sample Preparation: Ensure the monolith sample has a flat, representative surface. Mount it securely on a zero-background or low-profile silicon sample holder. No powdering is required.

- Instrument Setup: Configure the diffractometer in grazing incidence mode. Align the sample surface carefully in the beam path. Select Cu Kα source. Use parallel-beam optics with a long Soller slit collimator on the incident beam side to produce a well-collimated beam at low angles.

- Incident Angle Optimization: Conduct an incident angle (ω) scan (e.g., 0.2° to 2.0°) on the sample at a fixed 2θ angle corresponding to a strong expected diffraction peak from the coating. Select the optimal ω angle that maximizes the coating signal while minimizing the substrate signal (often 0.5°-1.5°).

- Measurement Parameters: With the optimal ω fixed, perform a coupled 2θ scan from 5° to 80°. Use a step size of 0.02°-0.05° and a longer counting time (3-10 s/step) due to lower diffracted intensity.

- Data Analysis: Analyze data with emphasis on identifying peaks unique to the surface coating. Peaks from the substrate (e.g., cordierite) will be significantly attenuated but may still appear. Modeling of X-ray penetration depth vs. sin(ω) can provide depth-profiling information.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials and Reagents for XRD Catalyst Analysis

| Item | Function in XRD Analysis |

|---|---|

| Zero-Background Holder (e.g., Silicon Single Crystal) | Provides a sample mount with no intrinsic diffraction peaks, essential for analyzing微量 samples or preventing background interference in GIXRD. |

| Standard Reference Material (e.g., NIST SRM 640e Silicon Powder) | Used for instrument calibration (peak position, line shape, resolution) to ensure data accuracy and inter-laboratory comparability. |

| Microtome or Ion Milling System | For preparing extremely flat cross-sections of catalyst pellets or coated monoliths for optimal GIXRD alignment and data quality. |

| Anhydrous Ethanol or Isopropanol | Solvent for slurry-based sample preparation (e.g., for spray-coating catalyst layers onto substrates for GIXRD studies). |

| Collimating Optics (Göbel Mirror, Soller Slits) | Shapes the X-ray beam; critical for producing a parallel beam in GIXRD setups to maintain constant illuminated area and resolution at low angles. |

| High-Throughput Multi-Sample Stage | Enables automated sequential measurement of multiple catalyst variants, essential for rapid screening in research and development. |

| In Situ/Operando Reaction Chamber | A sample environment cell that allows XRD data collection under controlled temperature, pressure, and gas flow to study catalysts under working conditions. Both BB and GIXRD configurations exist. |

Within the broader thesis on the Basic Principles of X-Ray Diffraction (XRD) for Catalyst Analysis Research, this chapter advances from static, ex situ characterization to dynamic, condition-specific analysis. Traditional XRD provides vital structural data—phase identification, crystallite size, lattice parameters—of catalysts before and after reaction. However, this post-mortem analysis often fails to capture the true active phase, metastable intermediates, or structural dynamics under realistic process conditions of temperature, pressure, and reactive gas atmospheres. Operando (from the Latin "working") and In Situ (in place) XRD methodologies bridge this gap by integrating the diffraction measurement with simultaneous reaction monitoring and control, enabling a direct correlation between a catalyst's structure and its performance in real-time. This technical guide details the principles, experimental protocols, and applications of these transformative techniques, framing them as the logical evolution of XRD's role in catalysis research.

Fundamental Principles: FromEx SitutoOperando

The core principle is the acquisition of XRD patterns while the catalyst is subjected to a controlled environment mimicking its real working conditions (e.g., in a flow of reactant gases at elevated temperature). The key distinction lies in the integration of analytical techniques:

- In Situ XRD: Measures the catalyst structure under non-ambient conditions (e.g., in a heated gas flow). It observes structural changes in place.

- Operando XRD: Combines in situ structural measurement (XRD) with simultaneous, quantitative measurement of catalytic activity/selectivity (e.g., by mass spectrometry or gas chromatography). It directly links structure while operating with function.

The experimental challenge is to design a reactor cell that is transparent to X-rays, allows uniform gas/solid contact, maintains precise thermal control, and minimizes diffraction background.

Experimental Protocols and Methodologies

Core Reactor Cell Design

Successful experiments rely on specialized environmental cells. Two primary designs dominate:

A. Capillary Microreactor

- Protocol: A thin-walled (e.g., 0.01 mm wall) glass or quartz capillary (0.5–2 mm diameter) is packed with the catalyst powder. The capillary is mounted on a goniometer head, connected to a gas delivery system via fine tubing, and heated by a hot air blower or resistive heater.

- Advantages: Excellent X-ray transmission, minimal background, fast gas switching, compatibility with laboratory and synchrotron sources.

- Limitations: Limited pressure range (typically <10 bar), potential for temperature gradients along the capillary.

B. Planar Membrane Reactor

- Protocol: A thin layer of catalyst is deposited onto a heated planar substrate (e.g., a silicon wafer with a microfabricated heater) or contained within a pocket sealed by X-ray transparent windows (e.g., polyimide, diamond).

- Advantages: More uniform temperature distribution, suitable for studying coatings or model catalysts (thin films), can integrate with other surface-sensitive techniques.

- Limitations: More complex design, potentially higher background scattering from windows.

Standard Operando Experiment Workflow

The following protocol is typical for studying a solid catalyst during gas-phase reaction:

- Catalyst Loading & Cell Assembly: The catalyst powder is loaded into the chosen reactor cell. The cell is sealed and connected to the gas manifold and analysis lines.

- System Leak Check: The entire gas system is pressurized and checked for leaks prior to heating.

- Pre-Treatment/Activation: The catalyst is heated under a specific gas flow (e.g., inert He, reducing H₂, or oxidizing O₂) according to its known activation protocol, while collecting XRD patterns intermittently or continuously.

- Reaction Phase: The gas flow is switched to the reactant mixture (e.g., CO + O₂ for oxidation, CO + H₂ for Fischer-Tropsch). The effluent gas stream is simultaneously analyzed by an online mass spectrometer (MS) or gas chromatograph (GC).

- Data Synchronization: XRD pattern acquisition timestamps are synchronized with activity data (MS/GC signals) and environmental parameters (T, P, flow rates).

- Post-Reaction Analysis: The catalyst may be cooled under reaction or inert gas, and a final ex situ XRD pattern may be collected for comparison.

Data Analysis Considerations

- Time-Resolved Rietveld Refinement: Sequential XRD patterns are analyzed using Rietveld refinement to extract quantitative phase composition, lattice parameters, and crystallite size as a function of time.

- Correlative Analysis: The extracted structural parameters are plotted alongside catalytic conversion/selectivity data to establish causal relationships.

Key Applications and Quantitative Data

Operando XRD has elucidated mechanisms across numerous catalytic reactions. Key findings are summarized in Table 1.

Table 1: Key Insights from Operando/In Situ XRD Studies in Catalysis

| Catalytic System | Reaction | Key Structural Insight | Quantitative Data Example | Reference (Type) |

|---|---|---|---|---|

| Cu/ZnO/Al₂O₃ | Methanol Synthesis (CO/CO₂+H₂) | Metallic Cu is the active phase; ZnO role is mainly structural promotion. Reduction of CuO → Cu occurs at ~200°C. | Cu crystallite size: 5-15 nm under reaction. Cu surface area correlates with activity. | Synchrotron Study |

| Fe-based Fischer-Tropsch | Fischer-Tropsch Synthesis (CO+H₂) | Active phase is χ-Fe₅C₂ (Hägg carbide), not metallic Fe or oxides. Formation occurs via reduction of Fe₂O₃ → Fe₃O₄ → α-Fe → FeₓCᵧ. | Carbide fraction >60% during optimal activity. Carburization rate depends on H₂/CO ratio. | Lab XRD-MS Study |

| Pd for Methane Oxidation | CH₄ + O₂ → CO₂ + H₂O | Cycle between PdO (active for CH₄) and Pd (active for O₂) depends on O₂ partial pressure and temperature. | Pd PdO transition temperature shifts with particle size and support. | In Situ XRD-MS |

| VOₓ/TiO₂ for SCR | NH₃-SCR of NOₓ | Monomeric vanadyl species are active; crystalline V₂O₅ formation leads to deactivation and unwanted SO₂ oxidation. | Threshold vanadium loading for V₂O₅ crystallization: ~1 monolayer. | Operando Study |

| Ni/La₂O₃ for Dry Reforming | CH₄ + CO₂ → 2H₂ + 2CO | La₂O₂CO₃ phase forms under reaction, which helps gasify carbon deposits and inhibits Ni sintering. | La₂O₂CO₃ identified above 550°C in CO₂-rich flow. Carbon deposition rate reduced by 70%. | Recent Study (2023) |

The Scientist's Toolkit: Essential Research Reagent Solutions & Materials

Table 2: Key Materials and Reagents for Operando/In Situ XRD Experiments

| Item | Function / Explanation |

|---|---|

| Quartz or Glass Capillary (Thin-Wall) | Serves as the microreactor vessel. Quartz offers higher temperature tolerance (>1000°C), while borosilicate glass is sufficient for many mid-temperature applications. Thin walls minimize X-ray absorption and background scattering. |

| X-ray Transparent Windows (Diamond, Polyimide, Beryllium) | Used to seal planar reactor cells. Single-crystal diamond offers the best combination of strength, thermal conductivity, and minimal scattering. Polyimide (Kapton) is a low-cost, flexible alternative for moderate conditions. |

| High-Purity Gas Manifold & Mass Flow Controllers (MFCs) | Delivers precise, controlled mixtures of reactive (H₂, O₂, CO, CH₄) and inert (He, Ar) gases to the reactor cell. Essential for establishing defined atmospheres and simulating process conditions. |

| Online Quadrupole Mass Spectrometer (QMS) or Micro-GC | The cornerstone of operando methodology. Provides real-time, quantitative analysis of reactor effluent, allowing direct correlation of catalyst activity/selectivity with structural changes observed by XRD. |

| Calibrated Heating System (Hot Air Blower/Resistive) | Provides precise and rapid temperature control of the reactor cell. Must be compatible with the sample stage and provide a stable thermal environment for the catalyst bed. |

| Standard Reference Materials (e.g., NIST LaB₆, Si) | Used for precise calibration of the goniometer and diffraction geometry, especially critical for capillary setups where alignment can be challenging. Ensures accurate lattice parameter determination. |

| High-Temperature Stable Adhesive/Cement | Used for mounting catalysts or windows in certain cell designs. Must be inert, vacuum-compatible, and stable over the intended temperature range without outgassing. |

Visualized Workflows and Relationships

Title: Operando XRD Experimental Data Acquisition Workflow

Title: From XRD Data to Catalytic Insight Analysis Pathway

X-ray diffraction (XRD) is a cornerstone technique in catalyst characterization, providing critical information on phase composition, crystal structure, and microstructural properties. For catalysts, performance is intrinsically linked to features such as active site density and stability, which are governed by crystallite size and lattice imperfections. Microstructural analysis via line profile broadening separates size-induced broadening from strain-induced effects, enabling researchers to correlate synthesis parameters with catalytic activity and durability.

Fundamental Principles of Line Broadening

The breadth of a diffraction peak is influenced by instrumental factors and sample-dependent effects. After instrumental correction, the remaining physical broadening ((\beta)) originates primarily from:

- Crystallite Size ((D)): Finite size of coherently diffracting domains (crystallites). This effect is independent of the diffraction order and follows a 1/cos(\theta) dependence.

- Microstrain ((\epsilon)): Non-uniform lattice distortions from defects, dislocations, or compositional variations. This effect varies with diffraction order, following a tan(\theta) dependence.

The Scherrer Equation: Crystallite Size Analysis

The Scherrer equation provides a primary estimate of volume-weighted average crystallite size from a single, isolated peak.

[ D = \frac{K \lambda}{\beta \cos\theta} ]

Where:

- (D) = Volume-weighted mean crystallite size (nm)

- (K) = Scherrer constant (shape factor, ~0.89 for spherical crystallites)

- (\lambda) = X-ray wavelength (nm)

- (\beta) = Integral breadth or FWHM of the peak after instrumental correction (in radians)

- (\theta) = Bragg angle

Experimental Protocol for Scherrer Analysis:

- Sample Preparation: Grind catalyst powder finely and homogeneously. Load into a low-background sample holder, ensuring a flat, level surface.

- Data Collection: Perform a slow, high-resolution scan over the isolated diffraction peak of interest (e.g., Cu (111) for Cu-based catalysts). Typical settings: step size 0.01°–0.02°, counting time 2–5 s/step.

- Instrumental Deconvolution: Measure a line profile standard (e.g., NIST SRM 660c LaB(_6)) under identical conditions to determine the instrumental broadening function.

- Peak Fitting: Fit the measured peak profile (e.g., with a pseudo-Voigt function) to determine the FWHM or integral breadth.

- Correction & Calculation: Subtract instrumental broadening (e.g., using the Stokes deconvolution method or simple quadratic subtraction: (\beta^2 = \beta{measured}^2 - \beta{instrumental}^2)). Apply the Scherrer equation.

Limitations: The Scherrer method assumes all broadening is from finite size, neglecting strain and other defects, and provides an average size for the crystallites contributing to that specific peak.

Williamson-Hall Plot: Deconvoluting Size and Strain

The Williamson-Hall (WH) method is a simplified integral breadth approach that separates size and strain contributions by analyzing multiple diffraction orders.

[ \beta \cos\theta = \frac{K \lambda}{D} + 4 \epsilon \sin\theta ]

A plot of (\beta \cos\theta) (y-axis) versus (4 \sin\theta) (x-axis) yields a straight line where:

- Y-intercept = (K \lambda / D) (Size contribution)

- Slope = (\epsilon) (Strain contribution)

Experimental Protocol for Williamson-Hall Analysis:

- Data Collection: Collect a full XRD pattern (e.g., 20°–80° 2(\theta)) of the catalyst sample and the instrumental standard.

- Peak Fitting & Correction: Identify all peaks from the phase of interest. Fit each peak to obtain (\beta{hkl}). Apply instrumental broadening correction to each (\beta{hkl}).

- Calculation & Plotting: For each corrected peak, calculate (\beta \cos\theta) and (4 \sin\theta).

- Linear Regression: Plot the values and perform a linear fit. A positive slope indicates the presence of tensile microstrain; a negative slope indicates compressive strain.

Table 1: Comparison of Scherrer and Williamson-Hall Methods

| Feature | Scherrer Equation | Williamson-Hall Plot |

|---|---|---|

| Primary Output | Average Crystallite Size ((D)) | Crystallite Size ((D)) & Microstrain ((\epsilon)) |

| Peaks Required | One isolated peak | Multiple peaks from the same phase |

| Strain Consideration | Neglected; assumes zero strain | Explicitly calculated |

| Assumptions | All broadening from finite size | Size and strain broadening are independent and additive |

| Best For | Quick, initial size estimate | More detailed microstructural analysis |

Advanced Considerations and Modern Practices

- Anisotropy: WH analysis assumes isotropic size and strain. Anisotropic effects cause scattering in the WH plot. Modified Williamson-Hall models (e.g., using specific (hkl)-dependent strain models) or Size-Strain Plot (SSP) methods can be applied.

- Whole Pattern Fitting: The Warren-Averbach method, performed via Fourier analysis of multiple orders, provides a more rigorous separation and a distribution of sizes. This is often implemented in modern Rietveld refinement software, which can model both size and strain effects directly during full-pattern fitting.

Workflow for XRD Microstructural Analysis

Key Features of a Williamson-Hall Plot

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for XRD Microstructural Analysis

| Item | Function & Description |

|---|---|

| High-Purity Silica/Zero-Background Holder | Sample holder made from single-crystal quartz or silicon, providing a flat surface and minimal parasitic scattering for accurate baseline measurement. |

| NIST SRM 660c (LaB(_6)) | Certified line profile standard from the National Institute of Standards and Technology. Used to measure the instrumental broadening function for accurate deconvolution. |

| Micro-Amortar and Pestle (Agate) | For gentle, contamination-free grinding of catalyst powders to reduce particle agglomeration and ensure a random orientation. |

| Reference Catalyst Samples | Well-characterized catalysts (e.g., from Johnson Matthey or other suppliers) with known crystallite size, used for method validation and calibration. |

| Pseudo-Voigt/Lorentzian Fitting Software | Essential for accurate peak profile decomposition to extract integral breadth or FWHM. Implemented in software like TOPAS, HighScore, or JADE. |

| Rietveld Refinement Suite | Advanced software (e.g., TOPAS, MAUD, FullProf) enabling whole-pattern fitting, including explicit modeling of crystallite size and microstrain distributions. |

X-ray diffraction (XRD) is a cornerstone analytical technique in catalyst research, providing definitive, quantitative insight into the crystalline phases that govern catalytic activity, selectivity, and stability. This whitepaper positions XRD not as a standalone tool, but as the fundamental structural validator within a broader characterization thesis. It is the primary method for determining bulk crystal structure, phase composition, crystallite size, and, under operando conditions, structural evolution during reaction. The following case studies on zeolites, supported metals, and metal oxides demonstrate how XRD data forms the critical foundation upon which performance properties are rationally explained and new catalysts are designed.

Case Study 1: Zeolite Catalysts

Zeolites are aluminosilicate crystals with well-defined microporous frameworks. XRD is indispensable for their identification and quality assessment.

Key XRD Analyses:

- Phase Identification: Matching the diffraction pattern to reference patterns (e.g., IZA database) confirms framework type (FAU, MFI, BEA, etc.).

- Crystallinity: The intensity of characteristic peaks is compared to a standard to determine relative crystallinity, crucial after synthesis or post-synthetic modifications.

- Unit Cell Parameter Calculation: For zeolites like FAU (X, Y), precise measurement of the (533) or (642) reflection allows calculation of the unit cell constant (a₀). This shifts linearly with the bulk Si/Al ratio via Vegard's law.

- Crystallite Size: Scherrer analysis on isolated peaks estimates average crystallite size, differentiating nano-sized from well-grown crystals.

Quantitative Data Table: XRD Analysis of Commercial Zeolites

| Zeolite Type (Framework Code) | Primary XRD Peak (2θ, Cu Kα) | Typical FWHM (Δ2θ) | Calculated Crystallite Size (nm) | Derived Unit Cell Parameter a₀ (Å) | Inferred Si/Al Ratio (from a₀) |

|---|---|---|---|---|---|

| Zeolite Y (FAU) | ~6.2° (111) | 0.12° | ~85 | ~24.65 | ~2.5 |

| ZSM-5 (MFI) | ~7.9° (101), 8.8° (200) | 0.18° | ~50 | - | Variable (from synthesis) |

| Zeolite A (LTA) | ~7.2° (200) | 0.10° | ~100 | ~24.60 | ~1.0 |

| Beta (BEA) | ~7.7° (101) | 0.25° | ~35 | - | Variable (from synthesis) |

Experimental Protocol: Zeolite Phase Identification & Crystallinity

- Sample Preparation: Grind a small amount of zeolite powder to a fine, homogeneous consistency using an agate mortar and pestle. Load into a zero-background silicon sample holder, ensuring a flat, level surface.

- Instrument Setup: Use a Bragg-Brentano geometry diffractometer with Cu Kα radiation (λ = 1.5418 Å). Set a voltage of 40 kV and current of 40 mA.

- Scan Parameters: Scan range: 5° to 50° (2θ). Step size: 0.02°. Counting time: 2 seconds per step. Use a slow rotation (~15 rpm) to improve particle statistics.

- Data Analysis: Perform background subtraction and Kα₂ stripping. Identify peaks by comparison to reference patterns. For crystallinity, integrate the area of key characteristic peaks (e.g., (533) for FAU, (501) for MFI) and compare to a highly crystalline reference standard.

XRD Workflow for Zeolite Characterization

Case Study 2: Supported Metal Catalysts

These catalysts feature active metal nanoparticles (e.g., Pt, Pd, Ni) dispersed on a high-surface-area oxide support (e.g., Al₂O₃, SiO₂, TiO₂).

Key XRD Analyses:

- Support Phase Identification: Characterizes the crystalline phase of the support (e.g., γ-Al₂O₃ vs. θ-Al₂O₃, anatase vs. rutile TiO₂).

- Metal Crystallite Size: The breadth of metal nanoparticle diffraction peaks (e.g., Pt (111) at ~39.8° 2θ) is analyzed using the Scherrer equation to estimate volume-averaged crystallite size.

- Detection Limit: XRD typically detects metal phases only when particles are > ~2-3 nm and the loading is > ~1-2 wt%. Highly dispersed atoms or sub-nm clusters are "XRD amorphous."

Quantitative Data Table: XRD Analysis of Supported Pt Catalysts

| Catalyst Formulation | Pt Loading (wt%) | Pt (111) Peak Position (2θ) | FWHM, β (Δ2θ) | Calculated Pt Crystallite Size (nm) | Visible Support Phases |

|---|---|---|---|---|---|

| Pt/Al₂O₃ | 1.0 | Not discernible | - | < 2.0 (amorphous) | γ-Al₂O₃ (broad peaks) |

| Pt/Al₂O₃ | 5.0 | 39.76° | 1.5° | ~5.7 | γ-Al₂O₃ |

| Pt/TiO₂ | 2.0 | 39.80° | 0.8° | ~11.0 | Anatase, Rutile |

| Pt/C (Graphitic) | 3.0 | 39.82° | 0.5° | ~18.0 | Graphite (002) at ~26° |

Experimental Protocol: Metal Crystallite Size Determination

- Sample Preparation: Lightly press powder into a holder to ensure a flat surface and preferred orientation minimization, especially for supported metals.

- High-Resolution Scan: Focus on the primary metal reflection region (e.g., 35°-45° 2θ for Pt (111)). Use a slower step scan (0.01° step, 5s/step) for accurate FWHM measurement.

- Scherrer Analysis:

- Isolate the metal peak using profile fitting (e.g., Pseudo-Voigt function).

- Extract the integral breadth (β) or FWHM after correcting for instrument broadening using a line-broadening standard (e.g., LaB₆, NIST SRM 660c).

- Apply the Scherrer equation: τ = Kλ / (β cos θ), where τ is crystallite size, K is the shape factor (~0.9), λ is X-ray wavelength, β is FWHM in radians, and θ is the Bragg angle.

Case Study 3: Metal Oxide Catalysts

Bulk and mixed metal oxides (e.g., V₂O₅-WO₃/TiO₂, CeO₂-ZrO₂, perovskites) are key oxidation and environmental catalysts.

Key XRD Analyses:

- Phase Composition & Solid Solutions: Identifies all crystalline phases present. Peak shifts indicate lattice expansion/contraction, confirming solid solution formation (e.g., in CeₓZr₁₋ₓO₂).

- Crystallite Size & Strain: Line broadening analysis (e.g., Williamson-Hall plot) can separate size-induced and microstrain-induced broadening effects.

- Operando XRD: Monitors phase changes in real-time under reactive gas flows (e.g., reduction of CuO to Cu, or CeO₂ lattice expansion upon reduction).

Quantitative Data Table: XRD Analysis of Select Metal Oxide Catalysts

| Catalyst System | Primary Phases Identified | Key Reflection for Analysis | Lattice Parameter Shift (vs. pure) | Primary Information Derived |

|---|---|---|---|---|

| V₂O₅-WO₃/TiO₂ (SCR) | Anatase TiO₂, Monoclinic WO₃ | Anatase (101) | Minor shift | TiO₂ support phase, WO₃ dispersion |

| Ce₀.₅Zr₀.₅O₂ | Single cubic phase | (111) cubic | Significant shift from pure CeO₂ | Confirms solid solution formation |

| LaFeO₃ (Perovskite) | Orthorhombic Perovskite | (121) peak | - | Phase purity, crystallinity |

| CuO/ZnO/Al₂O₃ (Methanol Synthesis) | CuO, ZnO, (γ-Al₂O₃) | CuO (11-1), ZnO (101) | - | Precursor phases pre-reduction |

Experimental Protocol: Williamson-Hall Analysis for Size/Strain

- Data Collection: Collect a high-quality pattern across a wide angular range (e.g., 20°-80° 2θ).

- Peak Fitting: Fit multiple well-separated peaks (≥5) from the phase of interest to determine their integral breadth (β_hkl).

- Plotting: For each peak, calculate β*cosθ (y-axis) vs. 4sinθ (x-axis), where β is in radians.

- Interpretation: A linear fit yields y-intercept = Kλ/τ (related to crystallite size) and slope = ε (microstrain).

Decision Logic for Metal Oxide XRD Data

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

| Item Name / Reagent | Function in Catalyst XRD Analysis |

|---|---|

| Zero-Background Holder | Silicon single crystal or quartz holder. Provides a featureless XRD background, crucial for analyzing weakly scattering or low-concentration phases. |

| NIST Standard Reference Material (e.g., LaB₆ 660c) | Used for instrument function calibration, specifically to determine the instrumental broadening profile for accurate Scherrer or Williamson-Hall analysis. |

| Micro-Mortar and Pestle (Agate) | For gentle, contamination-free grinding of powder samples to reduce preferred orientation and ensure a statistically representative sample. |

| Internal Standard (e.g., ZnO, Al₂O₃) | Powder of known lattice constant mixed with the sample. Used for precise calibration of diffraction angle (2θ) offset and for quantitative phase analysis (QPA). |

| Operando XRD Cell | A flow-through reactor cell with X-ray transparent windows (e.g., Be, Kapton). Allows collection of XRD patterns under controlled temperature and gas atmosphere. |

| Rietveld Refinement Software (e.g., GSAS-II, TOPAS) | Advanced software for full-pattern fitting to extract quantitative phase percentages, lattice parameters, and sometimes microstructural details. |

Quantifying Amorphous Content and Dispersion in Supported Catalyst Systems

The analysis of supported catalysts presents a significant challenge in heterogeneous catalysis research. Within the broader thesis on Basic Principles of X-Ray Diffraction for Catalyst Analysis, this whitepaper addresses a critical subtopic: the quantification of amorphous phases and active metal dispersion. While XRD excels at characterizing crystalline phases, its indirect application for amorphous content and dispersion is pivotal for understanding total catalyst composition and active site accessibility, parameters directly influencing activity, selectivity, and stability.

Core Principles and Data Interpretation

Supported catalysts typically consist of an active phase (often metallic or metal-oxide nanoparticles) dispersed on a high-surface-area support (e.g., γ-Al₂O₃, SiO₂, carbon). A significant portion of the support and sometimes the active phase may be amorphous or poorly crystalline, evading direct Bragg peak analysis.

- Quantifying Amorphous Content: The total scattering signal includes contributions from both crystalline and amorphous phases. The amorphous fraction is estimated by comparing the integrated intensity of the crystalline diffraction peaks to the total scattered intensity or by using an internal standard method.

- Assessing Metal Dispersion: XRD provides a volume-averaged crystal size via Scherrer analysis of peak broadening. For supported metal nanoparticles, this volume-averaged size can be related to dispersion (D), defined as the fraction of surface atoms, using geometric models, assuming specific particle shapes (e.g., cuboctahedra).

Table 1: Quantitative Data from XRD Analysis of a Model Pt/γ-Al₂O₃ Catalyst

| Parameter | Method | Result | Implication for Catalyst |

|---|---|---|---|

| Crystalline Pt size | Scherrer (Pt (111) peak) | 3.2 ± 0.5 nm | Volume-averaged particle diameter. |

| Pt Dispersion (D) | Geometric model (sphere) | ~35% | Fraction of surface Pt atoms. |

| Crystalline Support Phase | Phase ID (JCPDS) | γ-Al₂O₃ | Primary crystalline phase identified. |

| Estimated Amorphous Content | Rietveld Refinement / Internal Std. | ~20-30 wt.% | Includes amorphous Al-oxihydroxide, silica impurities. |

| Pt Crystallinity | Peak Area vs. Background | ~95% Crystalline | Most Pt is in detectable nanoparticle form. |

Experimental Protocols

Protocol 1: Amorphous Content Quantification via Internal Standard

Objective: Determine the weight fraction of amorphous material in a catalyst sample.

- Sample Preparation: Precisely mix a known weight fraction (e.g., 10 wt.%) of a crystalline standard (e.g., NIST corundum α-Al₂O₃, 50 nm) with the catalyst powder. Ensure homogeneous grinding.

- Data Acquisition: Acquire XRD pattern over a relevant 2θ range (e.g., 10-80°) with sufficient counting statistics.

- Pattern Fitting: Perform Rietveld refinement or whole-pattern fitting on the composite pattern.

- Calculation: The refined scale factor of the internal standard allows calculation of the absolute weight of all crystalline phases in the sample. The amorphous weight fraction (Wₐ) is derived from the mass balance:

Wₐ = 1 - (ΣW_crystalline) / (W_sample)

Protocol 2: Metal Nanoparticle Size and Dispersion

Objective: Determine the average crystallite size and estimated dispersion of the active metal phase.

- Data Acquisition: Collect high-quality XRD data with slow scan speed at the primary diffraction peak of the metal (e.g., Pt (111) at ~39.8° 2θ, Cu Kα).

- Peak Broadening Analysis:

a. Instrumental Broadening: Subtract the instrumental contribution measured from a line-broadening standard (e.g., LaB₆).

b. Scherrer Equation: Apply the Scherrer equation:

τ = Kλ / (β cosθ), where τ is the volume-averaged crystallite size, K is the shape factor (~0.9), λ is the X-ray wavelength, β is the FWHM in radians, and θ is the Bragg angle. - Dispersion Calculation: Using the volume-averaged diameter (d) from step 2b, calculate dispersion for spherical particles:

D ≈ 1.08 / dfor d in nm (simplified model). More accurate models require assumptions of particle shape and site density.

Visualization of Methodologies

XRD Workflow for Amorphous Content

XRD Workflow for Metal Size & Dispersion

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Key Materials for XRD Analysis of Supported Catalysts

| Item | Function & Rationale |

|---|---|

| High-Purity Internal Standards (e.g., NIST SRM 676a Corundum, Zinc Oxide) | Provides a known crystalline reference for quantitative phase and amorphous content analysis. Particle size should be well-characterized. |

| Line-Broadening Standards (e.g., LaB₆ (NIST SRM 660c), CeO₂) | Used to deconvolute instrumental broadening from sample-induced broadening for accurate crystallite size analysis. |